Energy-saving and consumption-reducing magnesium oxide flue gas desulfurization process and device

A desulfurization process, magnesium oxide technology, applied in the field of flue gas desulfurization, can solve problems such as high energy consumption, increased floor space of pre-scrubber, and restrictions on the development of flue gas desulfurization technology by magnesium oxide method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

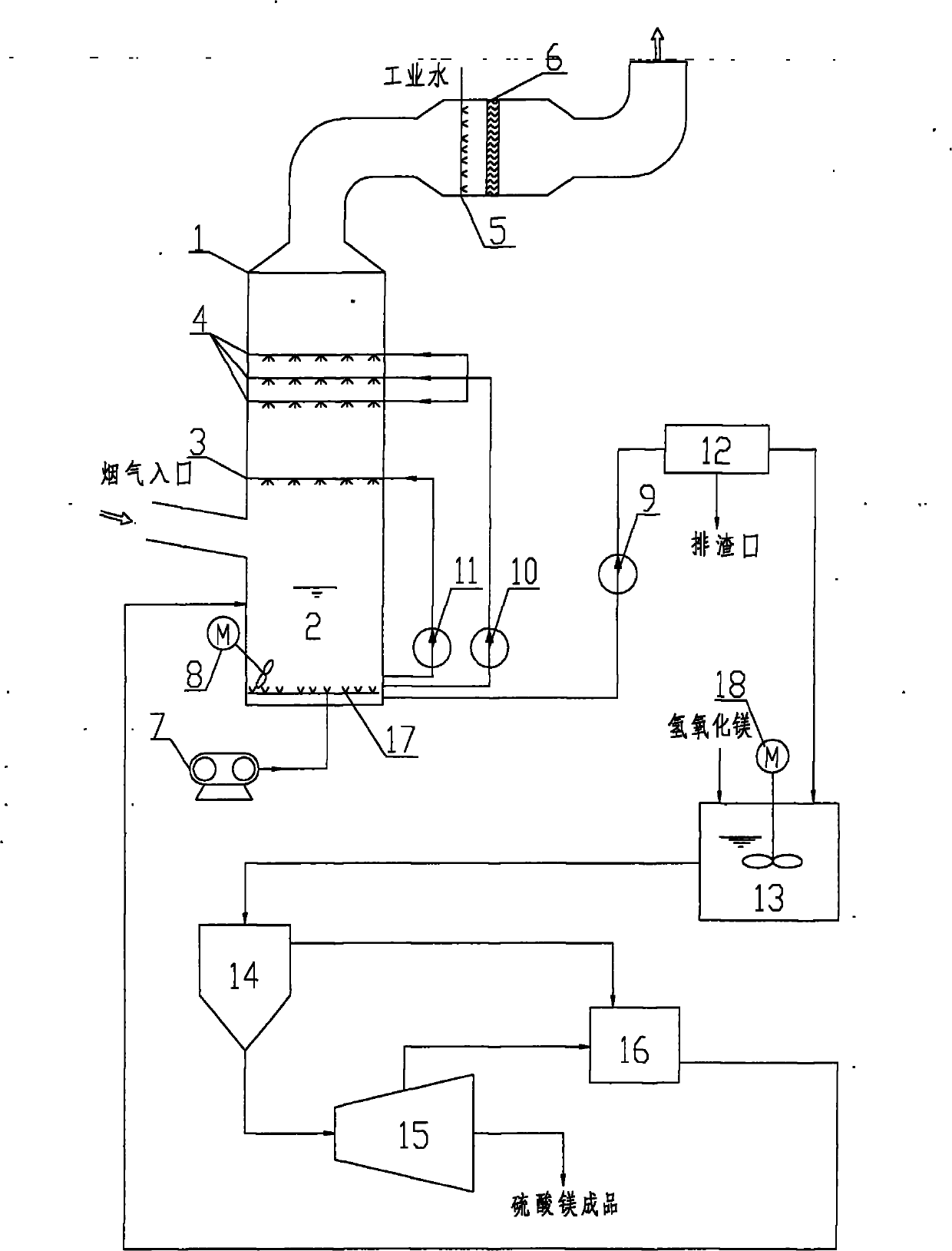

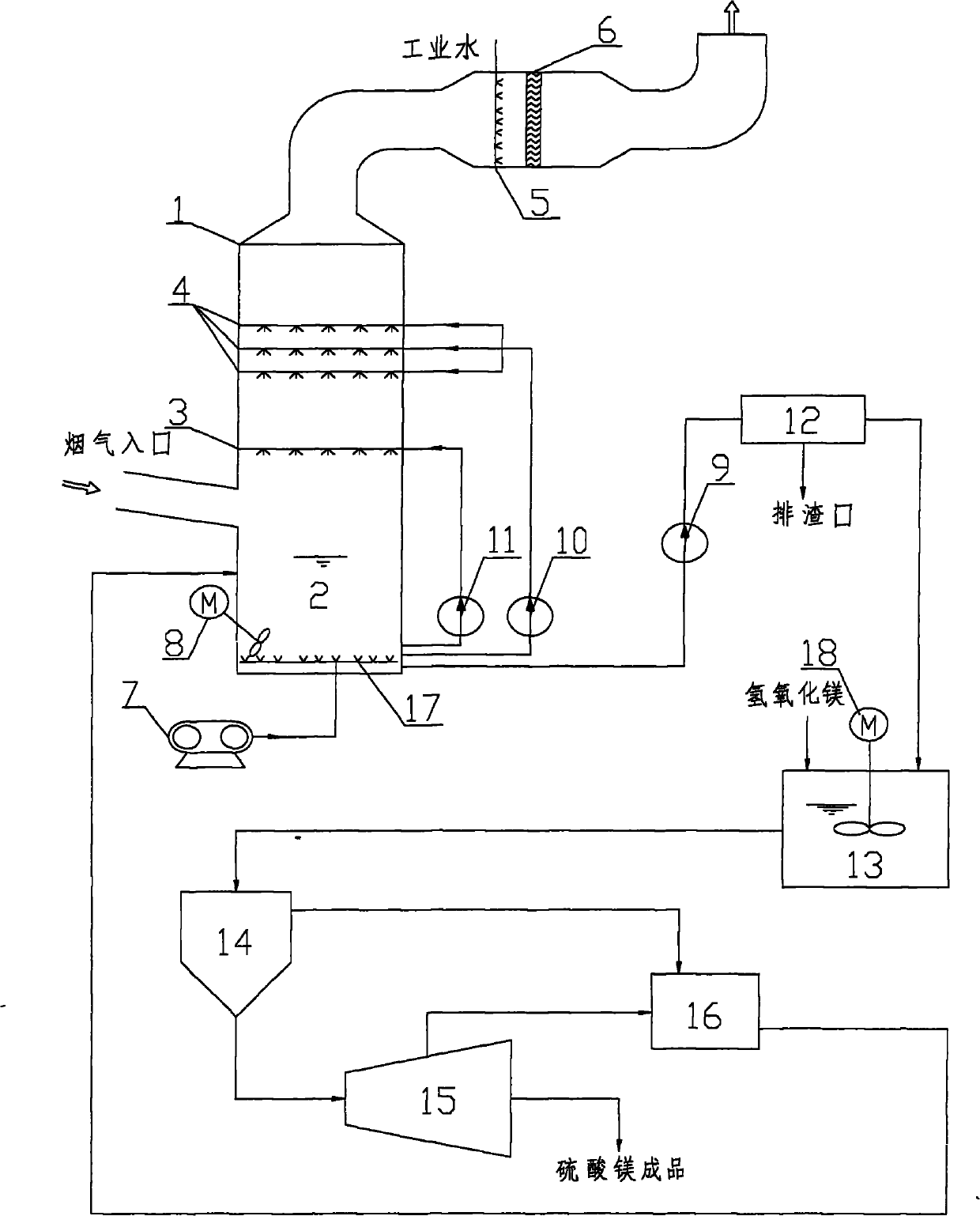

[0010] to combine figure 1 The specific embodiment of the present invention will be introduced in detail.

[0011] Such as figure 1 As shown, the high-temperature flue gas at 120-150°C after dedusting enters the absorption tower (1), and a cooling spray layer (3) is installed on the upper part of the inlet flue to cool and spray the incoming high-temperature flue gas to make the flue gas The temperature drops to 60-90°C, and the cooled hot flue gas enters the spray absorption layer (4). There are 2 to 3 spray layers in the absorption section, and the spray absorption liquid and the hot flue gas are contacted and washed in countercurrent to complete the process. SO 2 the absorption process. The absorption liquid is collected into the oxidation tank (2) at the bottom of the absorption tower (1), and the solution in the oxidation tank is oxidized by the aeration device (17) and the oxidation fan (7) to convert magnesium sulfite into magnesium sulfate. The cleaner flue gas aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com