Welding and positioning device for special-shaped parts in straight cylinder

A technology for welding positioning and special-shaped parts, which is used in welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of inaccurate welding positioning, unable to meet production needs, affecting assembly quality, etc., to achieve short positioning time and reduce assembly. Cost, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

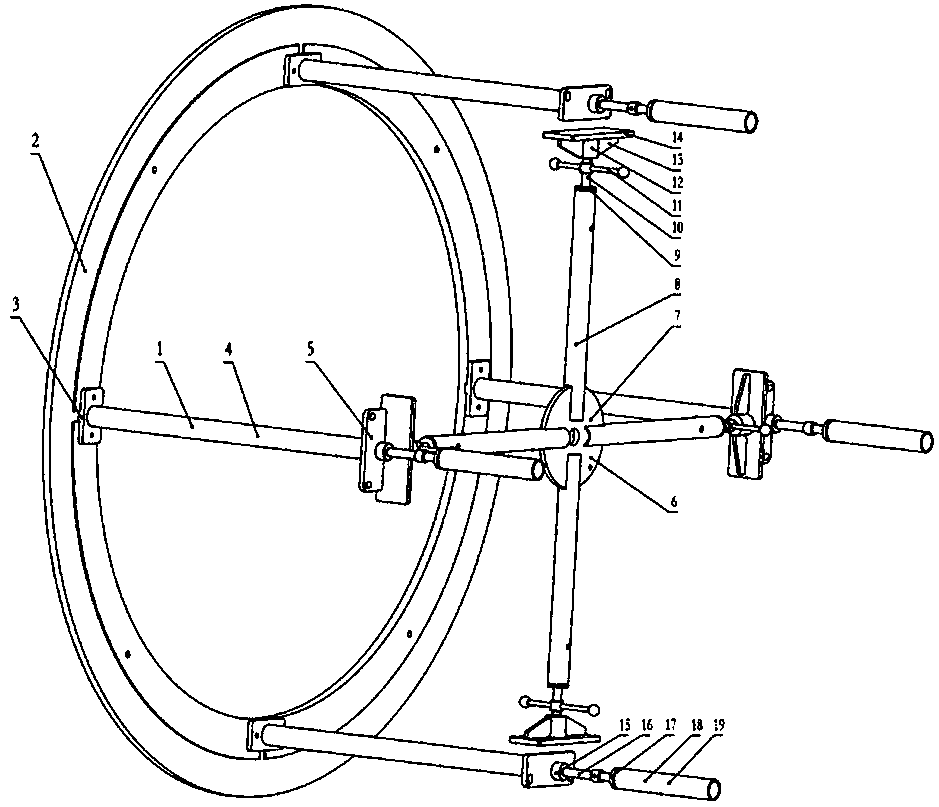

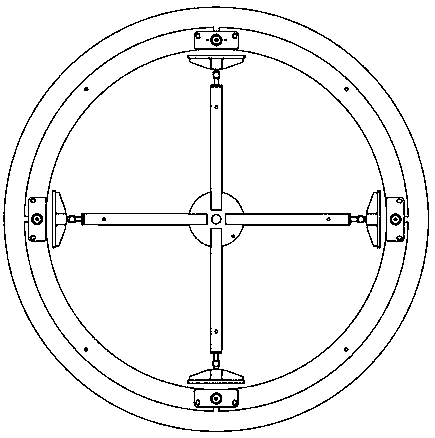

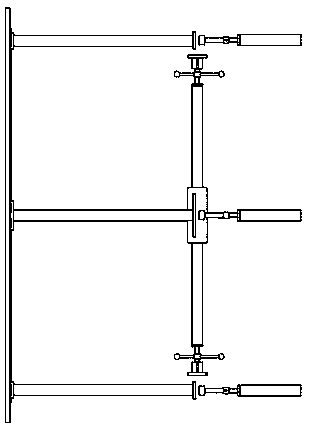

[0021] Such as Figure 1-Figure 3 As shown, the welding and positioning device for special-shaped parts in a straight cylinder of the present invention includes a flange 2, four positioning rod combinations 1, four support rod combinations 6 and four ejector rod combinations 19;

[0022] Four key grooves are evenly distributed along the circumferential direction on the annular surface of the flange 2;

[0023] The positioning rod combination 1 includes a positioning plate 3, a positioning rod 4 and a support plate 5, the positioning rod 4 is horizontally arranged, one end is connected with the positioning plate 3, and the other end is connected with the support plate 5;

[0024] Described strut assembly 6 comprises support rod 8, adjustment screw rod 10, adjustment handle 11, briquetting block 12 and pressing plate 14, and one end of support rod 8 is fixed with the first plug 9 with threaded hole, and one end of adjustment screw rod 10 is threaded Connected with the first plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com