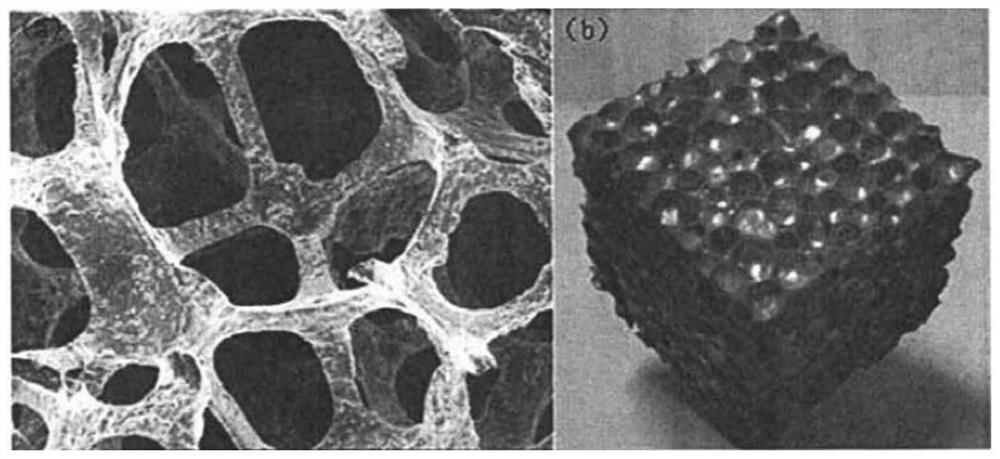

Lattice structure and its unit structure, lattice sandwich structure

A lattice structure and unit structure technology, applied in the field of energy-absorbing materials, can solve the problems of irreversible deformation, structural plastic deformation, and reduced impact resistance, and achieve the effect of reducing plastic strain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

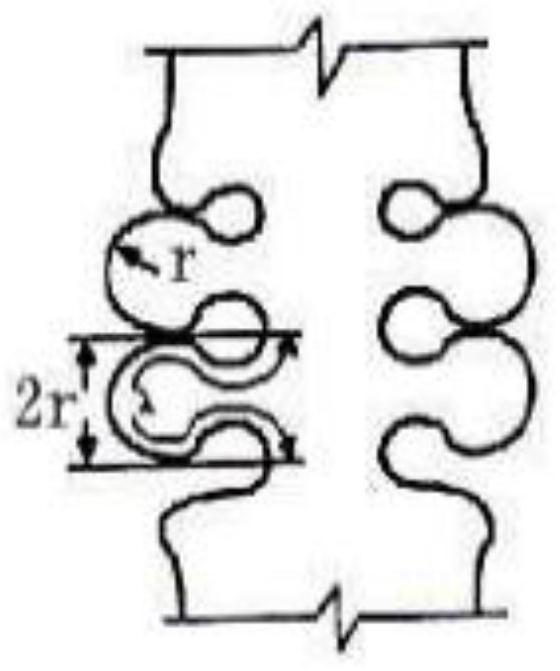

[0057] Such as Figure 4 and Figure 5 As shown, the unit structure 1 based on the lattice structure provided by this embodiment includes a first base 10, a second base 12, and a connecting rod 11 connecting the first base 10 and the second base 12 .

[0058] Taking x as the horizontal plane and y as the vertical plane as the reference coordinate system, in the normal placement state, the angle between the connecting rod and the horizontal plane is set as θ. The length of the connecting rod is L, the width of the connecting rod along the cross section perpendicular to the vertical plane where the central axis is located is W, and the thickness of the connecting rod along the cross section perpendicular to the vertical plane where the central axis is located is T .

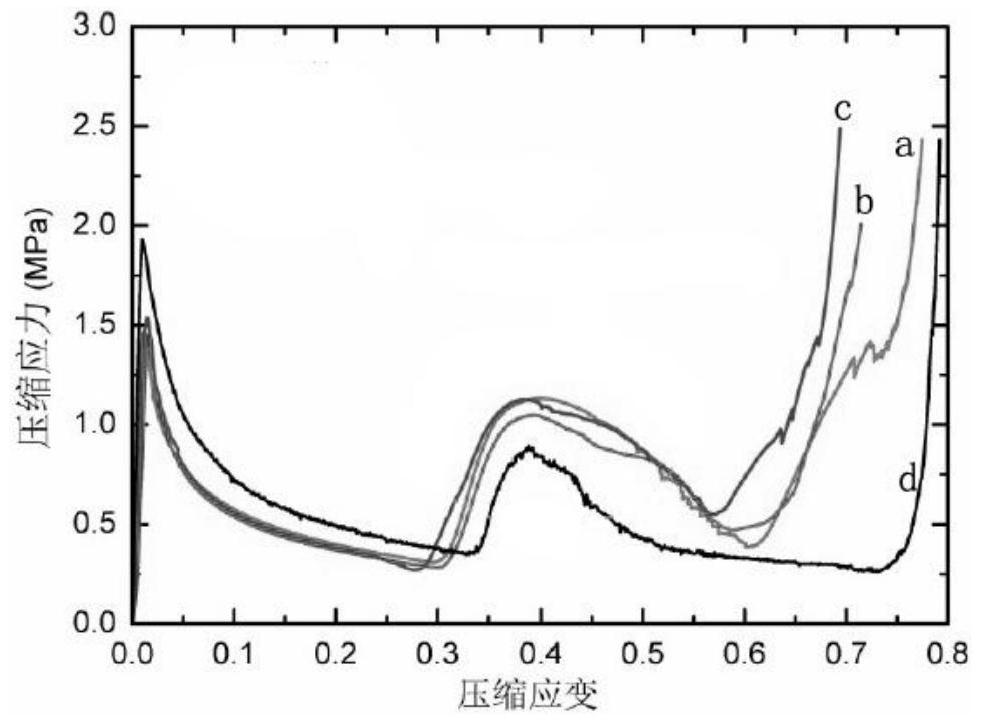

[0059] Take θ=45°, W / L=0.12, T≤W as the first parameter design of the connecting rod 11 in this embodiment as an example. At this time, the rod 11 is an Euler-Bernoulli beam, and it is analyzed using a numerica...

Embodiment 2

[0080] Such as Figure 17 As shown, this embodiment is based on the embodiment 1, and the surrounding side of the connecting rod 11 is provided with a reinforcing part 102 , and the reinforcing part 102 is used to locally adjust the energy absorption curve of the unit structure 1 .

[0081] The length of the reinforcing part 102 along the length direction of the connecting rod 11 is L 1 , the width along the cross-section perpendicular to the vertical plane is W 1 , where, 0.05≤L 1 / L≤0.15, 1.1≤W 1 / W≤1.2.

[0082]With θ=45°, W / L=0.1, T≤W, L 1 / L=0.5,W 1 / W=1.1 is an example of the parameter design of the connecting rod 11 in this embodiment, and the numerical simulation method (plane strain model) is used for analysis. Its force-displacement curve is as Figure 18 As shown, the strain energy-displacement curve is shown as Figure 19 shown. and Figure 13 and Figure 14 It can be seen from the comparison that the reinforcement part 102 can be used to locally adjust ...

Embodiment 3

[0089] Such as Figure 20 As shown, in this embodiment, on the basis of Embodiment 1, the connecting base 101 is provided with a splicing structure 103, and the splicing structure 103 is used for splicing and fixing different unit structures 1, or, The splicing structure 103 can also be used for splicing and fixing with an external mechanism.

[0090] Wherein, the splicing structure 103 is an insertion part or a groove part that can be engaged with the insertion part, and the splicing structures 103 that are spliced with each other are designed in cooperation.

[0091] Specifically, the splicing structure 103 provided on the connecting seat 101 of the first base 10 of one unit structure 1 can engage with the splicing structure 103 provided on the connecting seat 101 of the first base 10 of another unit structure 1, or can be engaged with another The splicing structure 103 provided on the connecting seat 101 of the second base 12 of a unit structure 1 can be engaged. For ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com