Milling cutter disc welding fixture and welding method applying same

A technology of welding tooling and cutter head, which is applied in welding equipment, laser welding equipment, manufacturing tools, etc., and can solve the problem of uncontrollable welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be described in detail below in conjunction with the accompanying drawings.

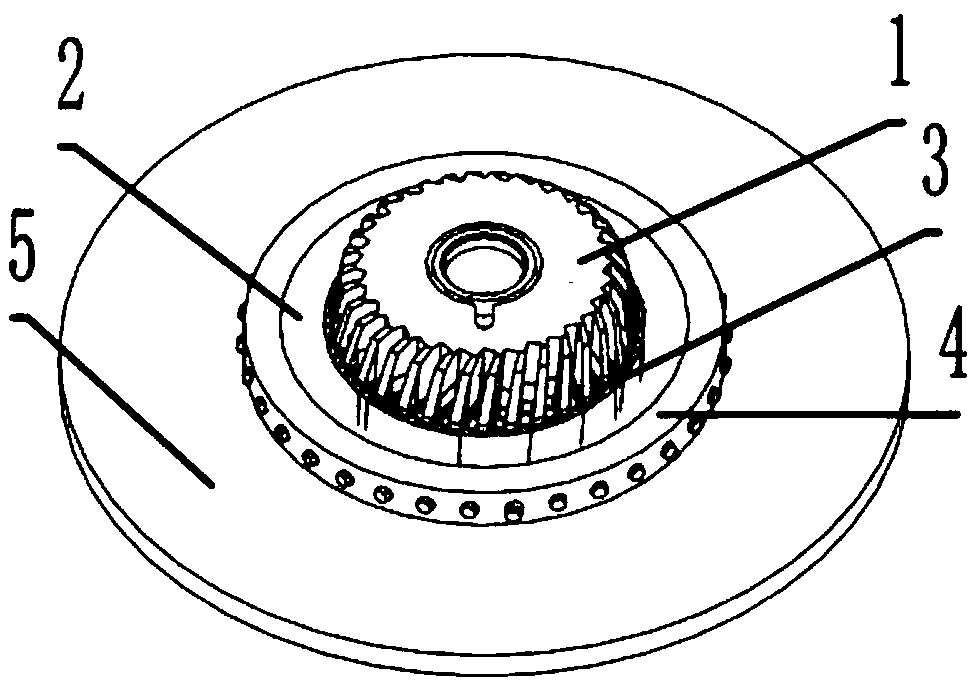

[0076] combine Figure 1-Figure 2 As shown, a milling cutter head welding tool disclosed in this embodiment includes a cutter head body 1, a cutter head outer ring 2, a base 5, a pre-tightening ring 4, and a cutter head positioning and clamping device 3; the cutter head The outer ring 2 is fixedly sleeved on the cutterhead main body 1, the preload ring 4 is connected with the cutterhead outer ring 2 through several sets of threaded connectors, and the preload ring 4 is also fixed on the base by screws 5, several sets of knife grooves are processed on the cutterhead main body 1, and a set of cutterhead positioning and clamping devices 3 are arranged in each group of cutterhead positioning and clamping devices 3, and the cutterhead positioning and clamping devices 3 are fixedly arranged on the base 5 on.

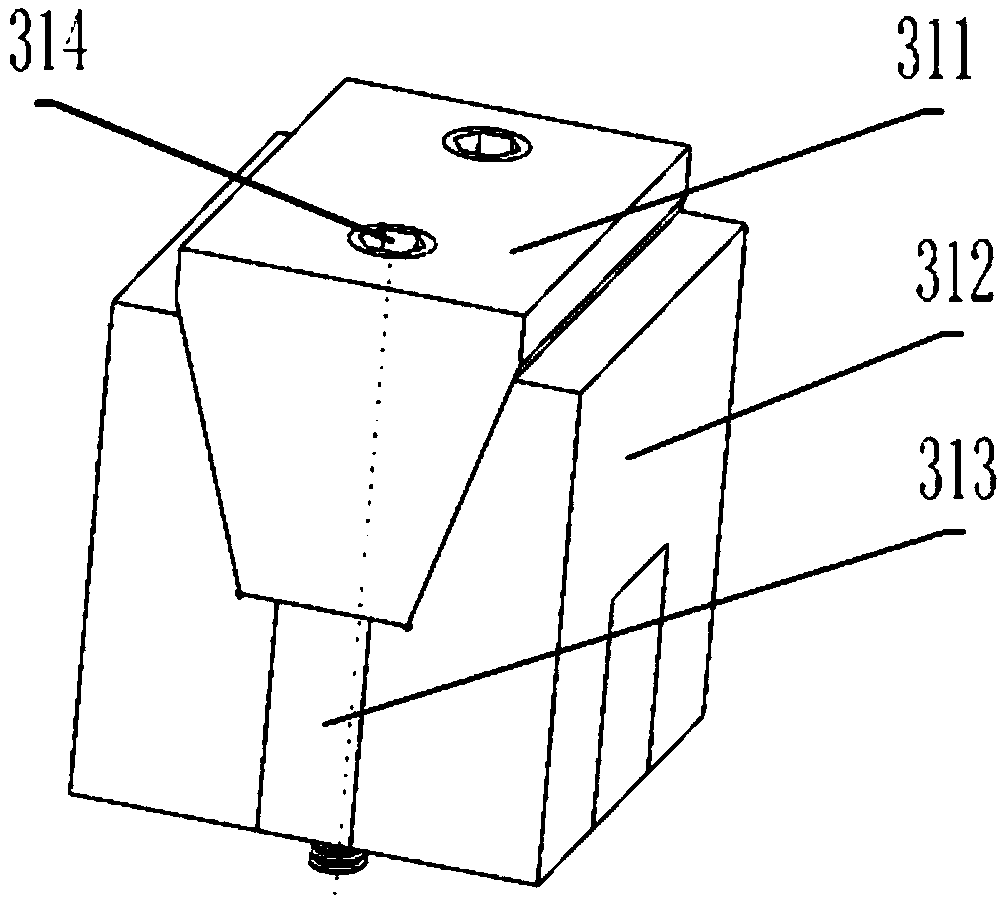

[0077] Specifically, the cutter head positioning and clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com