Large damaged foundation bolt butt joint method

A technology of anchor bolts and anchor bolts, which is applied in the field of large-scale damaged pre-embedded anchor bolts, can solve the problems of difficulty in guaranteeing strength and verticality and time-consuming, etc., achieve good shear resistance, enhance shear resistance, short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

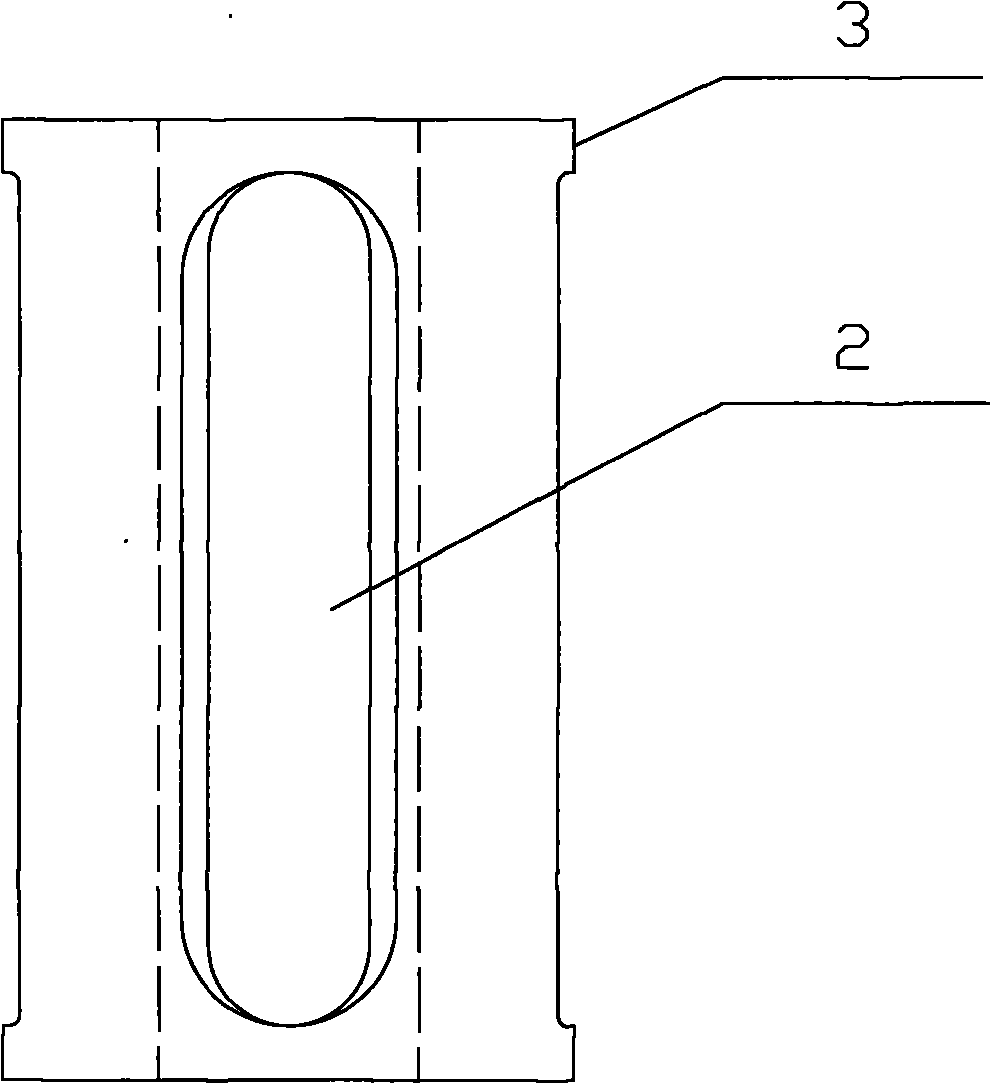

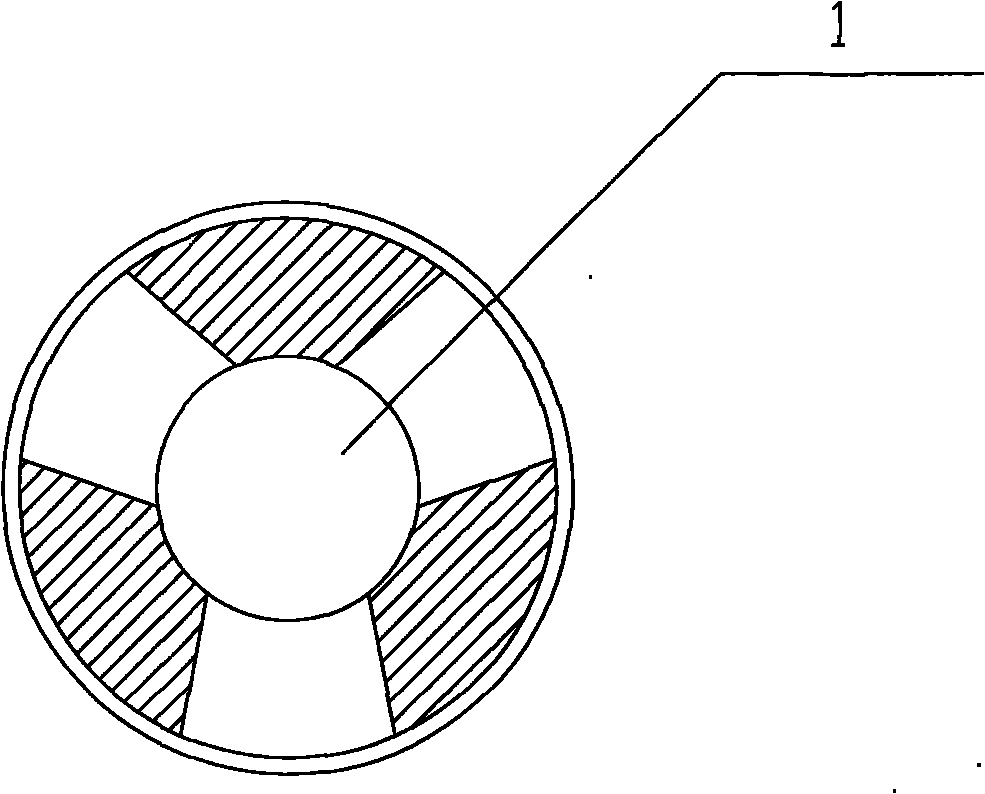

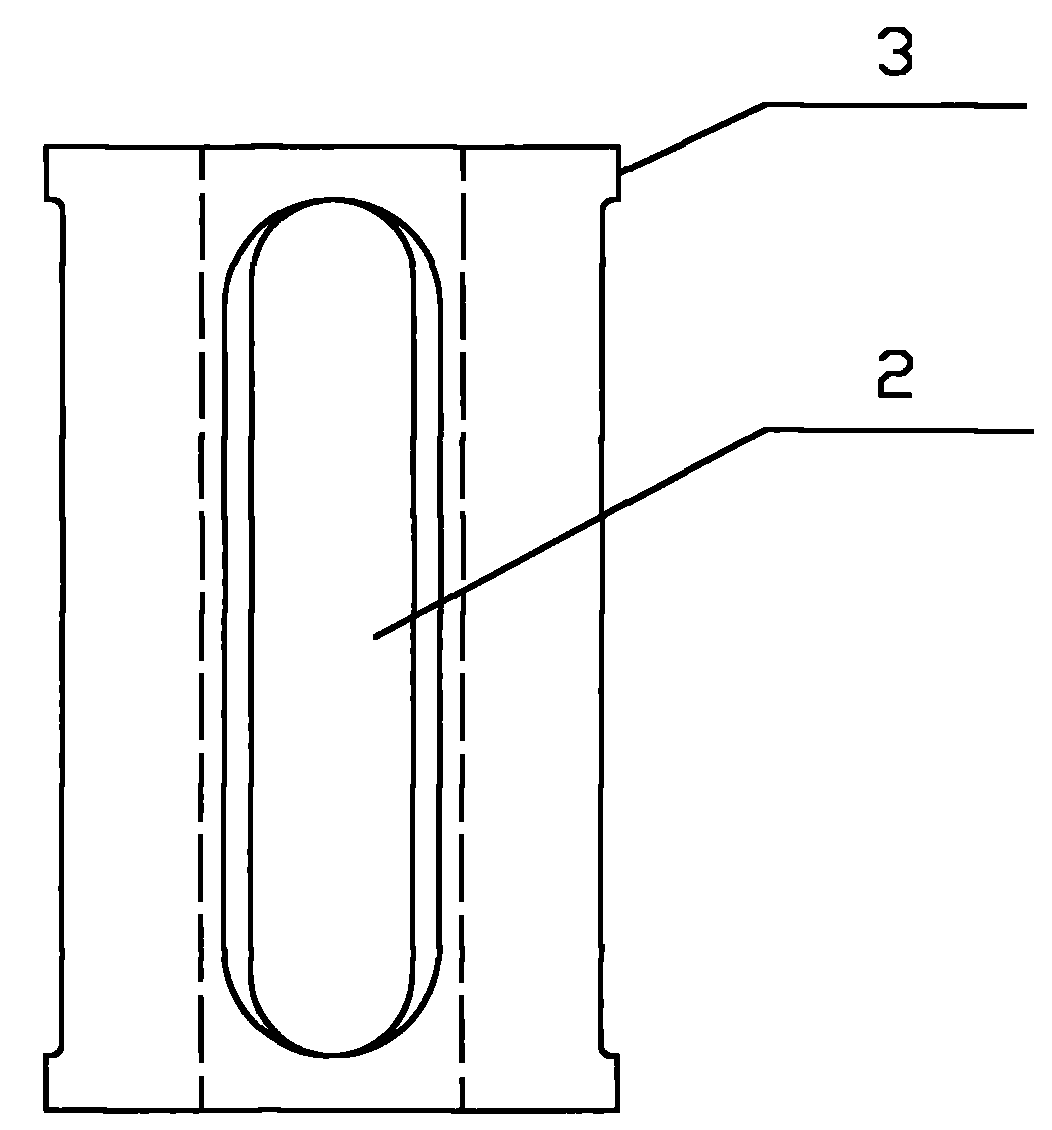

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] First, check the damaged anchor bolts. Generally, the damage of anchor bolts mainly occurs at the connection between the upper concrete bolts and the equipment. The vibration of the equipment causes the wear and tear of the upper threads of the bolts, or the high-pressure water and other media cause certain damage to the bolts. Corrosion, leading to bolt failure. Because the large-scale anchor bolts of the direct-buried type generally have to go deep into the concrete layer at a depth of more than 1m, if the entire anchor bolt is directly removed and replaced with a new bolt, firstly, it will cause great damage to the integrity of the concrete layer, and secondly, the construction The difficulty is also very high. The foundation generally adopts a concrete layer above C30, especially the deep foundation at the bottom. Because it is formed by one-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com