Desulfuration and mercury-removing combined smoke purifying process and system based on magnesium oxide method desulfuration process

A flue gas purification process, magnesium oxide technology, applied in the direction of magnesium/calcium/strontium/barium sulfide/polysulfide, mercury compounds, chemical instruments and methods, etc. The impact of the normal operation of electrostatic precipitators, the impact of equipment operation and maintenance, etc., to achieve the effect of resource utilization, small footprint, and small maintenance impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

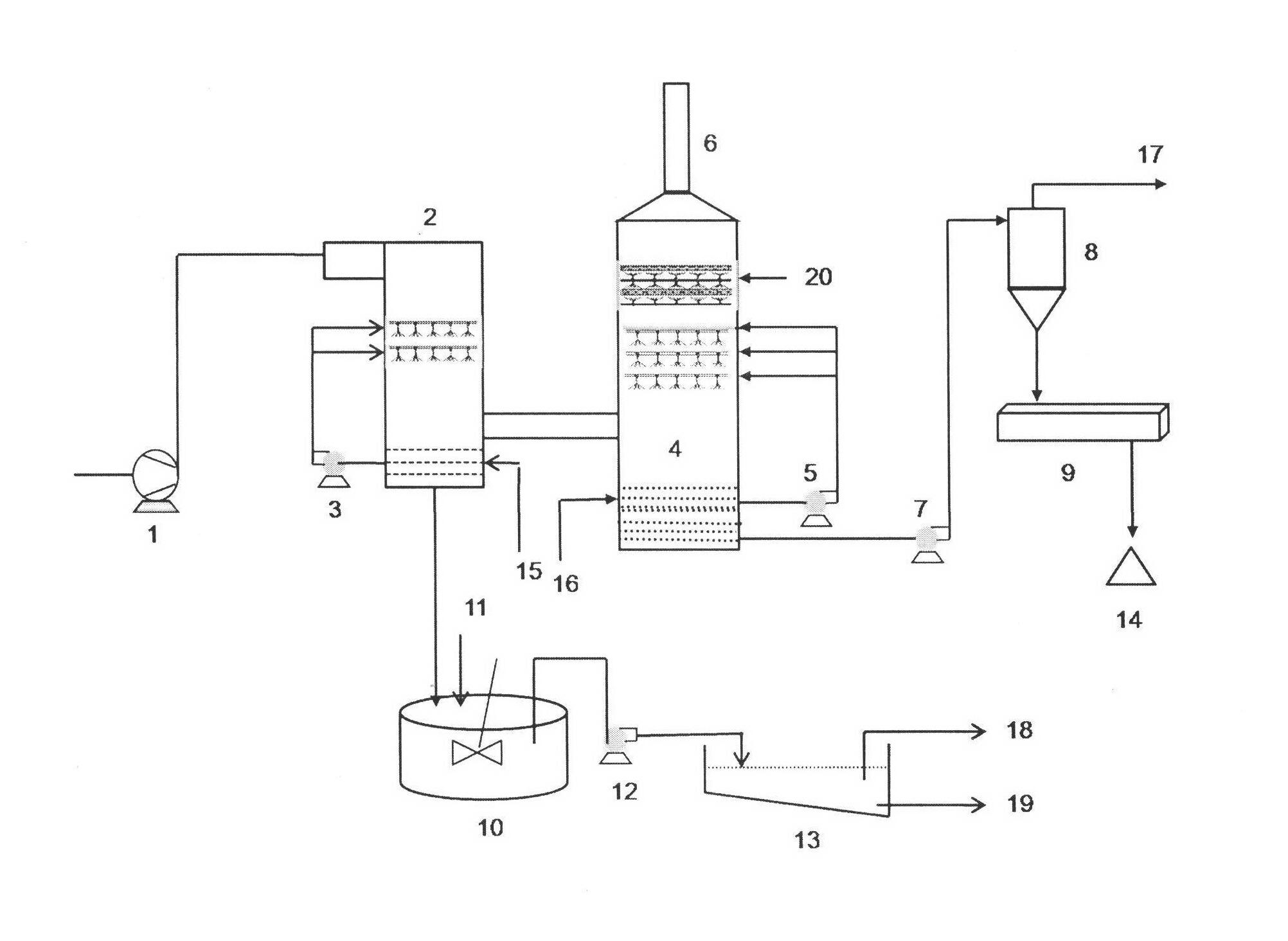

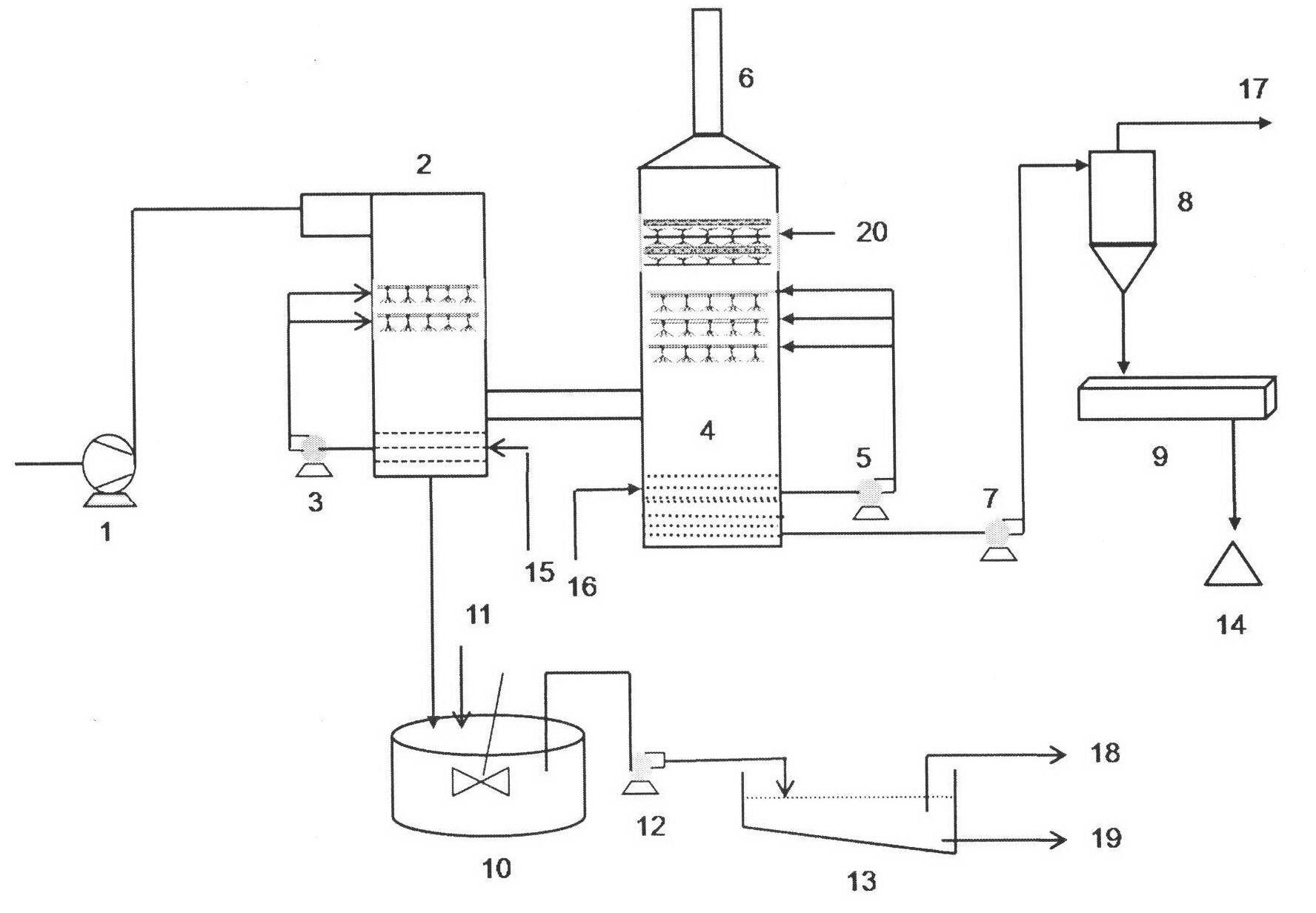

[0022] Combine the following figure 1 , the present invention will be further described.

[0023] A kind of combined desulfurization and demercuration flue gas purification process based on magnesium oxide method desulfurization process of the present invention is as follows:

[0024] 1. Using NaClO 2 As an oxidant, it is prepared as an aqueous solution with a mass concentration of 3%, according to the elemental Hg 0 Measuring the concentration, comparing the oxidizing agent with the elemental Hg 0 NaClO with a stoichiometric ratio of 1.10 to 1.20 2 After the aqueous solution is pumped into the pre-washing tower, the introduced coal-fired flue gas is rinsed by means of empty tower circulation spraying, and the elemental mercury Hg in the flue gas 0 with NaClO 2 Oxidation reaction occurs to rapidly generate divalent ion mercury Hg which is easily soluble in water 2+ . A chemical reaction takes place as follows:

[0025] Main reaction:

[0026] 2Hg+4NaClO 2 +2H 2 O→2H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com