Fuel tank assembly and vehicle

A technology of fuel tank and assembly, applied in the field of fuel tank assembly and vehicle, can solve the problems of easy falling off of fuel tank, large load of cable tie, punctured, etc., so as to reduce plastic strain and cable tie stress, improve service life, and eliminate direct Collision and squeeze effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

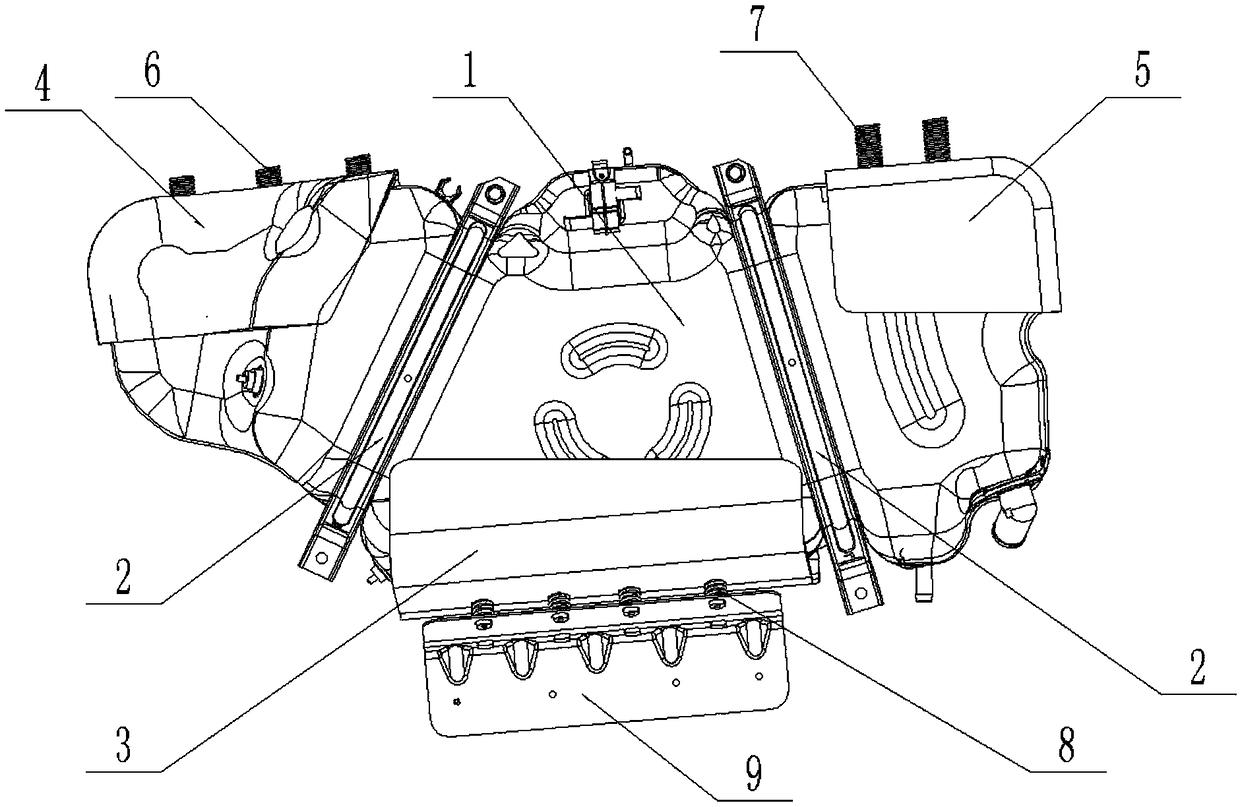

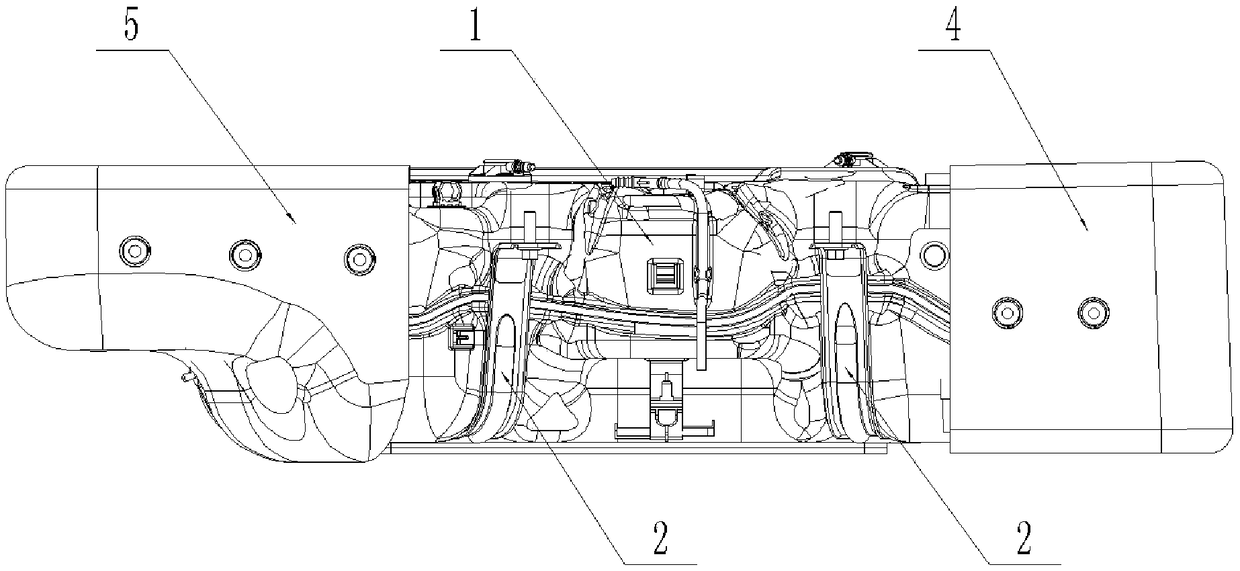

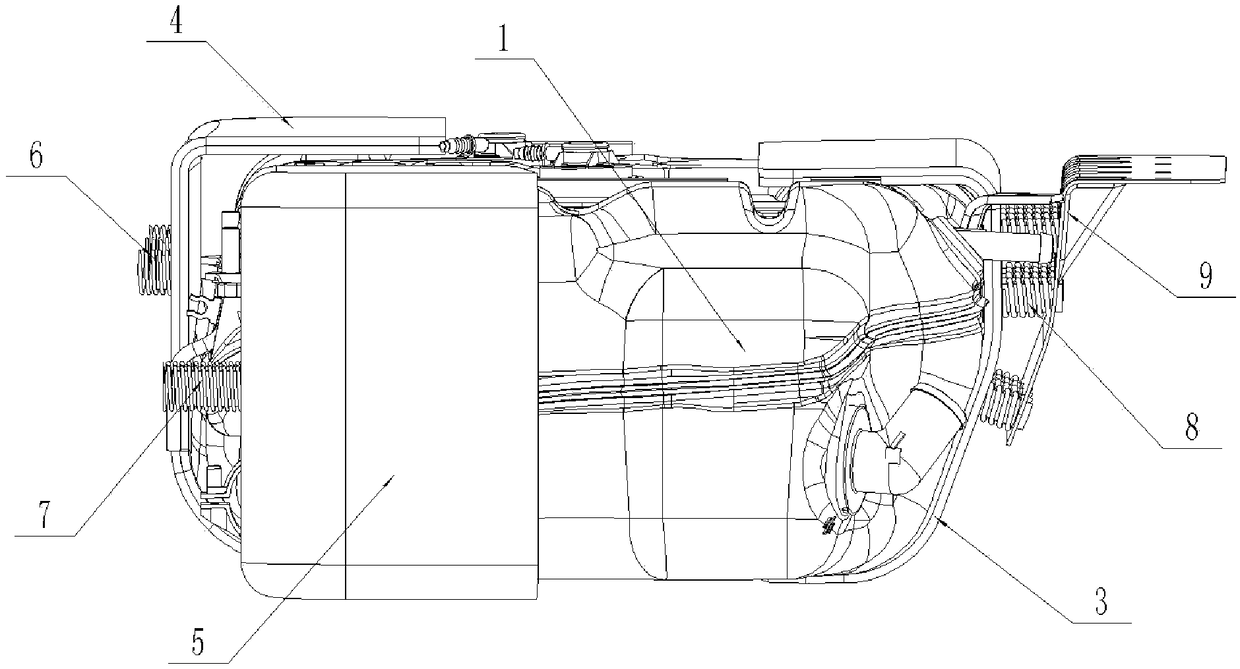

[0038] like figure 1 and figure 2 As shown, the fuel tank assembly provided by the embodiment of the present invention includes: a fuel tank body 1 and a cable tie 2 suspended from the fuel tank body 1, and is characterized in that both ends of the cable tie 2 are fixedly connected to the vehicle body along the traveling direction of the vehicle body A flexible device is arranged between the fuel tank body 1 and the vehicle body, and the flexible device abuts against the side wall of the fuel tank body 1 facing the traveling direction of the vehicle body, and / or, the side wall facing away from the traveling direction of the vehicle body. Wherein, both ends of the cable tie 2 are fixedly connected to the lower end of the vehicle body, and the fuel tank body 1 is located between the cable tie 2 and the vehicle body. When car body collision and speed change are considered, the force between the fuel tank body 1 and the car body is generally distributed along the longitudinal di...

Embodiment 2

[0055] The vehicle provided by the embodiment of the present invention includes: the fuel tank assembly provided by the first embodiment. Since the technical effect of the vehicle provided in this embodiment is the same as that of the fuel tank assembly provided in Embodiment 1, it will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com