Method for removing various pollutants in fume by combining discharge plasmas and absorption

A technology for discharging plasma and pollutants, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation. It can solve problems such as ineffective oxidation, and achieve the effect of low investment and operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

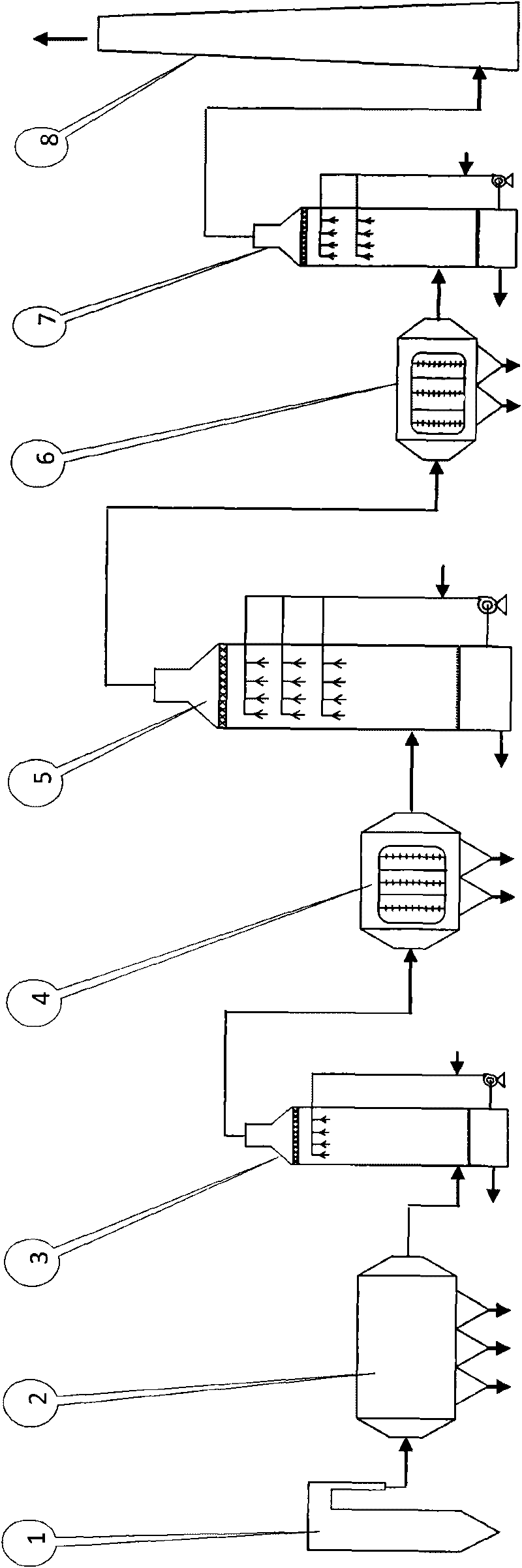

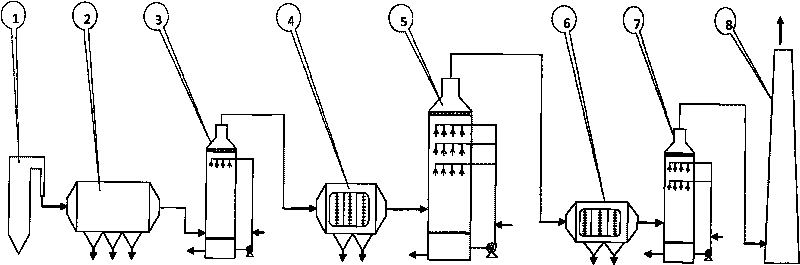

Image

Examples

Embodiment 1

[0049] The simulated flue gas temperature in the laboratory is 60°C, containing 2800mg / m 3 SO 2 , 560mg / m 3 NO x , 150μg / m 3 Mercury with a flow rate of 12m 3 / h. Firstly, in the pre-washing tower 3, the sodium sulfate aqueous solution with a concentration of 2.8M from the primary absorption tower 5 is used for pre-washing, and then pass through the primary discharge plasma reactor 4 and the primary absorption tower 5 respectively. The initial absorption liquid of the primary absorption tower 5 is prepared with industrial grade caustic soda and water, and the pH value of the circulating absorption liquid is maintained at 7-7.5. After being discharged from the primary absorption tower 5, the SO in the flue gas 2 , NO x and mercury concentrations were reduced to 120mg / m 3 , 130mg / m 3 and 128 μg / m 3 . Then, the flue gas passes through the secondary discharge plasma reactor 6 and the secondary absorption tower 7 in sequence. The initial absorption liquid of the seconda...

Embodiment 2

[0051] The simulated flue gas temperature in the laboratory is 60°C, containing 3100mg / m 3 SO 2 , 545mg / m 3 NO x , 140μg / m 3 Mercury with a flow rate of 12m 3 / h. Utilize the mixed aqueous solution of ammonium sulfate and ammonium bisulfate from the primary absorption tower 5, the concentration is 2.6M to pre-wash in the pre-washing tower 3, then pass through the primary discharge plasma reactor 4 and the primary absorption tower 5 respectively. The initial absorption liquid of the primary absorption tower 5 is prepared by adding industrial ammonium water to maintain the pH value of the circulating absorption liquid at 6.3-6.8. After being discharged from the primary absorption tower 5, the flue gas SO 2 , NO x and mercury concentrations were reduced to 173mg / m 3 , 210mg / m 3 and 122 μg / m 3 . Then, the flue gas passes through the secondary discharge plasma reactor 6 and the secondary absorption tower 7 in sequence. The initial absorption liquid of the secondary coll...

Embodiment 3

[0053] The actual coal-fired flue gas 3000m is led out from the flue gas conveying pipe after bag dust removal treatment 3 / h, the flue gas temperature is 85°C, containing 2580mg / m 3 SO 2 , 516mg / m 3 NO x , 102μg / m 3 Mercury, 88mg / m 3 fine particles. In the pre-washing tower 3, the mixed aqueous solution of ammonium sulfate and ammonium bisulfate from the primary absorption tower 5 with a concentration of 2.9M is used for pre-washing, and then pass through the primary discharge plasma reactor 4 and the primary absorption tower 5 respectively. The initial absorption liquid of the primary absorption tower 5 is prepared by adding industrial ammonium water to maintain the pH value of the circulating absorption liquid at 6.3-6.8. , after being discharged from the primary absorption tower 5, the flue gas SO 2 , NO x , mercury and fine particulate matter concentrations were reduced to 245mg / m 3 , 160mg / m 3 , 91 μg / m 3 and 40mg / m 3 . Then, the flue gas passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com