Double-tower ammonia-method desulfurization process

An ammonia desulfurization and tower technology, applied in the field of flue gas desulfurization, can solve the problems of low aerosol content, inability to remove aerosols, low recovery rate, etc., and achieve the effects of high recovery rate, easy operation and less aerosol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

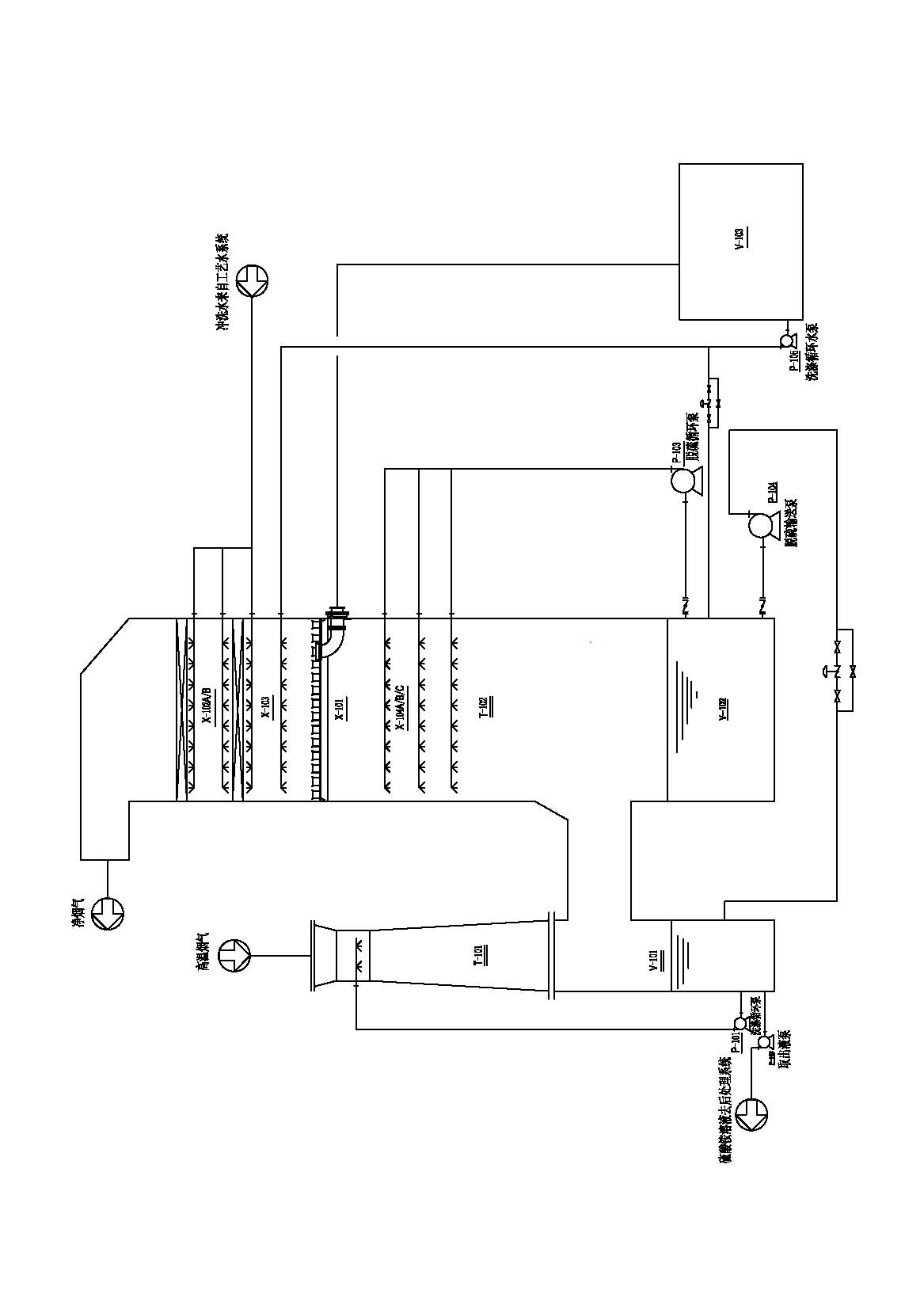

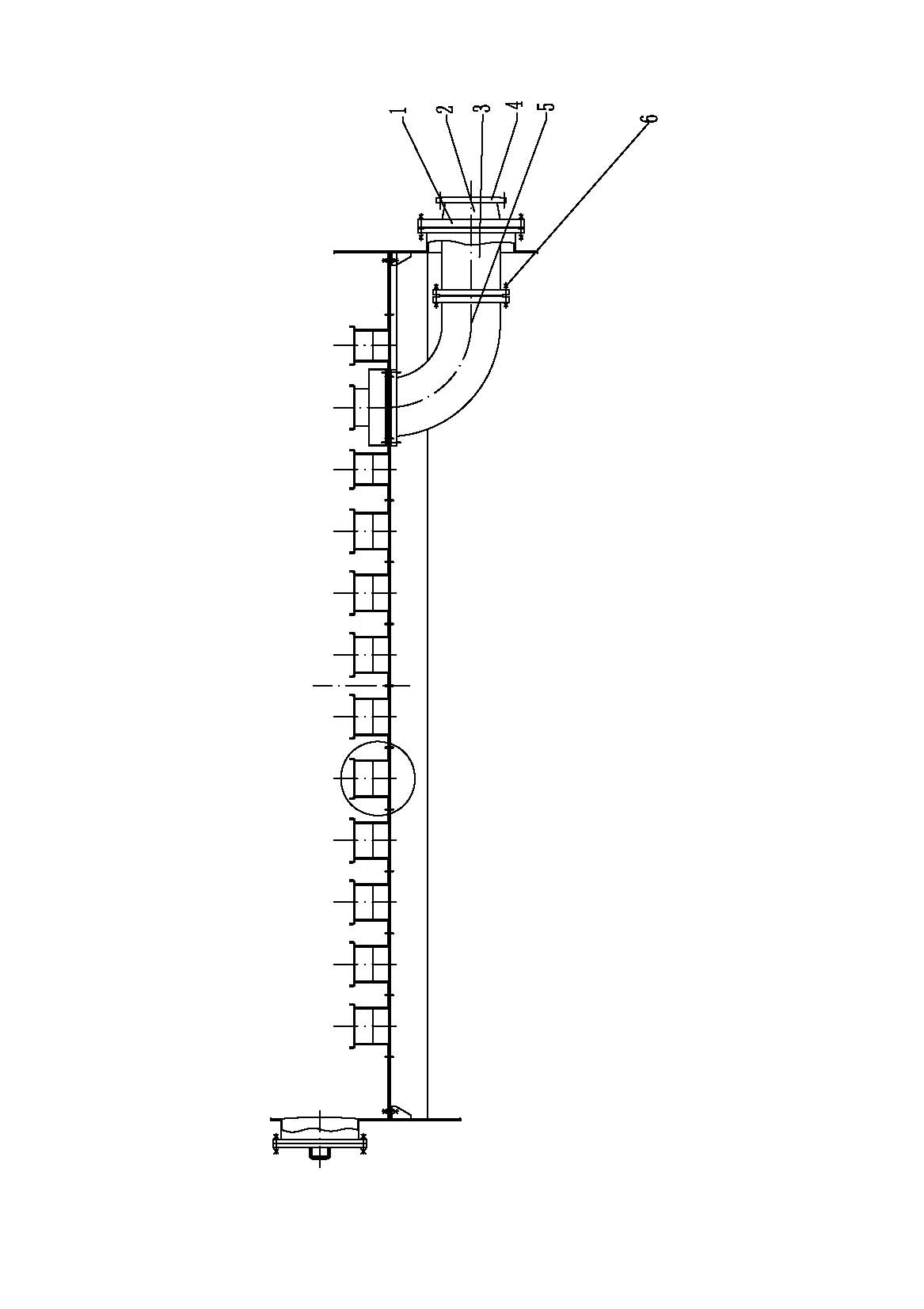

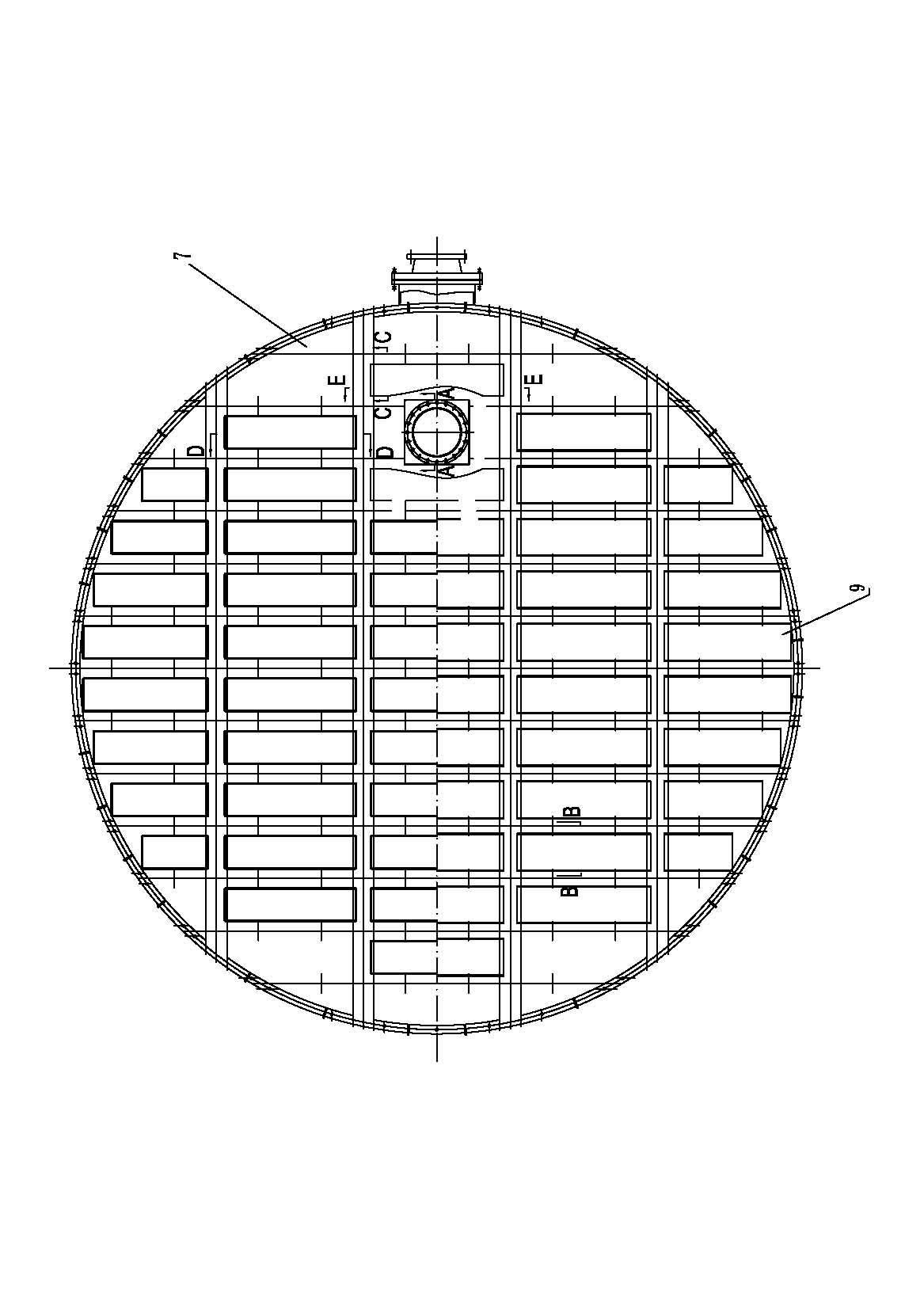

[0026] like Figure 1-4 shown.

[0027] A double-tower ammonia desulfurization process, which includes the following steps:

[0028] Firstly, let the high-temperature flue gas enter the pre-washing tower from the top of the pre-washing tower T-101; at the same time, spray the spray liquid on the entering high-temperature flue gas at the top of the pre-washing tower to reduce the temperature of the flue gas from 110-160°C to 50-75°C; the spray liquid uses an ammonium sulfate solution with a concentration (m / m) of 10-20% (m / m), and the volume ratio of the spray liquid to the high-temperature flue gas is 0.3-0.6:1 (spray liquid The unit of flow is L / h, and the flow unit of flue gas is m 3 / h), after the high-temperature flue gas reacts with the spray liquid, an ammonium sulfate absorption slurry with a concentration (mass percentage) of 30-40% (m / m) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com