Metal adhesive and preparation method thereof

An adhesive and metal technology, applied in the direction of adhesives, non-polymer adhesive additives, non-polymer organic compound adhesives, etc. Good adhesive properties and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

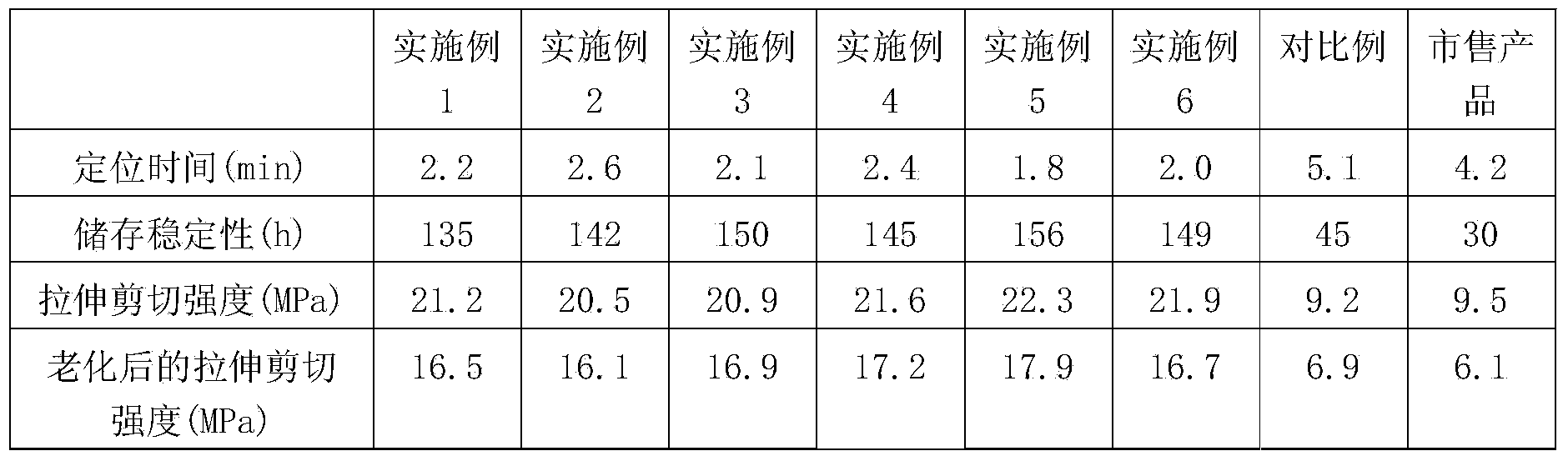

Examples

Embodiment 1

[0016] An adhesive for metal, comprising in parts by weight: 10 parts of E-51 epoxy resin, 5 parts of polyurethane formate, 10 parts of methacrylic glycol double fat, 2 parts of polyethylene, propylene oxide phenyl ether 1 part, 5 parts of barium phenolic resin, 3 parts of 8-hydroxyquinoline, 1 part of hexamethylenetetramine, 2 parts of nitrile rubber, 2 parts of tricresyl phosphate, 1 part of aluminum oxide, and 1 part of polysulfide rubber , 1 part of attapulgite, 2 parts of polyvinyl butyral, 3 parts of diethylenetriamine, 2 parts of ethylenediamine, 5 parts of triethanolamine, and 10 parts of acetone.

[0017] The particle size of the aluminum oxide is 200-300 mesh.

[0018] The particle size of the concave-convex bar graph is 100-300 mesh.

[0019] The preparation method of above-mentioned adhesive for metal, comprises the following steps:

[0020] Step 1, E-51 epoxy resin, barium phenolic resin, urethane formate, aluminum oxide and nitrile rubber are dispersed in aceto...

Embodiment 2

[0025] An adhesive for metal, comprising in parts by weight: 12 parts of E-51 epoxy resin, 7 parts of polyurethane formate, 14 parts of methacrylic glycol double fat, 3 parts of polyethylene, propylene oxide phenyl ether 2 parts, 6 parts of barium phenolic resin, 4 parts of 8-hydroxyquinoline, 2 parts of hexamethylenetetramine, 3 parts of nitrile rubber, 4 parts of tricresyl phosphate, 2 parts of aluminum oxide, 3 parts of polysulfide rubber , 2 parts of attapulgite, 3 parts of polyvinyl butyral, 5 parts of diethylenetriamine, 4 parts of ethylenediamine, 85 parts of triethanolamine, and 14 parts of acetone.

[0026] The particle size of the aluminum oxide is 200-300 mesh.

[0027] The particle size of the concave-convex bar graph is 100-300 mesh.

[0028] The preparation method of above-mentioned adhesive for metal, comprises the following steps:

[0029] Step 1, E-51 epoxy resin, barium phenolic resin, urethane formate, aluminum oxide and nitrile rubber are dispersed in ace...

Embodiment 3

[0034] An adhesive for metal, comprising in parts by weight: 16 parts of E-51 epoxy resin, 8 parts of urethane formate, 15 parts of methacrylic glycol double fat, 7 parts of polyethylene, propylene oxide phenyl ether 4 parts, 7 parts of barium phenolic resin, 6 parts of 8-hydroxyquinoline, 4 parts of hexamethylenetetramine, 3 parts of nitrile rubber, 5 parts of tricresyl phosphate, 3 parts of aluminum oxide, 2 parts of polysulfide rubber , 2 parts of attapulgite, 4 parts of polyvinyl butyral, 6 parts of diethylenetriamine, 8 parts of ethylenediamine, 10 parts of triethanolamine, and 15 parts of acetone.

[0035] The particle size of the aluminum oxide is 200-300 mesh.

[0036] The particle size of the concave-convex bar graph is 100-300 mesh.

[0037] The preparation method of above-mentioned adhesive for metal, comprises the following steps:

[0038] Step 1, E-51 epoxy resin, barium phenolic resin, urethane formate, aluminum oxide and nitrile rubber are dispersed in acetone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com