Patents

Literature

46results about How to "No welding deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel induction heating solid phase welding method and butt welding machine tool

InactiveCN101623794ARealize welding automationLow priceWelding/cutting auxillary devicesAuxillary welding devicesButt weldingTransformer

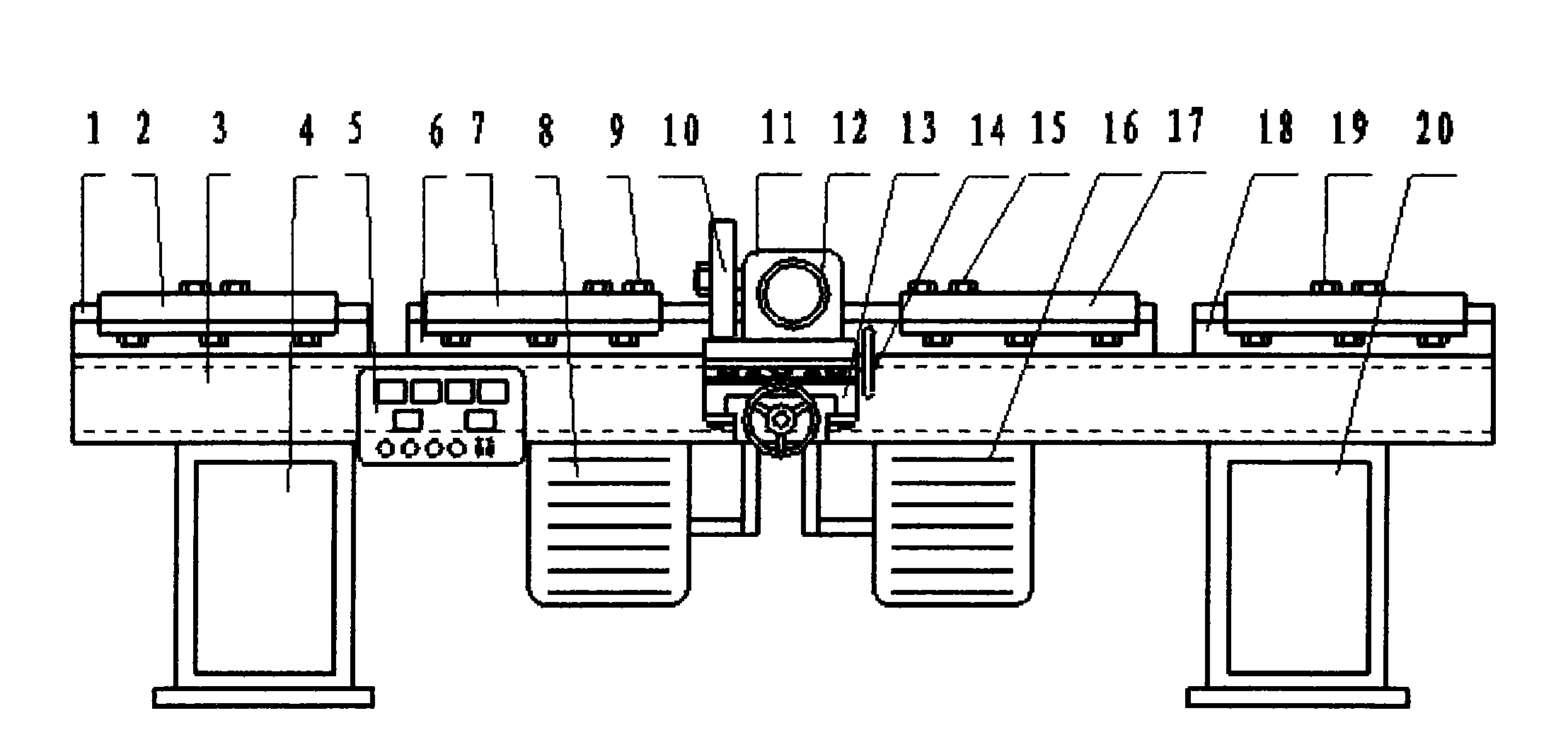

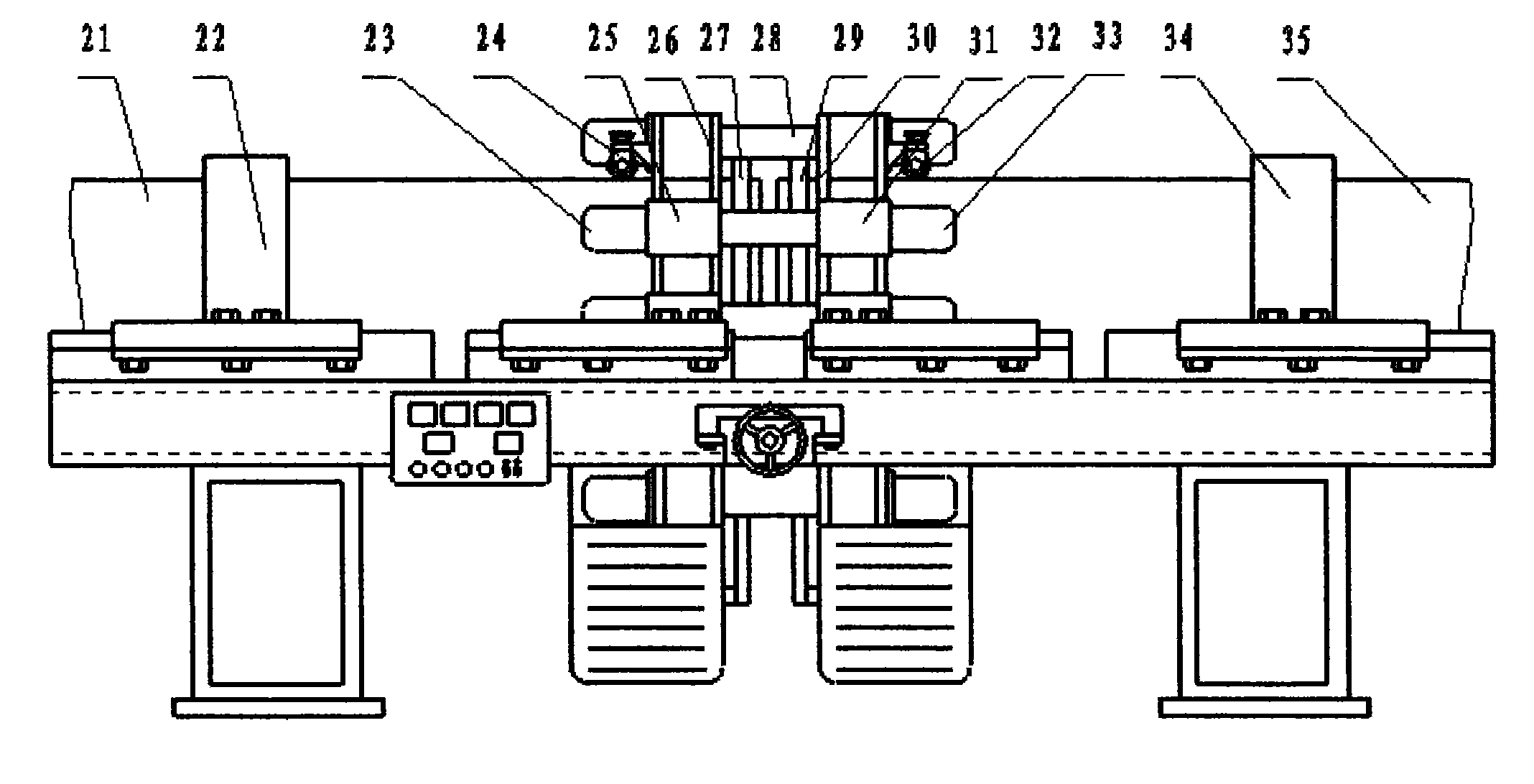

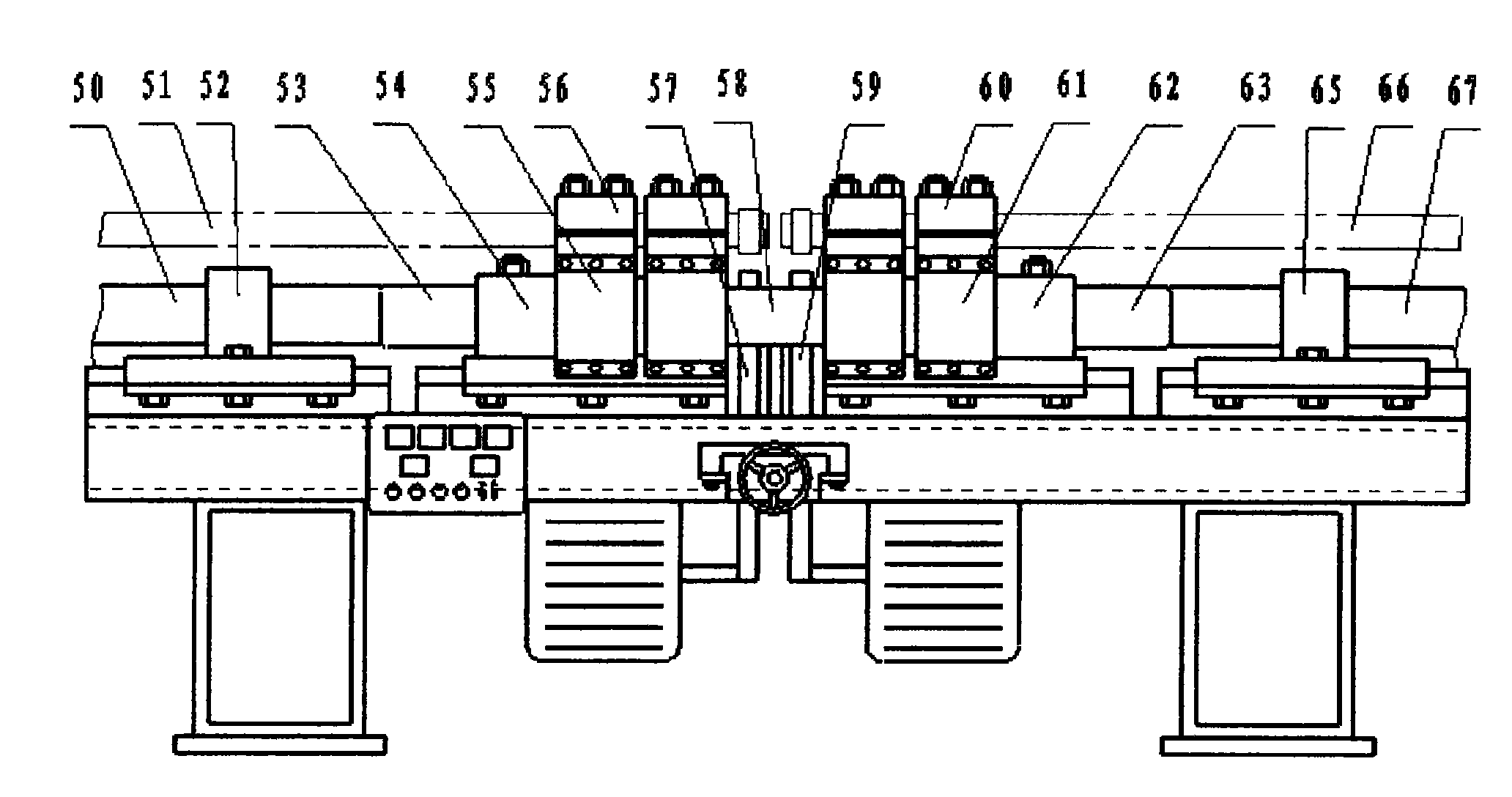

The invention relates to a steel induction heating solid phase welding method and a butt welding machine tool. The butt welding machine consists of a machine body and a butt welding clamp, wherein the machine body mainly comprises a machine tool body, an electric cabinet, a welding controller, a left main guide rail, a left main slide rail, a left induction heating transformer, a tool holder, a right induction heating transformer, a right main guide rail, a right main slide rail and a hydraulic cabinet; and the hydraulic steel tube and steel rail butt welding clamp mainly comprise a left hydraulic cylinder, a left hydraulic cylinder fixing seat, a left steel rail fixing clamp, a left induction heating ring, a connecting rod of a piston rod, a right induction heating ring, a right steel rail fixing clamp, a right hydraulic cylinder fixing seat and a right hydraulic cylinder. The butt welding clamp is arranged on the end face to be welded of the steel product; and the induction heating rings are sleeved on the end face to be welded of the steel product respectively; an induction heating power supply is connected with the primary of the induction heating transformer by a cable, and the secondary of the induction heating transformer is connected with the induction heating rings respectively; and the induction heating rings can heat the end faces to be welded of two steel products to a thermoplastic state in a shot time, and the upsetting pull force is generated on the welding clamp, so that the two steel products are welded together.

Owner:陈炯

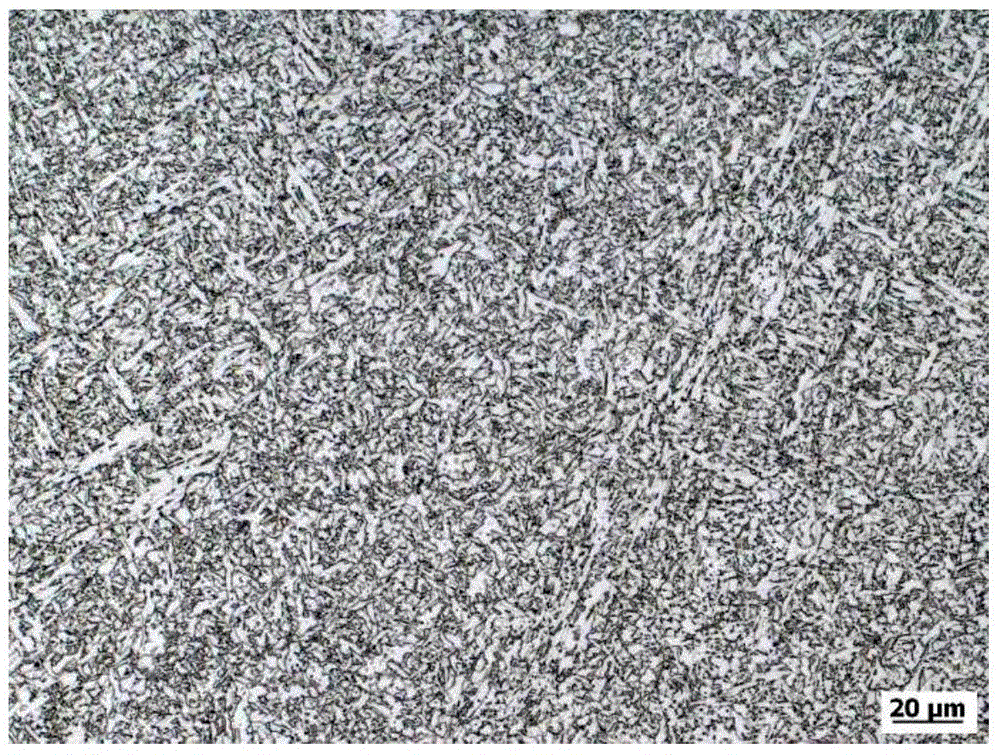

Submerged-arc welding technology of big-thickness low-temperature steel plate with yield strength of 690MPa grade

ActiveCN103447672AThe disadvantage of preventing serious welding deformationNo weld cracksArc welding apparatusWorkpiece edge portionsSheet steelWeld seam

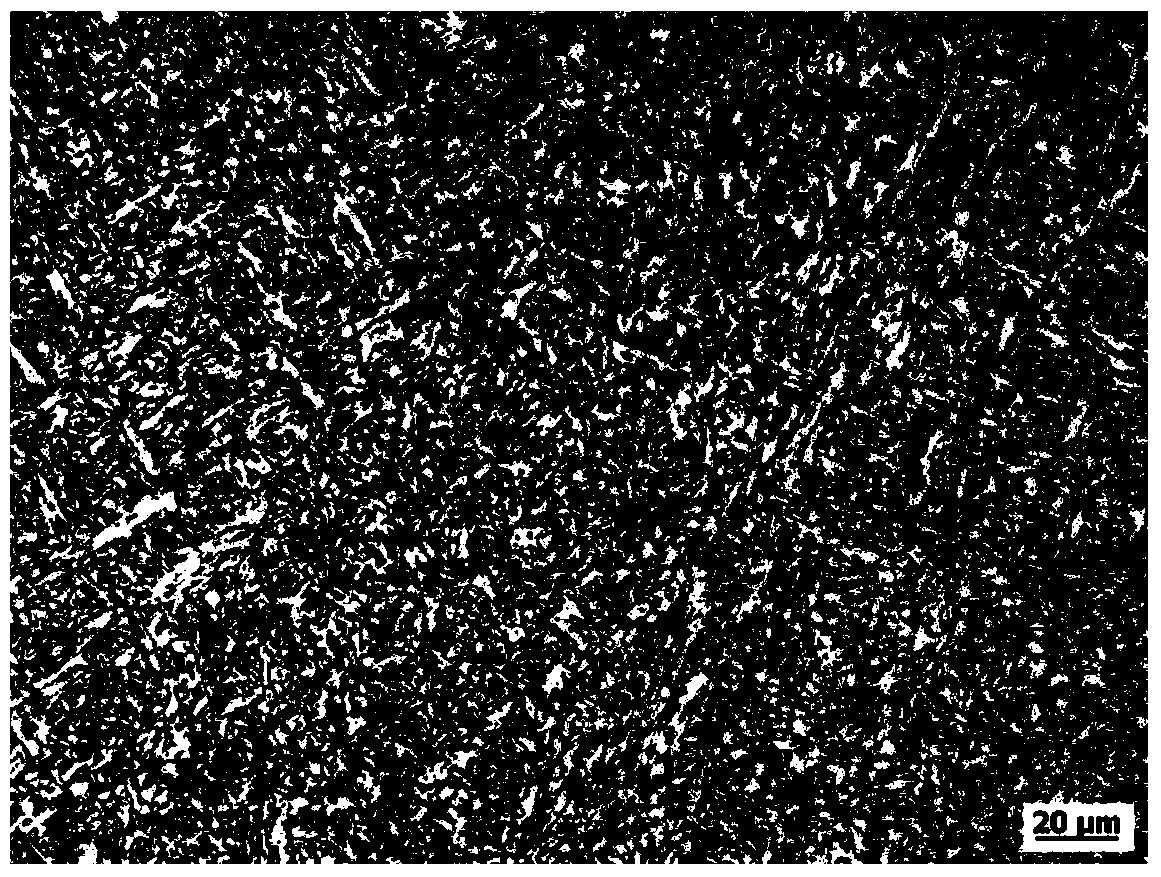

The invention relates to a submerged-arc welding technology of a big-thickness low-temperature steel plate with yield strength of 690MPa grade. The method comprises the following steps: (1) carrying out a welding cold crack sensitivity test on the steel plate to confirm the needed lowest preheating temperature; (2) adopting a welding groove with a symmetrical double-U shape, wherein the groove angle is 25-35 degrees, the thicknesses of truncated edges are 3-5mm, and the gaps between the truncated edges are 1-2mm; (3) adopting a welding wire with the tensile strength of more than or equal to 830MPa and the impacting energy of more than or equal to 100J at the temperature of -60 DEG C; (4) controlling the welding current to be 450-680A, the welding voltage to be 29-36V, the welding speed to be 38-50cm / min, the weld heat input to be 15-40kJ / cm and the flux baking system to be 350 DEG C*2.5h; (5) adopting gas shield welding with a single-sided welding and two-sided molding STT technology to carry out backing weld, and then carrying out unfolding submerged-arc welding until the steel plate is fully filled. All mechanical properties of a welding joint obtained by the method meet the requirements of the classification society, and particularly, a weld seam area and a welding heat affected zone can maintain higher low temperature impact toughness.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

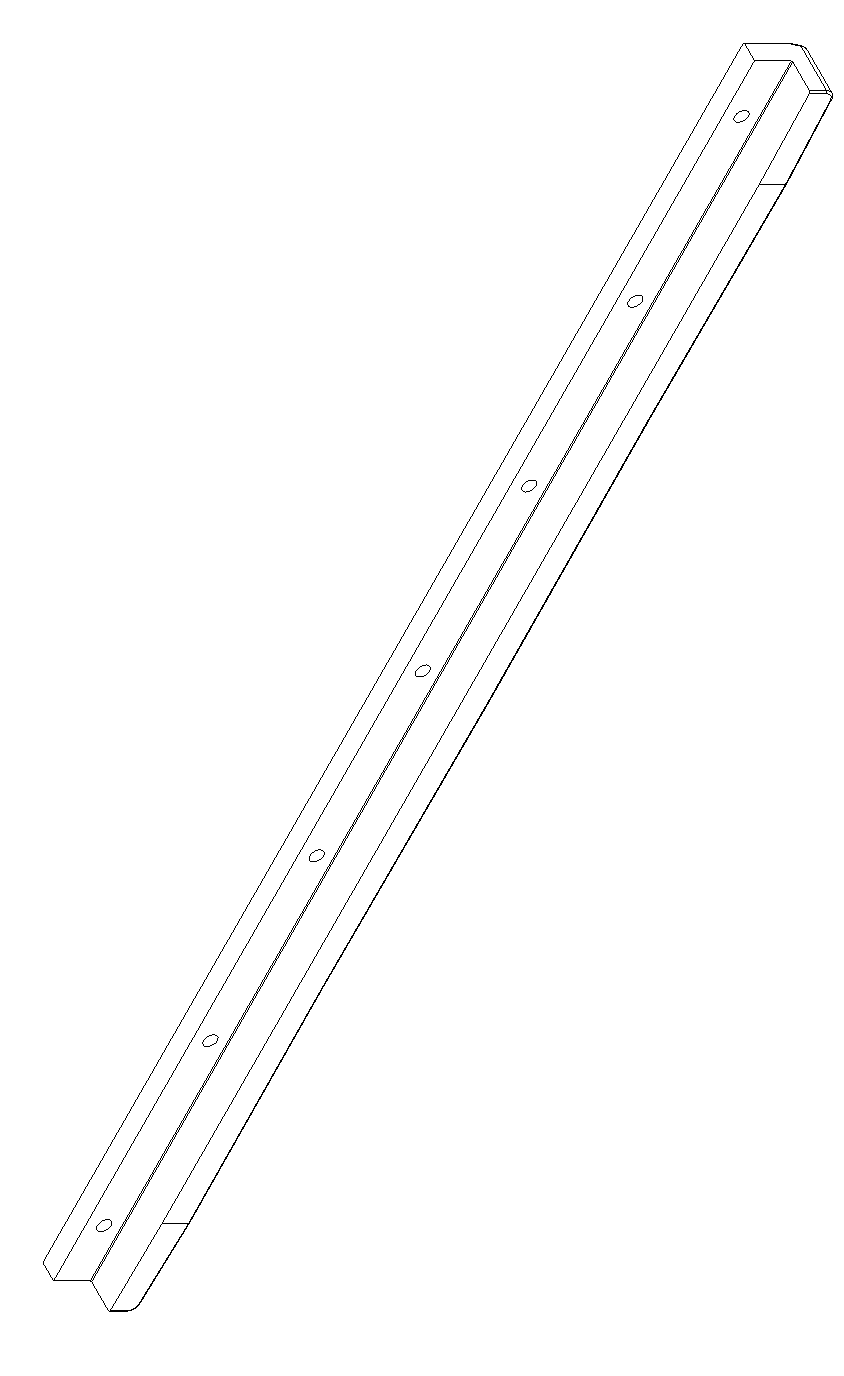

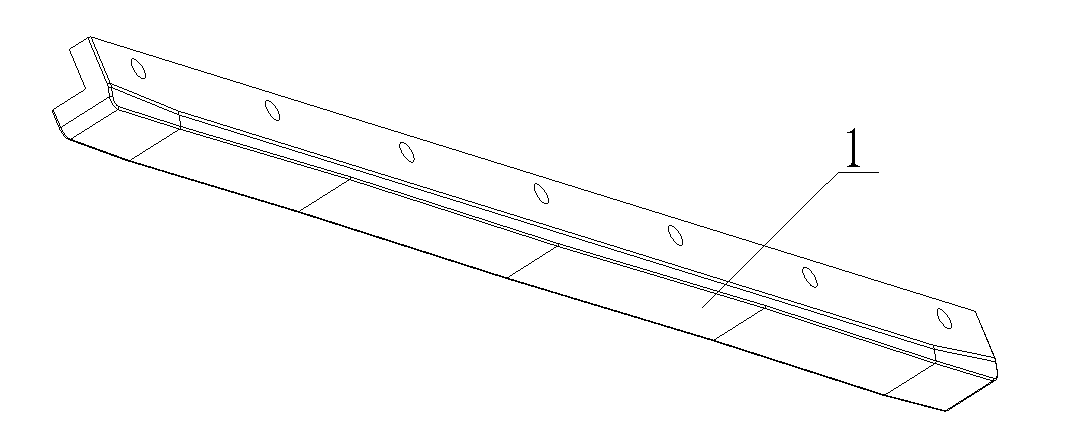

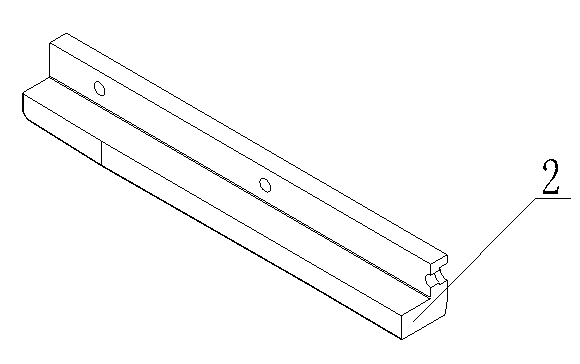

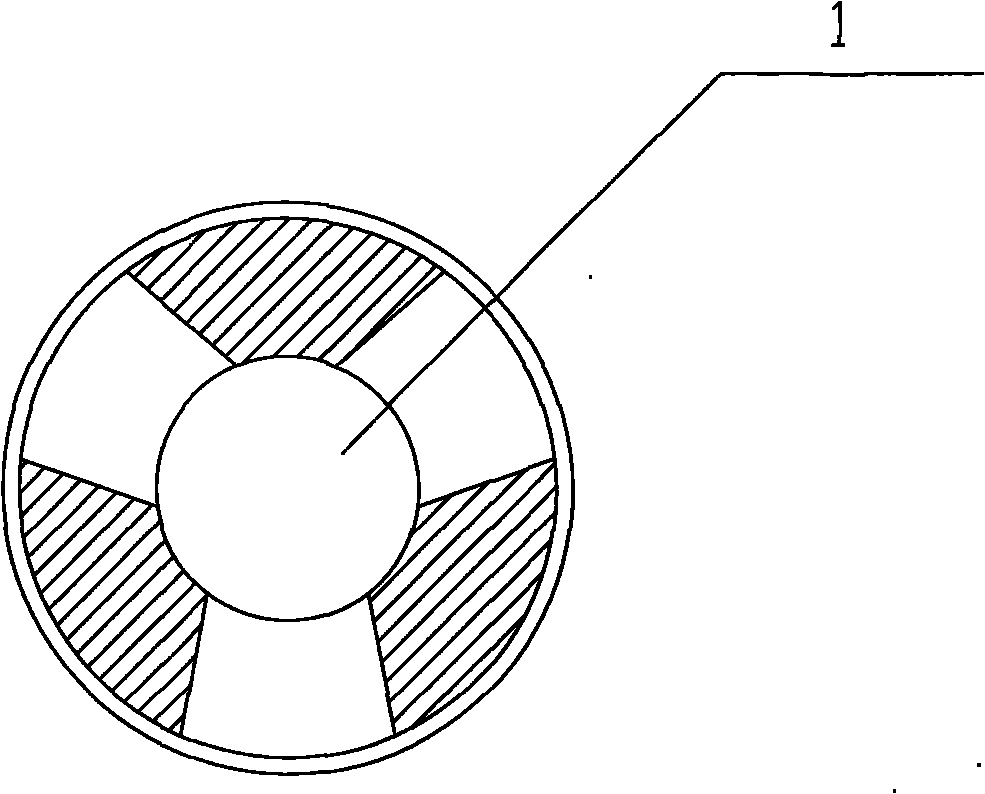

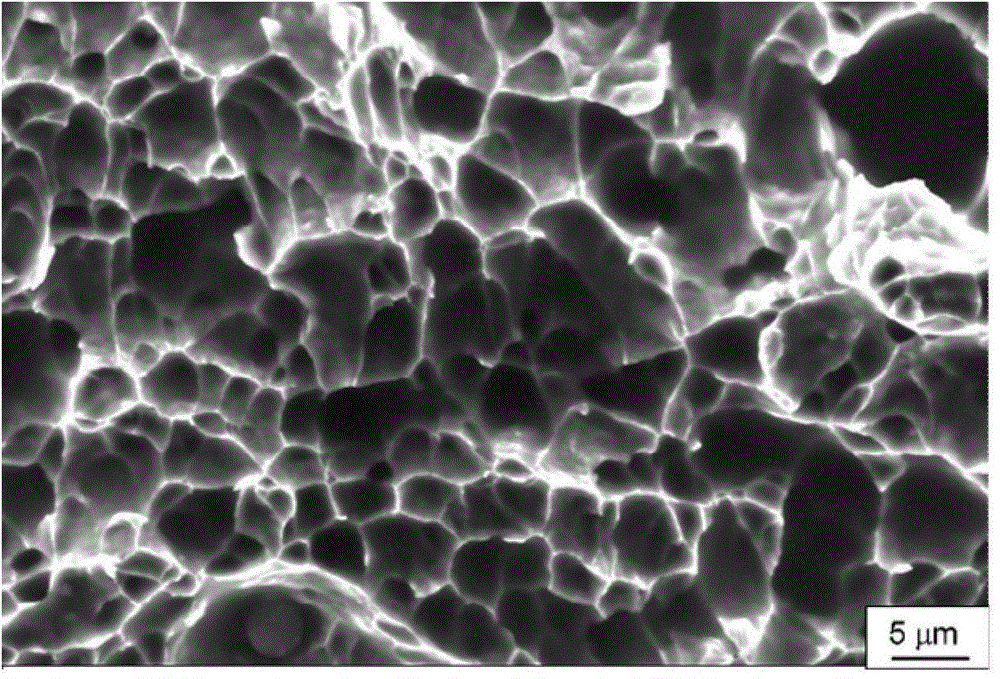

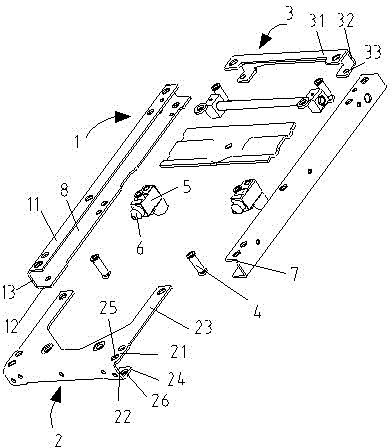

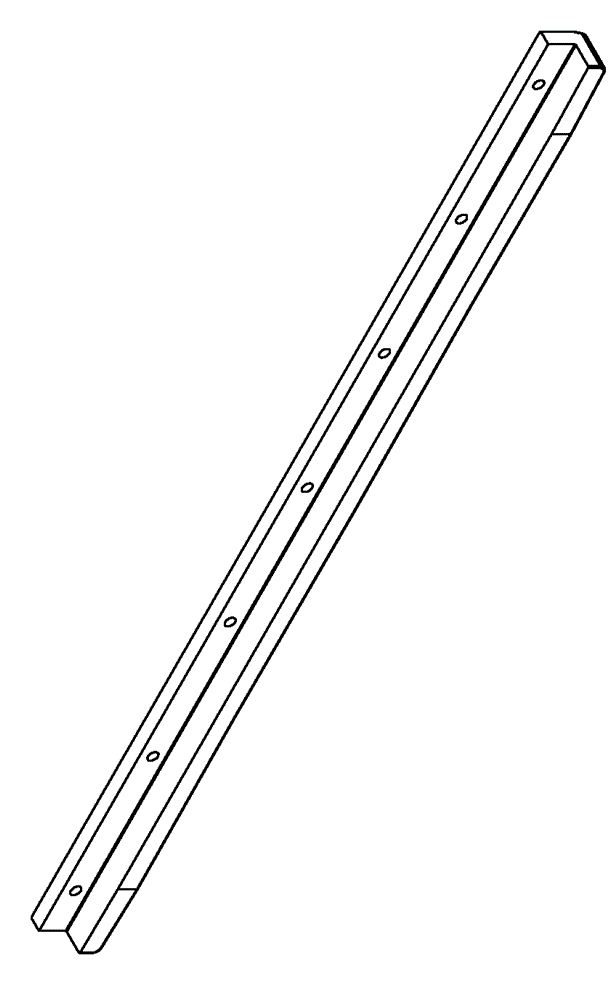

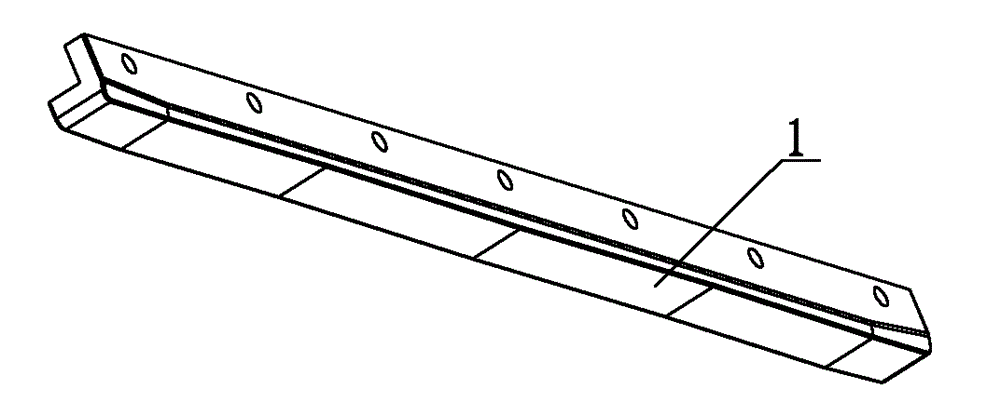

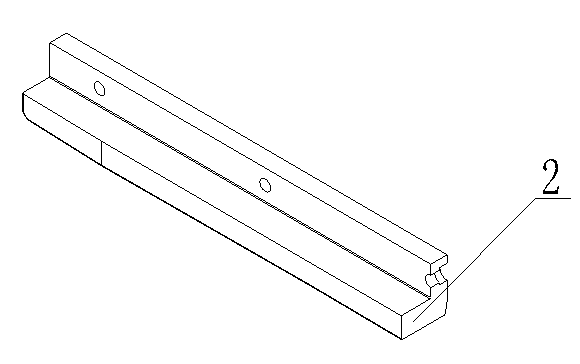

Processing method of twisted guide rail

The invention relates to a processing method of a twisted guide rail. A cross section of the twisted guide rail is L-shaped; the lower surface of the twisted guide rail consists of a horizontal area and a plurality of sections of continuous inclined planes. The processing method comprises the steps of: a, adopting a forgeable piece as a blank; b. performing coarse processing, processing a reinforcing rib by making use of the material on the forgeable piece when performing coarse processing; c, after finishing the coarse processing, performing a hardening and quenching work procedure, a tire matching and shape righting work procedure and a nondestructive testing work procedure of a semi-finished product; d, semi-finish machining and straightening workpieces; e. finish machining: machining all of the surfaces into a finished-product dimension, retaining the reinforcing rib; f, surface quenching: sensing and heating by adopting semi-circle; g, removing the reinforcing rib, grinding and polishing; and h, performing nondestructive testing. The processing method is suitable for processing a slender slide rail that has a large length-width ratio, a surface quenching hardness HRC of 50-56, a tensile strength Rm of 1000-1150N / mm<2>, a cross section of an unstable geometrical shape and a sliding surface of a twisted surface.

Owner:TIANJIN SERI MACHINERY EQUIP

Submerged-arc welding process of stainless steel plate larger than 80mm in thickness

InactiveCN105127564AQuality improvementSimple welding processArc welding apparatusWelding/soldering/cutting articlesSheet steelEngineering

The invention discloses a submerged-arc welding process of a stainless steel plate larger than 80mm in thickness. The submerged-arc welding process comprises the following steps: beveling the steel plate, wherein symmetrical double U-shaped bevels are adopted, the angle of each bevel is 45 to 55 degrees, the truncated edge is 3mm to 5mm in thickness, and the clearance of the truncated edge is 2mm to 3mm; cleaning up the bevel of a weldment, 20-mm area in each side of the bevel and the surface of a to-be-welded position; selecting a welding wire which is 3mm to 4mm in diameter and is made from the same material of the weldment; baking a solder for 1 to 2 hours at the temperature of 300 to 400 DEG C before welding; during welding, performing bottom welding on the front surface of a metal plate by adopting gas shielded welding, subsequently filling a welding bead by adopting submerged-arc welding, turning over after filling the welding bead, removing the previous gas shielded welding bead from the reverse surface by adopting carbon arc gouging, exposing a submerged-arc welding bead in the front surface and then performing submerged-arc welding until the welding bead is filled. The welding process disclosed by the invention is simple and good in formation of the welding line; the obtained welded joint is good in quality and free of welding cracks and welding deformation.

Owner:ANHUI FUHUANG STEEL STRUCTURE

Large damaged foundation bolt butt joint method

The invention relates to a large damaged foundation bolt butt joint method comprising a special socket. The special socket is a hollow cylindrical cylinder, the upper end and the lower end of the socket are respectively provided with a reinforced hoop, and the diameter of the reinforced hoop is bigger than that of the socket. The method comprises the following steps: cutting off the damaged part of the damaged foundation bolt; polishing the burr on the cutting part until the cutting part is smooth; arranging a new foundation bolt at the cutting part, and sheathing the special socket to carry out butt joint to the new foundation bolt and the damaged foundation bolt; welding and fixing the joint of the new foundation bolt and the damaged foundation bolt as well as the joint of the new foundation bolt, the damaged foundation bolt and the socket. The invention is suitable for the basic direct embedded foundation bolt of electromechanical equipment, plant steel structure pillars, equipment bearing heavy load or vibratory shock and the like, has short construction time, and can ensure butted strength and verticality.

Owner:MCC BAOSTEEL TECH SERVICE

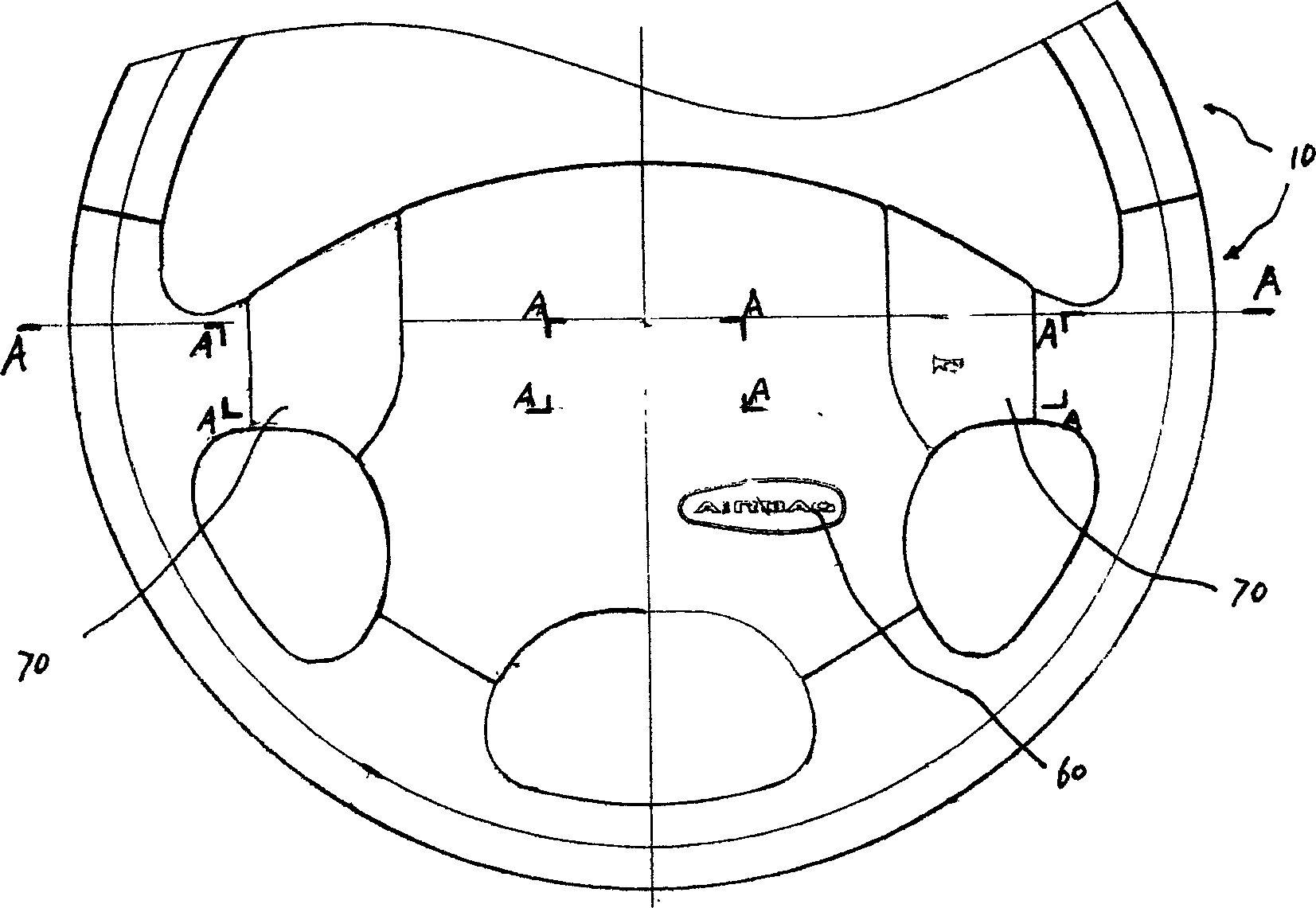

Steering wheel and its manufacture method

The present invention discloses a steering wheel for automobile and its production method. Said steering wheel includes a magnesium alloy skeleton wheel body containing ring upper portion wheel rim, lower portion base seat and several auxiliary ribs between them which are die-cast into one integrated structure, the upper portion wheel rim of small half-portion of said wheel body is covered with ABS covering layer, its exterior is covered with transferred layer with peach wood grain, and other portion of the described upper portion wheel rim is equipped with foamed layer, and the exterior of said foamed layer is covered with leather layer. Said invented product quality is reliable, and its appearance and hand feel can be obviously improved.

Owner:SHUNDA WUHU AUTOMOBILE DECORATION

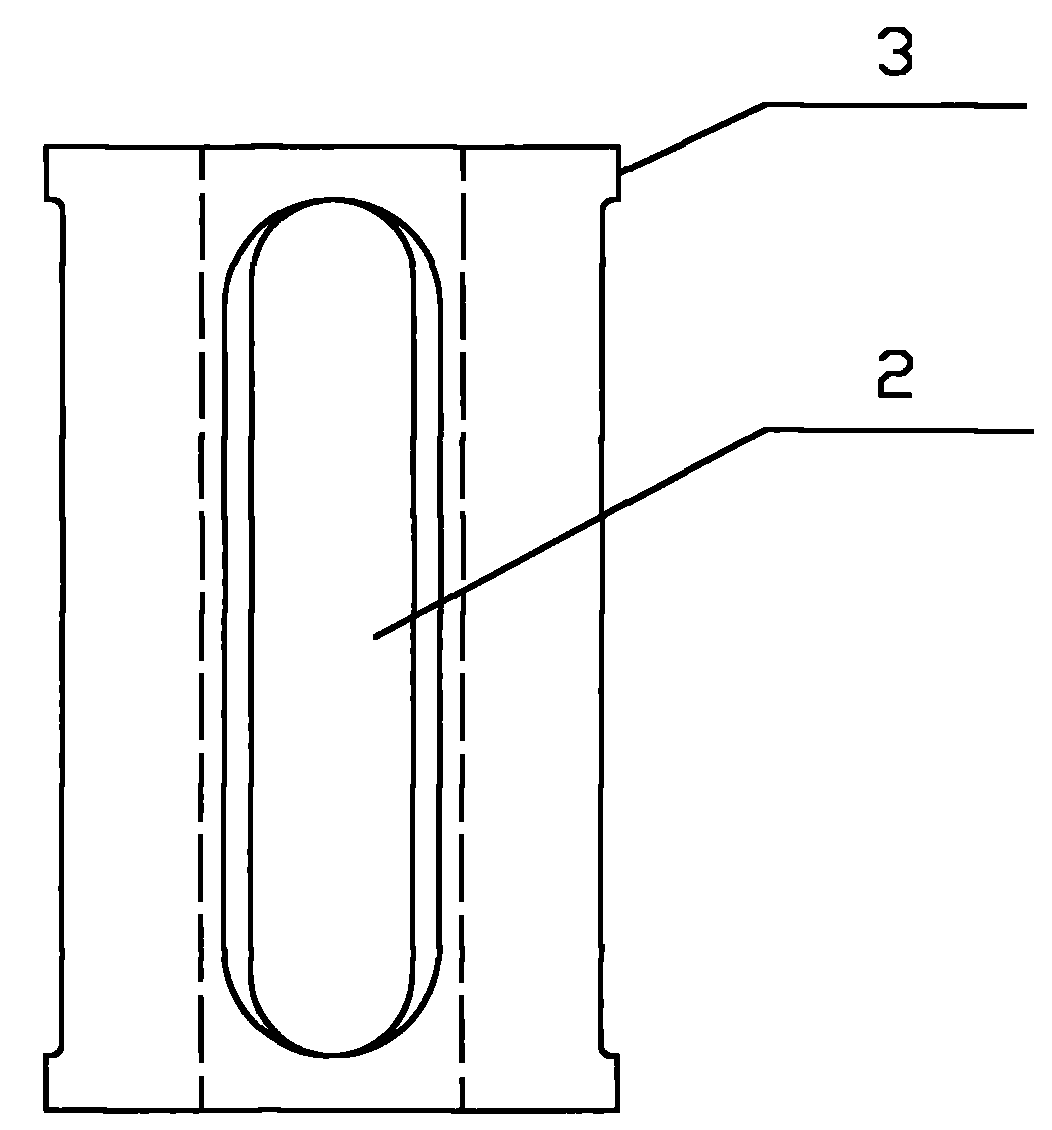

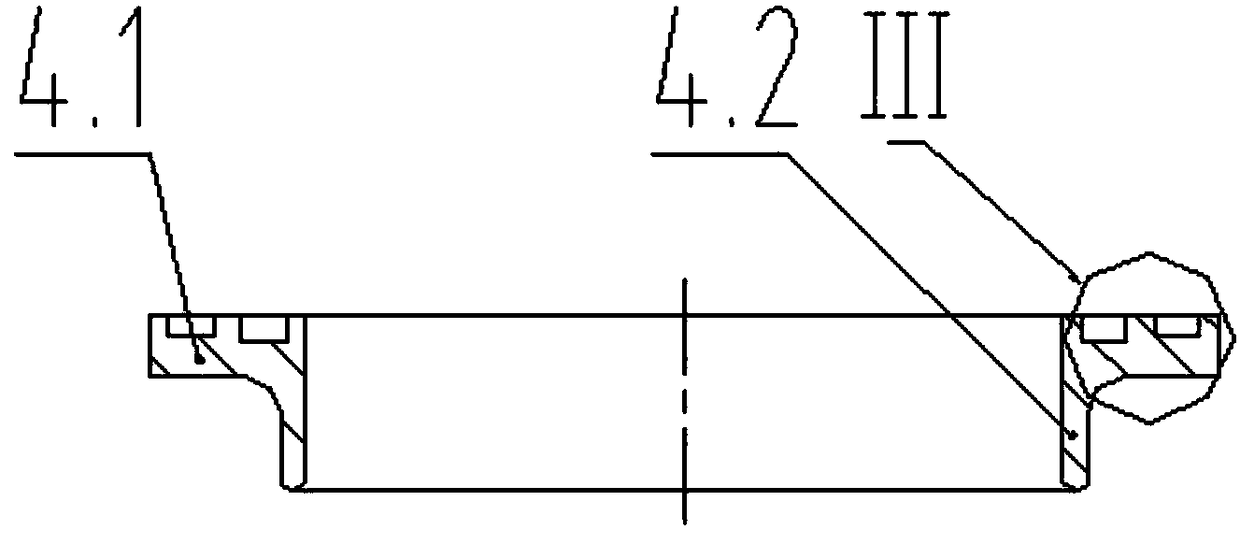

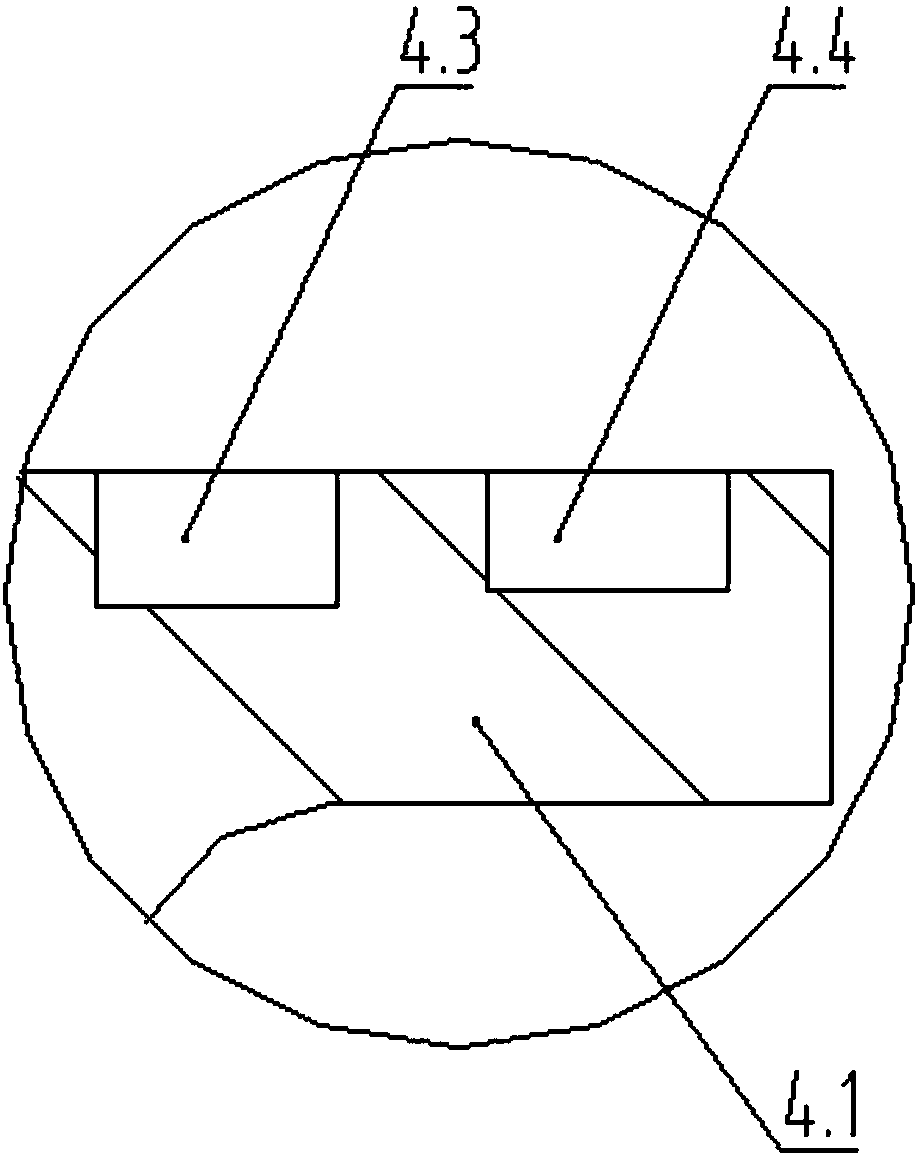

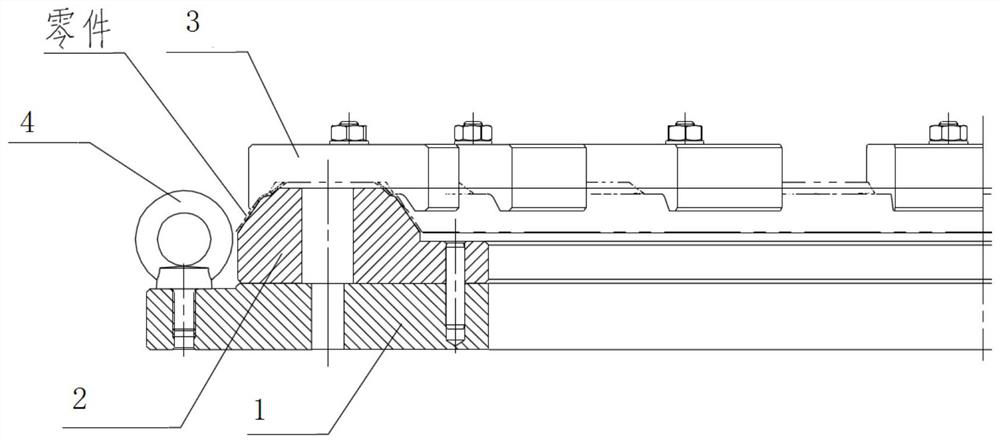

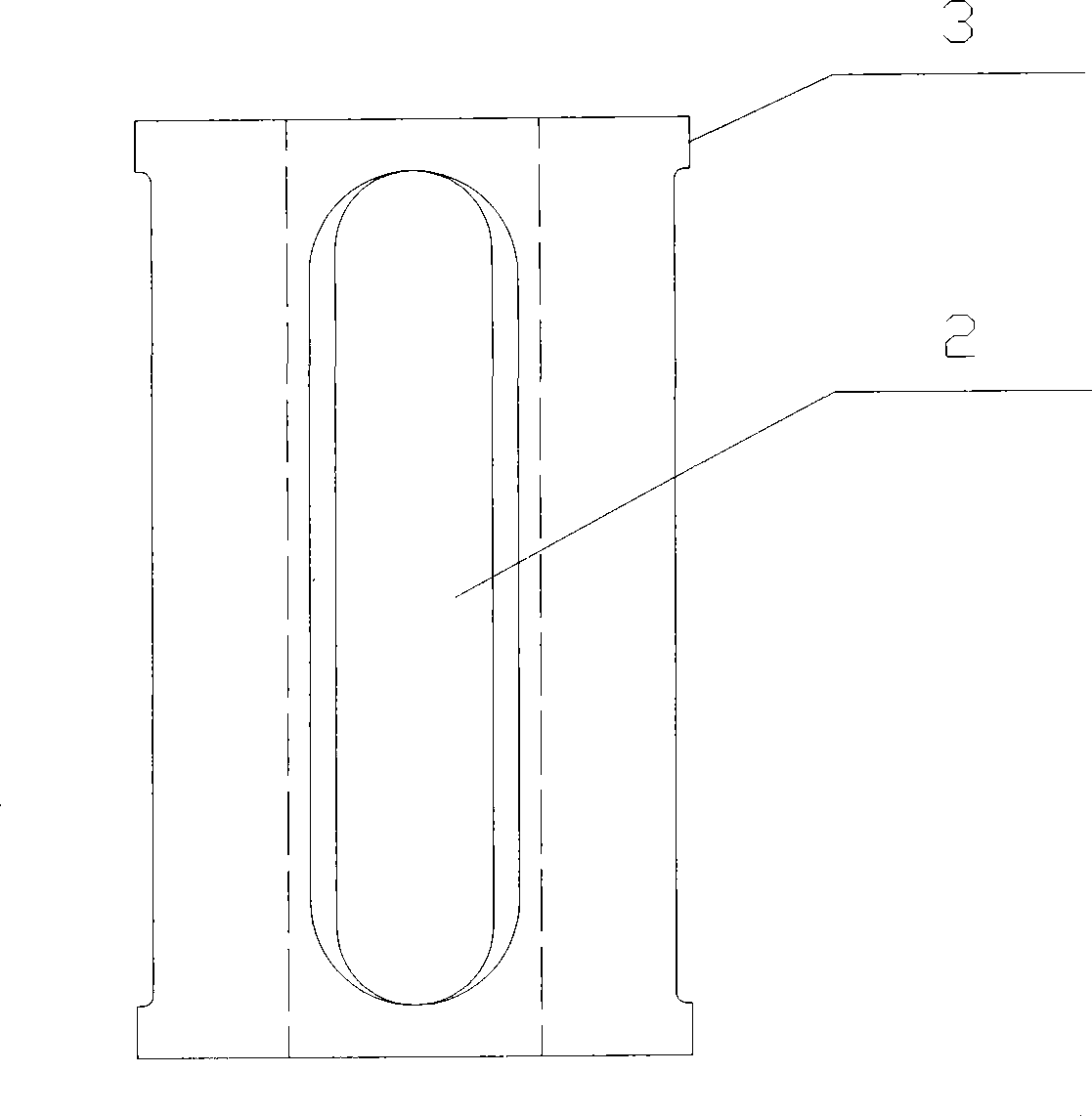

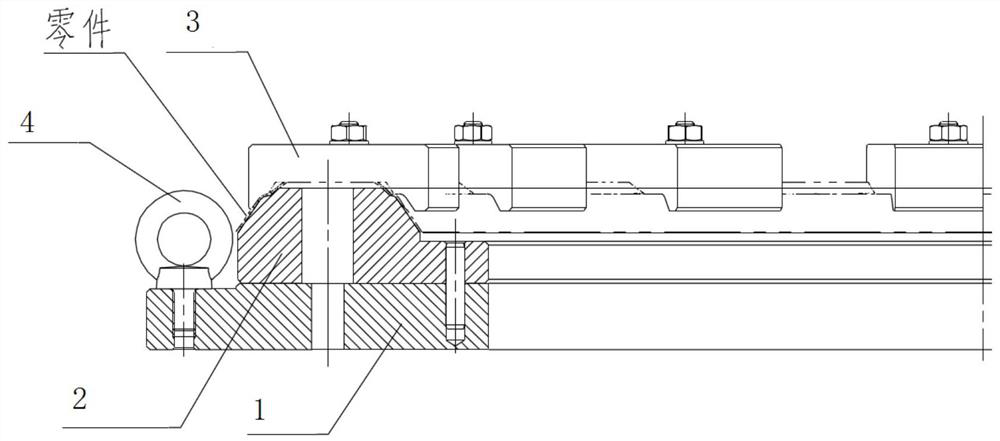

Support cylinder assembly with two sealing grooves for three-way shell

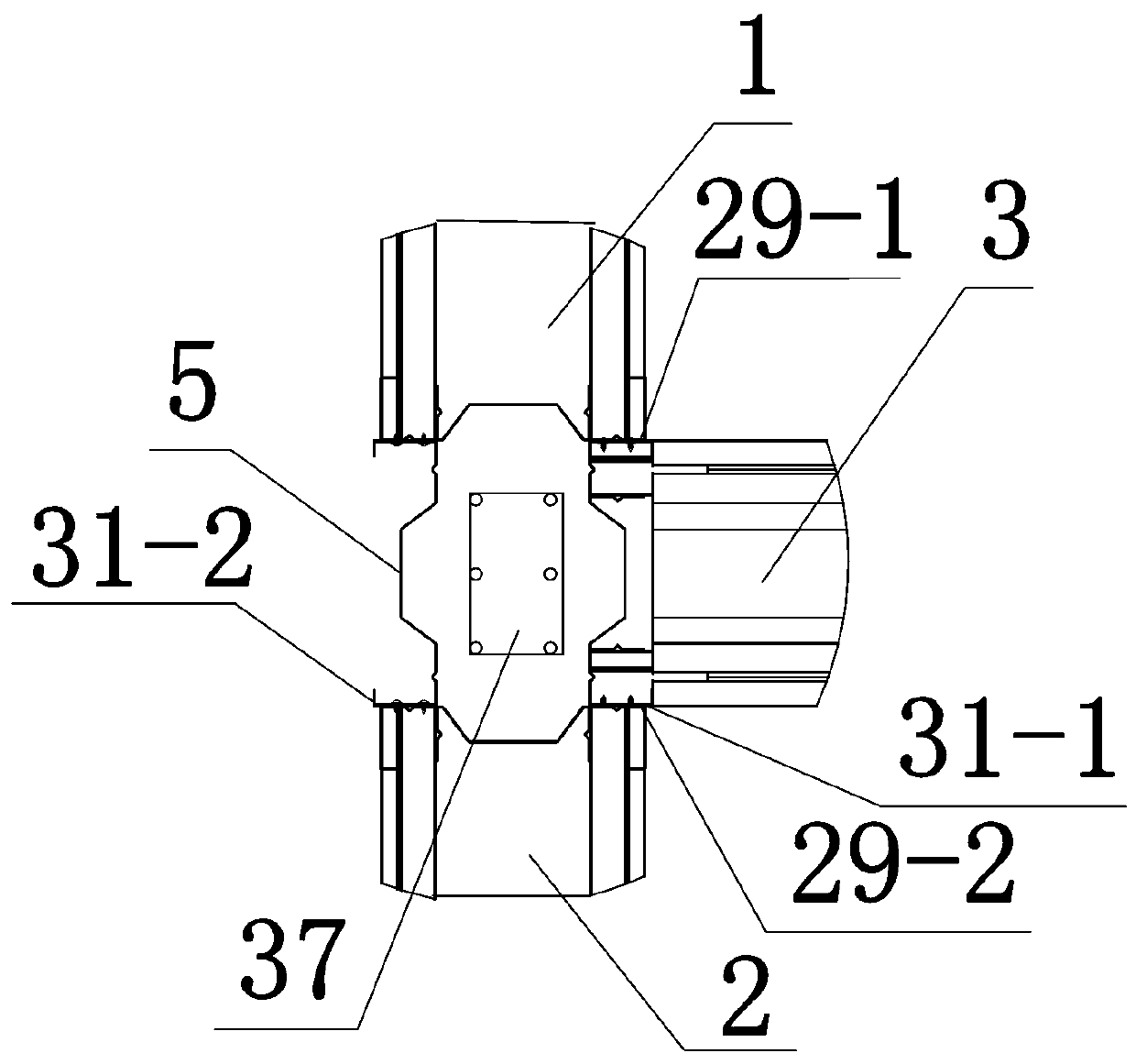

InactiveCN108400562ANo welding stressNo welding deformationBus-bar/wiring layoutsGroove widthEngineering

The invention discloses a support cylinder assembly with two sealing grooves for a three-way shell. The support cylinder assembly comprises a support cylinder flange and a support cylinder, wherein one end of the support cylinder is turned up to form a support cylinder flange, namely the support cylinder and the support cylinder flange are of an integrated structure; further improvement is that anouter sealing groove II and an inner sealing groove II which are coaxially sheathed and have the same groove width are arranged on the end face, facing outwards, of the support cylinder flange; and the depth of the outer sealing groove II is smaller than the depth of the inner sealing groove II. According to the support cylinder assembly, no welding stress exists, so that welding deformation is avoided, and furthermore, the structural strength is high, and the sealing effect is good.

Owner:孙萍

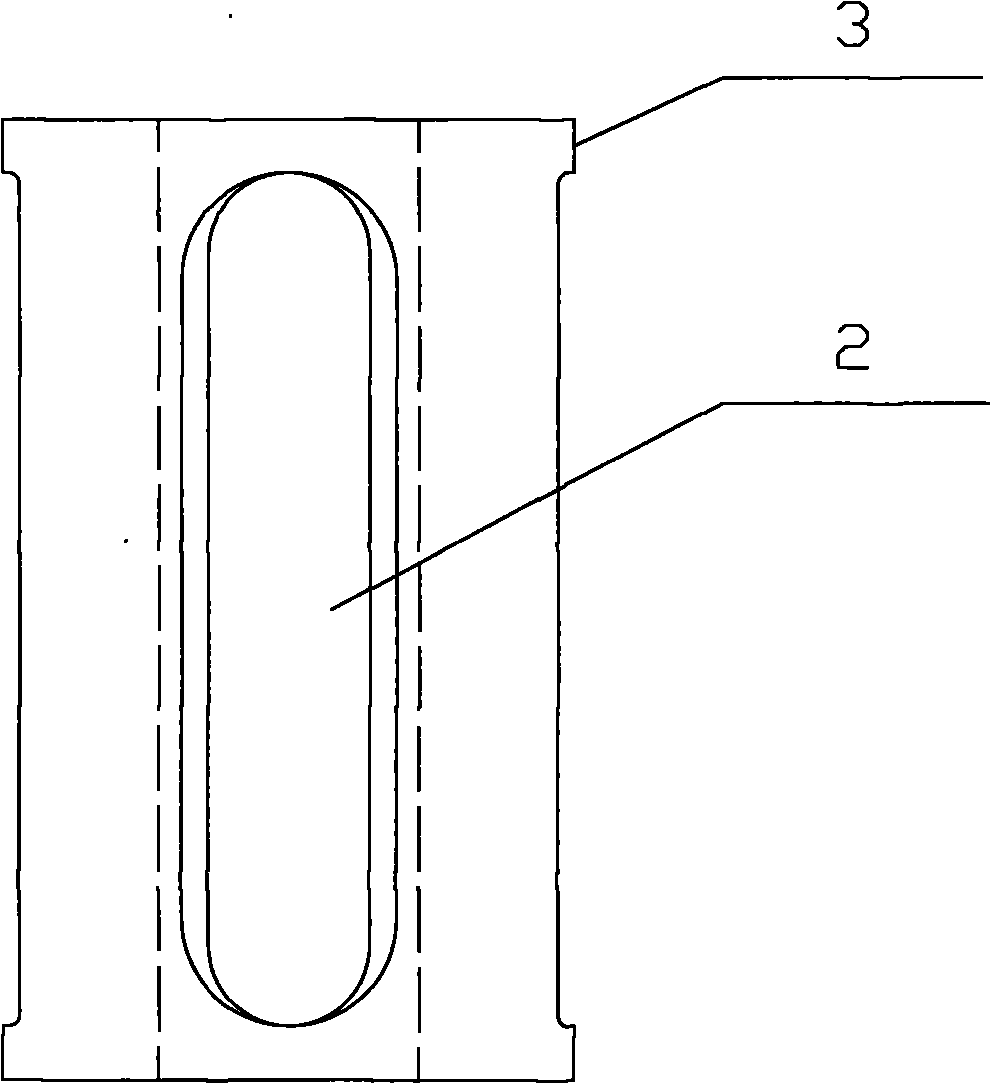

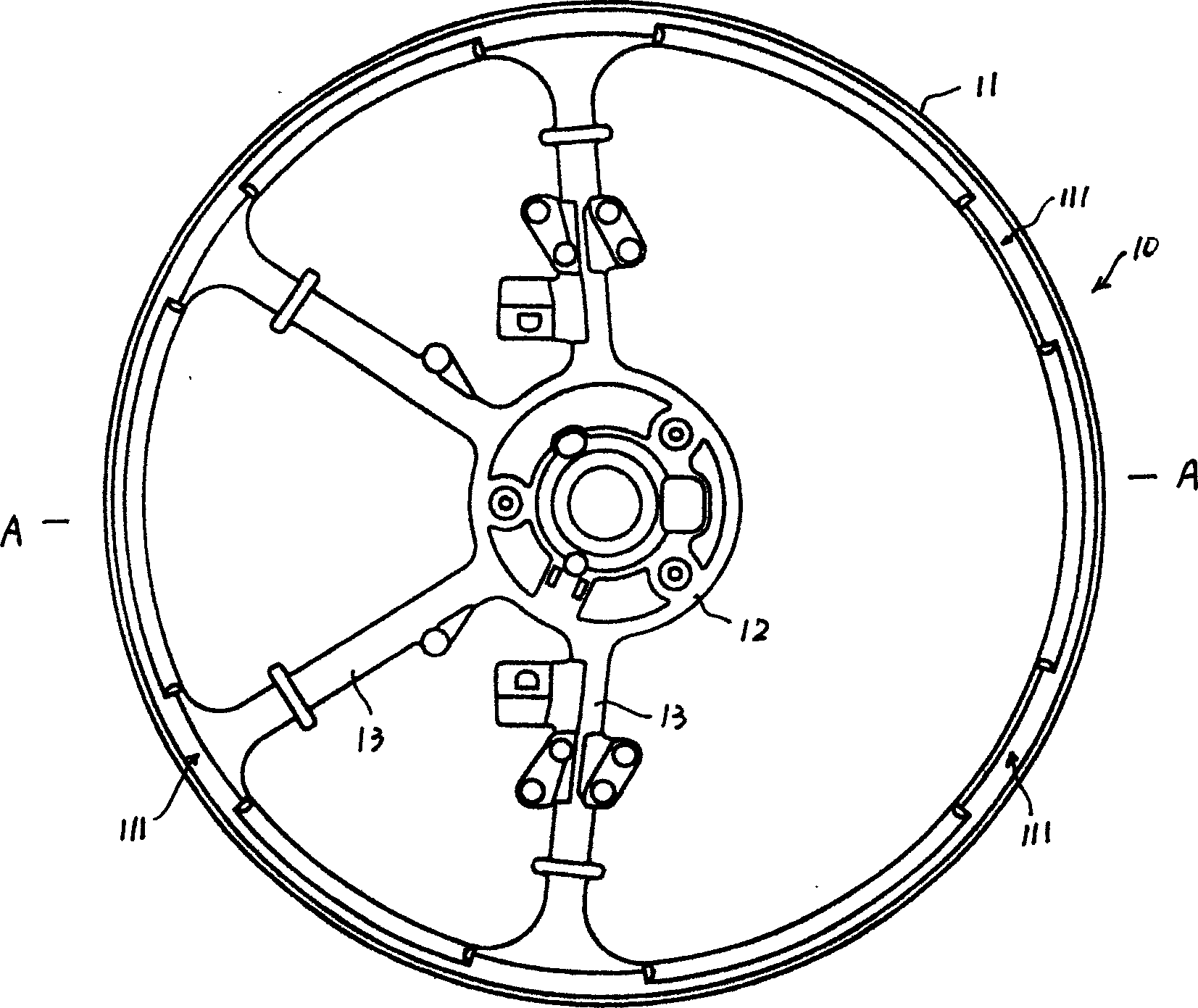

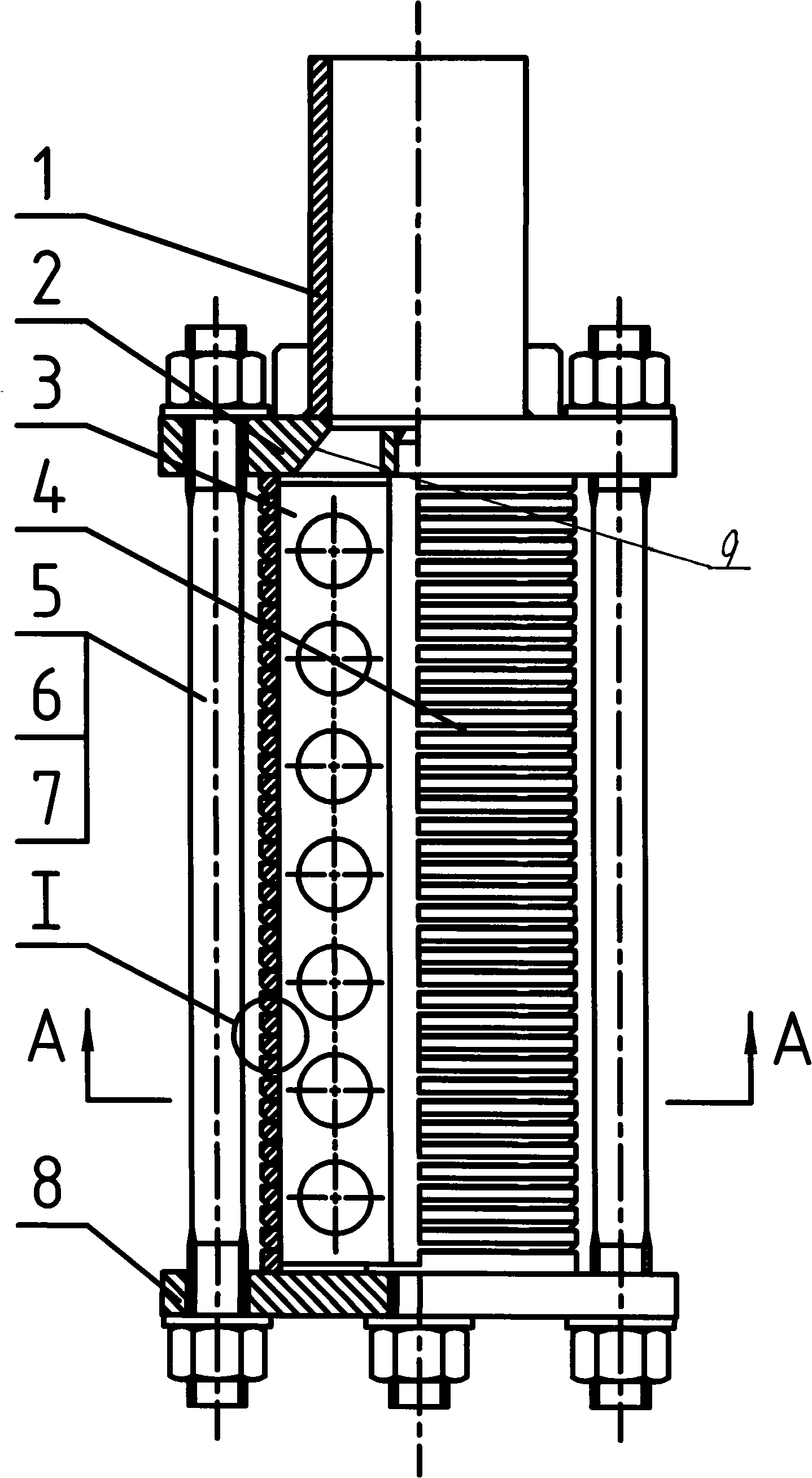

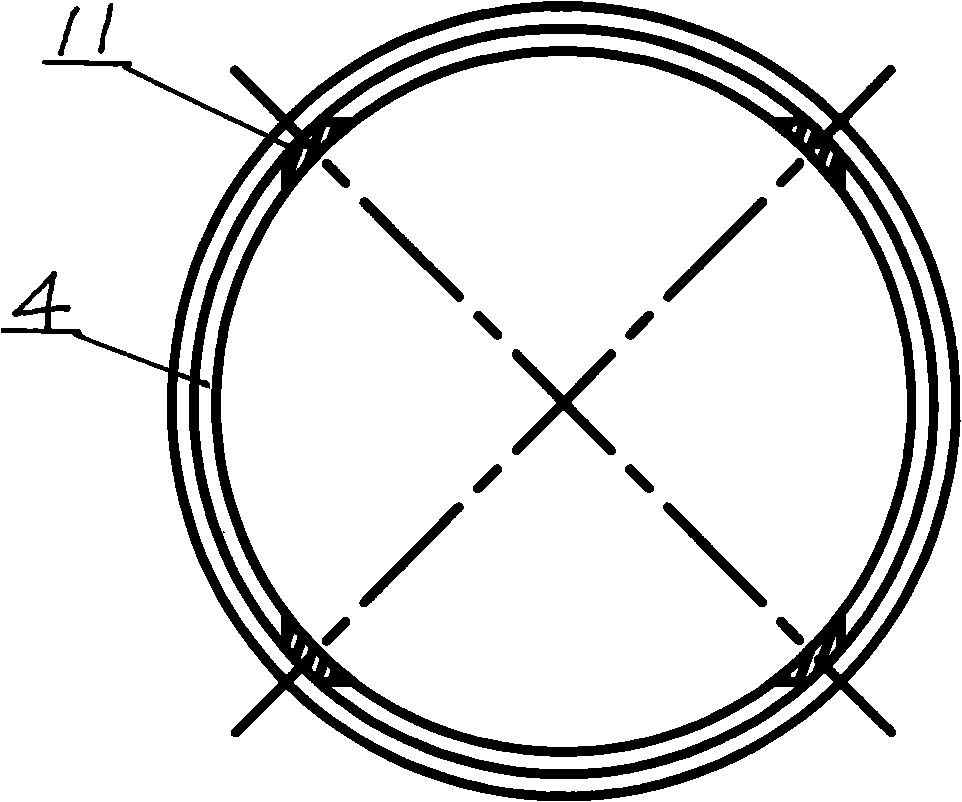

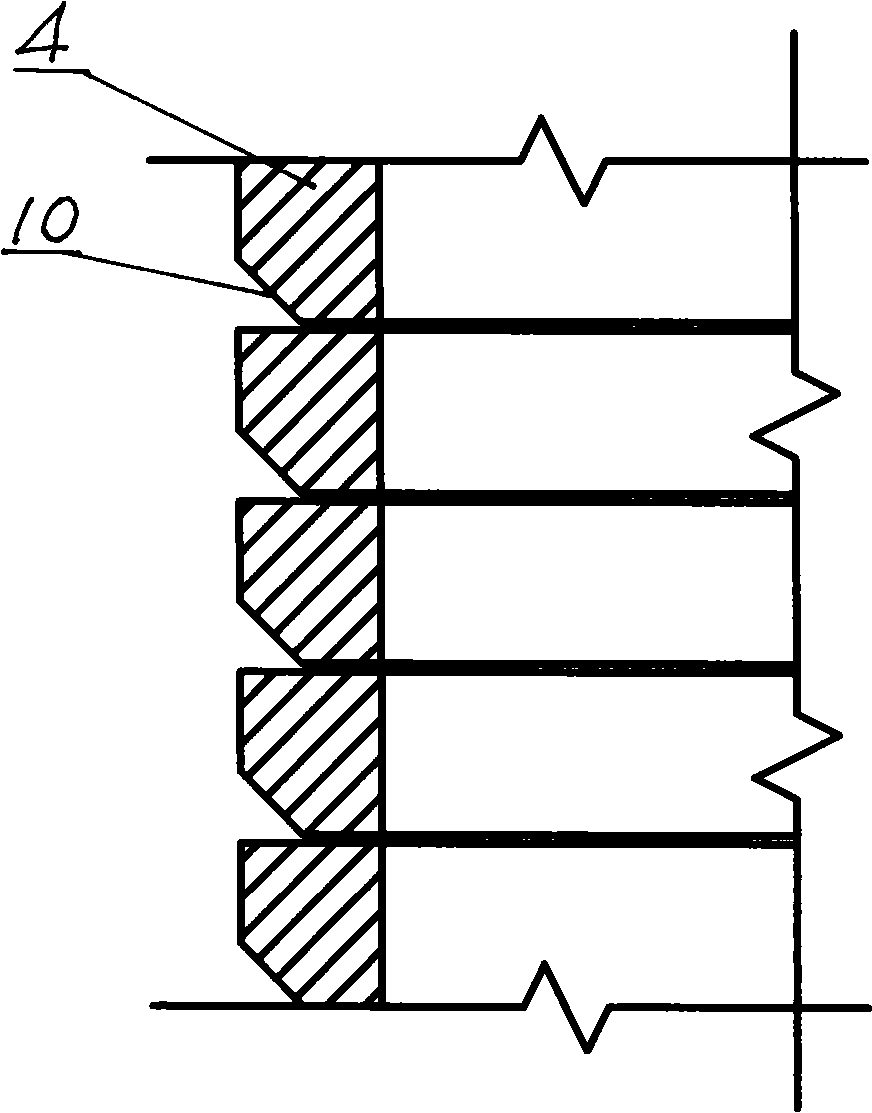

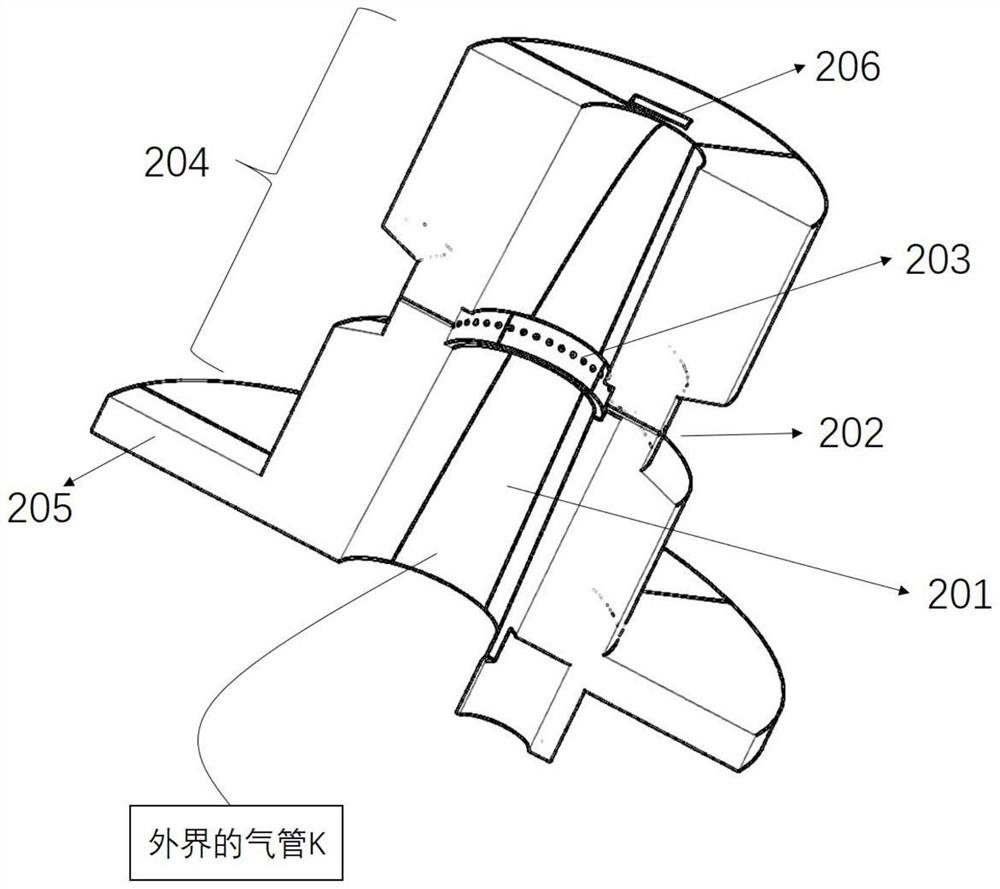

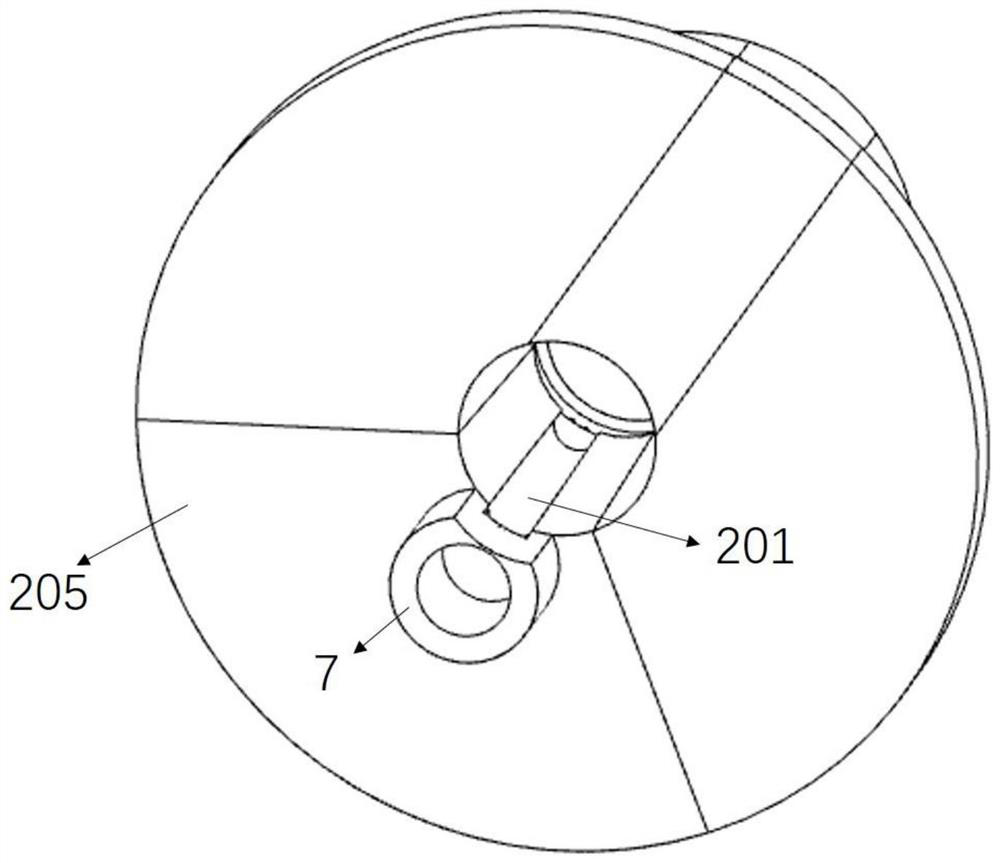

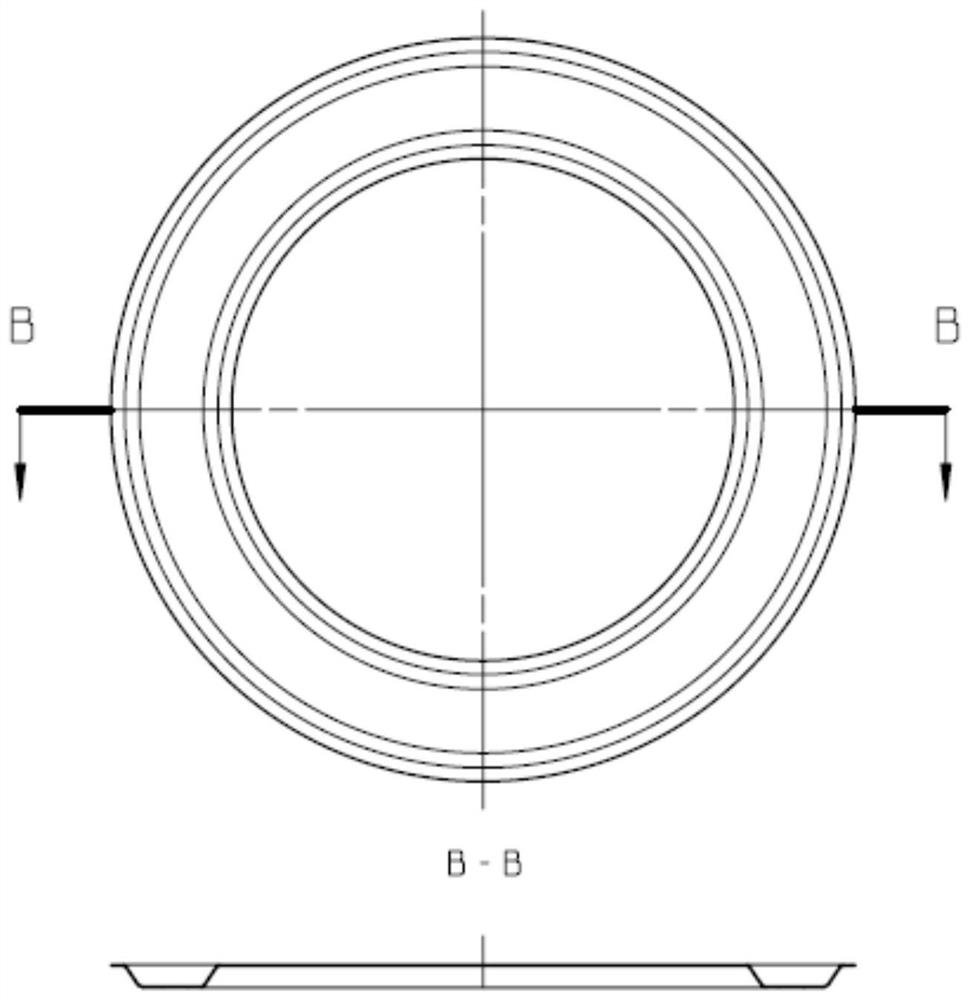

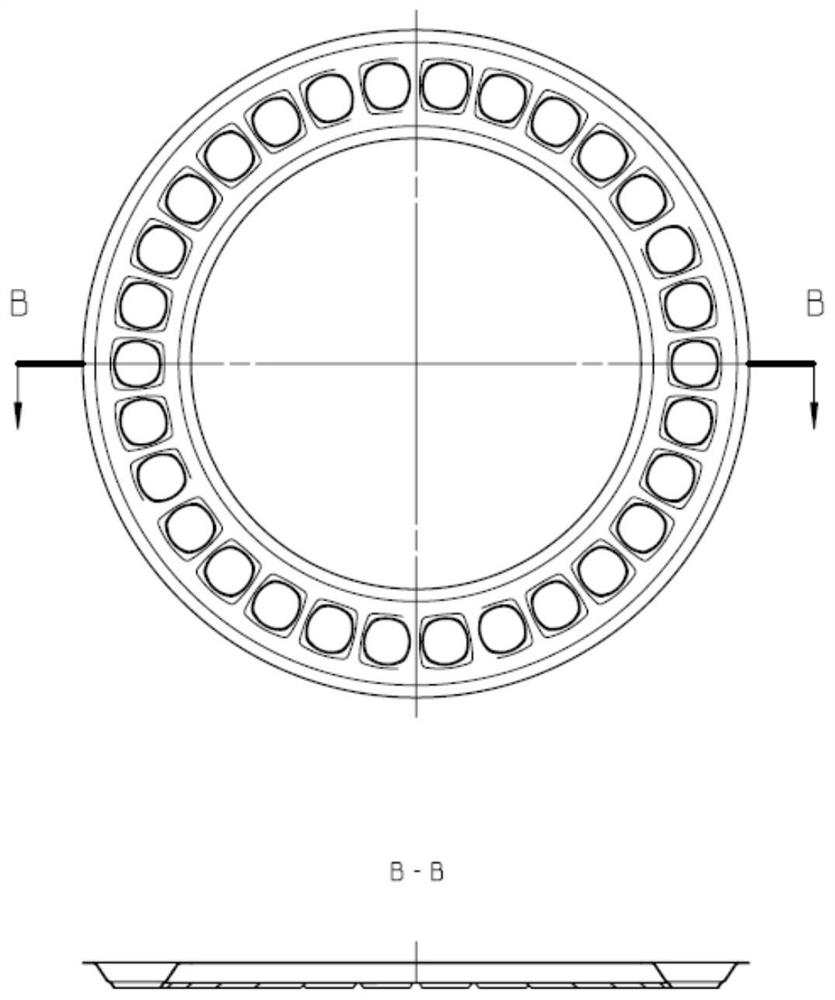

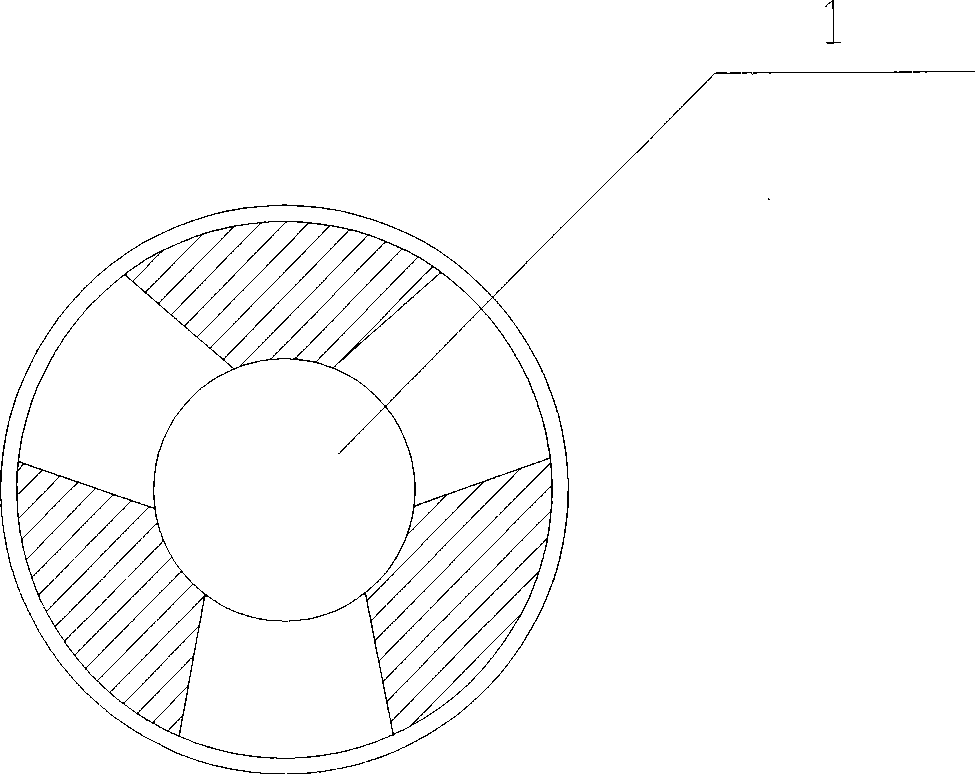

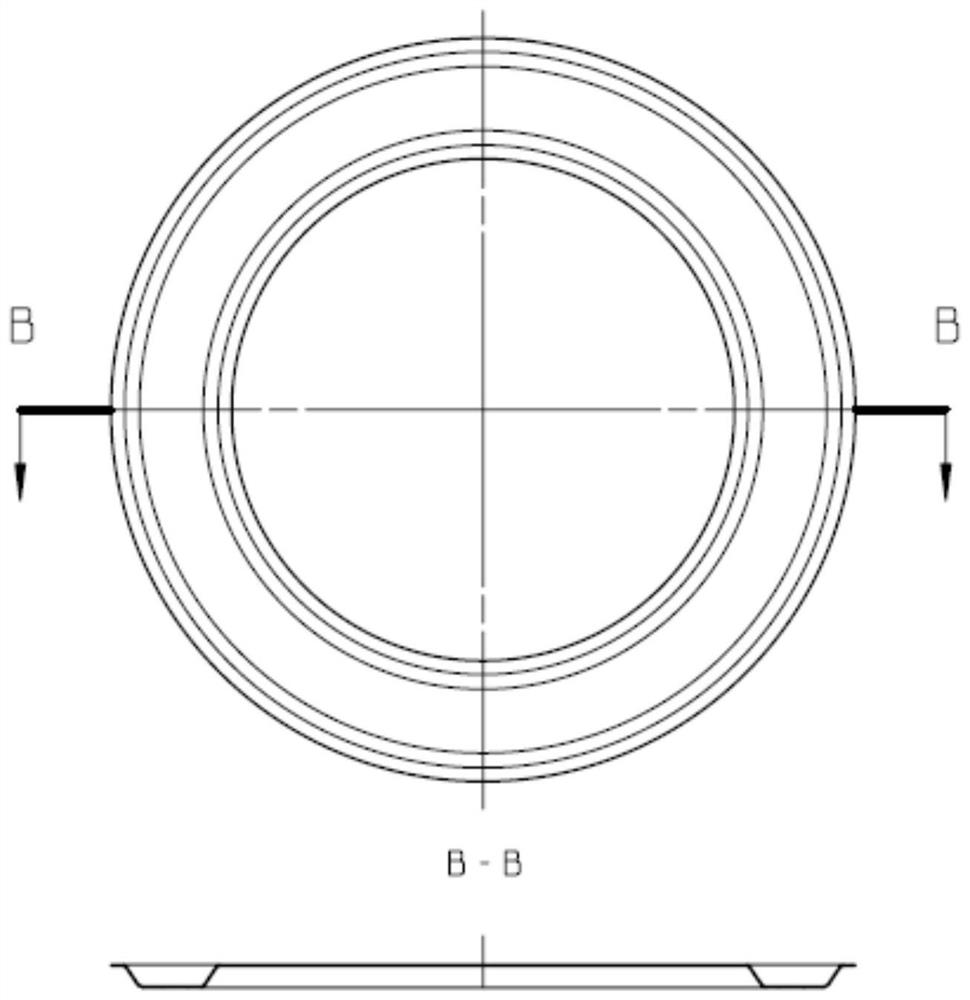

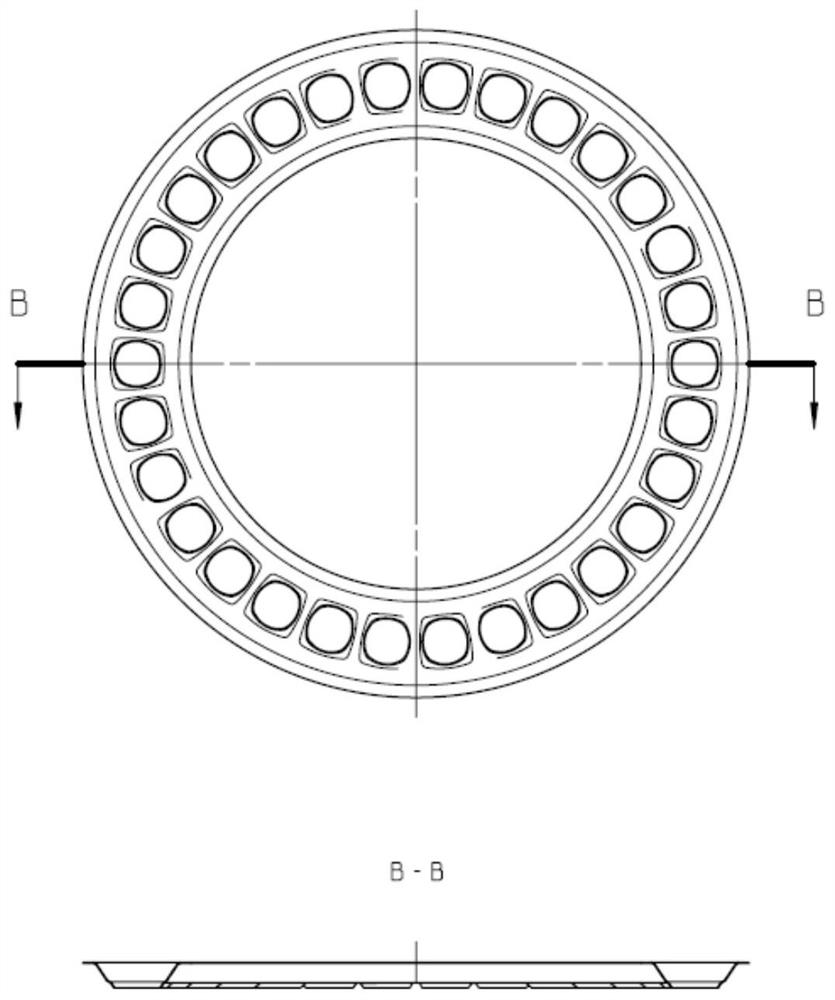

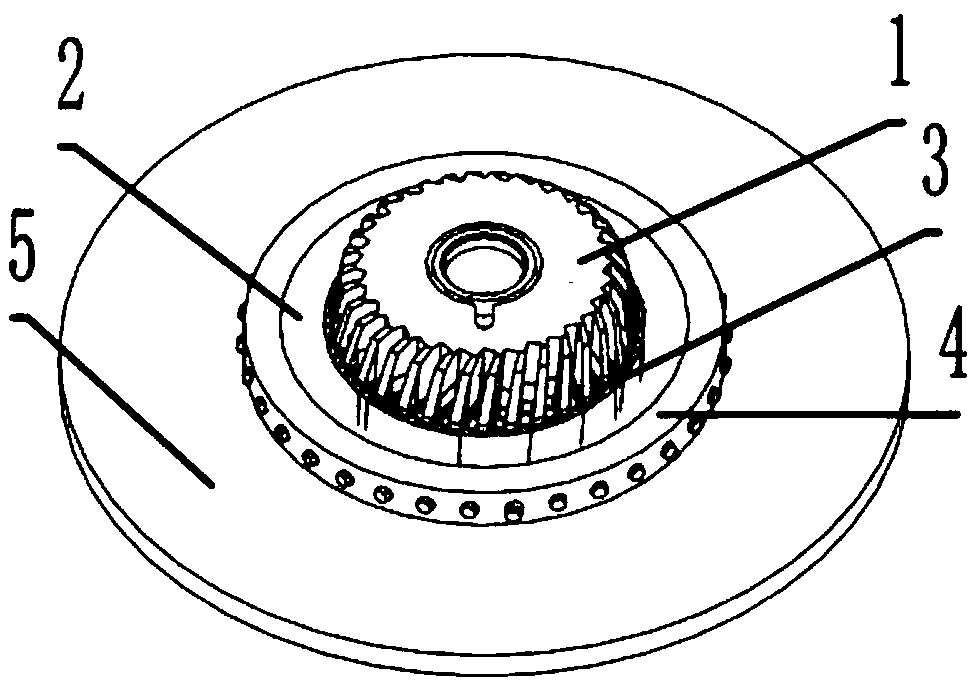

Filter head apparatus of nuclear plant desalting device

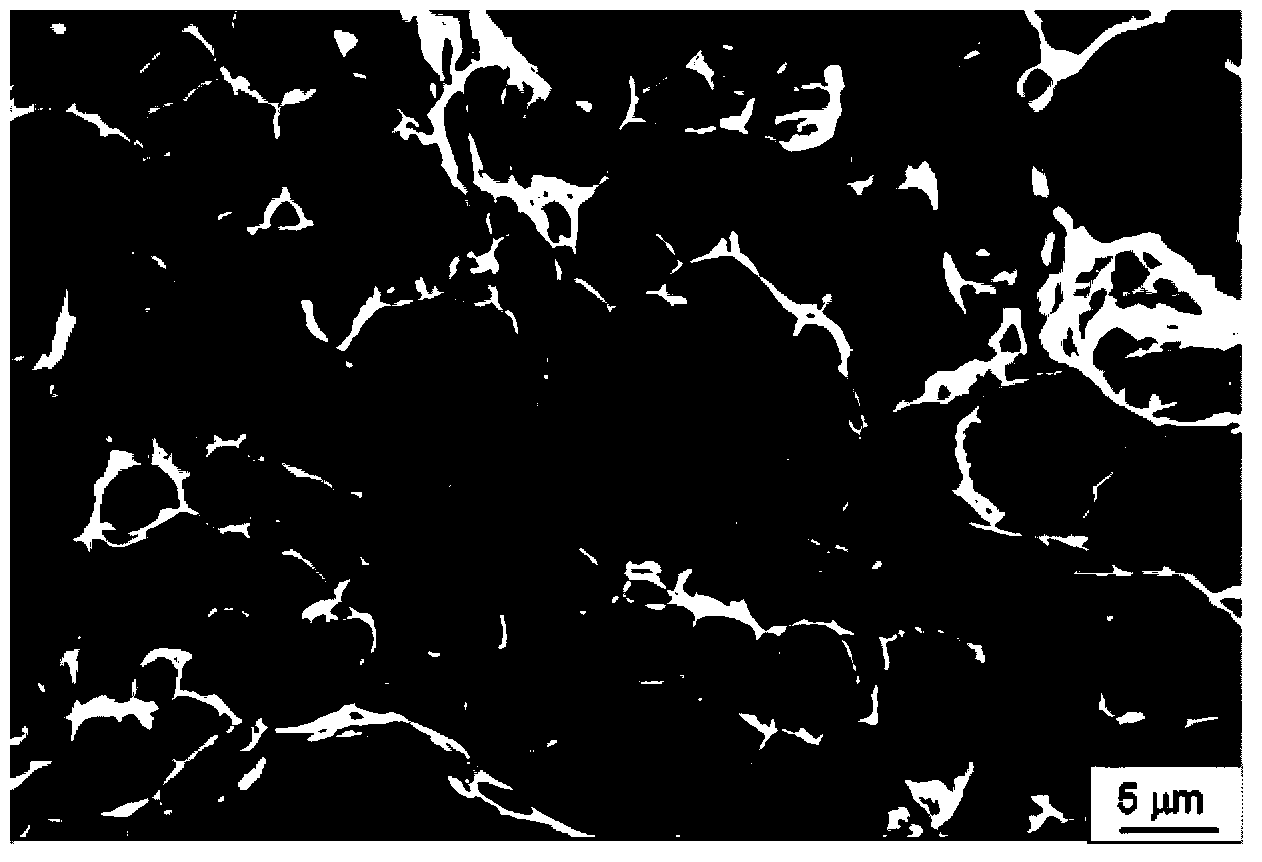

InactiveCN101323468ASimple structureHigh strengthWater/sewage treatment by ion-exchangeNuclear plantWater flow

The invention relates to a filter head apparatus of a desalter used for a nuclear power plant which is a part of a water treatment equipment of the nuclear power plant and belongs to the water treatment field. The apparatus is mainly characterized by the improvement to the structure of existing sheet-superposed type filter head apparatuses, in particular to the structure improvement of filter tubes formed by a plurality of superposed sheets which is changed into an integrated structure formed by processed water-filtering apertures and isolating ribs. The invention has high intensity and no welding distortion, and can be finely processed by a machine tool with steady apertures and high accuracy, thus guaranteeing the flow aperture and enhancing the quality of purified water. The filter head apparatus of the invention can displace the existing sheet-superposed filter head apparatus.

Owner:何鹰 +1

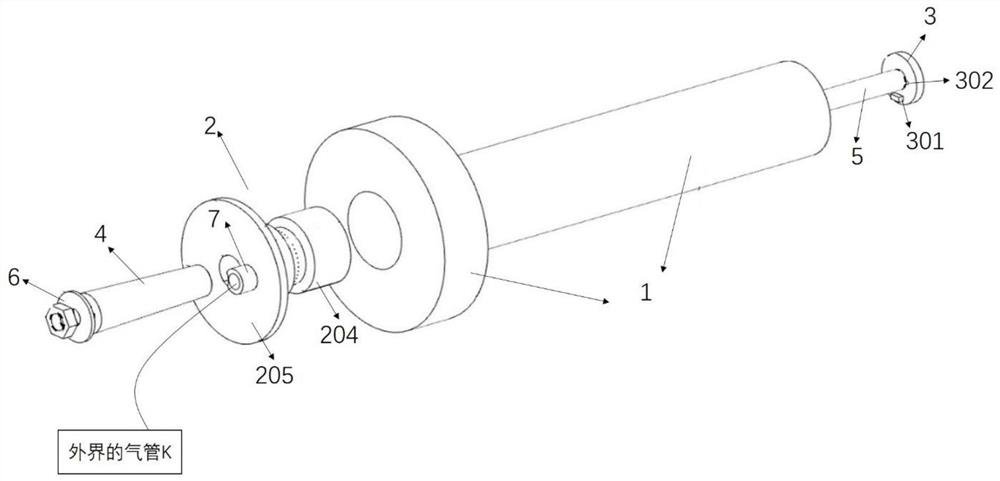

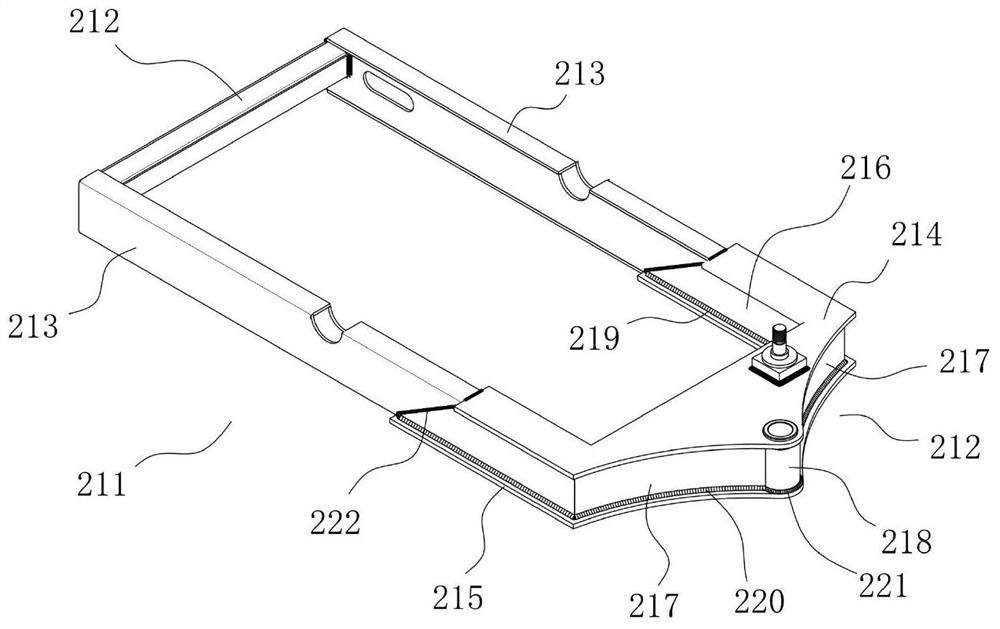

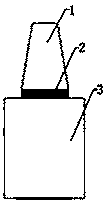

Welding protection device and method used for thin-walled pipe

PendingCN112059527ASolve space problemsSolve efficiency problemsWelding/cutting auxillary devicesAuxillary welding devicesShielding gasStructural engineering

The invention discloses a welding protection device used for a thin-walled pipe. The welding protection device comprises a fastening casing pipe and a top cover. The first end of the fastening casingpipe penetrates into the thin-walled pipe, the second end of the fastening casing pipe clamps the second end of the thin-walled pipe, the outer wall of the fastening casing pipe cooperates with the inner wall of the thin-walled pipe, a first groove is formed in the inner wall of the fastening casing pipe in the axial direction of the fastening casing pipe, and the second end of the first groove communicates with an air pipe. A second groove is formed in the outer wall of the fastening casing pipe in the circumferential direction of the fastening casing pipe. Multiple through holes are evenly distributed in the bottom end of the second groove and communicate with the first groove and the second groove. The top cover is detachably connected with the first end of the fastening casing pipe, the outer diameter of the top cover is larger than the inner diameter of the fastening casing pipe, and the first groove is sealed. By means of the welding protection device, the problems that the welding space of the thin-walled pipe is limited and the welding efficiency is low are solved, the thin-walled pipe is expanded through the fastening casing pipe and a fastening pin, shielding gas is directly and evenly distributed into the second groove through the first groove, welding deformation of the thin-walled pipe is avoided, the defect that the welding space is limited is overcome, and the welding efficiency is improved.

Owner:SHANGHAI ELECTRIC NUCLEAR POWER EQUIP CO LTD

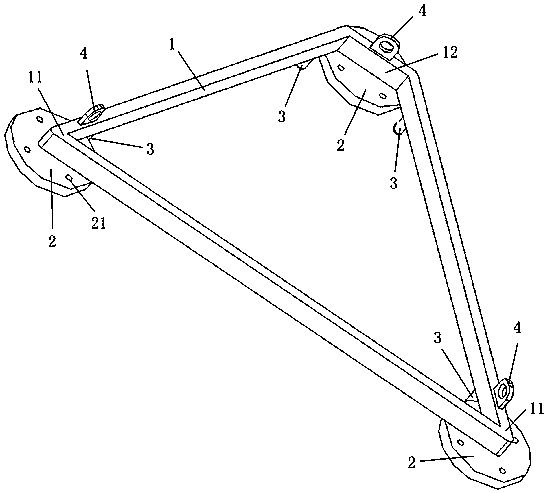

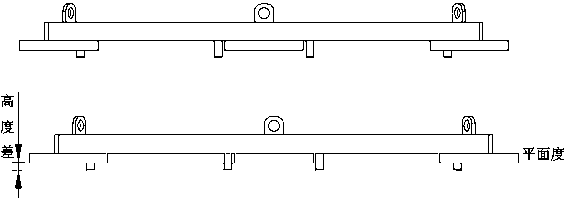

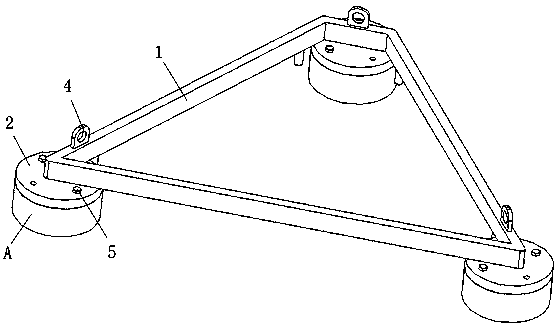

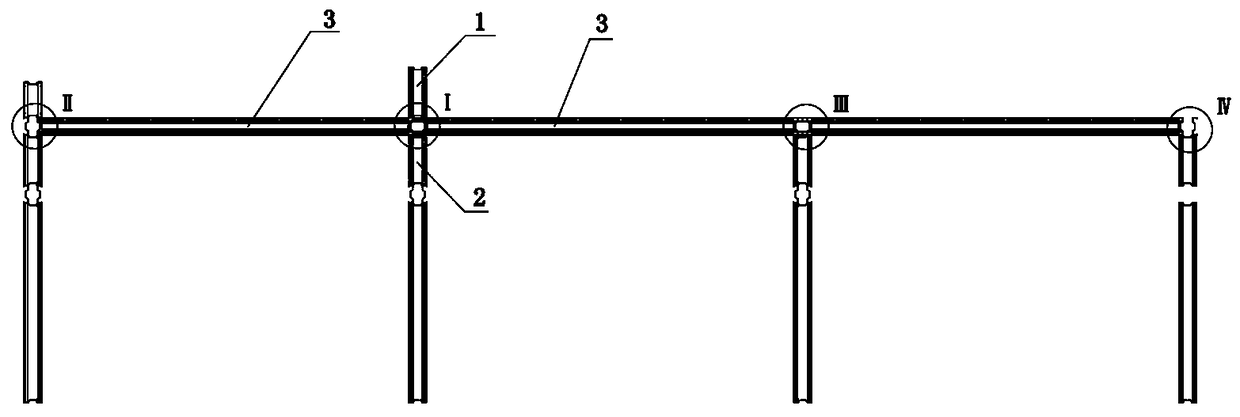

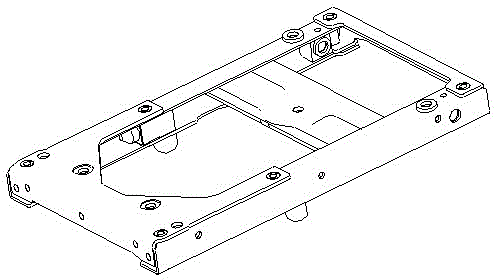

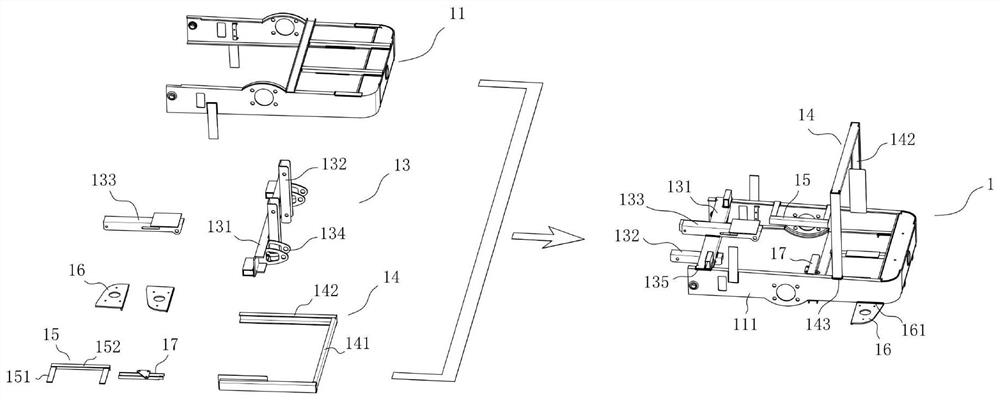

Welding tooling for pantograph mounting seat assembly welding and pantograph mounting seat welding method

ActiveCN110877182AGuaranteed flatnessAvoid errorsWelding/cutting auxillary devicesAuxillary welding devicesControl cellHeight difference

The invention relates to the technical field of pantograph mounting, and discloses a welding tooling for pantograph mounting seat assembly welding and a pantograph mounting seat welding method. The welding tooling comprises a tooling framework and a planeness control unit and a height positioning unit which are mounted on the tooling framework, wherein the planeness control unit comprises a plurality of positioning plates which are arranged according to the number, the dimensions and the relative positions of pantograph mounting seats for a train for the city field; each pantograph mounting seat corresponds to one positioning plate in a jointing manner; the entire planeness of the planeness control unit is adaptive with the corresponding pantograph mounting seat; through holes are formed in the positioning plates to allow the pantograph mounting seats to be mounted; and the height positioning unit comprises a plurality of positioning columns which are equidirectionally arranged with the positioning plates on the tooling framework, the height of each positioning column is greater than the thickness of the corresponding positioning plate, and the height difference is equal to the distance difference between the upper surface of each pantograph mounting seat and the surface of a pantograph plate. The planeness control unit and the height positioning unit are combined, so that theplaneness of the upper surfaces of the planeness mounting seats can be effectively guaranteed to meet requirements.

Owner:HUNAN LIANCHENG TRACK EQUIP CO LTD

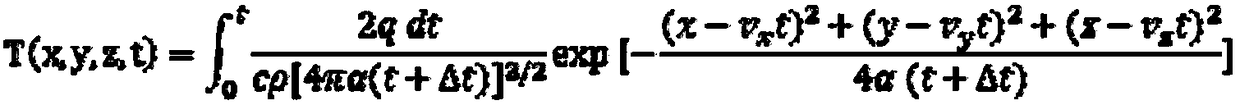

Flame tube head machining device and method

ActiveCN112091543AThe molding process is simpleShort processing cycleOther manufacturing equipments/toolsPositioning apparatusClip deviceStructural engineering

The invention discloses a flame tube head machining device and method. An annular blank is adopted and placed in a forming die to form a U-shaped structure, then heat treatment is carried out, and flame tube convex hulls are formed through stretching. The machining device is adopted for clamping parts, end face turning machining is carried out, and the convex hulls are milled on the premise that aclamping device is not detached. When the convex hulls are milled, the convex hulls are pressed at intervals, the convex hulls which are not pressed are milled firstly, then the milled convex hulls are pressed, and therefore the remaining convex hulls are milled. The mode that the multiple convex hulls are milled at the same time is adopted during milling. The machining method is simple, the machining period is short, the machining cost is low, and the machining quality is good.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

Special sleeve for butt joint of macrotype broken stone bolt and butt joint method thereof

The invention relates to a special butt joint sleeve for a large breakage anchor bolt and the butt joint method thereof. The sleeve is a hollow cylindrical sleeve; reinforced hoops are respectively arranged on the upper end and lower end of the sleeve; a vertical waist-shaped long hole is arranged on the sleeve. The butt joint method includes that: the breakage part of the anchor bolt is cut off; the burrs on the cut off position are polished to be smooth; a new anchor bolt is arranged on the cut off position and the special sleeve is nested to process the butt joint of the new bolt and the old bolt; the connection position of the new bolt and the old bolt and the connection position of the new bolt, the old bolt and the sleeve are welded for fixation. Wherein, the upper end and the lower end of the sleeve respectively have the same distance to the connection positions of the new bolt and the old bolt. The opposite angle welding is adopted between the sleeve, the new bolt and the old bolt. The special butt joint sleeve for a large breakage anchor bolt and the butt joint method thereof are applicable to the imbedded anchor bolts of electromechanical devices, workshop steel structure columns and the foundations of the overloading bearing device or the vibration impact device, have short construction time and guarantee the butt joint intensity and the perpendicular degree.

Owner:MCC BAOSTEEL TECH SERVICE

A processing device and processing method for the head of a flame cylinder

ActiveCN112091543BThe molding process is simpleAchieve moldingOther manufacturing equipments/toolsPositioning apparatusEngineeringStructural engineering

The invention discloses a processing device and a processing method for the head of a flame tube. Using an annular blank, the annular blank is first put into a forming mold to form a U-shaped structure, then heat-treated, and then stretched to form the convex hull of the flame tube, which is assembled by a processing device. Clamp the part, process the end face of the car, and mill the convex hull without disassembling the clamping device. When milling the convex hull, press the convex hull at intervals, mill the uncompressed convex hull first, and then compress the milled convex hull , and then mill the remaining convex hulls, using the method of milling multiple convex hulls at the same time. The invention has the advantages of simple processing method, short processing period, low processing cost and good processing quality.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

Submerged-arc welding technology of big-thickness low-temperature steel plate with yield strength of 690MPa grade

ActiveCN103447672BThe disadvantage of preventing serious welding deformationNo weld cracksArc welding apparatusWorkpiece edge portionsSheet steelWeld seam

The invention relates to a submerged-arc welding technology of a big-thickness low-temperature steel plate with yield strength of 690MPa grade. The method comprises the following steps: (1) carrying out a welding cold crack sensitivity test on the steel plate to confirm the needed lowest preheating temperature; (2) adopting a welding groove with a symmetrical double-U shape, wherein the groove angle is 25-35 degrees, the thicknesses of truncated edges are 3-5mm, and the gaps between the truncated edges are 1-2mm; (3) adopting a welding wire with the tensile strength of more than or equal to 830MPa and the impacting energy of more than or equal to 100J at the temperature of -60 DEG C; (4) controlling the welding current to be 450-680A, the welding voltage to be 29-36V, the welding speed to be 38-50cm / min, the weld heat input to be 15-40kJ / cm and the flux baking system to be 350 DEG C*2.5h; (5) adopting gas shield welding with a single-sided welding and two-sided molding STT technology to carry out backing weld, and then carrying out unfolding submerged-arc welding until the steel plate is fully filled. All mechanical properties of a welding joint obtained by the method meet the requirements of the classification society, and particularly, a weld seam area and a welding heat affected zone can maintain higher low temperature impact toughness.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

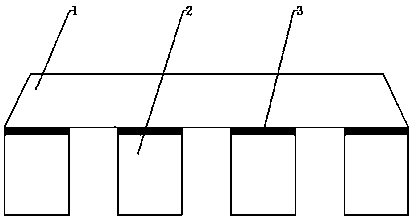

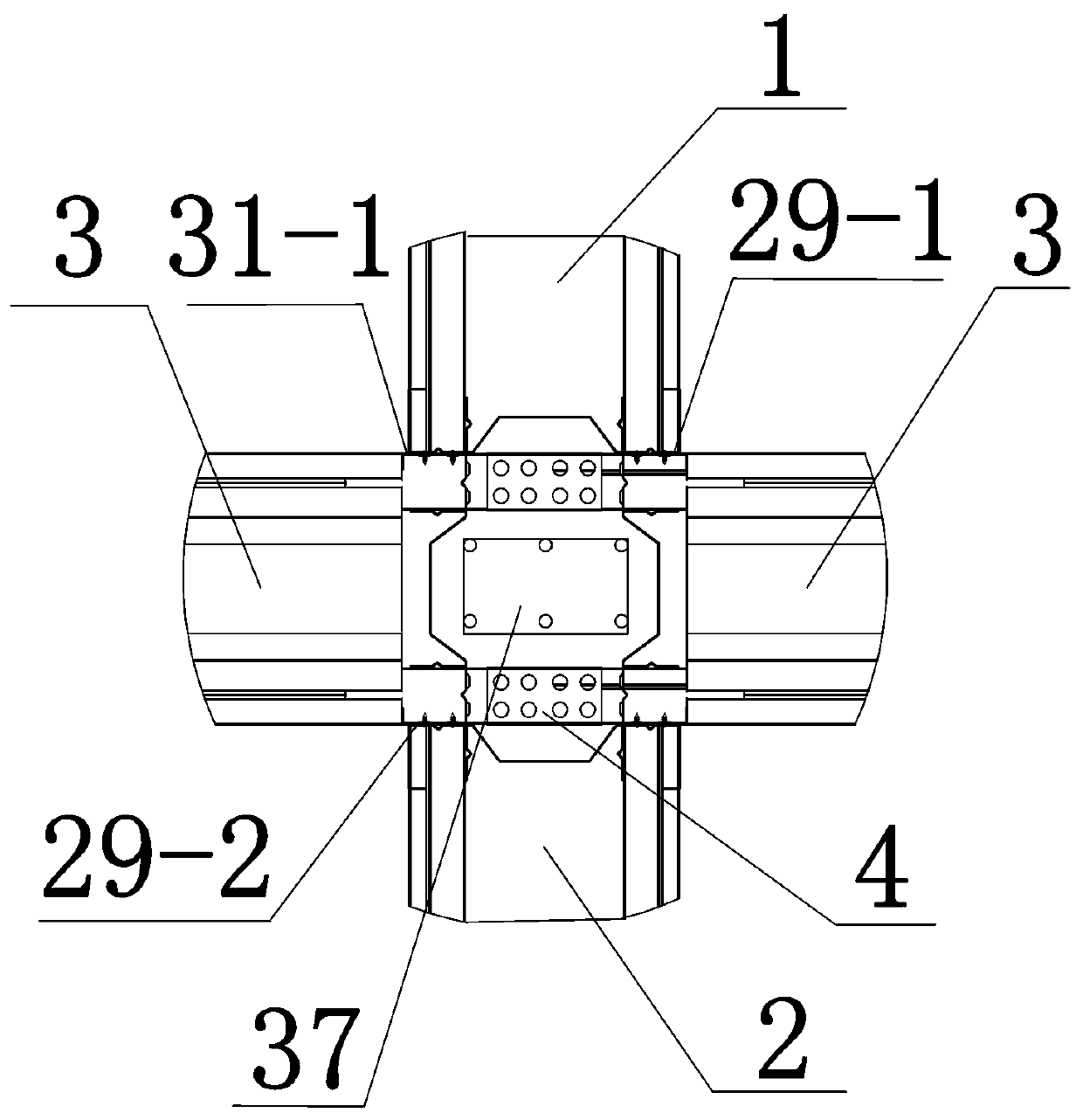

Construction method for connecting floor slabs and wall surface joints of multilayer light steel structure building

The invention belongs to the technical field of building overall structures and particularly relates to a construction method for connecting floor slabs and wall surface joints of a multilayer light steel structure building. The construction method is characterized by comprising the following steps of (1) modular production of floor slab structures of the light steel structure fabricated building,(2) modular production of wall surface structures of the light steel structure fabricated building, and (3) connecting forms of the different floor slabs and different wall surface structure modules.The joints are simple in structure and convenient to mount, integrity is good after completion, and connecting is firm, also durable and stable; seam mounting parts are concealed inside seams, thus the attractiveness of surface decoration is not affected, and the seams can also be arranged in the junctions of the wall surfaces and the floor slabs; the joints do not affect passing and connecting of water and electricity pipelines pre-arranged in the floor slabs; and through the connecting method of the joints, the problem that when the area of the single floor slab is large, the length and thewidth exceed the limits, and consequently, the floor slabs cannot be transported is solved.

Owner:辽宁福瑞达建筑科技有限公司

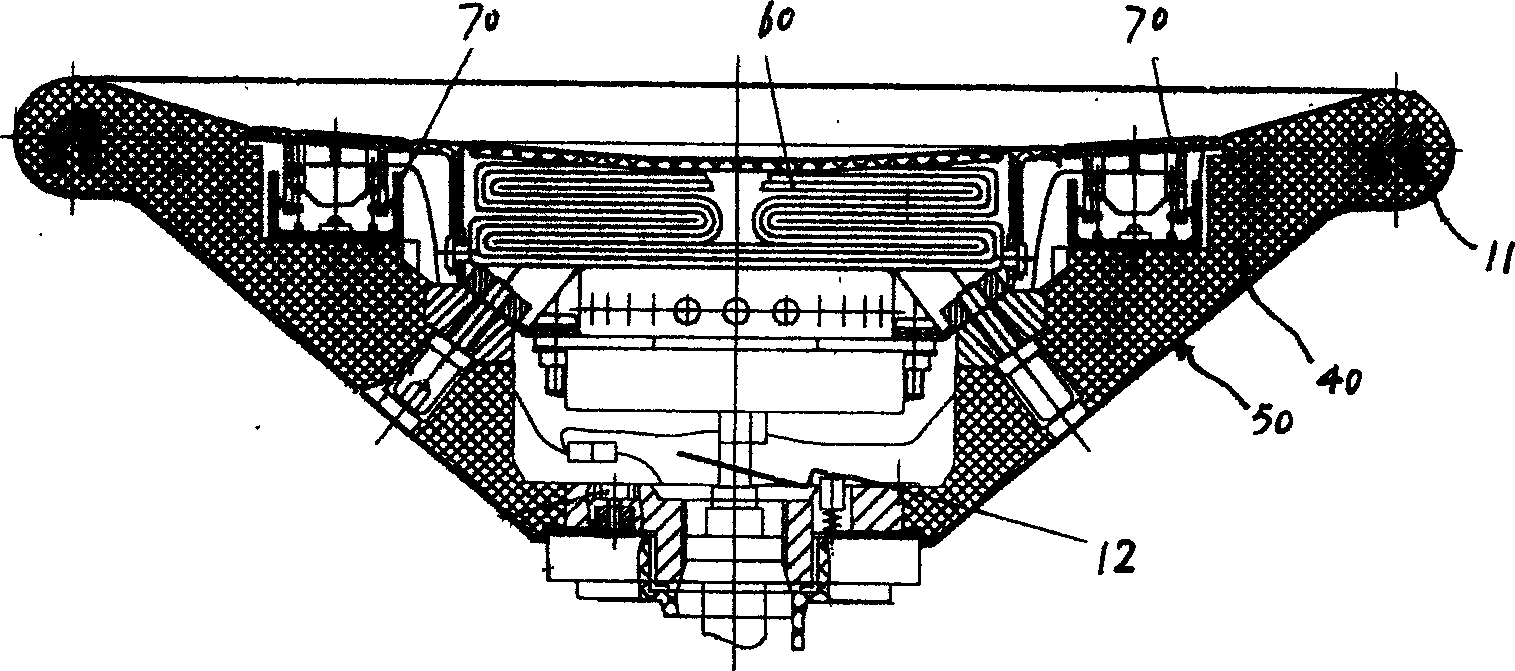

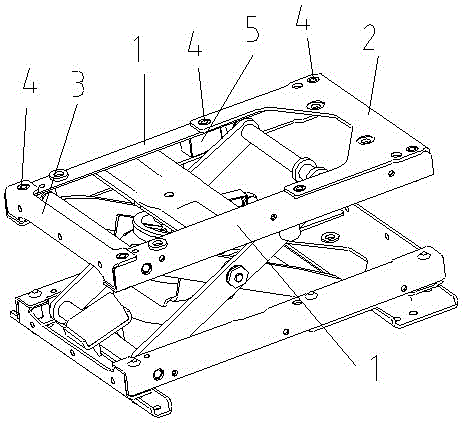

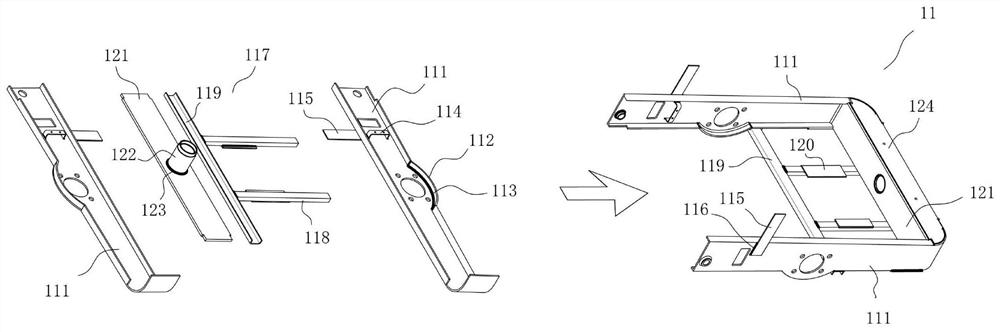

car seat shock absorber

The invention discloses a car seat damping device, which comprises an upper frame, a lower frame and a shear shank assembly arranged between the upper frame and the lower frame, wherein the upper frame comprises two borders, a first cross beam and a second cross beam; each border is provided with a chute; the first cross beam is connected with the two borders respectively through fasteners; the second cross beam is connected with the two borders respectively through fasteners; the lower frame has the same structure as the upper frame, and the lower frame and the upper frame are symmetrically arranged up and down. According to the invention, the upper frame and the lower frame have stable structures without welding deformation, and can be detached, so that the car seat damping device is simple and practical; and the chutes in the upper frame and the lower frame are not deformed easily, so that the stable operation of the damping device is ensured and the service life of the damping device is prolonged.

Owner:常州华阳万联汽车附件有限公司

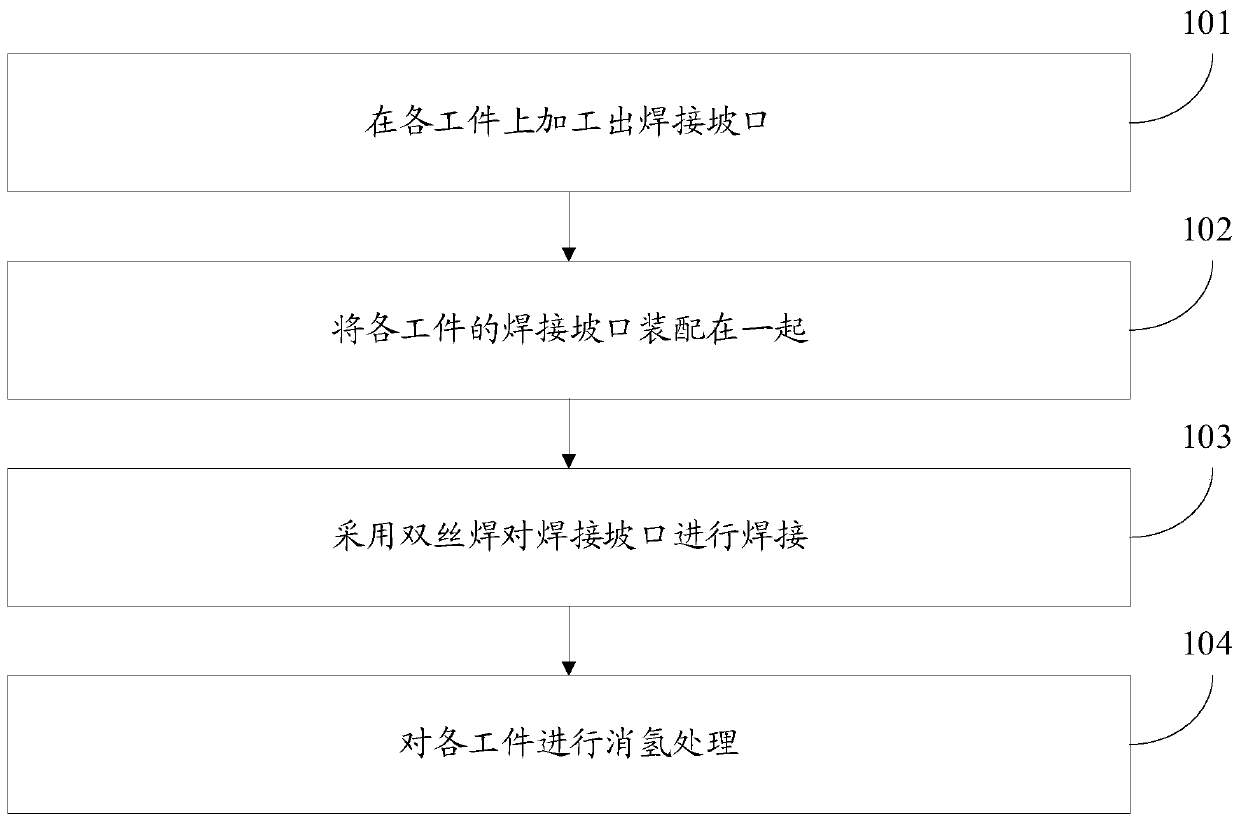

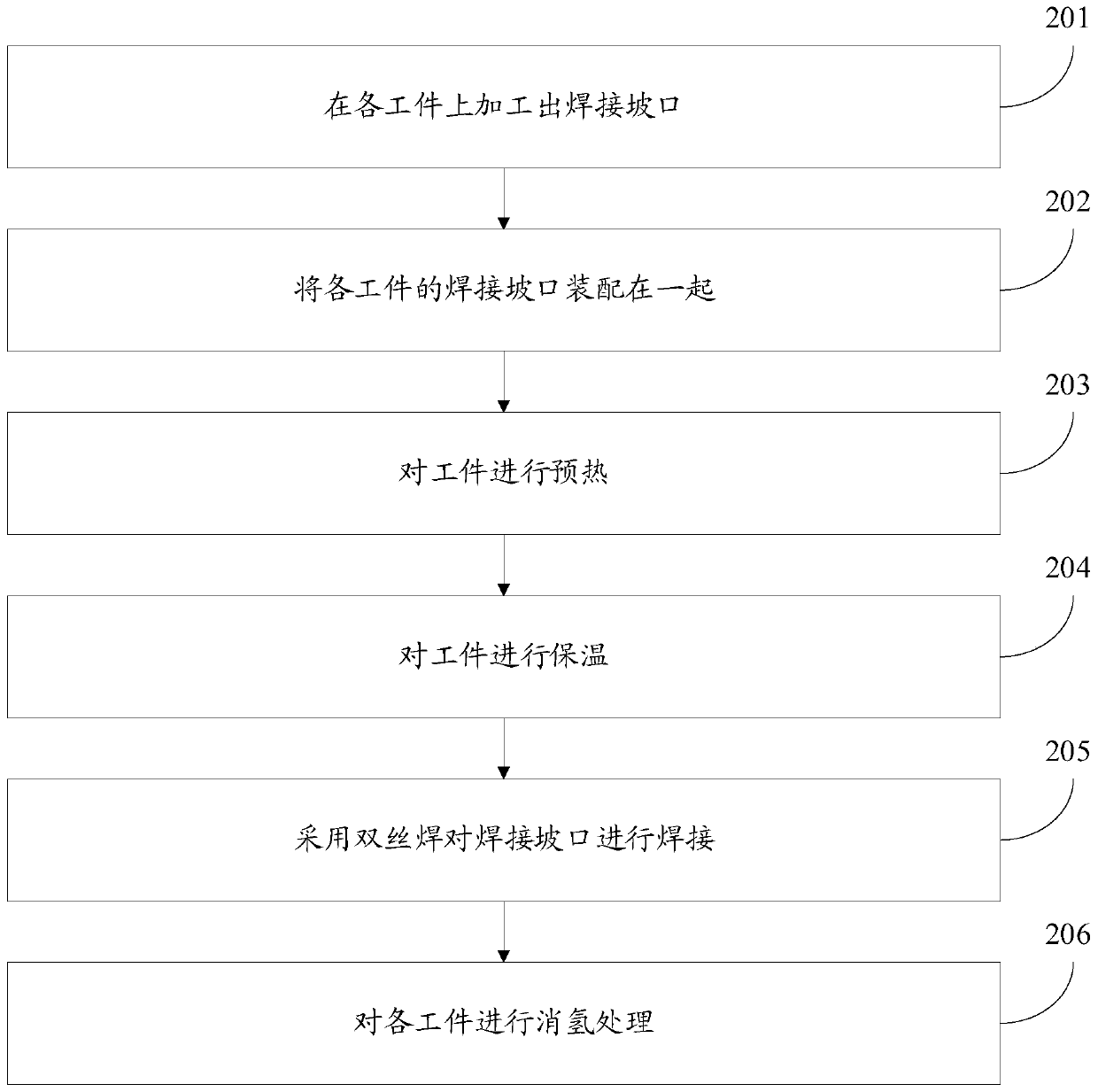

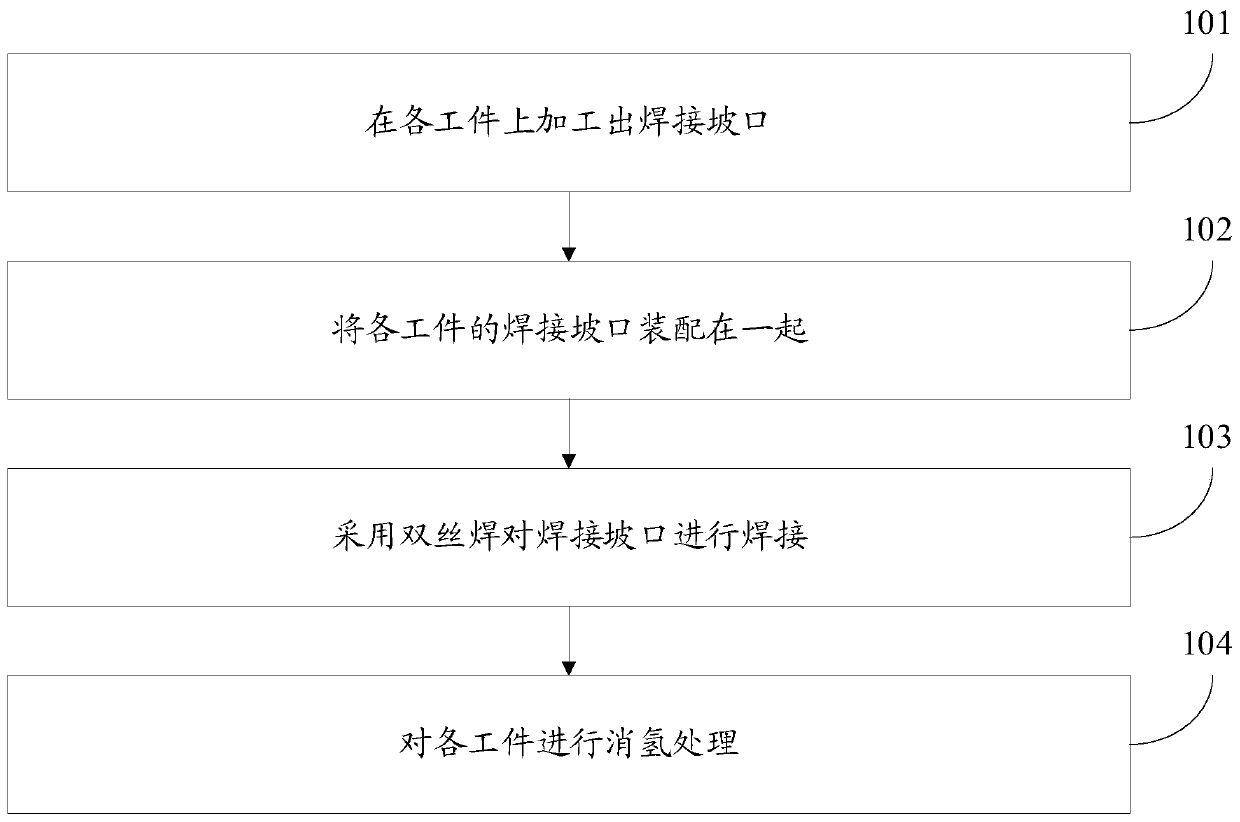

Double-wire welding method

The invention discloses a double-wire welding method and belongs to the technical field of welding. The welding method comprises the following steps that a welding groove is machined in each workpiece; welding grooves of the workpieces are assembled together; the welding grooves are welded through double-wire welding, a pulse welding mode is adopted by a front wire of the double-wire welding, thewelding grooves are welded for the first time, a cold metal transition welding mode is adopted for a rear wire of the double-wire welding, and second-time welding is performed on the welding grooves;and hydrogen removal treatment is carried out on each workpiece. According to the double-wire welding method, the welding efficiency can be improved, and the welding deformation can be reduced.

Owner:WUHAN MARINE MACHINERY PLANT

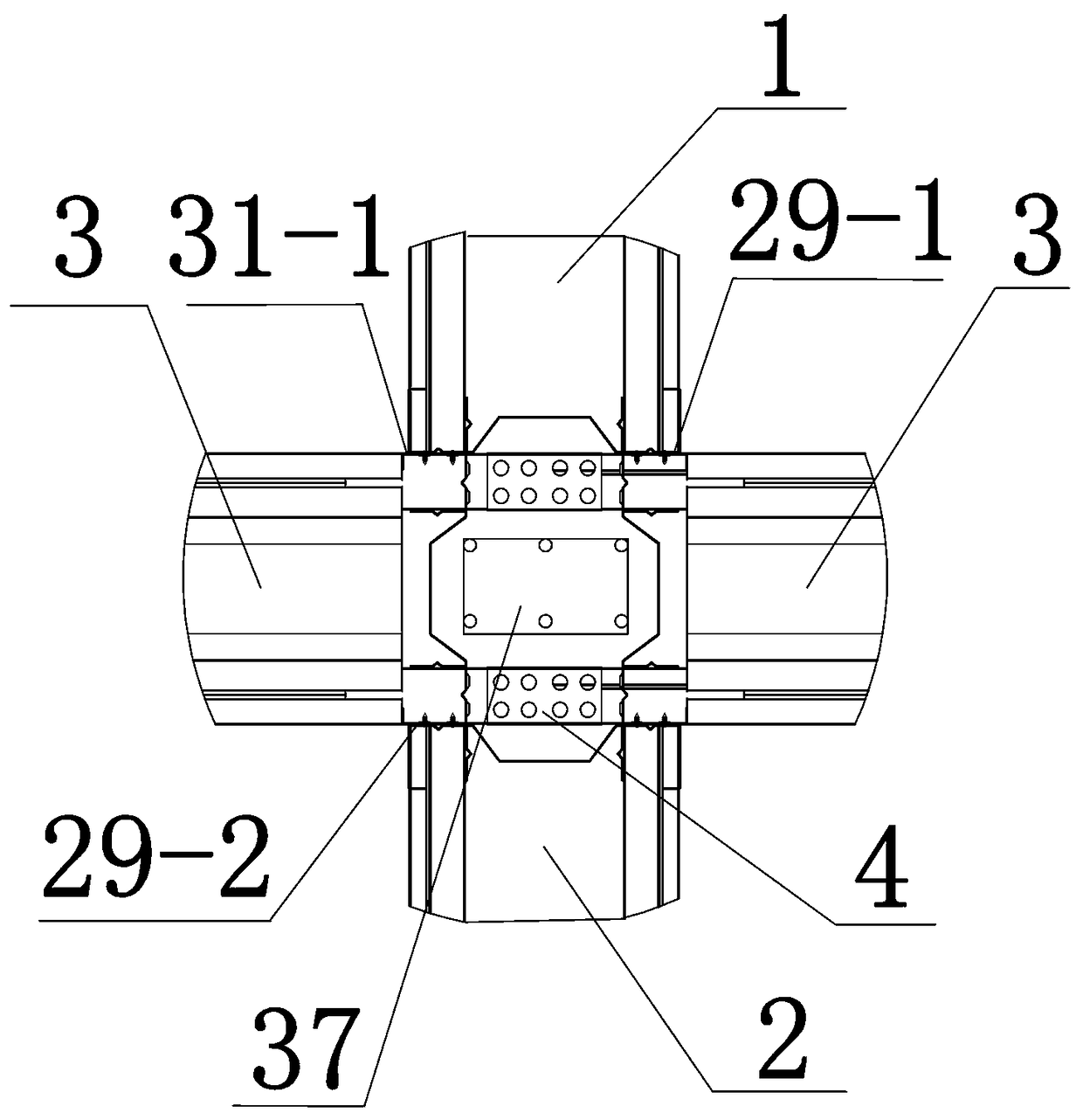

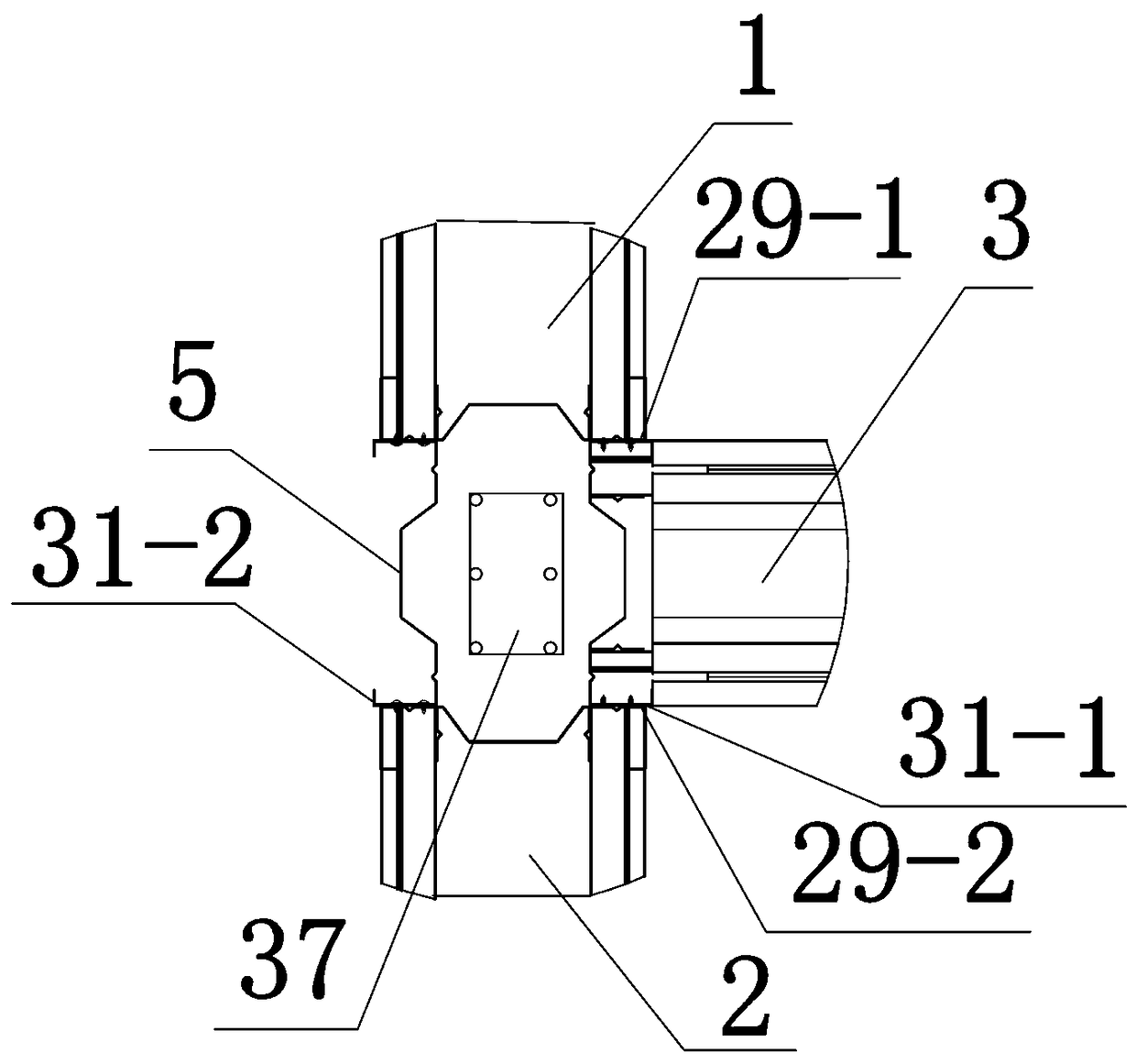

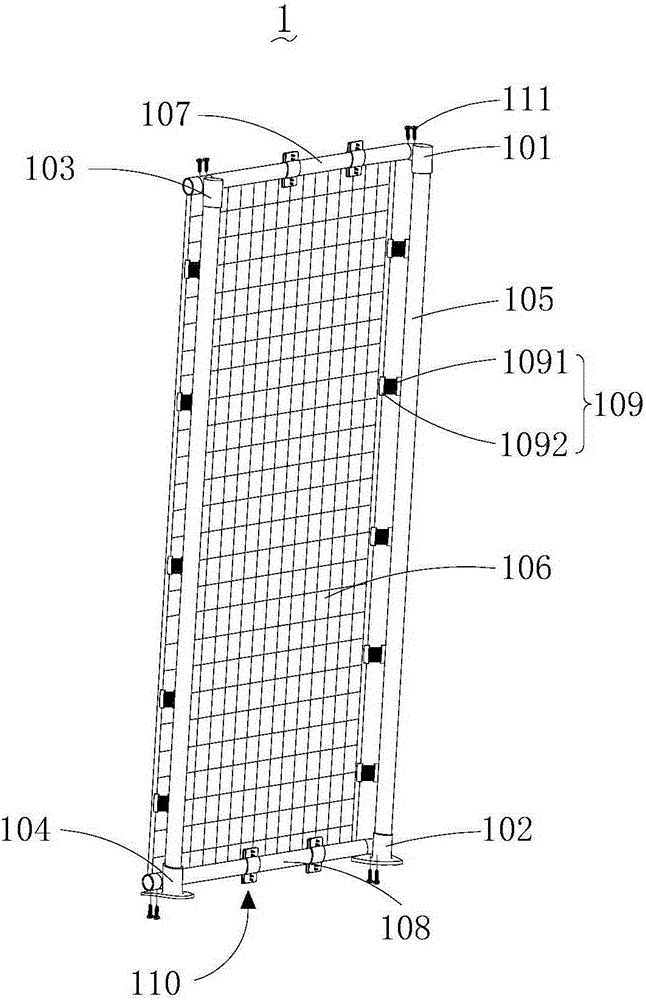

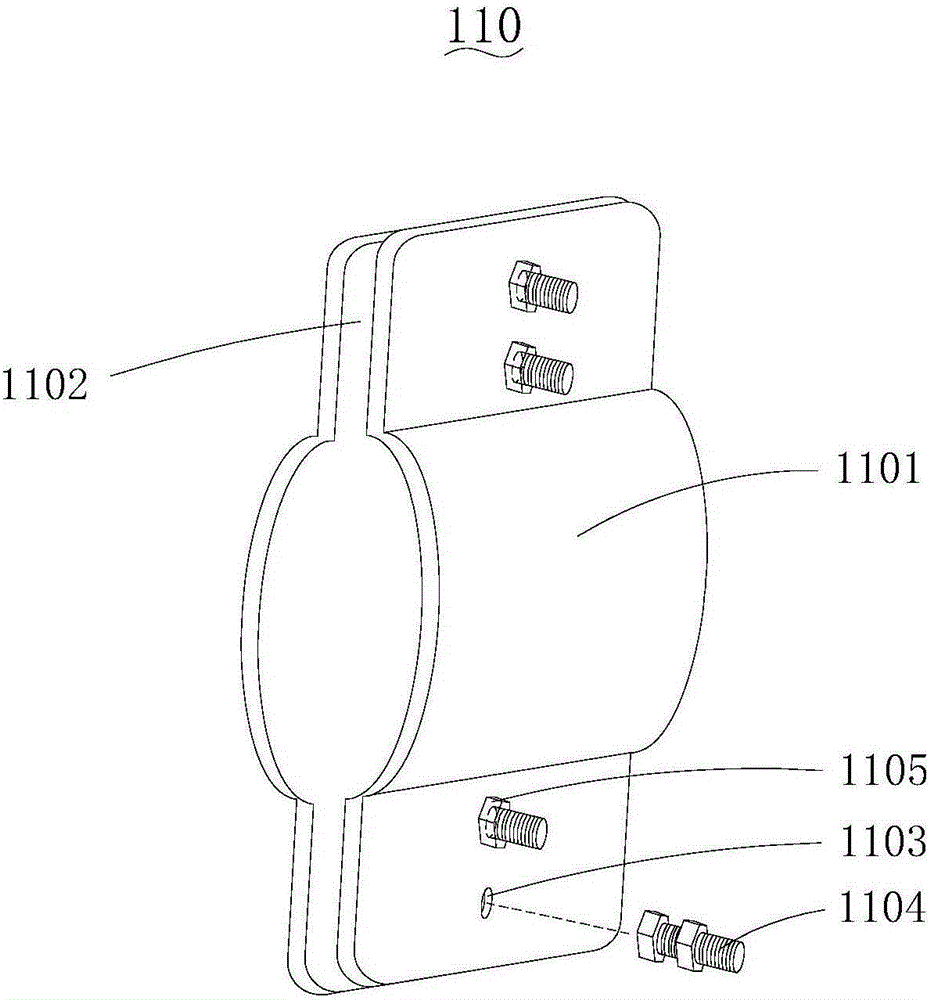

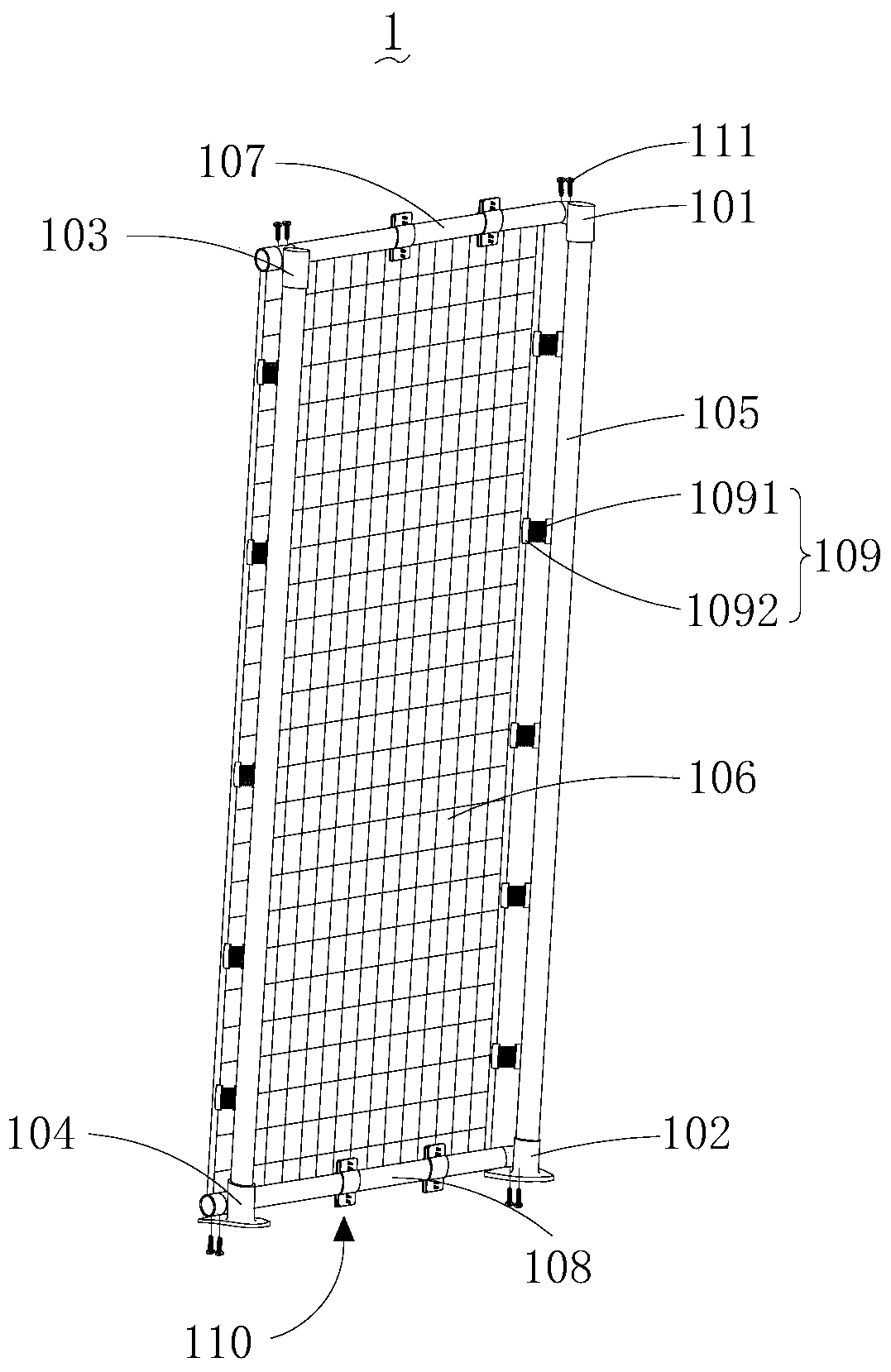

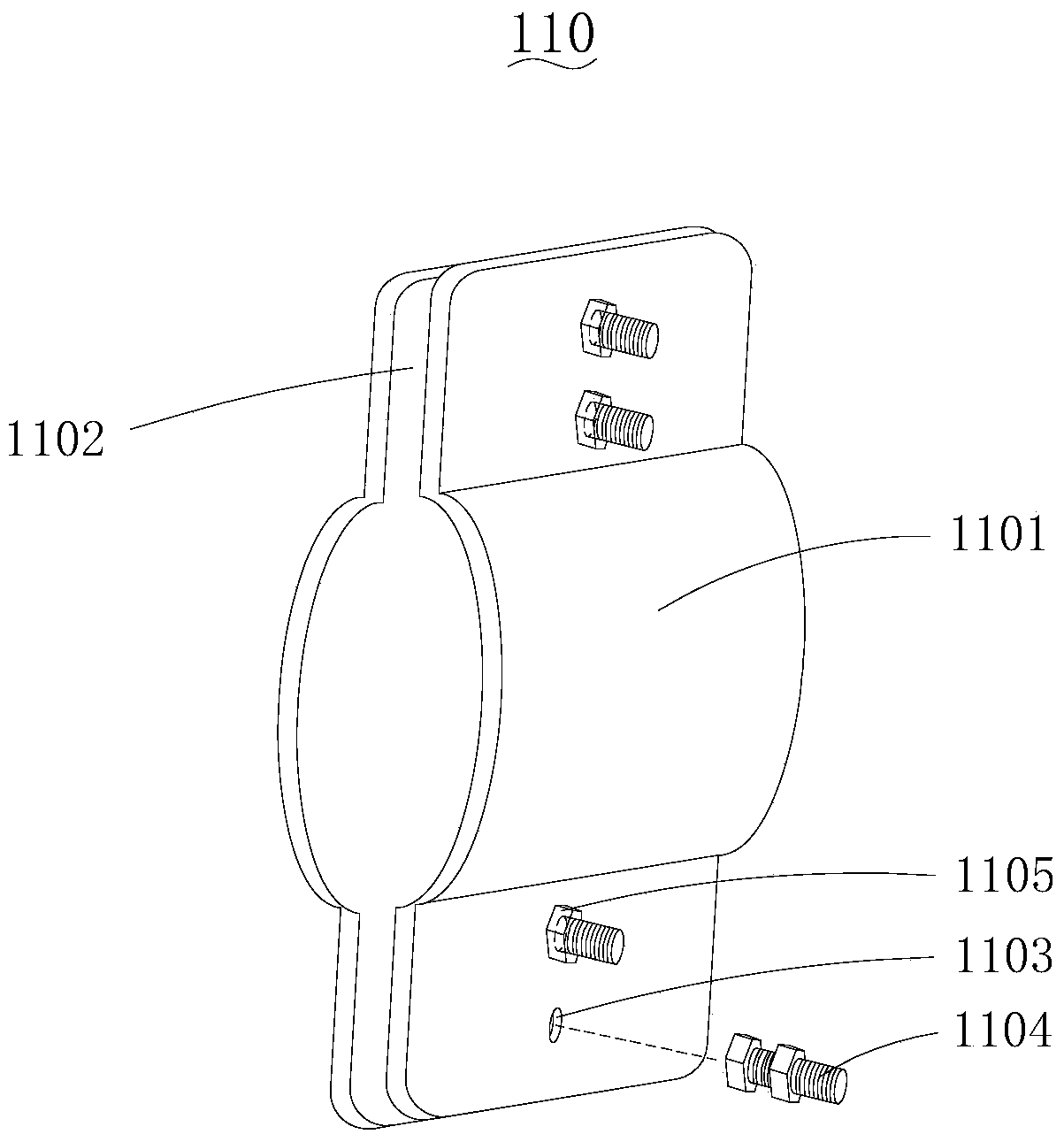

Suspended aluminum alloy cage type football field purse net device

ActiveCN105169683ANo appearance defectsNo welding deformationSki bindingsWater-skiingMaterials scienceHeavy weight

The invention provides a suspended aluminum alloy cage type football field purse net device. The suspended aluminum alloy cage type football field purse net device comprises a connecting corner, a connecting corner base, a connecting through piece, a connecting through base, two columns, a purse net, an upper hanging beam, a lower hanging beam, a plurality of spring seats and a plurality of sliding blocks. The connecting corner and the connecting corner base are arranged at the two ends of one column respectively. The connecting through piece and the connecting through base are arranged at the two ends of the other column respectively. The two ends of the upper hanging beam are connected with the connecting corner and the connecting through piece respectively, and the two ends of the lower hanging beam are connected with the connecting corner base and the connecting through base respectively. The plurality of the spring seats are arranged on the two columns respectively. The plurality of the sliding blocks are arranged on the upper hanging beam and the lower hanging beam respectively. The purse net is connected with the sliding blocks and the spring seats. According to the suspended aluminum alloy cage type football field purse net device, the technical problems that in the prior art, the purse net device is inconvenient to install and dismantle, and the purse net is inconvenient to convey because of the heavy weight are solved.

Owner:HEBEI QIFAN TEACHING EQUIP MFG

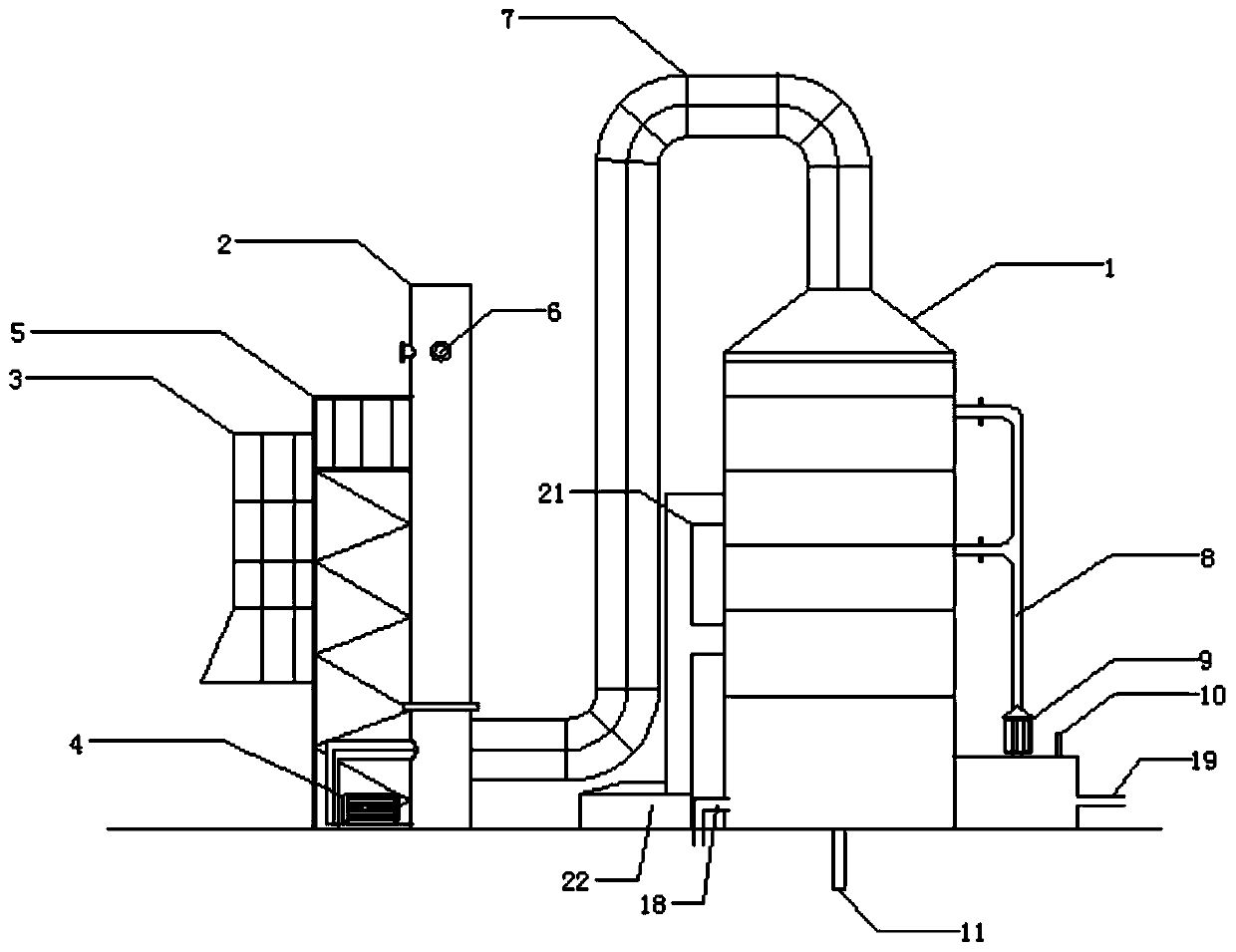

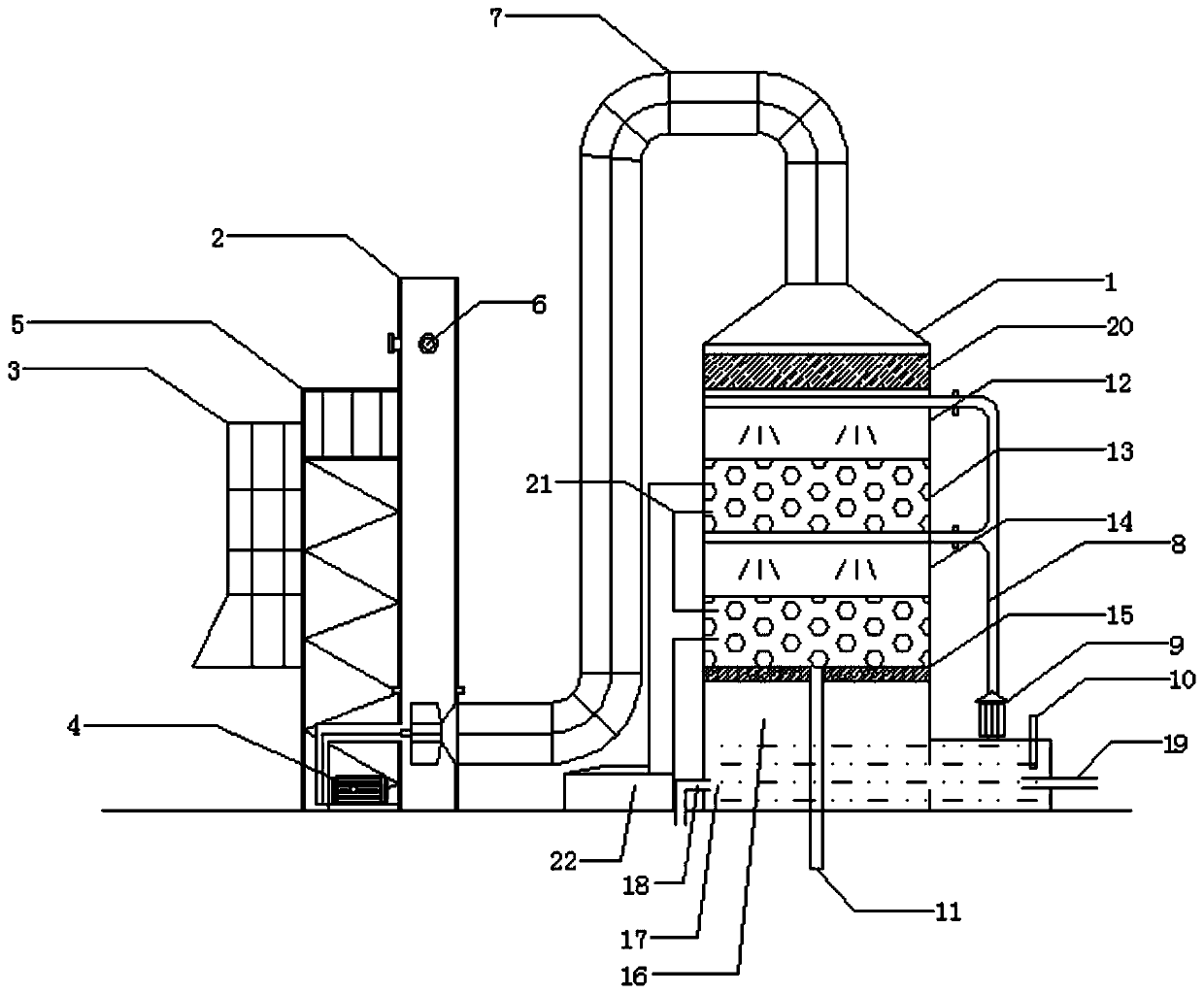

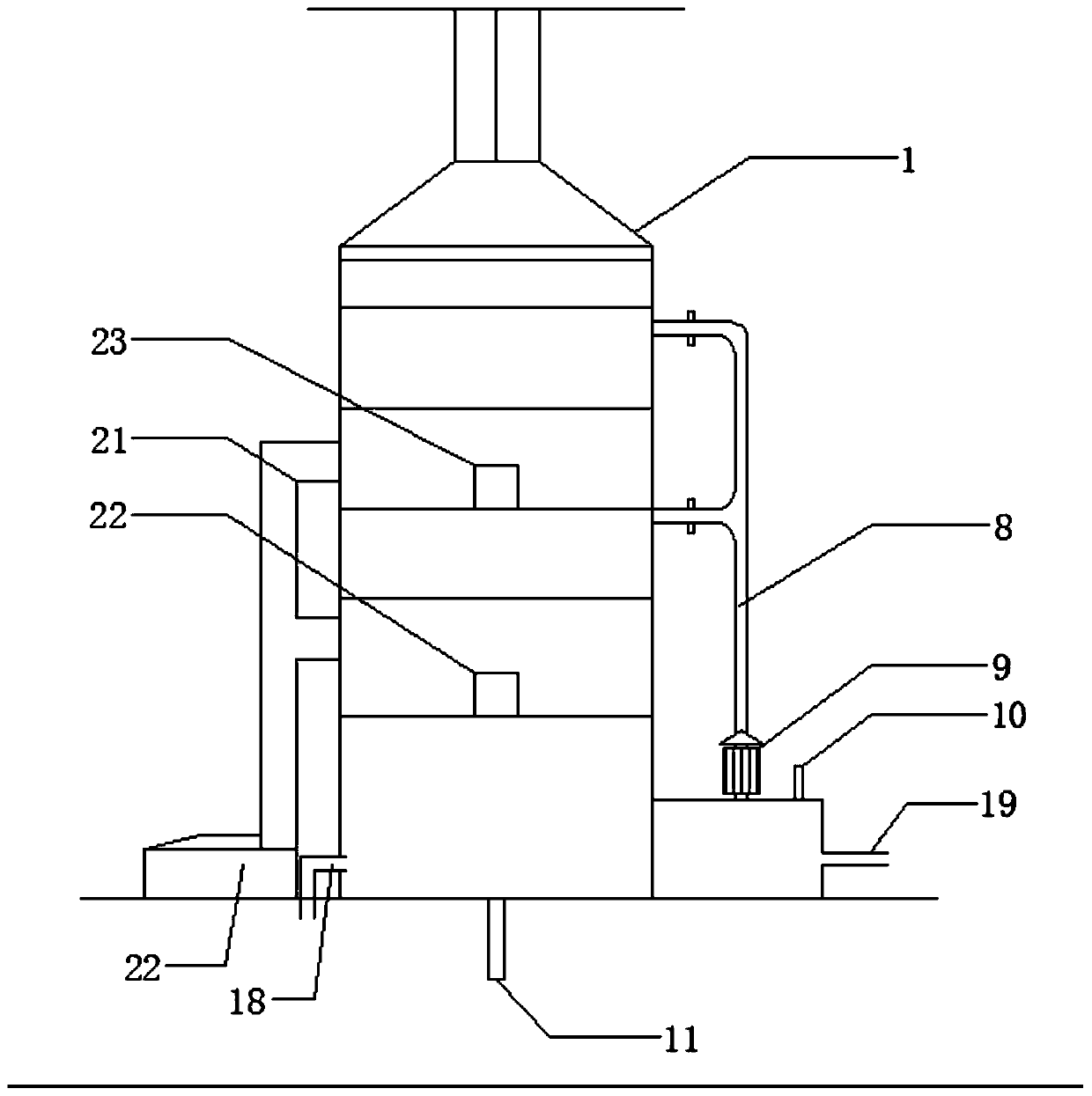

High-efficiency and low-consumption dirt discharge system of water washing tower

PendingCN110787616AReduce the situation where the filler cannot be deliveredThe purpose of solving the low efficiency of manpower feeding fillerDispersed particle separationMicro perforated plateEnvironmental engineering

The invention discloses a high-efficiency and low-consumption dirt discharge system of a water washing tower. The system comprises a main body of the water washing tower, wherein the top of the insideof the water washing tower is connected with a waste gas discharge chimney through a waste gas guide pipe, a plurality of observation ports are arranged at the upper part of the outer surface of thewaste gas discharge chimney, a fan is arranged at the lower part of one side of the waste gas discharge chimney, and one side of the waste gas discharge chimney is fixedly provided with an observationplatform. The fan adopts means such as riveting and biting, the surface is clean and flat, a silencing-type box body of the fan adopts the assembly design of a frame and a box body, the frame is formed through stretching once by using an advanced metal cold bending machine unit, corrosion resistance is strong, an inner layer is a galvanized silencing micro-perforated plate, an interlayer is ultra-fine glass wool, and thereby the fan is especially suitable for places of large air volume ventilation and smoke discharge.

Owner:关振华

Chassis underframe welding integrated application system and welding method

ActiveCN113199124AReduce welding distortionImprove welding quality and welding efficiencyManipulatorResistance welding apparatusVehicle frameManufacturing engineering

The invention discloses a chassis underframe welding integrated application system and a welding method. The welding method comprises the following steps that 1, all scattered workpieces of a front frame are respectively welded into assemblies, and then all the assemblies are welded into the front frame in a manner of conducting manual spot welding and robot full welding in sequence; 2, all scattered workpieces of a rear frame are welded into assemblies respectively, and then all the assemblies are welded into the rear frame in a manner of conducting manual spot welding and robot full welding in sequence; and 3, the front frame and the rear frame after full welding of a robot are checked, and repair welding is manually conducted on special dead angle positions where a welding gun of the robot cannot reach. According to a welding process provided by the invention, the frame welding deformation can be reduced, the welding method is suitable for welding a chassis underframe of an electric sweeper, and the frame welding efficiency and welding quality are further improved.

Owner:GUANGXI UNIV +1

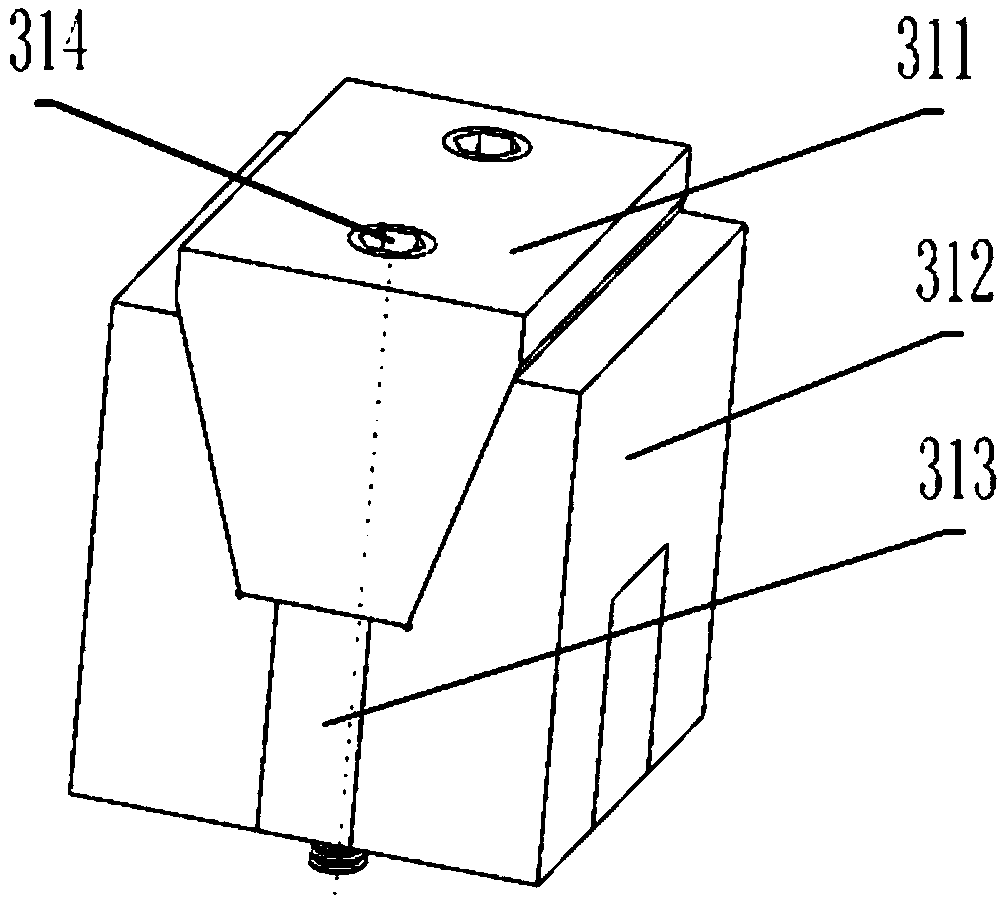

Milling cutter disc welding fixture and welding method applying same

InactiveCN109249130AReduce plastic strainSolve uncontrollable problemsLaser beam welding apparatusMilling cutterEngineering

The invention relates to the technical field of milling cutter disc welding, in particular to a milling cutter disc welding fixture and a welding method applying the same and solves problems of weldment shape changing and dimensional accuracy reduction due to welding deformation in a welding process of a milling cutter disc. A cutter disc outer ring fixedly sleeves a cutter disc body, and a pre-tightening ring is connected with the cutter disc outer ring through a plurality of groups of threaded connectors and fixed to a base through a screw. The cutter disc body is provided with a plurality of groups of cutter grooves, and cutter disc positioning and clamping devices are arranged in the cutter grooves respectively and fixedly arranged on the base. By arrangement of the positioning and clamping devices in the cutter grooves of the cutter body, cutter groove wall positioning and clamping are completed in a welding process, so that welding deformation in the welding process is avoided; by adjustment of the positioning and clamping devices, control of welding deformation at any time in the welding process can be guaranteed, and the problem of uncontrollable welding deformation is solved.

Owner:HARBIN UNIV OF SCI & TECH

A high conductivity prebaked anode steel claw

The invention relates to an aluminum electrolysis prebaked anode steel claw and belongs to the technical field of electrolytic aluminum industry, and particularly provides a novel high-conductivity prebaked anode steel claw which is good in conductivity, low in cost, small in deformation and long in service life. The novel high-conductivity prebaked anode steel claw comprises a cross beam, a claw head and a welding line. The material of the cross beam or the claw head is low-carbon low-silicon non-oriented electrical steel or other high-conductivity steel, and the cross beam and a steel claw are connected by consumable electrode mixed gas arc welding. According to the invention, through optimal selection of the cross beam and the claw head and selection of a proper welding process, anode drop is remarkably reduced, the electrical conductivity and the flexural behavior of the steel claw are improved, and the life of the anode steel claw is effectively prolonged, and therefore, economic benefit is improved.

Owner:WUHAN UNIV

Processing method of twisted guide rail

The invention relates to a processing method of a twisted guide rail. A cross section of the twisted guide rail is L-shaped; the lower surface of the twisted guide rail consists of a horizontal area and a plurality of sections of continuous inclined planes. The processing method comprises the steps of: a, adopting a forgeable piece as a blank; b. performing coarse processing, processing a reinforcing rib by making use of the material on the forgeable piece when performing coarse processing; c, after finishing the coarse processing, performing a hardening and quenching work procedure, a tire matching and shape righting work procedure and a nondestructive testing work procedure of a semi-finished product; d, semi-finish machining and straightening workpieces; e. finish machining: machining all of the surfaces into a finished-product dimension, retaining the reinforcing rib; f, surface quenching: sensing and heating by adopting semi-circle; g, removing the reinforcing rib, grinding and polishing; and h, performing nondestructive testing. The processing method is suitable for processing a slender slide rail that has a large length-width ratio, a surface quenching hardness HRC of 50-56, a tensile strength Rm of 1000-1150N / mm<2>, a cross section of an unstable geometrical shape and a sliding surface of a twisted surface.

Owner:TIANJIN SERI MACHINERY EQUIP

Suspended aluminum alloy cage football field fence device

ActiveCN105169683BNo appearance defectsNo welding deformationSki bindingsWater-skiingEngineeringCantilever

The invention provides a hanging fence device of an aluminum alloy cage type football field. The suspended aluminum alloy cage football field fence device includes connecting corners, connecting corner bases, connecting straight-throughs, connecting straight-through bases, two columns, fences, upper hanging beams, lower hanging beams, multiple spring seats and multiple sliders, The connection corner and the connection corner base are respectively arranged at two ends of a column, the connection straight-through and the connection straight-through base are respectively arranged at two ends of another column, and the two ends of the upper suspension beam are respectively connected to the connection The corner is directly connected to the connection, the two ends of the lower suspension beam are respectively connected to the connection corner base and the connection straight-through base, a plurality of the spring seats are respectively arranged on the two columns, and a plurality of the sliders are respectively arranged on the upper suspension beam and the lower suspension beam, The fence connects the slider and the spring seat. The suspended aluminum alloy cage-type football field fence device provided by the present invention solves the technical problems of inconvenient disassembly and installation, bulky and inconvenient transportation in the prior art.

Owner:HEBEI QIFAN TEACHING EQUIP MFG

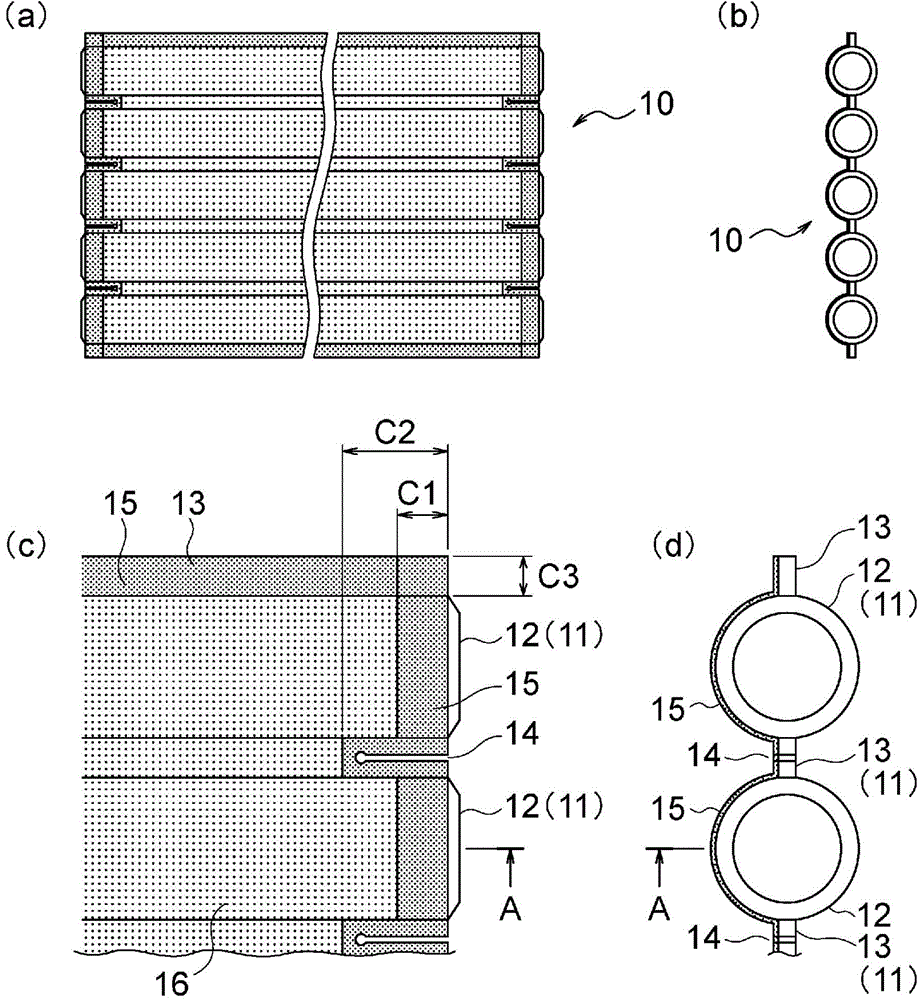

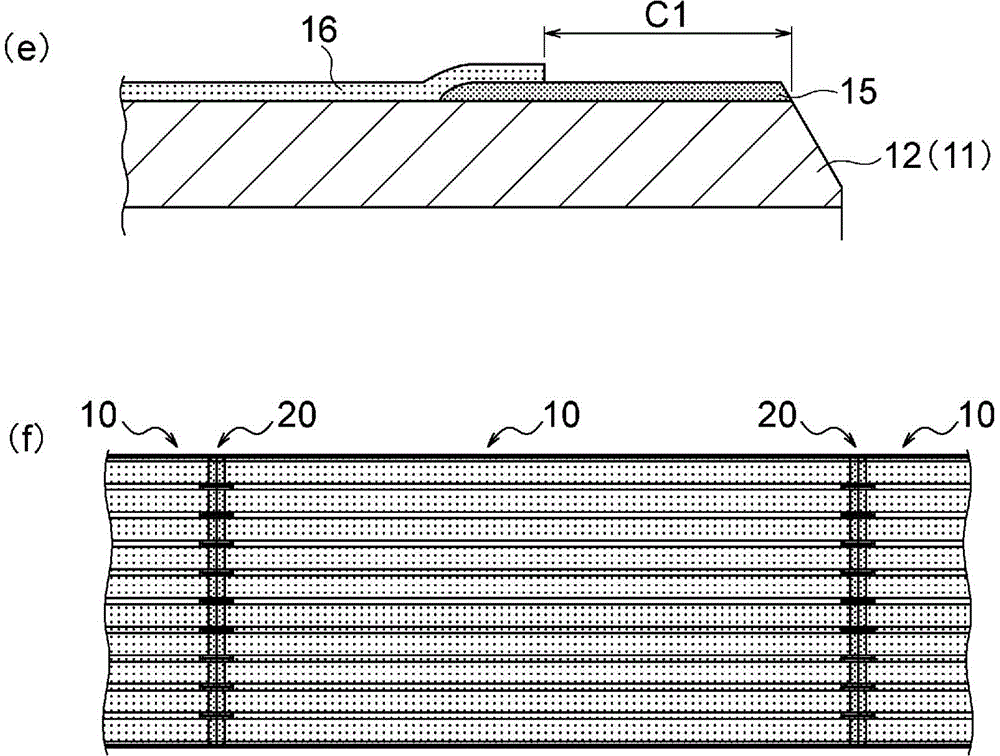

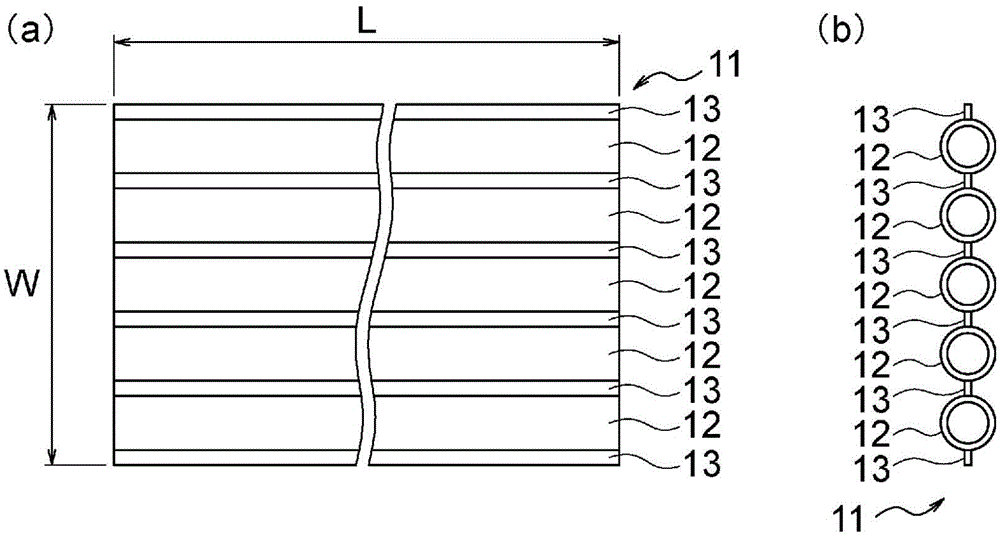

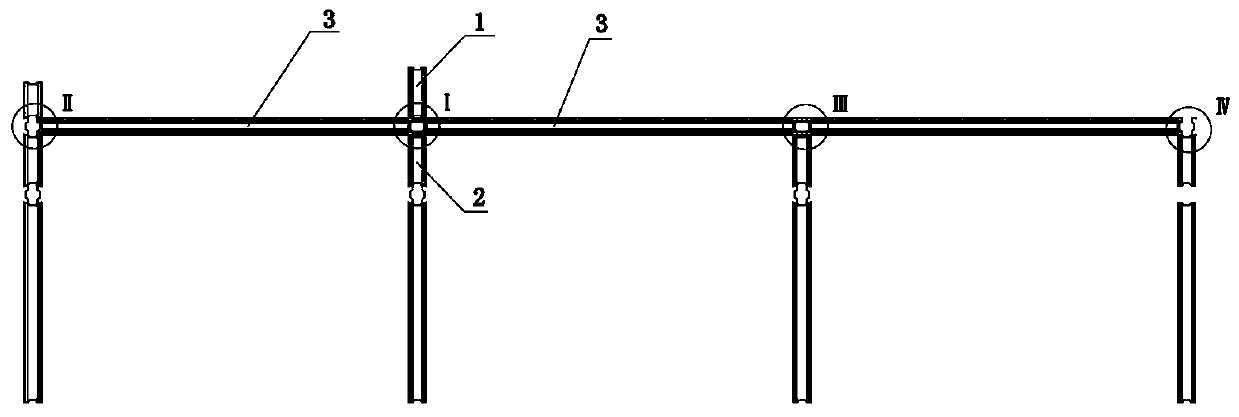

Alloy-coated boiler component

InactiveCN103180480BNo welding deformationEfficient preparationMolten spray coatingArc welding apparatusThermal sprayingAlloy

Provided is an alloy-coated boiler component which is to be welded at an end thereof, wherein a melted coating (15) with a first alloy material comprising not less than 1.5 % and not more than 2.5 % of B, not less than 3.5 % and not more than 4.0 % of Si, not more than 0.4 % of C, and not less than 12.0 % and not more than 17.0 % of Cr, and the balance being Ni and incidental impurities, is applied to the metallic base material on an end region including the end and its proximity and, a melted coating (16) of a second alloy material comprising more than 2.5 % and not more than 4.0 % of B, more than 4.0 % and not more than 5.0 % of Si, not less than 0.5 % and not more than 0.9 % of C, and not less than 12.0 % and not more than 17.0 % of Cr, and the balance being Ni and incidental impurities, is applied to the metallic base material on a non-end region other than the end region (percentages are expressed in terms of mass percentages). This alloy-coated boiler component has melted coatings which can be formed by thermal spraying-fusing treatment on the whole area of the metallic base material and the melted coating formed on the end region is superior in thermal shock resistance and resistance to shock.

Owner:DAI ICHI HIGH FREQUENCY

Joint connection method between floor slab and wall of multi-storey light steel structure building

ActiveCN109322411BExtended service lifeRealize modular productionWallsFloorsFloor slabJoint (building)

The invention belongs to the technical field of building overall structures and particularly relates to a construction method for connecting floor slabs and wall surface joints of a multilayer light steel structure building. The construction method is characterized by comprising the following steps of (1) modular production of floor slab structures of the light steel structure fabricated building,(2) modular production of wall surface structures of the light steel structure fabricated building, and (3) connecting forms of the different floor slabs and different wall surface structure modules.The joints are simple in structure and convenient to mount, integrity is good after completion, and connecting is firm, also durable and stable; seam mounting parts are concealed inside seams, thus the attractiveness of surface decoration is not affected, and the seams can also be arranged in the junctions of the wall surfaces and the floor slabs; the joints do not affect passing and connecting of water and electricity pipelines pre-arranged in the floor slabs; and through the connecting method of the joints, the problem that when the area of the single floor slab is large, the length and thewidth exceed the limits, and consequently, the floor slabs cannot be transported is solved.

Owner:辽宁福瑞达建筑科技有限公司

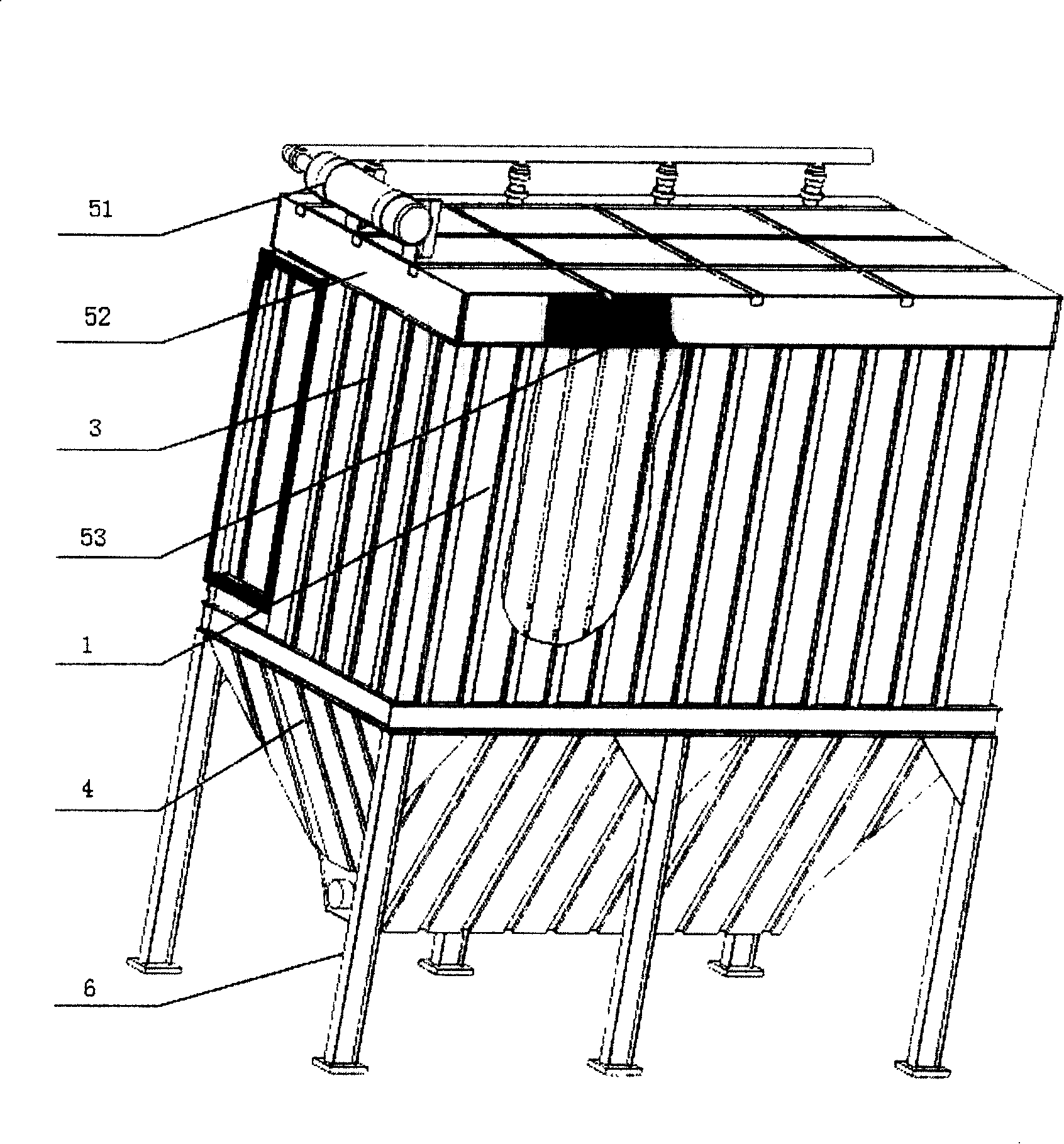

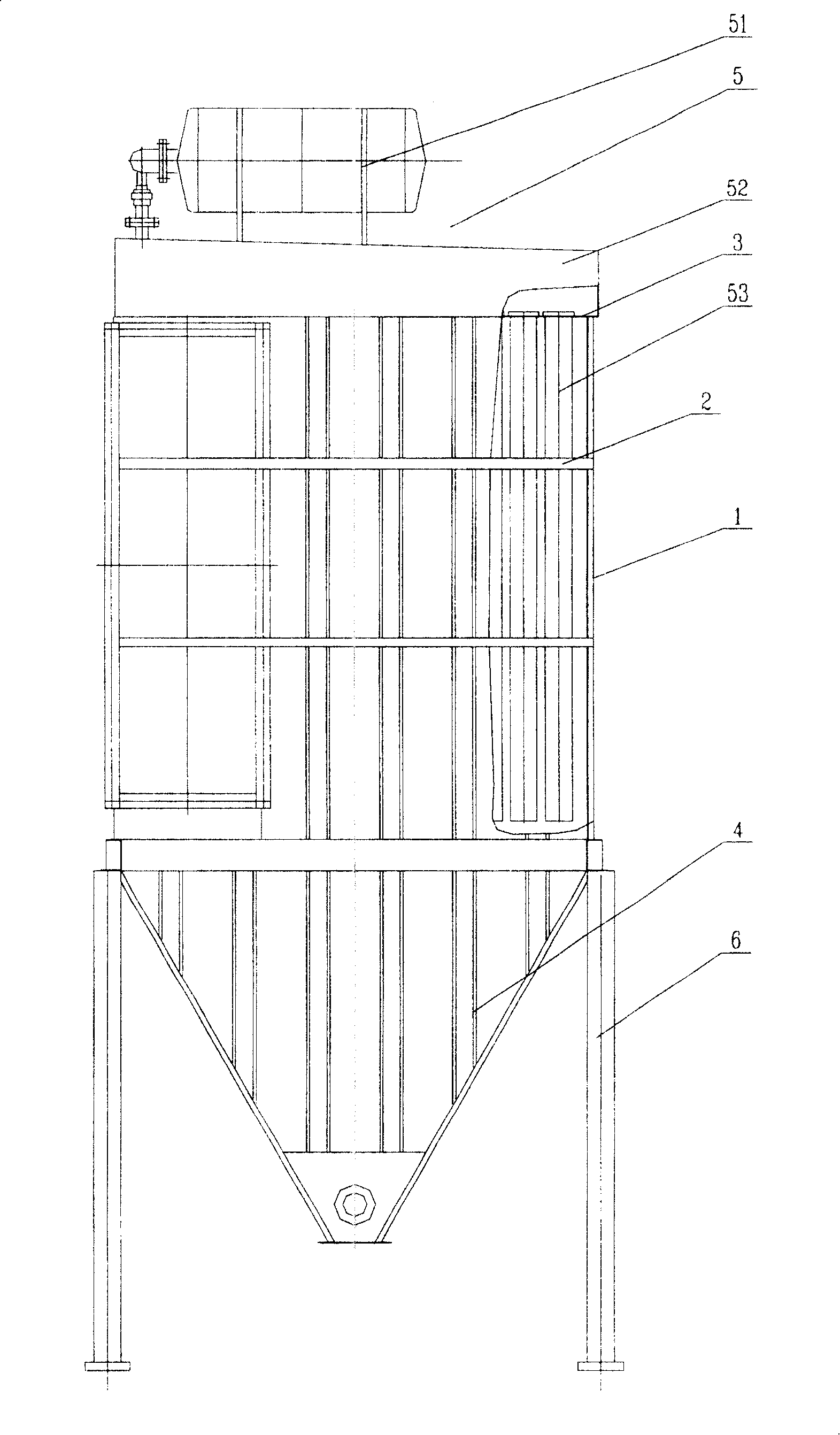

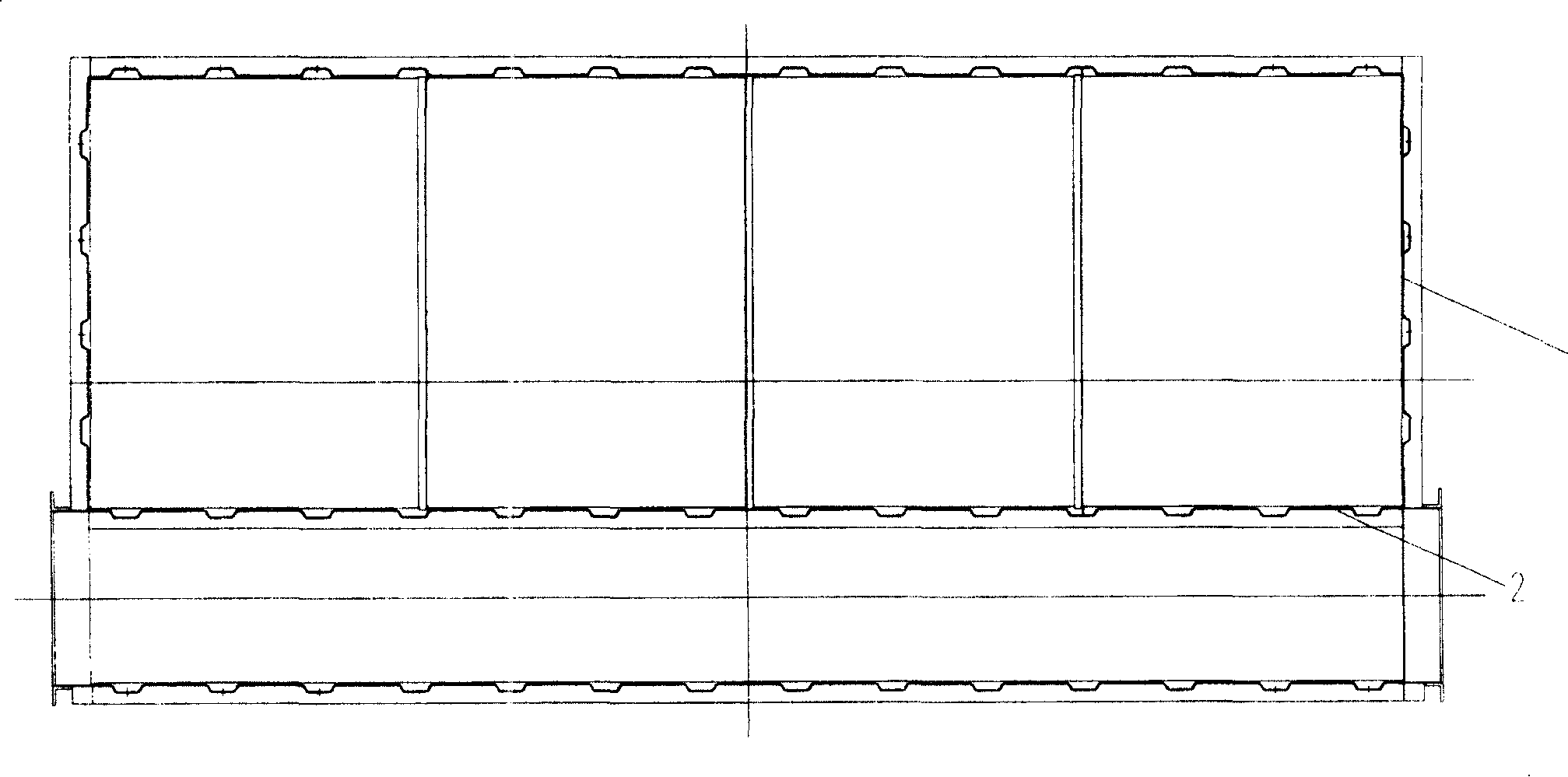

Wave plate shape bag type dust collector

The invention discloses a wave plate bag-type dust cleaner, which comprises but not limited to: a out shell plate separated by some separation plates, color plates opposite to separation plates, an ash bucket connected to shell plate, and an impulse dust cleaning component part; wherein, all shell plate, separation plates and ash bucket are manufactured by wave plate pressed steel of trapezoid, angle steel, arc or similar shape to bear acted force without destabilizing and gas pressure when cleaning dust. This invention cuts traditional stiffener, saves material, reduces cost, realizes automatic high-efficient production, and ensures product appearance quality.

Owner:JIEHUA HLDG

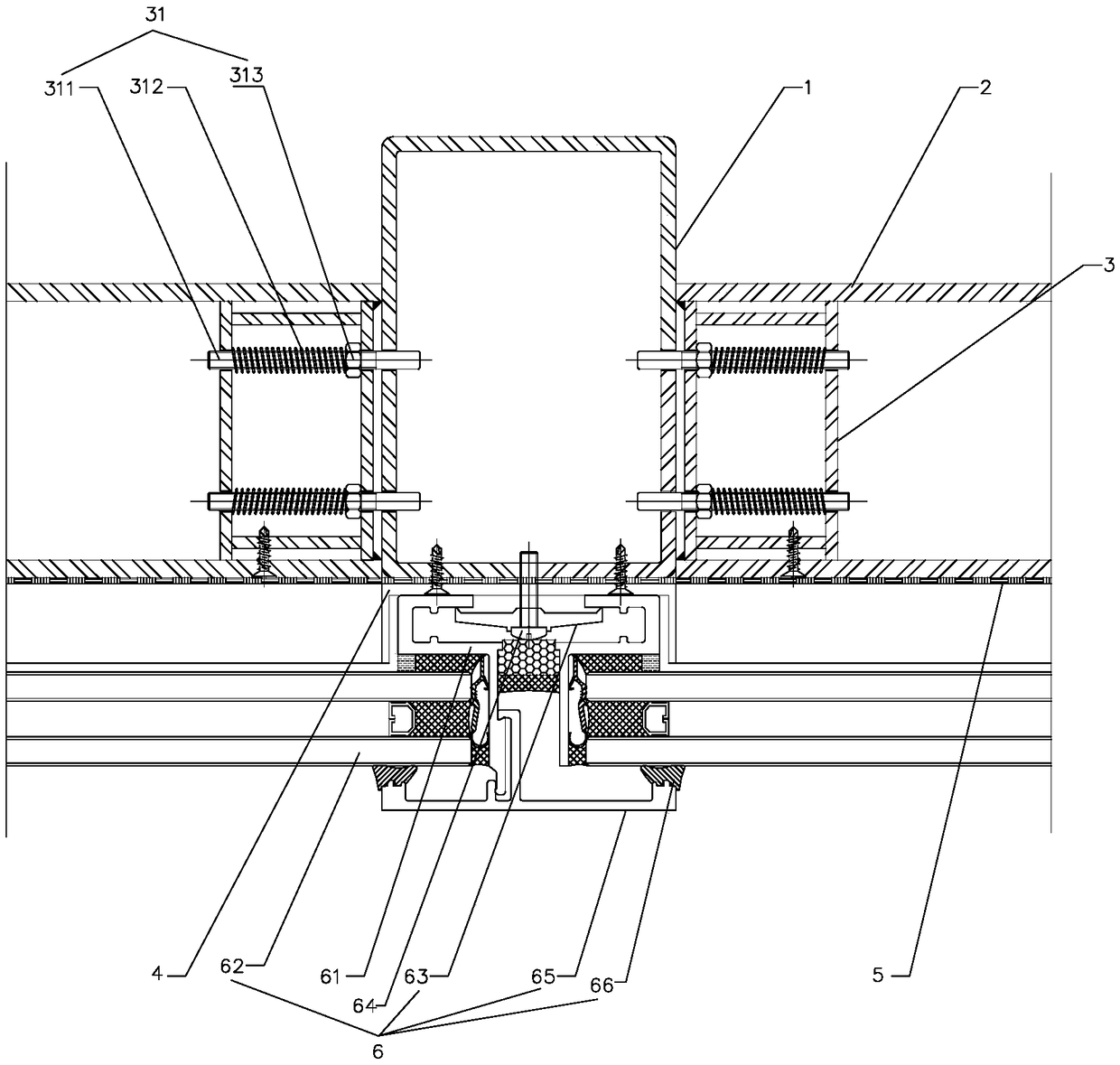

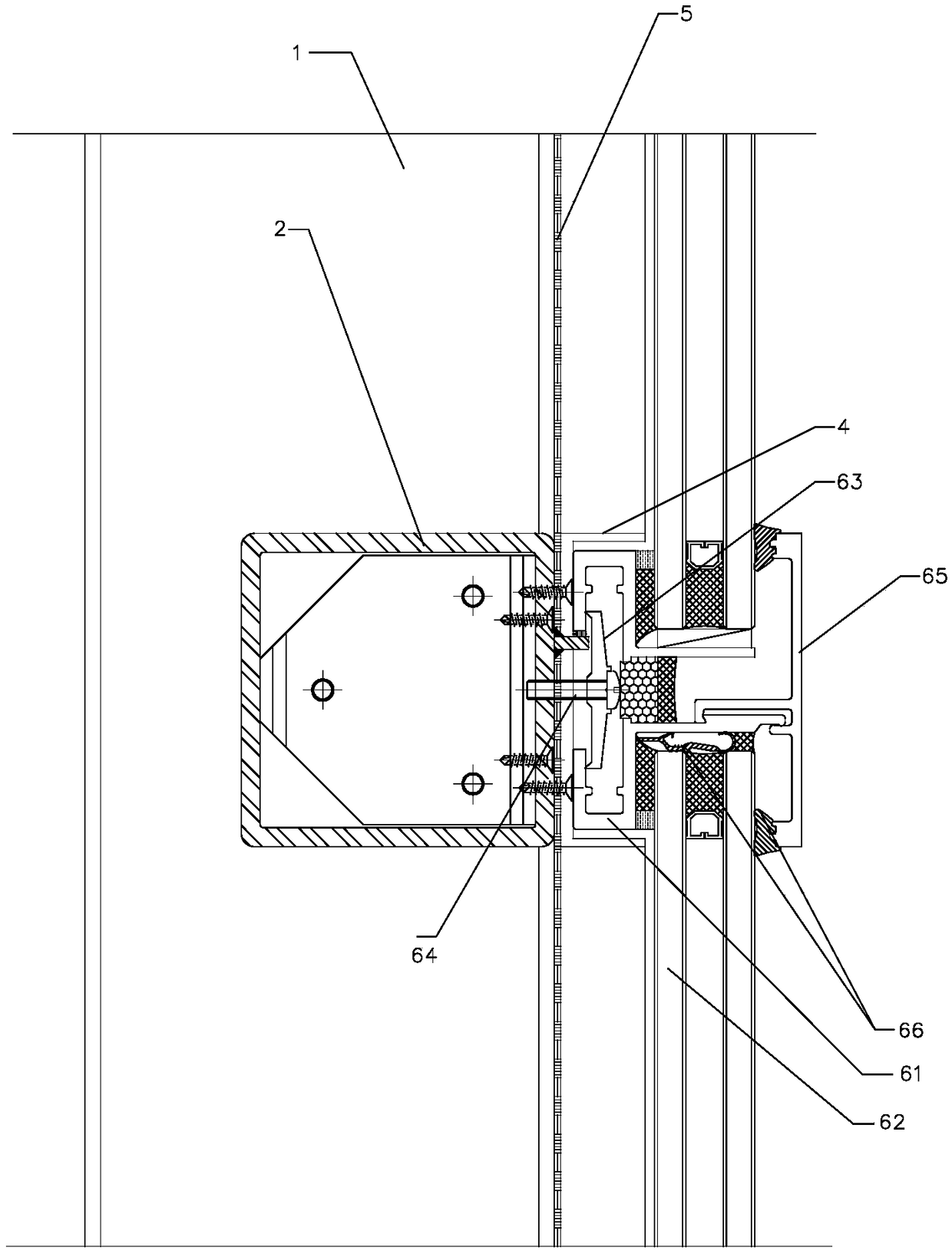

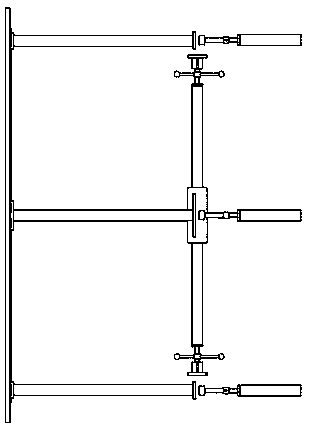

Steel pipe glass curtain wall system

PendingCN109339301ANo welding deformationNice appearanceWallsUltimate tensile strengthWelding deformation

The invention provides a steel pipe glass curtain wall system, which comprises a cross beam and a vertical column. The cross beam is a square steel pipe, and the vertical column is a rectangular steelpipe; the vertical column and the cross beam are mechanically connected through a connecting piece provided with a spring screw; and the vertical column and the cross beam are not connected in a welded mode, and thus welding deformation is avoided. The steel pipe glass curtain wall system has the advantages of beautiful appearance, low construction cost, high strength and rigidity, convenient construction and the like.

Owner:HUAQIAO UNIVERSITY

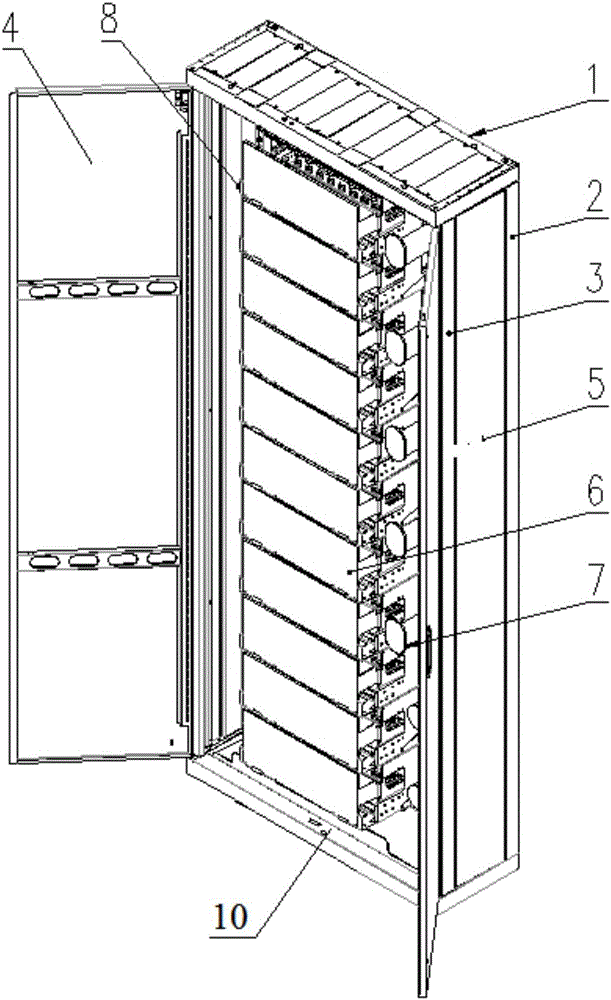

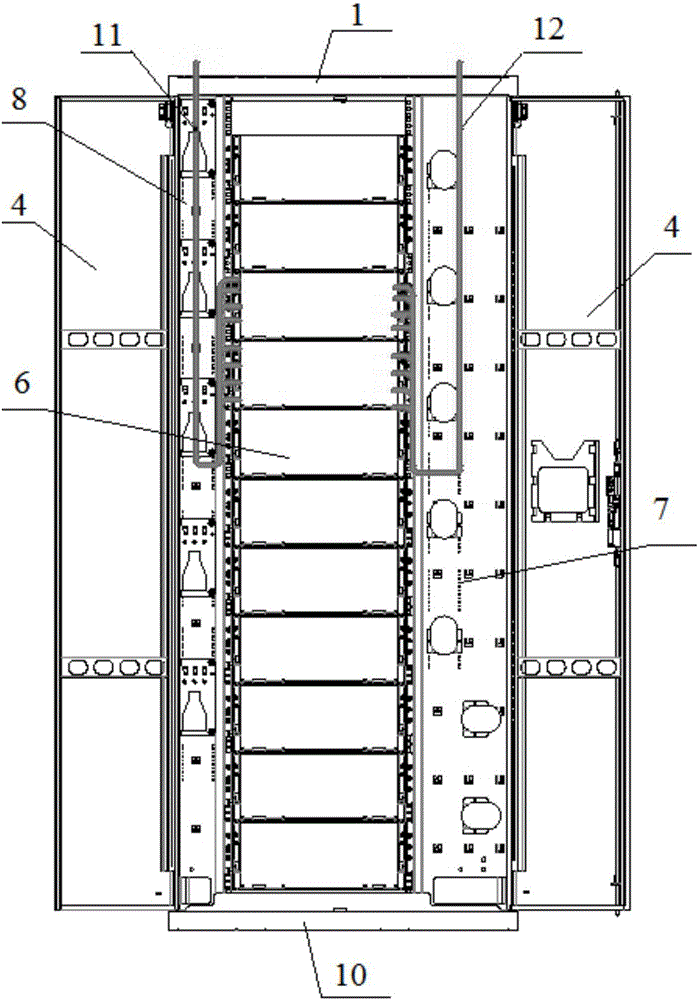

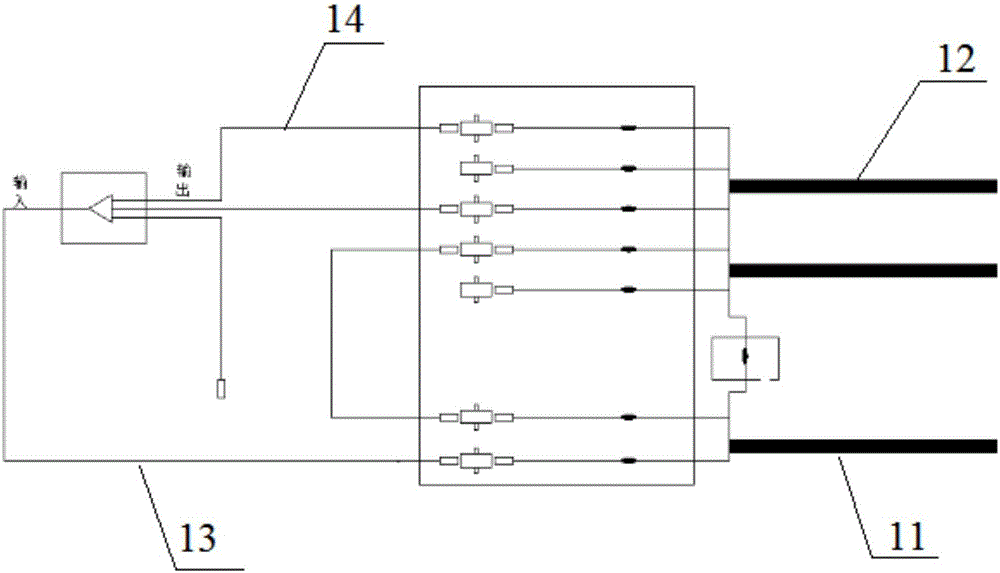

Assembly-type optical fiber distribution frame

InactiveCN106199863AEasy to assembleQuick assemblyFibre mechanical structuresDistribution frameComputer module

The invention discloses an assembly-type optical fiber distribution frame, and the frame comprises a top plate, a bottom plate, two integrated rear vertical columns which are disposed between the top plate and the bottom plate and are perpendicular to the top plate and the bottom plate, two front vertical columns which are disposed between the top plate and the bottom plate and are perpendicular to the top plate and the bottom plate, and side plates which are disposed between the integrated rear vertical columns and the front vertical columns. The top plate, the bottom plate, the integrated rear vertical columns, the front vertical columns and the side plates form an optical fiber distribution frame with an accommodation space. The two front vertical columns are respectively connected with a door plate through a movable spring cotter. The interior of the accommodation space is sequentially provided with an optical cable fixing grounding protection device, a 19-inch module unit, and an optical fiber winding storage assembly. The frame saves the complex welding technology, saves time and labor, has no welding deformation, is accurate in structural size, can carry out the modular disassembly and maintenance of the body after a cabinet is accidentally damaged, is easy to modify, is convenient for engineering installation, is large in capacity, is convenient to convey, is quick in installation, is clear in wiring, and is convenient to operate.

Owner:JIANGSU HENGTONG OPTICAL NETWORK TECH CO LTD +1

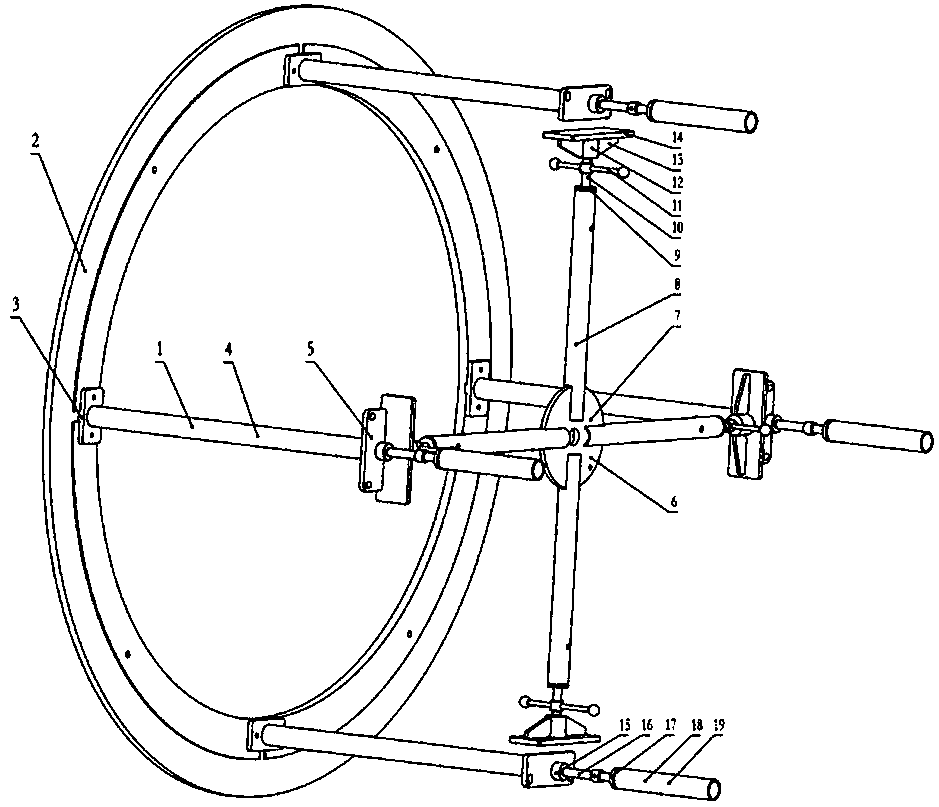

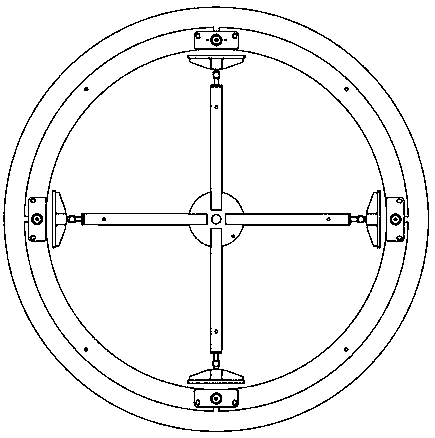

Welding and positioning device for special-shaped parts in straight cylinder

ActiveCN107081549BShort positioning timeHigh positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCircular face

Owner:CHANGZHI QINGHUA MACHINERY FACTORY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com