Equipment and method for rolling magnesium/aluminum composite plate to inhibit magnesium alloy edge cracks

A technology of aluminum composite panels and magnesium alloys, applied in metal processing equipment, metal rolling, metal rolling, etc., can solve problems such as insufficient material utilization, magnesium/aluminum composite panel production, limited application range, and low yield , to achieve the effect of weakening stress and plastic strain, reducing size limit and suppressing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

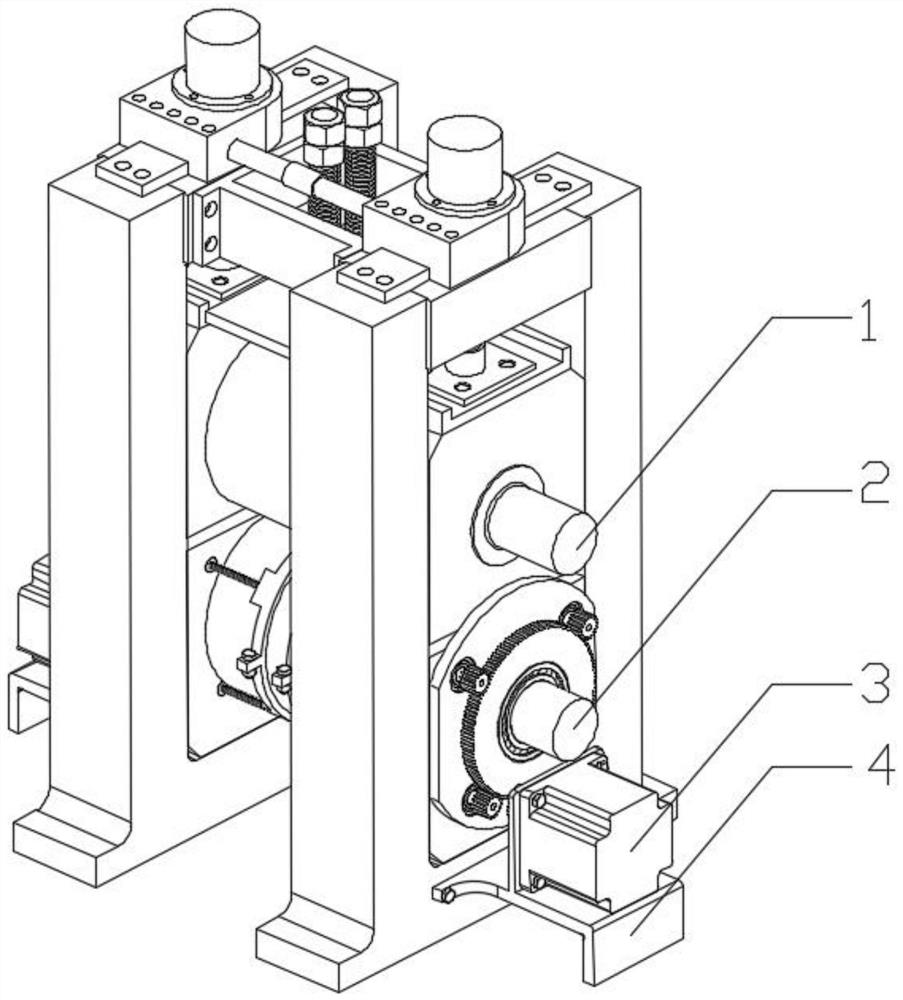

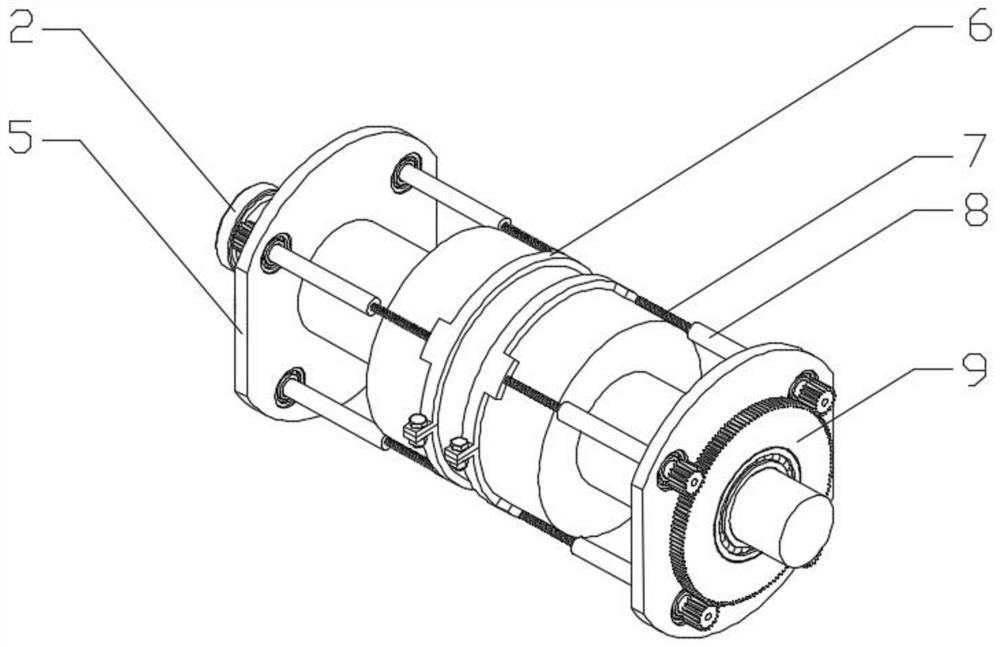

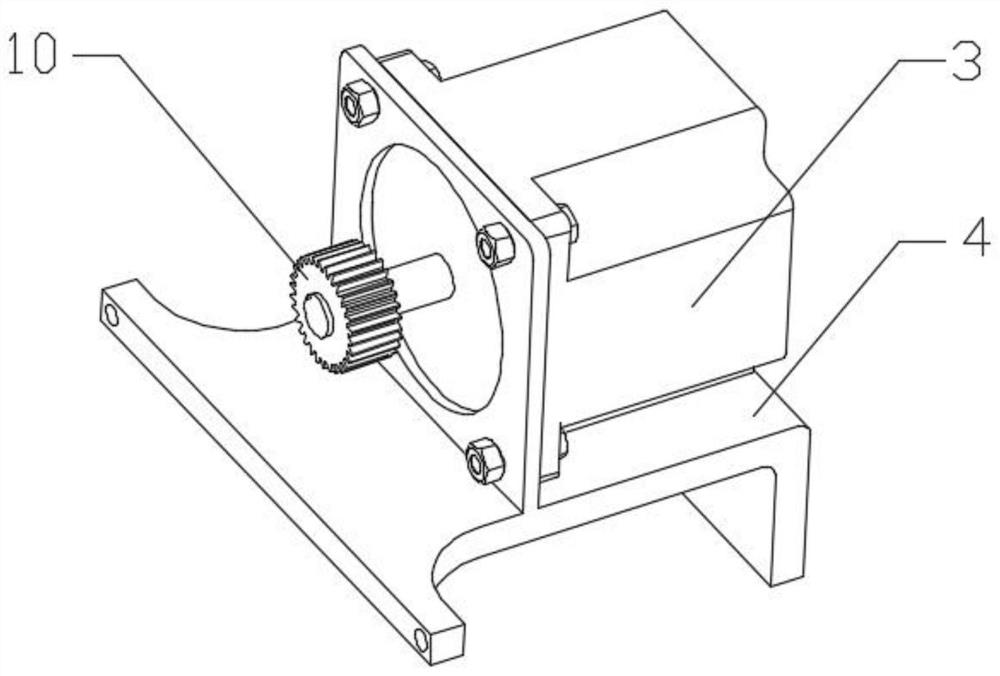

[0031] Such as Figure 1 to Figure 3 As shown, an equipment for rolling magnesium / aluminum composite plates to suppress edge cracking of magnesium alloys includes an upper roll 1, a lower roll 2 and a rolling mill stand, and two rolling width-limiting retaining rings 6 are installed on the lower roll 2 , used to weaken the stress and plastic strain of the side edge of the plate along the axial direction of the roll. The rolling width-limiting retaining ring 6 is composed of two semicircular buckles fixed by bolts, and the rolling width-limiting retaining ring 6 and the lower roll 2 are clearance fit. The material of the rolled width-limiting retaining ring 6 is T2 red copper. On the left and right sides of the rolling mill frame, a motor support 4 is installed, a motor 3 is arranged on the motor support 4, a pinion 10 is arranged on the output shaft of the motor 3, and the pinion A large gear 9 is engaged and connected, and the large gear 9 is installed on the roller shaft o...

Embodiment 2

[0041] A method for suppressing edge cracking of magnesium alloys by rolling a magnesium / aluminum composite plate, comprising the following steps:

[0042] S1, select retaining ring: prepare rolling width-limiting retaining ring 6 with an inner ring diameter of 151 mm and an outer ring diameter of 156 mm, and install it on the lower roll 2;

[0043] S2. Moving the retaining ring: powered by the motor 3, the rolled width-limiting retaining ring 6 is driven to move, so that the horizontal distance between the two rolling width-limiting retaining rings 6 is 80mm;

[0044] S3, adjust the roll gap: adjust the pressing of the rolling mill so that the roll gap between the upper roll 1 and the lower roll 2 is 5.6 mm;

[0045] S4. Batch making: prepare AZ31B magnesium alloy plates with a size of 100mm×80mm×3mm and 5052 aluminum alloy plates with a size of 100mm×80mm×5mm, and use a grinder to grind the surfaces to be bonded to magnesium and aluminum alloys to remove surface impurities. ...

Embodiment 3

[0050] S1, select retaining ring: prepare rolling width-limiting retaining ring 6 with an inner ring diameter of 151 mm and an outer ring diameter of 159 mm, and install it on the lower roll 2;

[0051] S2. Moving the retaining ring: powered by the motor 3, the rolled width-limiting retaining ring 6 is driven to move, so that the horizontal distance between the two rolling width-limiting retaining rings 6 is 110 mm;

[0052] S3, adjust the roll gap: adjust the pressing of the rolling mill so that the roll gap between the upper roll 1 and the lower roll 2 is 7mm;

[0053] S4. Batch making: prepare AZ31B magnesium alloy plates with a size of 120mm×110mm×4mm and 5052 aluminum alloy plates with a size of 120mm×110mm×6mm, and use a grinder to grind the surfaces to be bonded to magnesium and aluminum alloys to remove surface impurities. Buckle the surfaces of the two boards to be joined and use aluminum wire to bind them at a distance of 10-15mm from the head of the board to keep th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com