Fixture and etching method for one-sided area etching

A technology for regional corrosion and fixtures, which is applied in the field of corrosion fixtures and corrosion fixtures, can solve the problems of deep corrosion of unsuitable silicon corrosion liquid, difficulty in timely discharge of air bubbles, damage to protected areas, etc., to improve corrosion quality, prevent excessive corrosion, Uniform effect of corrosive liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

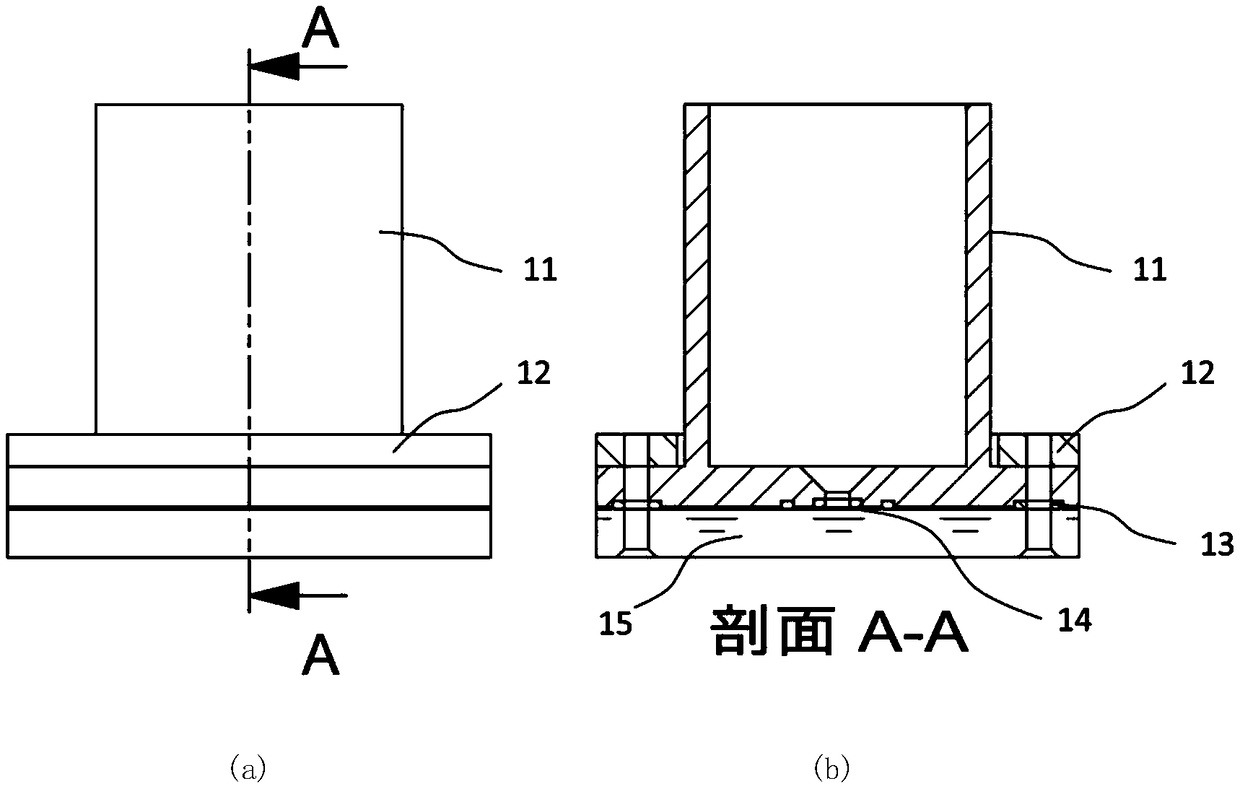

[0046] figure 1 It is a structural schematic diagram of the corrosion fixture of this embodiment. The figure (a) is a schematic diagram of the overall appearance, and the figure (b) is a cross-sectional view of the section A-A in the figure (a). The corrosion fixture includes a fixture upper part 11 , a pressure balance ring 12 , an O-ring set 13 and a glass slide 15 . figure 1 14 is the corroded chip.

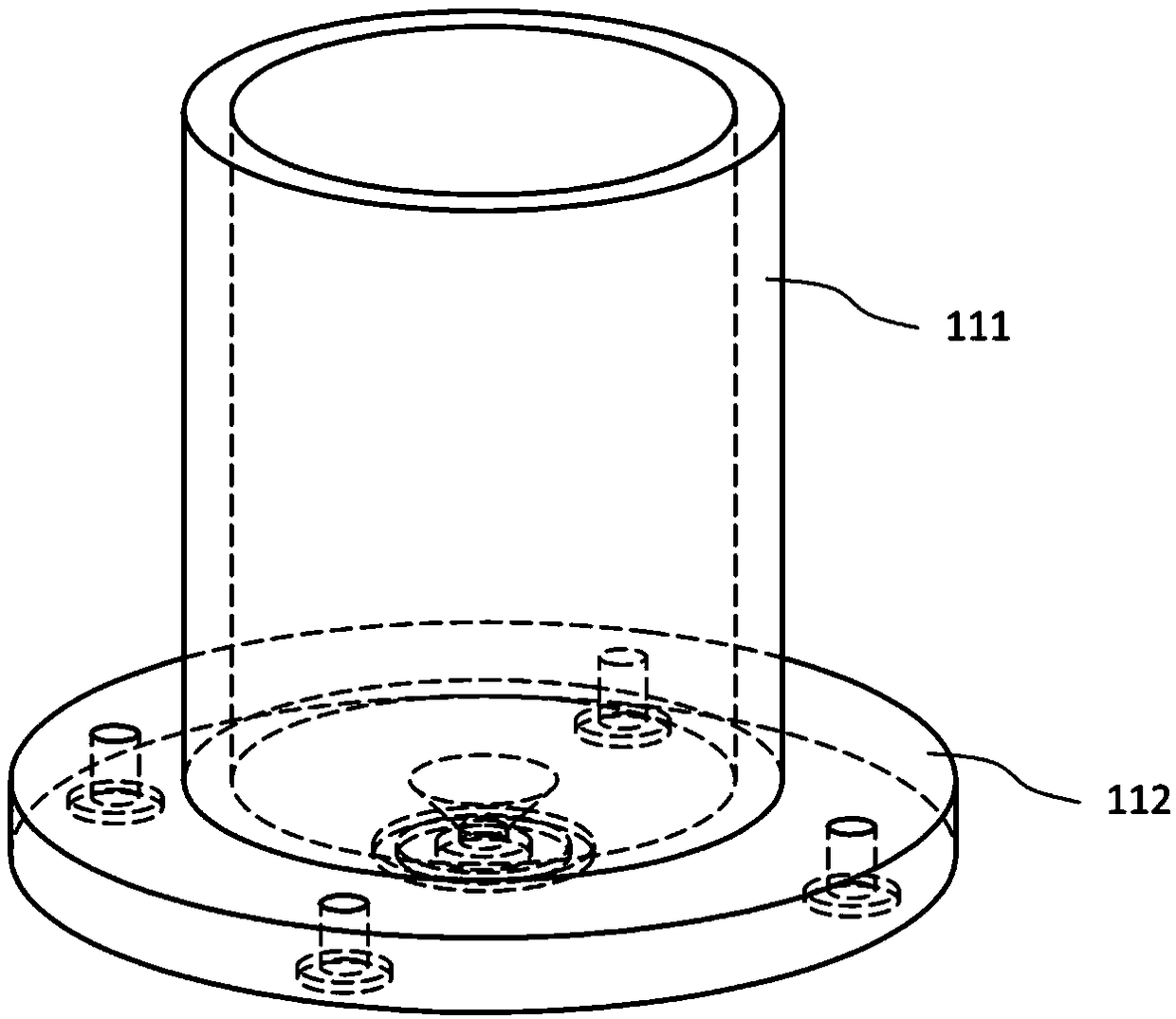

[0047] figure 2 It is a structural schematic diagram of the upper part 11 of the fixture. The upper part 11 of the jig is cylindrical and includes a tubular part 111 and a chassis 112, 111 and 112 are fixedly connected or integrally formed. The chassis 112 is provided with through holes, that is, screw holes (four screw holes are shown in the figure) around the chassis 112 for screw fixing. The tubular part 111 is used to contain the corrosion solution. A through hole is provided in the middle of the chassis 112 , that is, in the middle of the bottom of the upper part 1...

Embodiment 2

[0063] The difference between this embodiment and Embodiment 1 is that the pressure balance ring 12 in Embodiment 1 is removed, and the glass slide 15 and the upper part 11 of the fixture are directly fixed together. With this solution, although the pressure of the screw is not as uniform as in Example 1, the purpose of corrosion can be better achieved.

Embodiment 3

[0065] The difference between this embodiment and Embodiment 1 is that the glass slide 15 is replaced by a non-transparent slide. With this solution, although the light transmission of the slide cannot be used to realize the end point detection, other methods can be used to detect whether the corrosion is complete, such as by timing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com