Sulphoaluminate cement with ardealite as main raw material and preparation method thereof

A technology of sulphoaluminate cement and main raw materials, which is applied in the field of construction cement materials, can solve the problems of low utilization rate of phosphogypsum, achieve low cost, simple preparation process, and promote the formation of minerals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

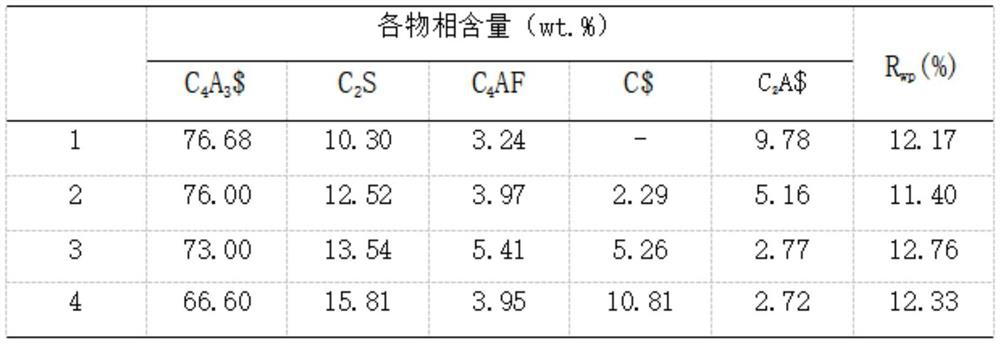

Examples

preparation example Construction

[0037] In a preferred embodiment, the preparation method of the phosphogypsum cement clinker comprises the following steps:

[0038]S1 weighs phosphogypsum, limestone and bauxite by parts by weight, pulverizes, and mixes to prepare phosphogypsum cement raw meal;

[0039] Preferably, in step S1, the grinding is performed until the sieve percentage of the 200-mesh square-hole sieve is less than 8%, and the specific surface area is greater than 400m 2 / kg; when grinding, phosphogypsum, limestone and bauxite can be weighed first and then ground separately, or phosphogypsum, limestone and bauxite can be weighed and ground together; there is no special requirement for the grinding device. Any device known to those skilled in the art can be used, as long as the aforementioned grinding requirements can be met;

[0040] Preferably, in step S1, the specific operation of the mixing is as follows: taking the ground phosphogypsum, limestone and bauxite fine powder, adding water with 5% of...

Embodiment 1

[0049] Weigh 500g of phosphogypsum, 1268g of limestone and 1498g of bauxite, mix and grind to obtain cement raw meal.

[0050] The preparation method of the phosphogypsum sulfoaluminate cement clinker described in the present embodiment is as follows:

[0051] (1) Weigh quantitatively the above-mentioned phosphogypsum, limestone and bauxite and grind them through a 200-mesh square-hole sieve. The percentage of sieve residue is less than 8%, and the specific surface area is greater than 400m 2 / kg, add water with 5% mass of all fine powders, pour it into a ball mill and mix for 10 minutes until uniform, and put the slurry into a 40°C oven to dry for 10 minutes.

[0052] (2) Add about 10% water to the obtained raw meal after mixing and press it into a test cake with a mold, put it into a high temperature furnace for calcination, and the calcination temperature is 1250°C. After the calcination is completed, the cooling rate is 5-10°C / min, cooled to room temperature, and then the...

Embodiment 2

[0054] Weigh 660g of phosphogypsum, 1247g of limestone and 1427g of bauxite and mix and grind to obtain cement raw meal.

[0055] The preparation method of the sulfoaluminate cement clinker described in this example is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com