Patents

Literature

36results about How to "No appearance defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

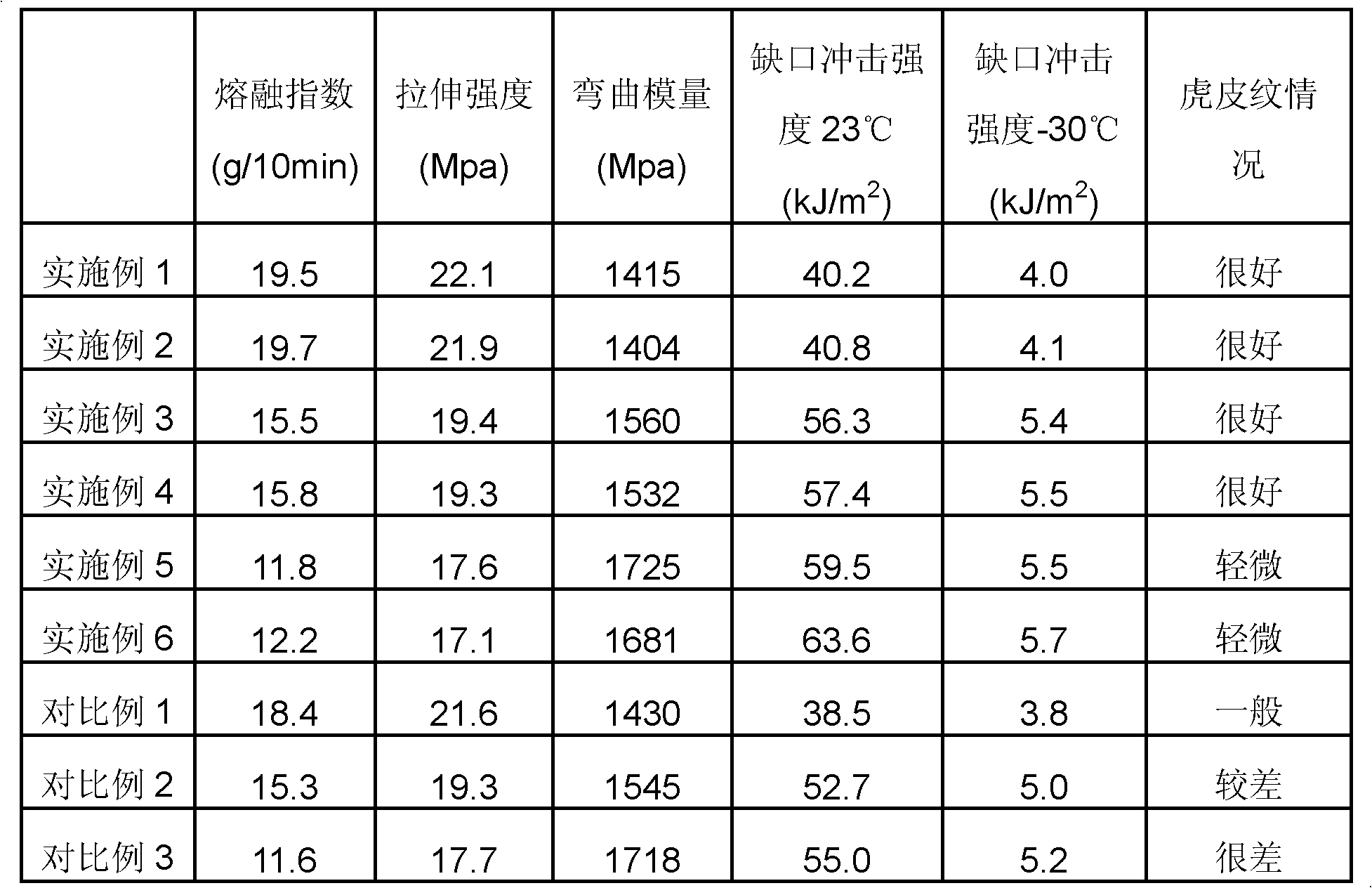

Polypropylene composite material for automotive instrument panel and preparation method for polypropylene composite material

The invention discloses a polypropylene composite material for an automotive instrument panel and a preparation method for the polypropylene composite material. The polypropylene composite material comprises the following components in percentage by weight: 45 to 80 percent of polypropylene, 10 to 30 percent of inorganic filler, 5 to 20 percent of toughening agent polyolefin elastomer (POE), 2 to 10 percent of polybutylene-1, 0.1 to 2 percent of antioxidant, 0.1 to 1 percent of light stabilizer, 0 to 3 percent of anti-scratch aid and 0 to 3 percent of the balance. The polypropylene composite material has excellent rigid-tough balance; the low-temperature notch strength is far higher than that of general polypropylene composite materials; the injection molding cycle is short; apparent defects such as tiger skin and the like are avoided on the surfaces of injection-molded sample pieces; and the characteristics efficiently meet the requirements of automotive instrument panels.

Owner:SHANGHAI PRET COMPOSITES

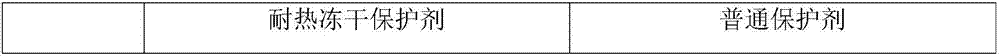

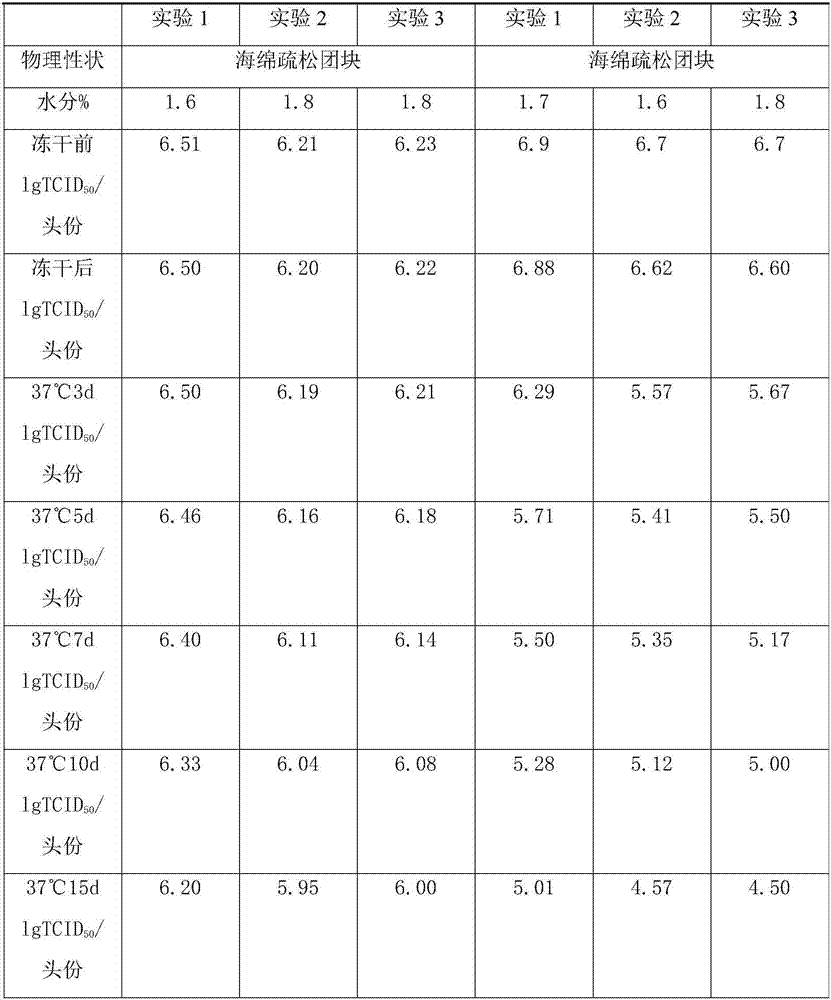

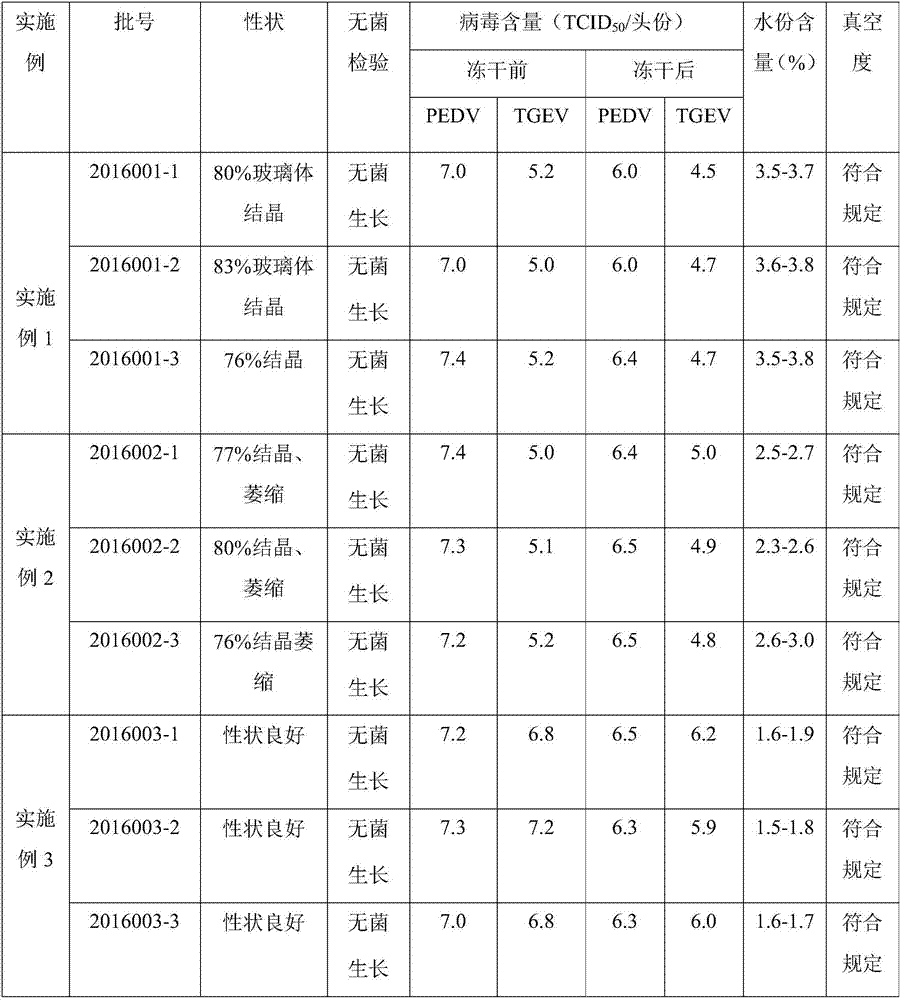

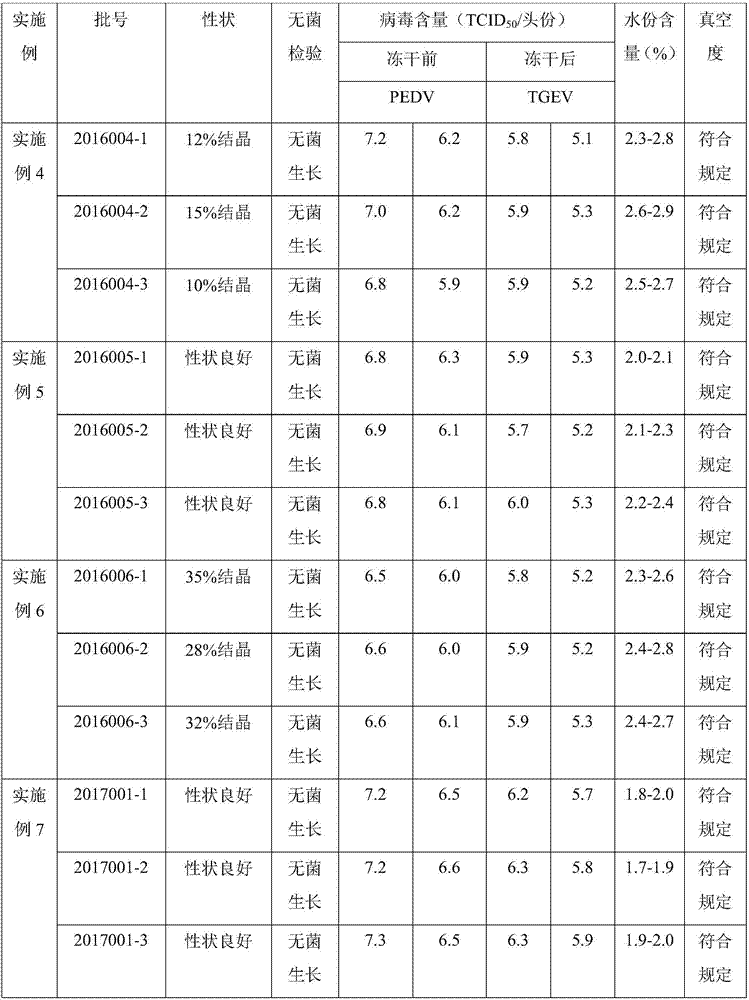

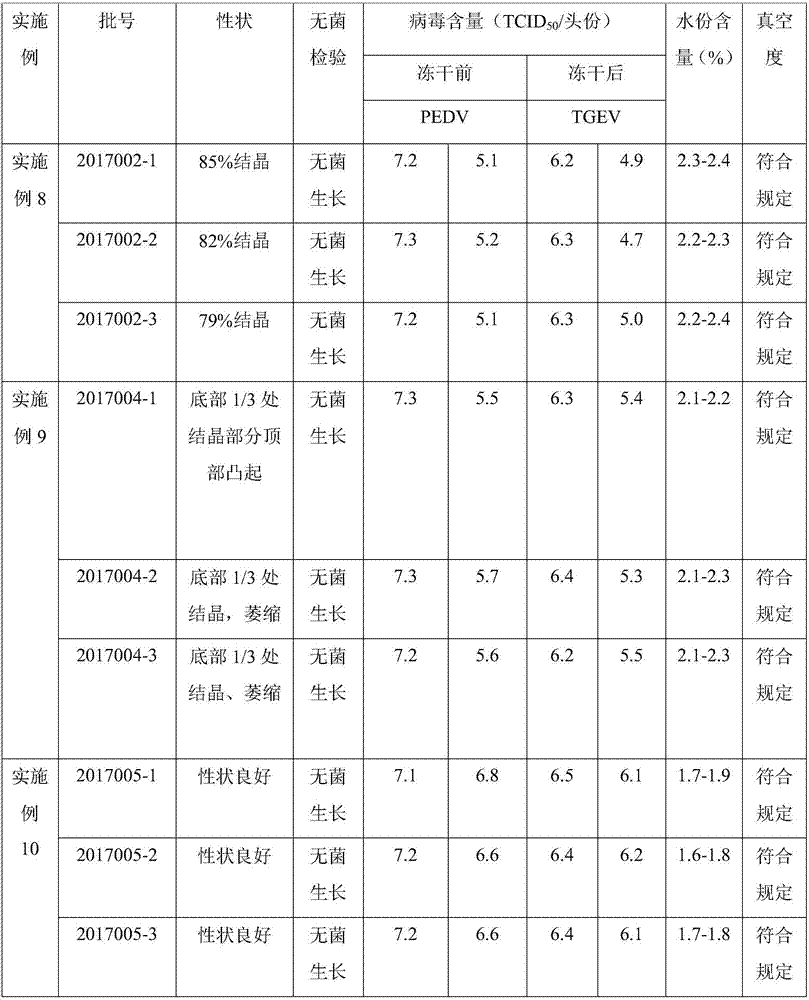

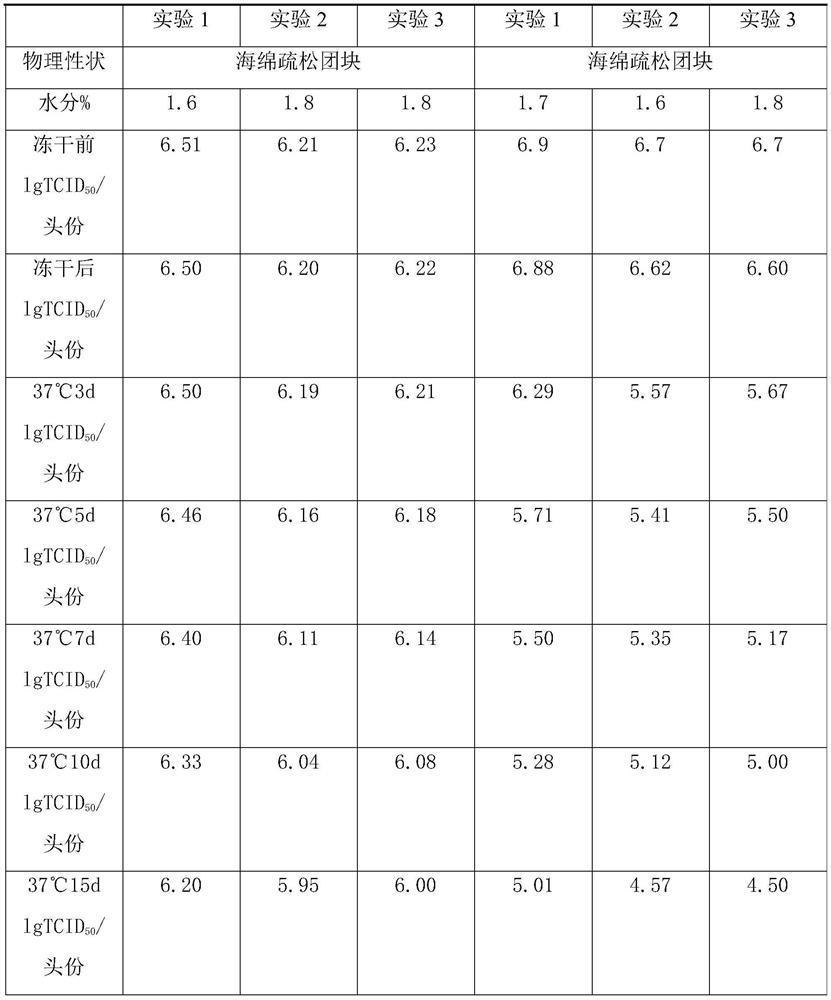

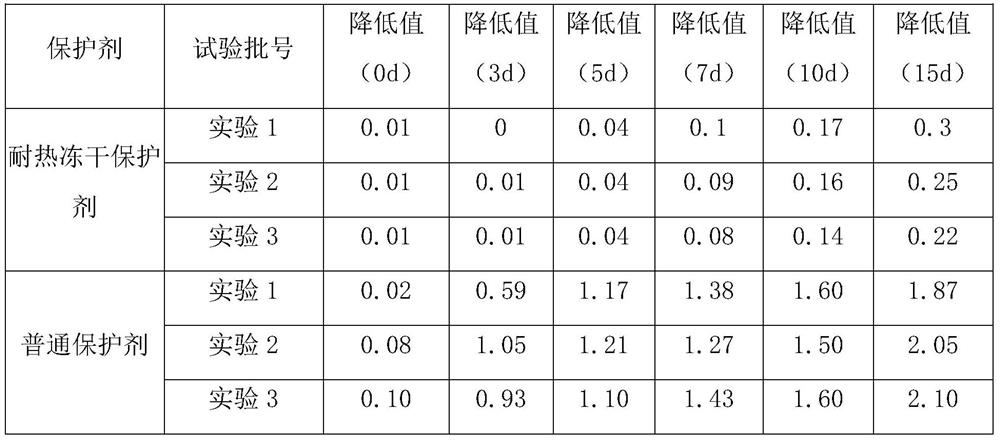

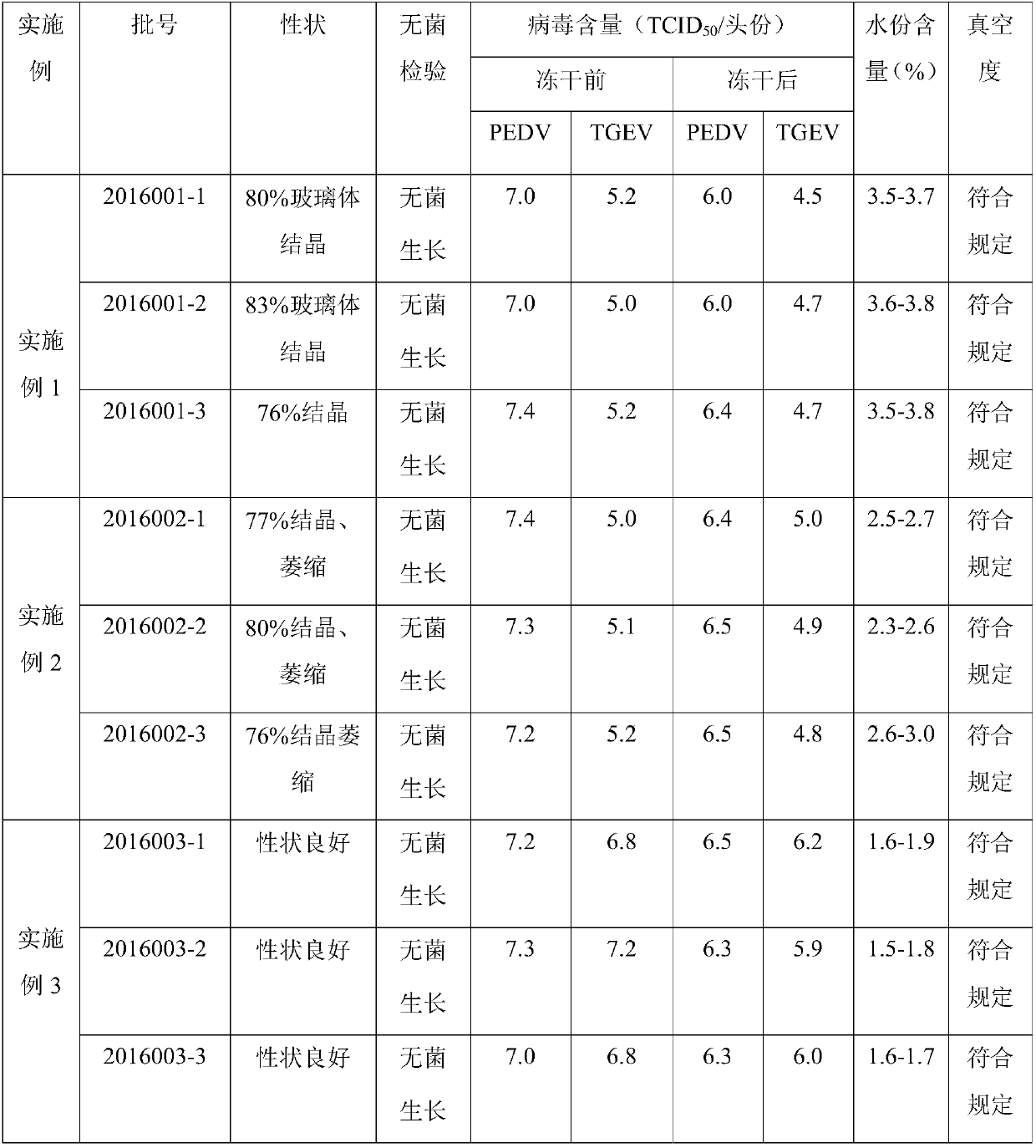

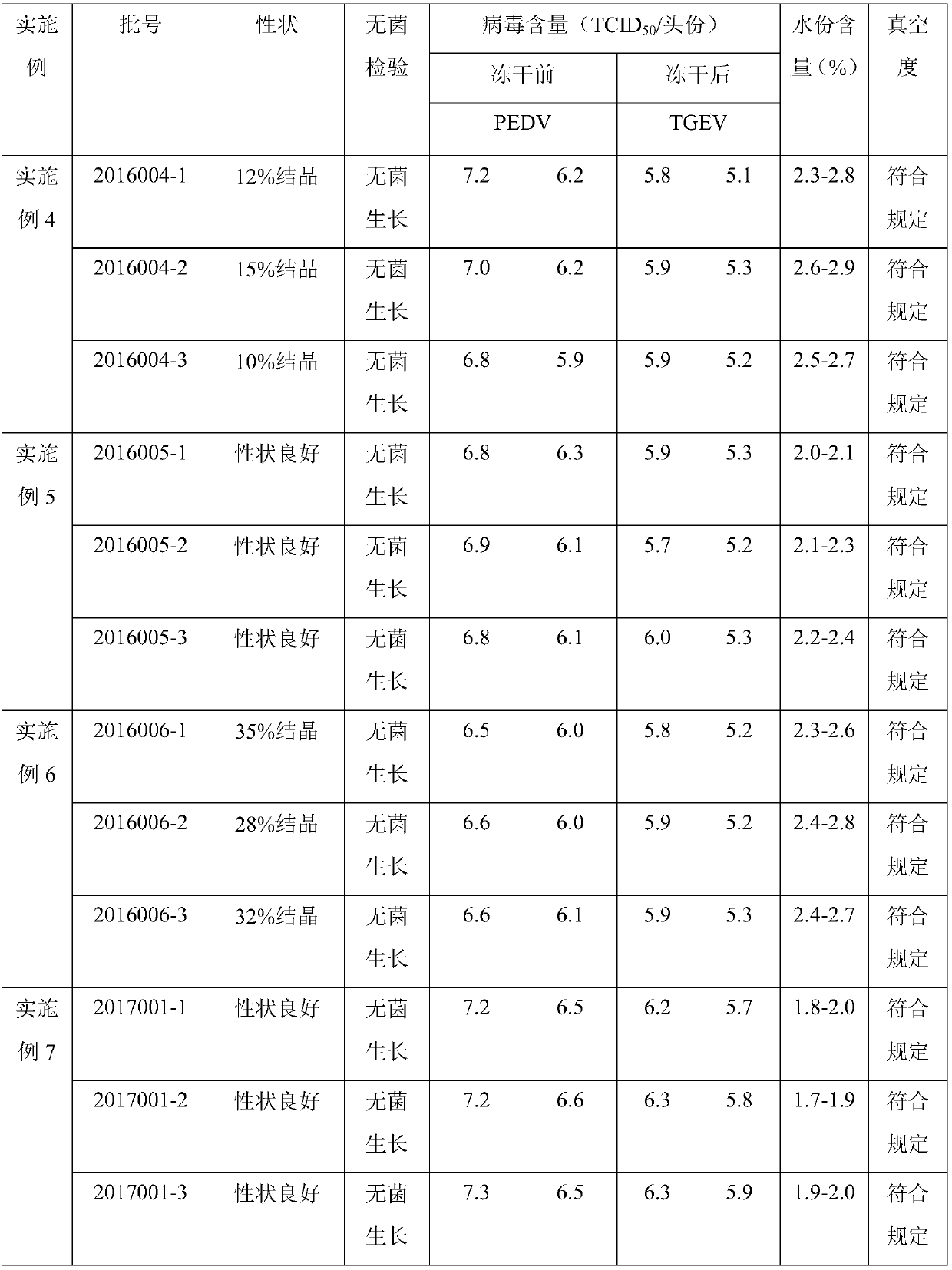

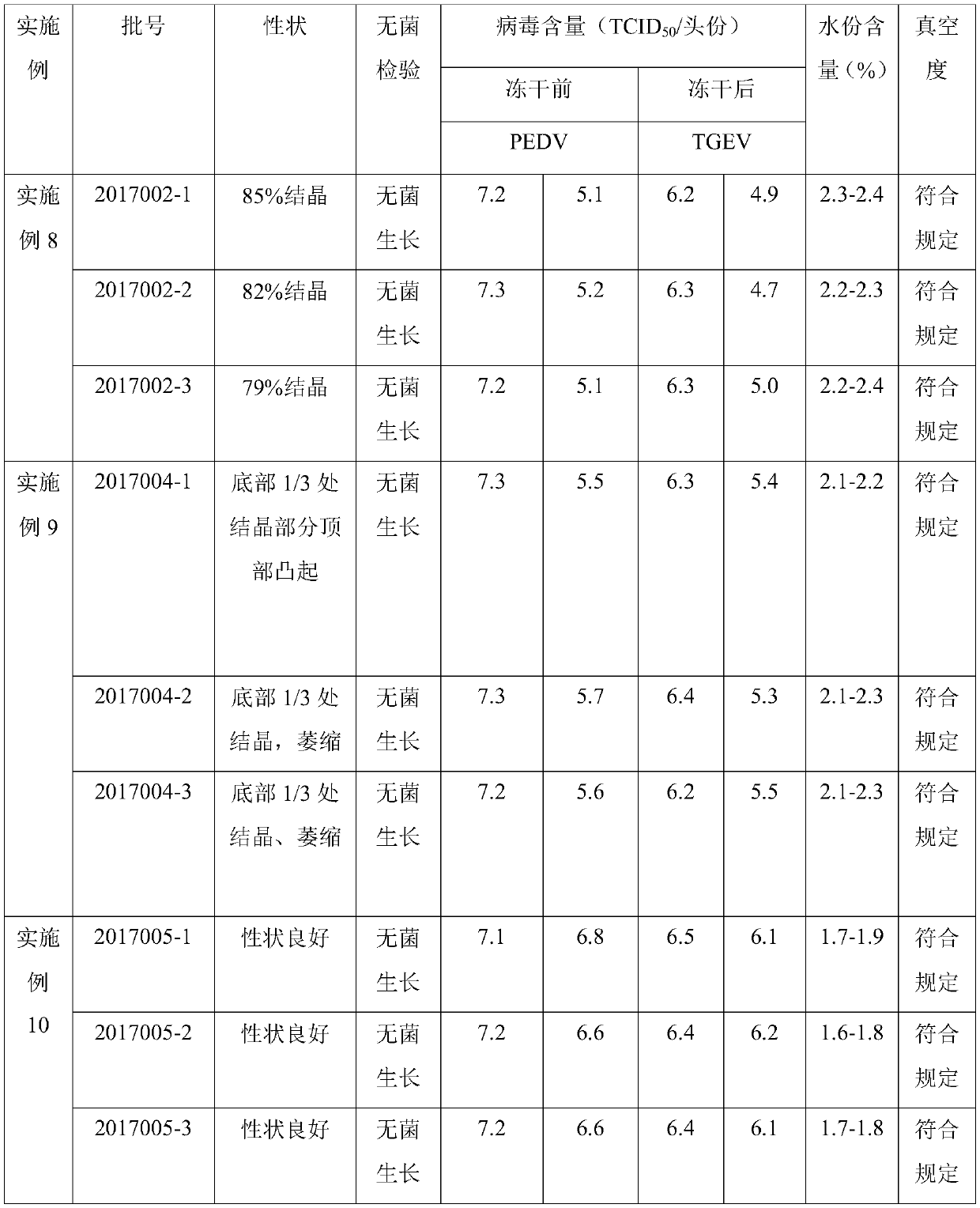

Heatproof lyoprotectant for live vaccine against pseudorabies and preparation method thereof, and lyophilized vaccine and preparation method thereof

ActiveCN107281481AFunction increaseImprove protectionViral antigen ingredientsAntiviralsMonosodium glutamateSucrose

The invention provides a heatproof lyoprotectant for a live vaccine against pseudorabies. The heatproof lyoprotectant comprises, by weight, 3 to 10 parts of gelatin, 1 to 5 parts of trehalose, 5 to 15 parts of sucrose, 0.1 to 2 parts bovine serum albumin, 1 to 8 parts of tryptone, 2 to 10 parts of enzyme-hydrolyzed casein, 1 to 5 parts of thiourea, 0.8 to 2 parts of L-monosodium glutamate, 0.1 to 3 parts of arginine, 0.5 to 5 parts of polyvinylpyrrolidone (PVP-K30) and 0.1 to 2 parts of mannitol. The invention also discloses a preparation method of the heatproof lyoprotectant and a lyophilized vaccine prepared from the heatproof lyoprotectant. When the heatproof lyoprotectant is used for protecting the vaccine and a specific lyophilization process is employed, lyophilization loss of viruses can be effectively reduced, the temperature tolerance of the viruses can be improved, and the vaccine can still maintain good physical properties and titer after long-term storage; i.e., the vaccine has stable characters and has the characteristics of heat resistance and long storage time.

Owner:SICHUAN HUAPAI BIO PHARMA

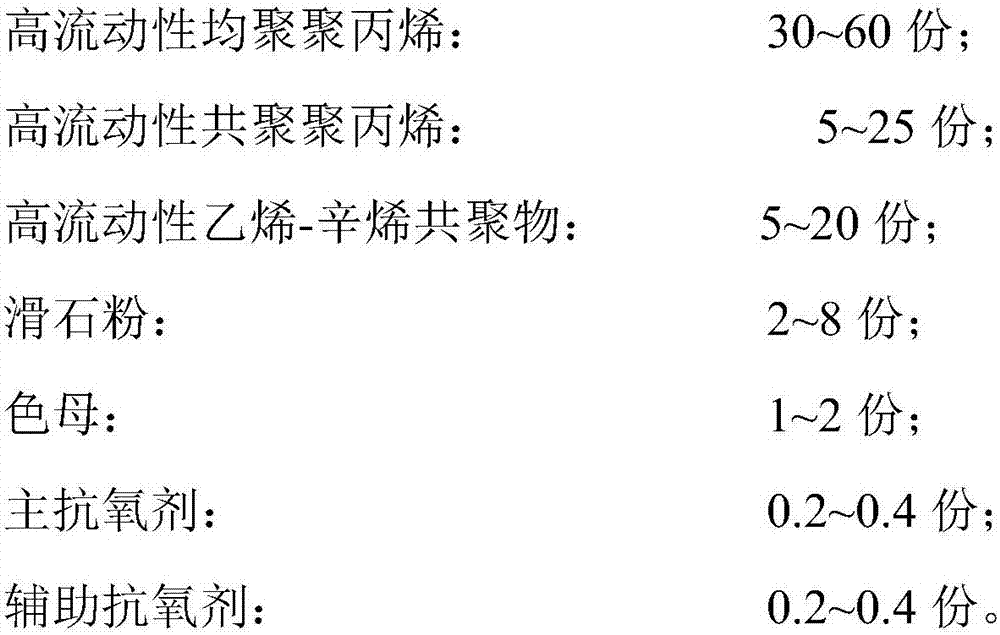

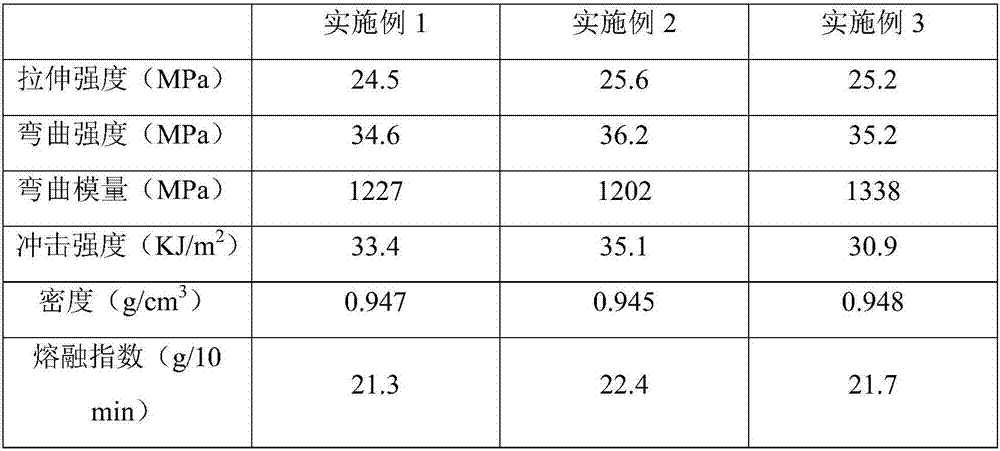

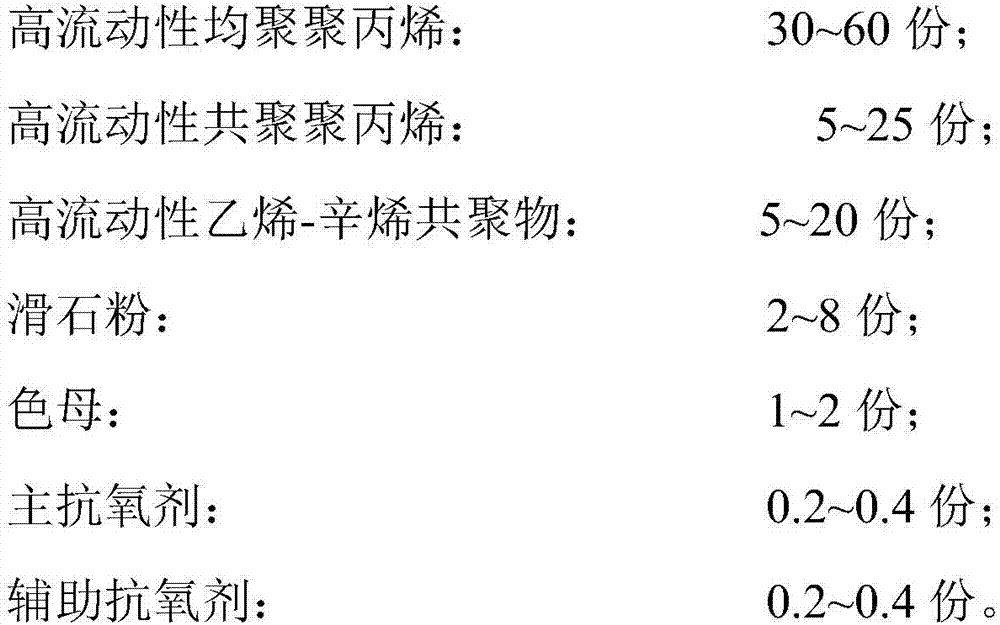

Low-density high-fluidity high-rigidity talcum powder filled polypropylene material

The invention provides a low-density high-fluidity high-rigidity talcum powder filled polypropylene material which is prepared from the following components in parts by weight: 30-60 parts of high-fluidity homo-polypropylene, 5-25 parts of high-fluidity co-polypropylene, 5-20 parts of a high-fluidity ethylene-octylene copolymer, 2-8 parts of talcum powder, 1-2 parts of a color master batch, 0.2-0.4 part of a main antioxidant and 0.2-0.4 part of an auxiliary antioxidant. According to the low-density high-fluidity high-rigidity talcum powder filled polypropylene material disclosed by the invention, the material maintains high rigidity under the condition that the filling amount of the talcum powder is small. The parts prepared by using the material can be kept at good functionality.

Owner:TIANJIN KINGFA NEW MATERIAL

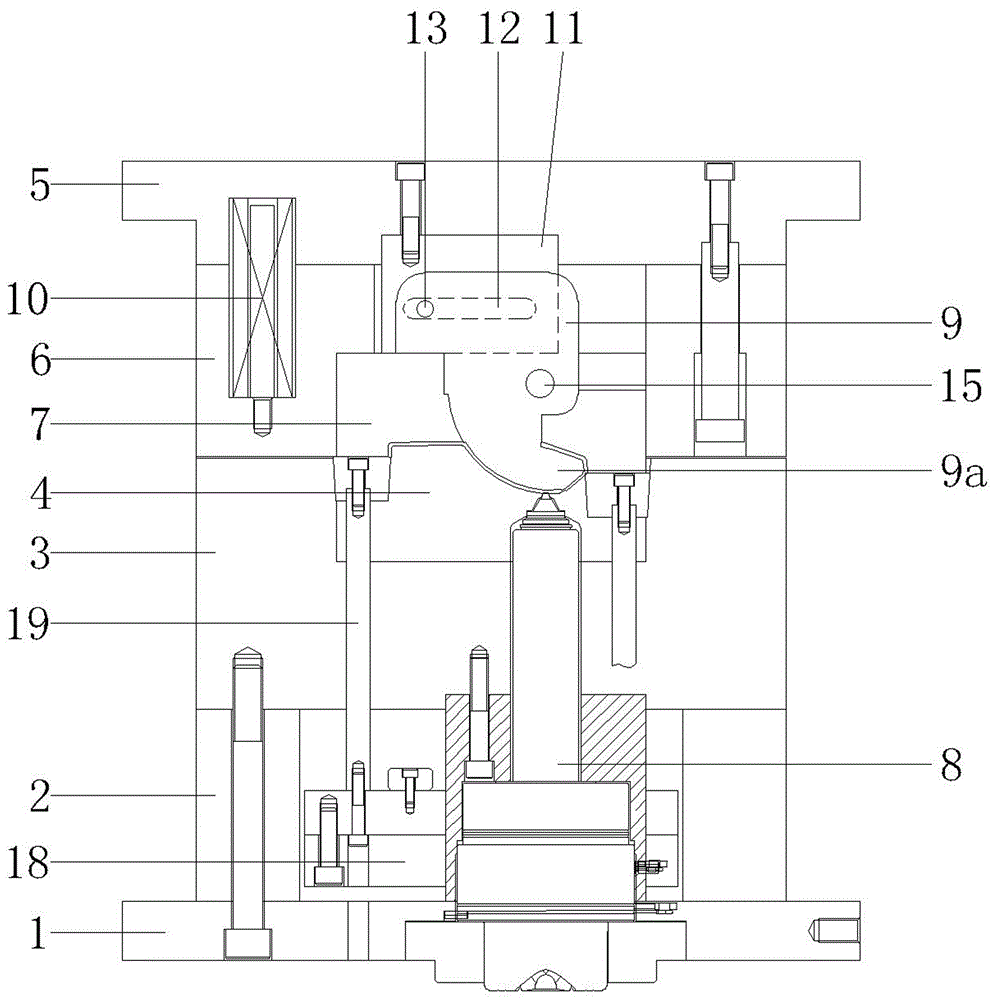

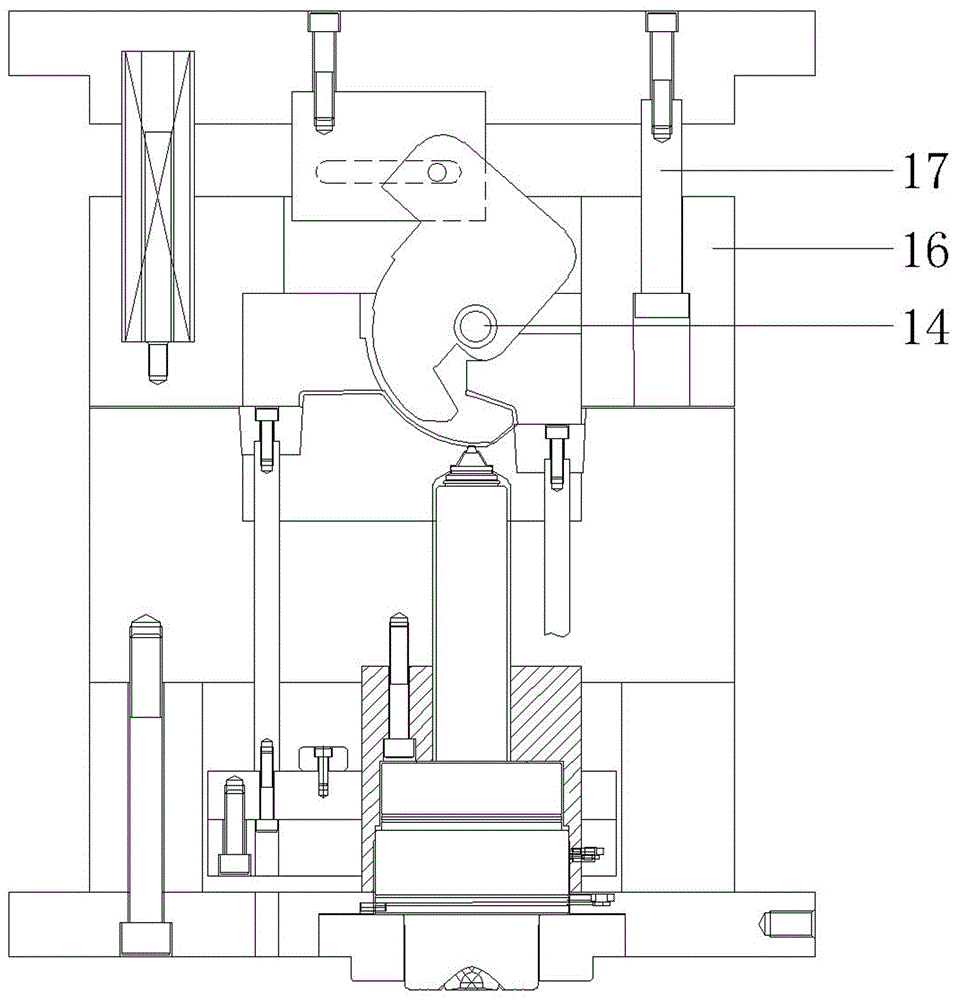

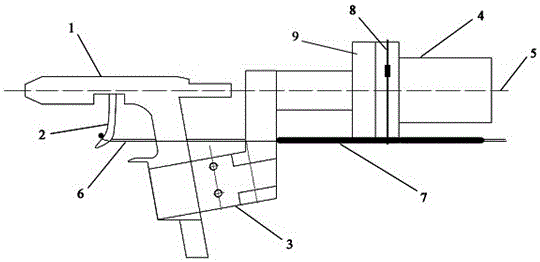

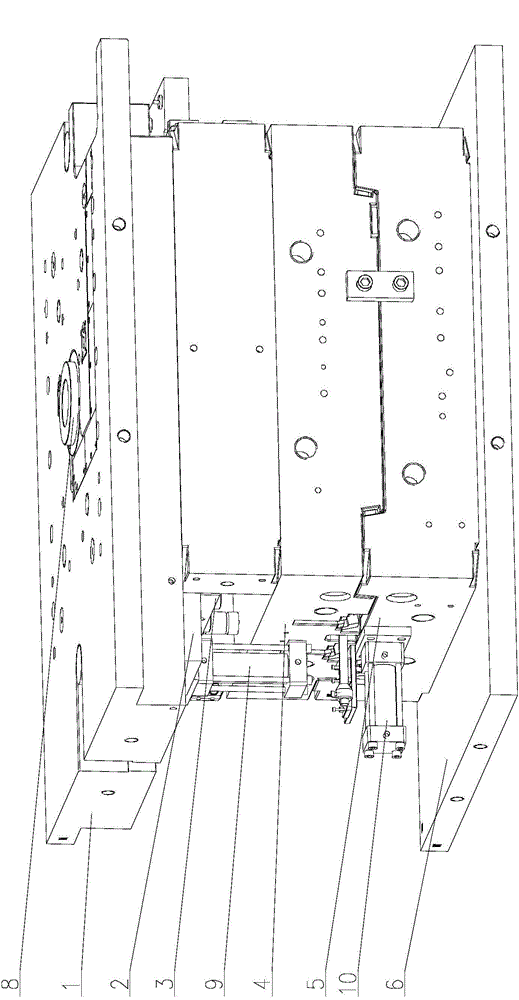

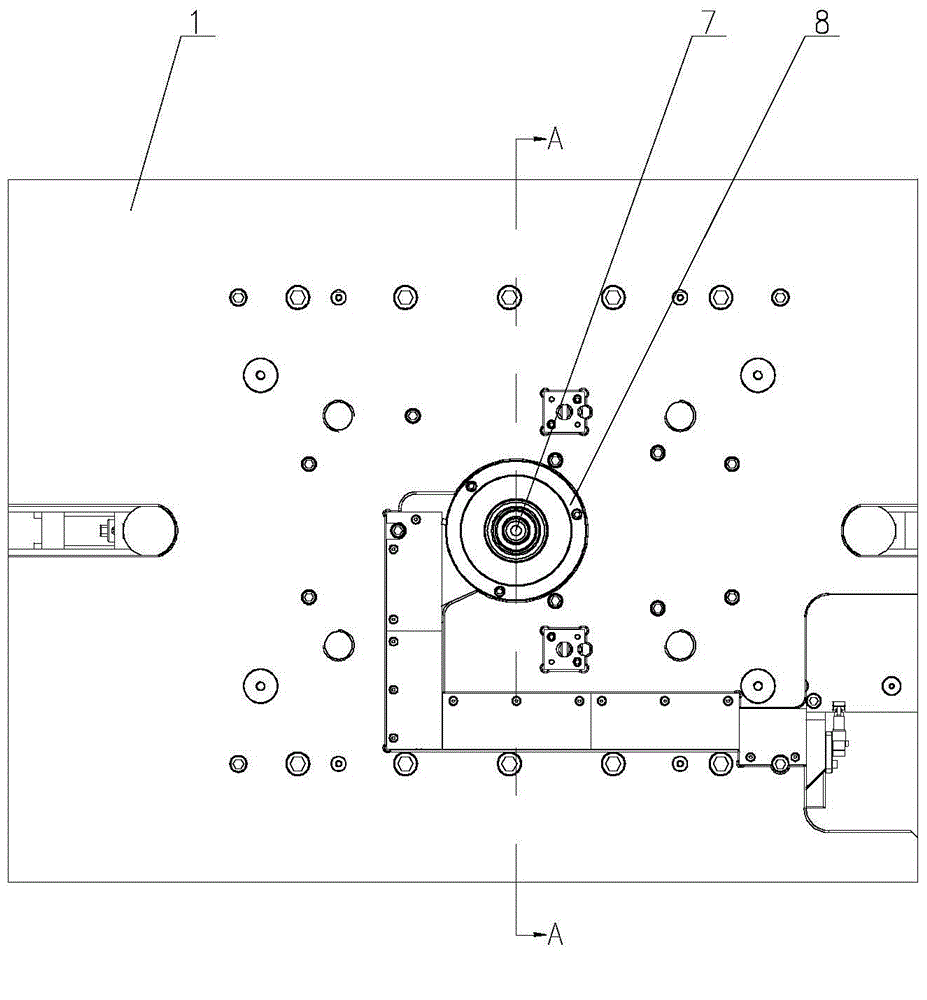

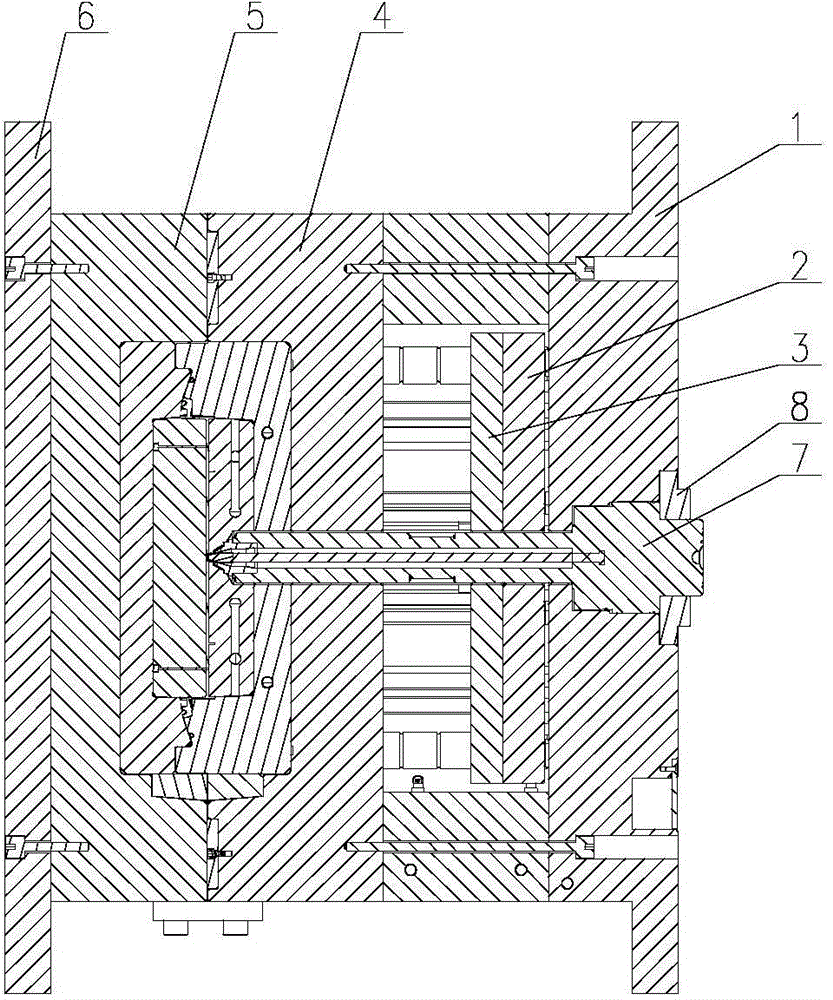

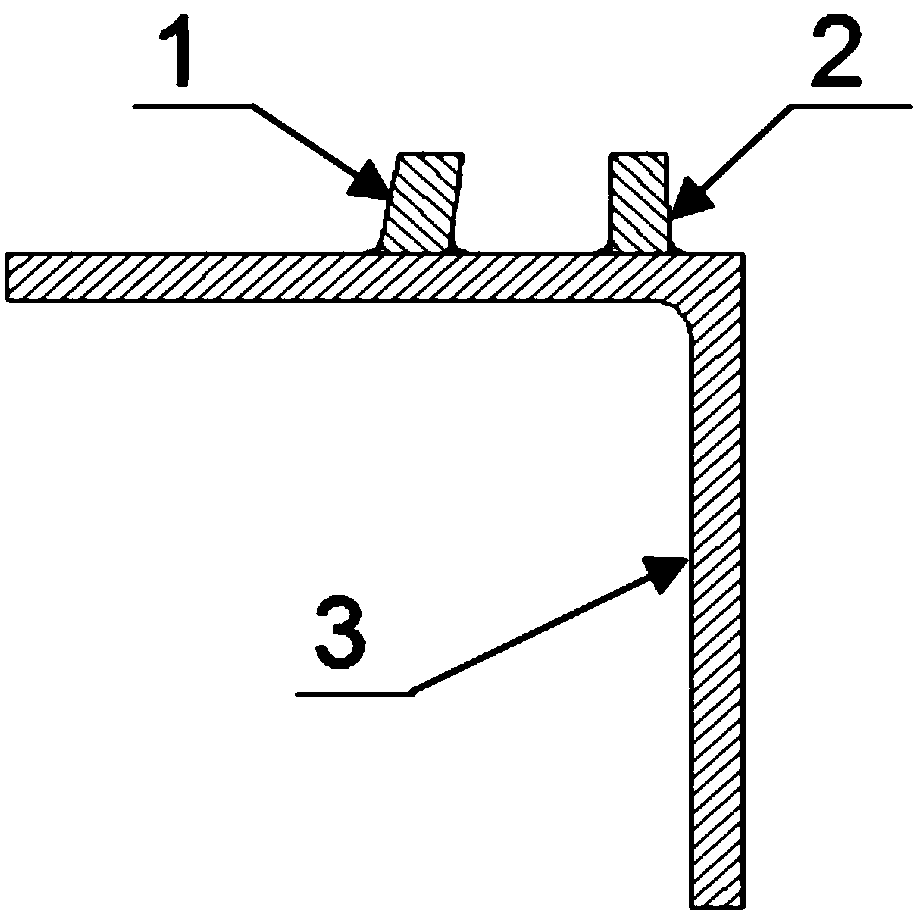

Rotational core pulling mechanism for injection mould

The invention provides a rotational core pulling mechanism for an injection mould, belongs to the technical field of moulds, and aims at solving the problems of long production period and poor positioning reliability of the existing die injection adopting the rotational core pulling mechanism. The mechanism comprises a rotational core pulling block which is hinged with a movable mould embedding block, wherein a forming part for forming an inwards-concaved inverted buckle of a plastic part is arranged at the lower part of the rotational core pulling part; a driving structure is arranged between a movable mould seat board and the rotational core pulling block and is used for driving the rotational core pulling block to rotate around a point where the rotational core pulling block is hinged with the movable mould embedding block during mould opening; a spring is arranged between the movable mould seat board and a movable mould board and is used for enabling the movable mould board to cling to a fixed mould board all the time within a specified mould opening range; a pulling structure is arranged between the movable mould seat board and the movable mould and is used for pulling the movable mould board to separate from the fixed mould board when the mould opening distance is beyond the specified distance. The mechanism has the advantages that the mould injection production cycle can be effectively reduced, and persistent reliable positioning can be achieved.

Owner:ZHEJIANG TAIZHOU MEIDUO MOLD CO LTD

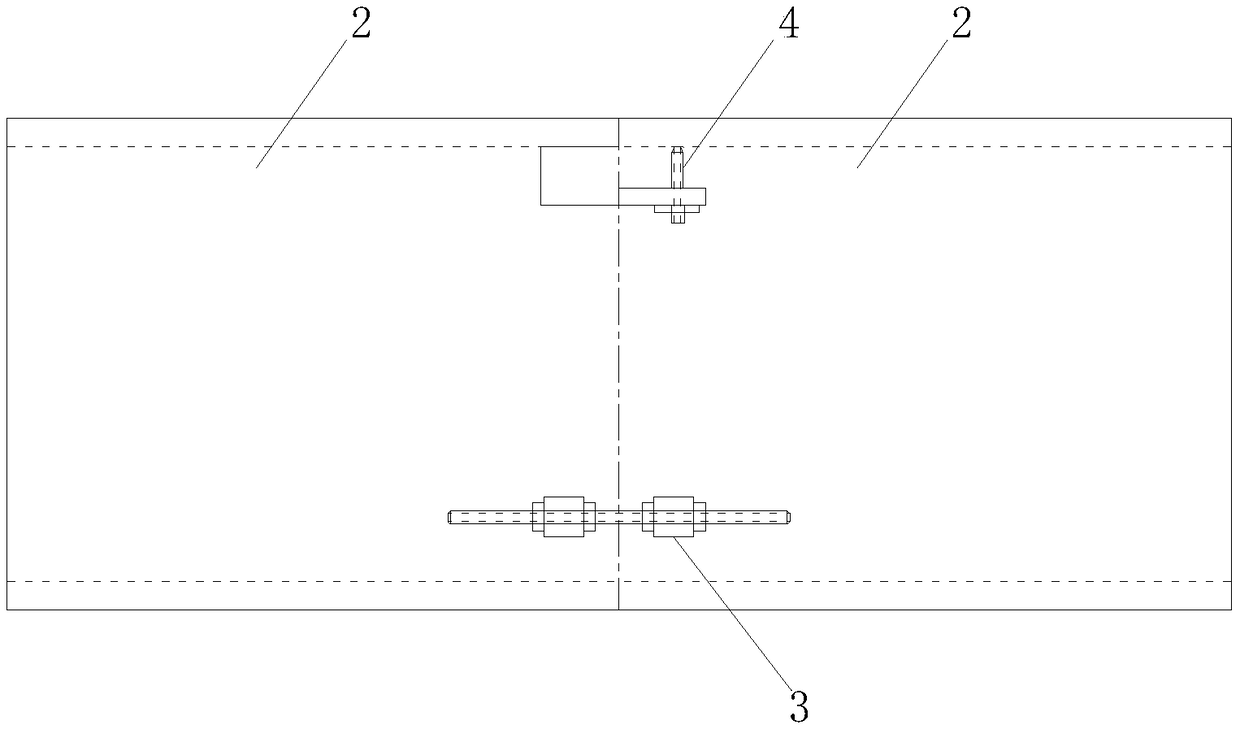

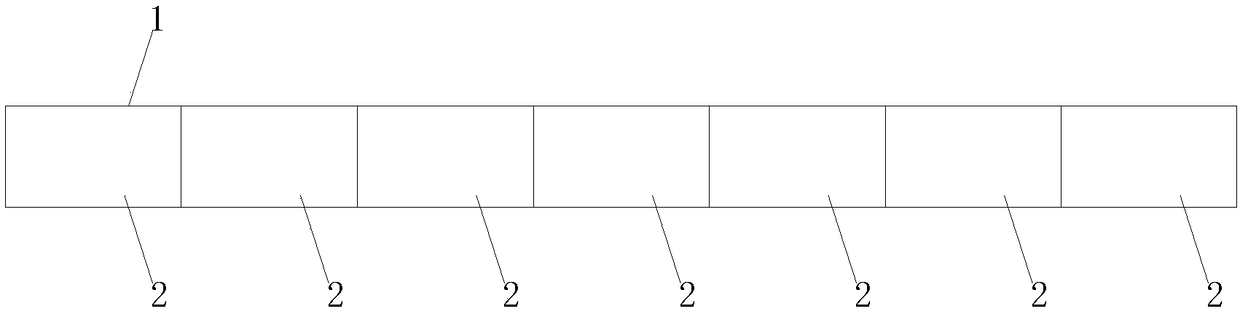

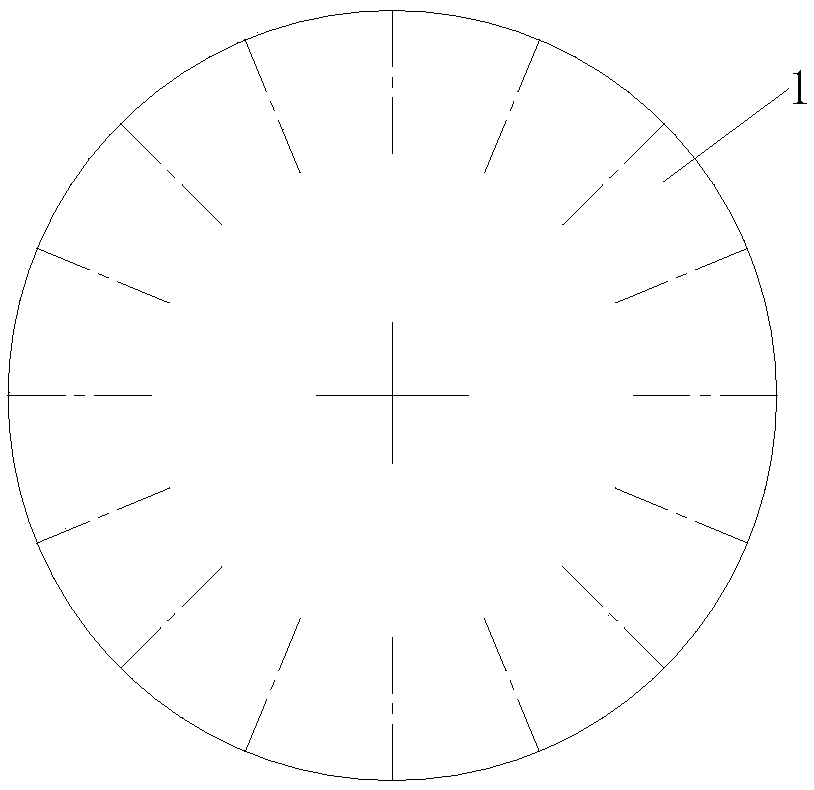

Rotary kiln body pair-combining splicing-assembly alignment device and construction method

InactiveCN109317847AHolisticNo appearance defectsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWeld line

The invention discloses a rotary kiln body pair-combining splicing-assembly alignment device and a construction method and belongs to the technical field of rotary kiln installation. The rotary kiln body pair-combining splicing-assembly alignment device comprises a barrel body, the barrel body is composed of seven barrel sections, the inner surface of each barrel section is provided with a lengthways adjusting device and a radial adjusting device correspondingly, each lengthways adjusting device is composed of a fixed support seat, an inner side nut, a fixed screw rod and an outer side nut, and each radial adjusting device is composed of an L-shaped fixed block, a radial adjusting nut and a radial adjusting bolt. By means of the rotary kiln body pair-combining splicing-assembly alignment device and the construction method, the barrel body is divided into parts and performed ground splicing-assembly, lifting in the air is performed after the barrel body is formed into segments by splicing-assembly, the work efficiency is effectively improved, the construction cost is lowered, when the welding line separation distance of the adjacent barrel sections is larger or smaller, adjustment can both be performed through the lengthways adjusting devices, sunken positions can further be jacked up utilizing the radial adjusting bolts, and the fact that the barrel body has integrity and no appearance defects after construction is finished is guaranteed.

Owner:CHINA MCC17 GRP

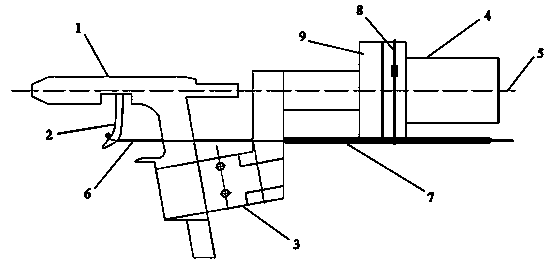

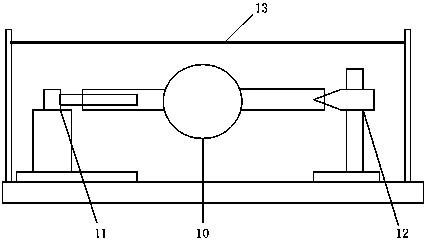

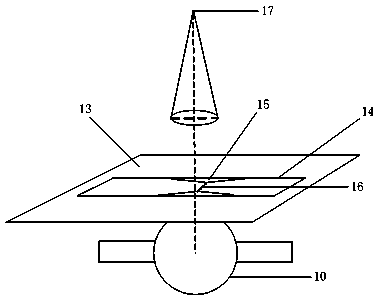

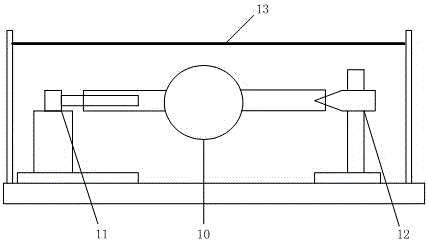

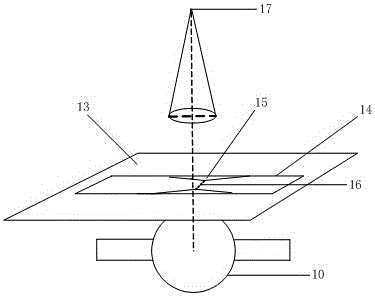

Spray method for carbon-doped coating on spherical surface

ActiveCN104384087AUniform colorNo appearance defectsSpraying apparatusPretreated surfacesSurface roughnessCarbon doped

The invention provides a spray method for a carbon-doped coating on a spherical surface. The spray method comprises the following steps of clamping a manual spray gun in a robot arm; clamping a spherical workpiece in a spray device; proportioning a coating; spraying by using a robot; performing curing treatment. According to the spray method for the carbon-doped coating on the spherical surface, the appearance quality and the thickness uniformity of the coating on the spherical surface are improved, the surface roughness Sa is smaller than 1.6mu m, and the thickness uniformity reaches + / -5mu m.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Reduced glutathione for injection and pre-freezing method thereof

InactiveCN105434368AGood resolubilityEliminate Product Safety RisksPowder deliveryDigestive systemGlutathione-SHFreeze dry

The invention relates to a reduced glutathione for injection and a pre-freezing method thereof. The pre-freezing method includes the following steps that S1, a glutathione solution is prepared and filled; S2, the partition plate temperature of a freeze-drying machine is reduced to be -25 to -35 DEG C; S3, the filled glutathione solution in the step S1 is put on a partition plate of the freeze-drying machine after the step S2 is completed, constant temperature is kept for 2 to 6 hours after the temperature of a product is reduced to be -25 to -35 DEG C, and a reduced glutathione frozen body is obtained, wherein a vacuum pump is started within 0.5 to 1 hour before constant temperature completion in the step S3 to enable the vacuum degree to be smaller than 10 Pa. The reduced glutathione used for injection and prepared by means of the pre-freezing method has the advantages of being high in safety, simple in freeze-drying operation, good in resolubility and stable and reliable in product quality.

Owner:GUANGZHOU BAIYUNSHAN MINGXING PHARM CO LTD

Segmented automobile instrument board and assembly method thereof

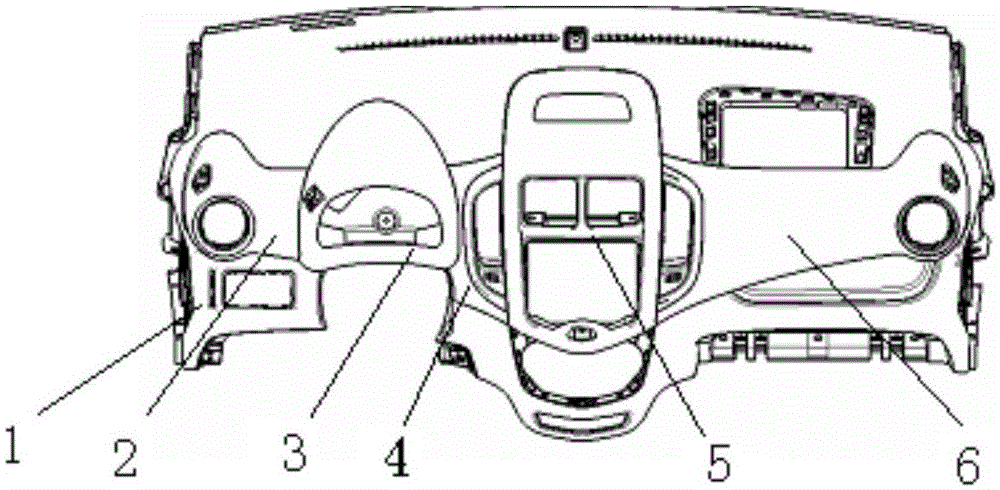

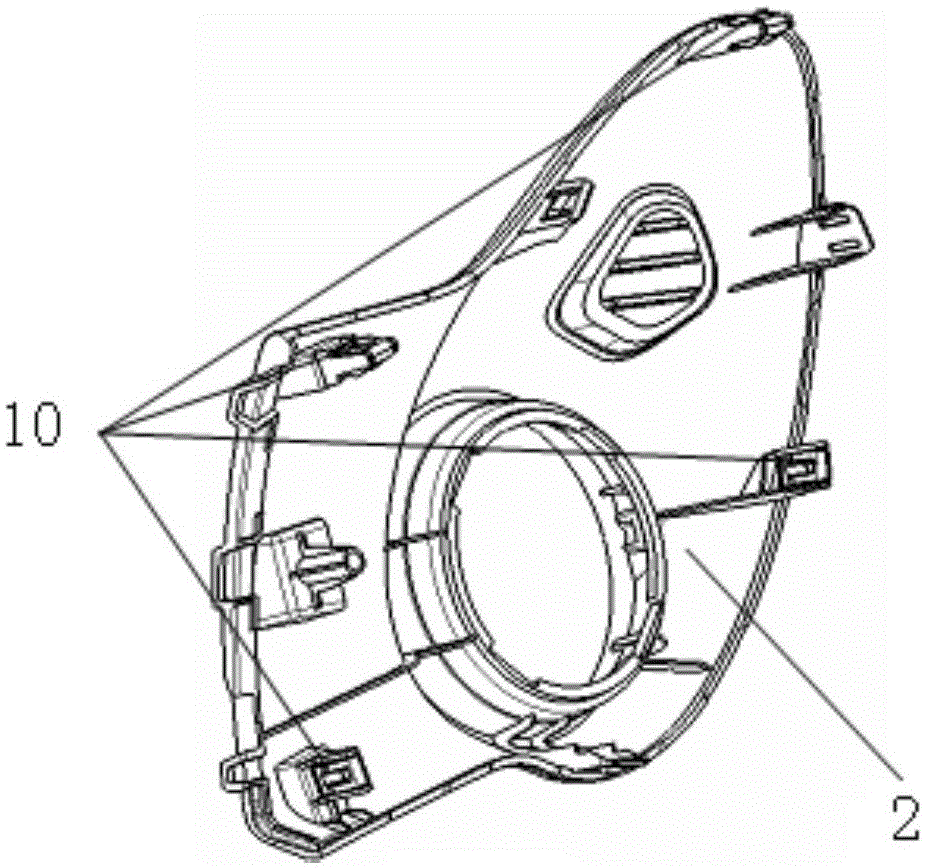

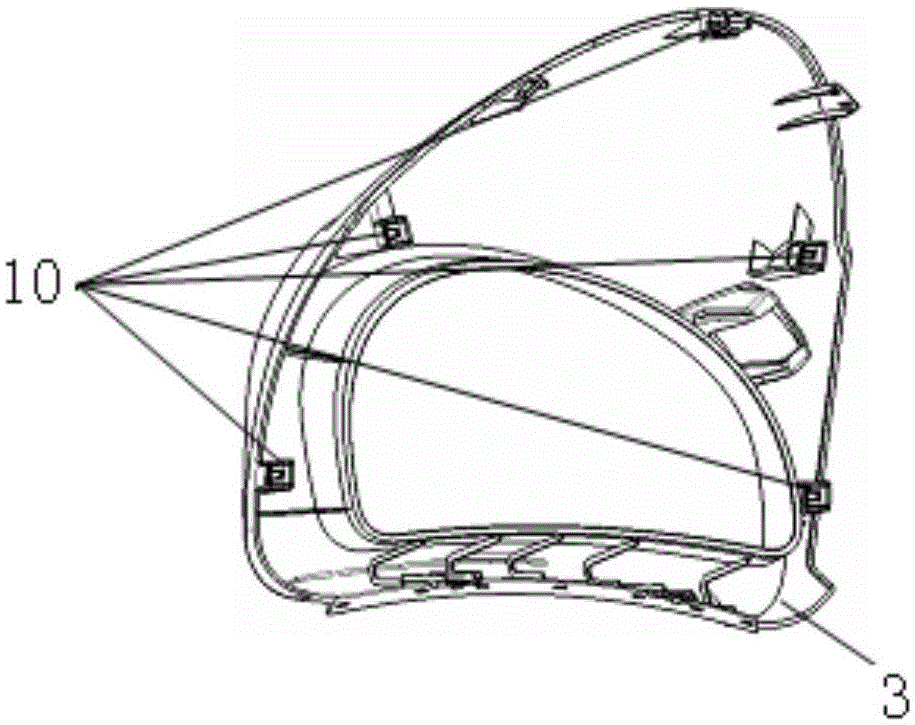

InactiveCN105059120AFlexible in color matchingEasy to assemble and disassembleDashboardsInstrument clusterElectrical and Electronics engineering

The invention discloses a segmented automobile instrument board. The automobile instrument board comprises an instrument board body, a left decorative cover board, a combined instrument hood, a central left decorative cover board, a central control panel and a right decorative panel, wherein the left decorative cover board, the combined instrument hood, the central left decorative cover board, the central control panel and the right decorative panel are sequentially connected to the instrument board body in a clamping manner from left to right; the central left decorative cover board and the right decorative panel are connected with the instrument board body through self-tapping screws. The invention further discloses an assembly method of the segmented automobile instrument board. According to the assembly method disclosed by the invention, a topic appearance surface is cut into a plurality of modules, and then the modules are assembled, so that the instrument board is flexible in color matching, and the instrument board can meet individualized demands of users.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

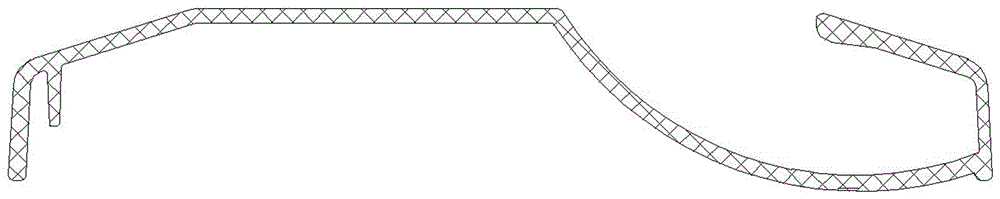

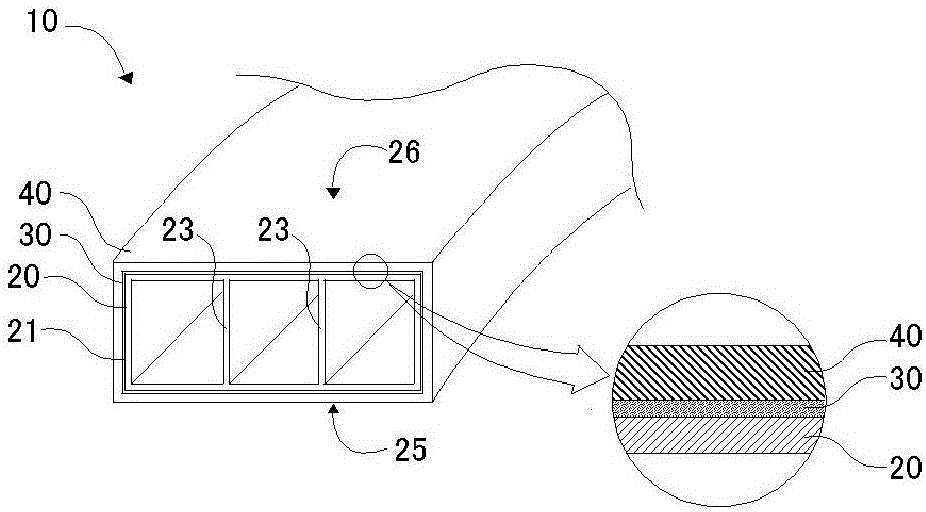

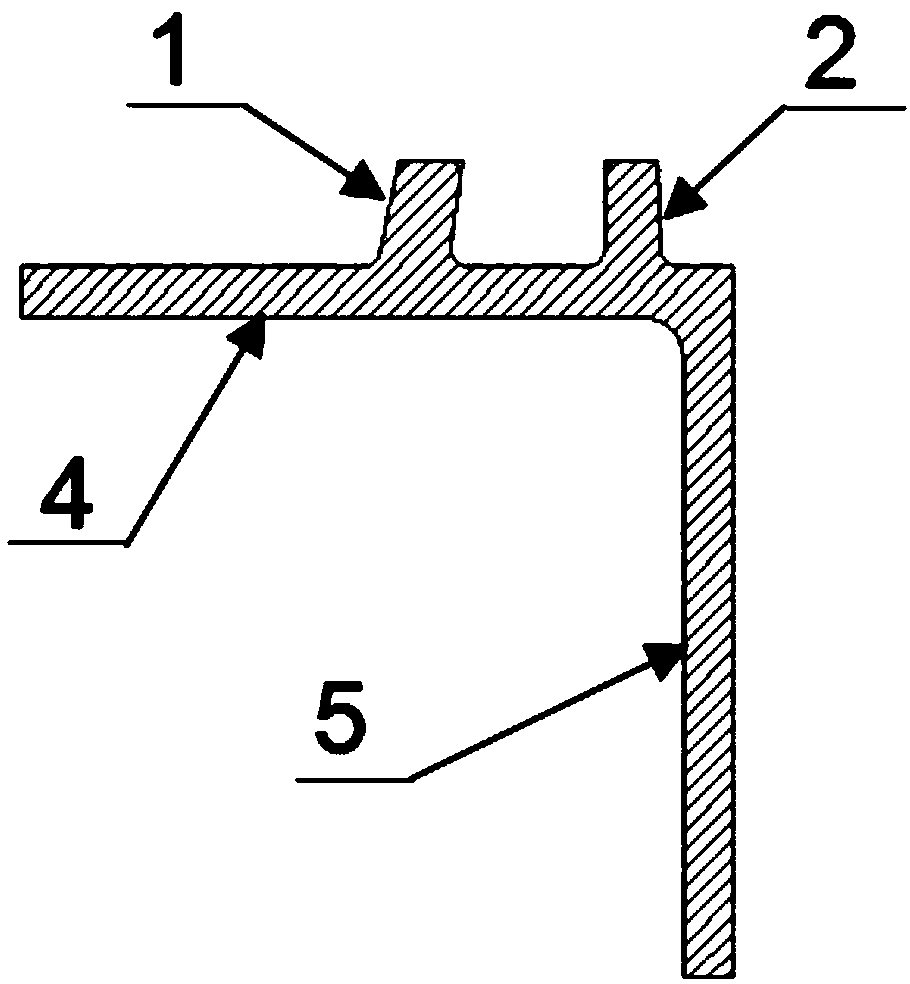

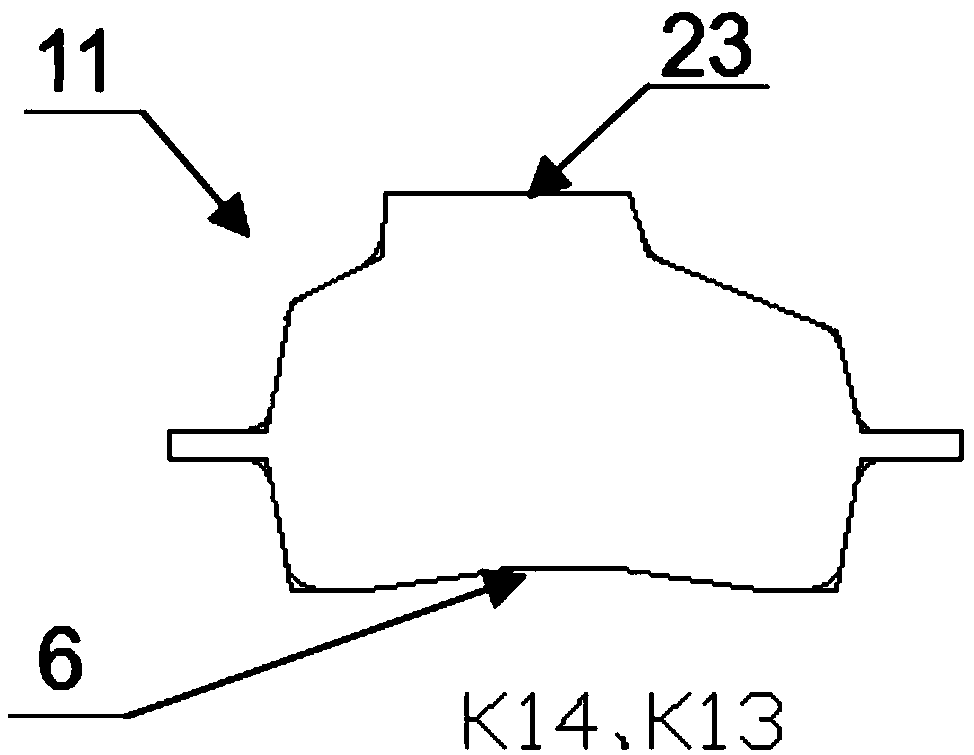

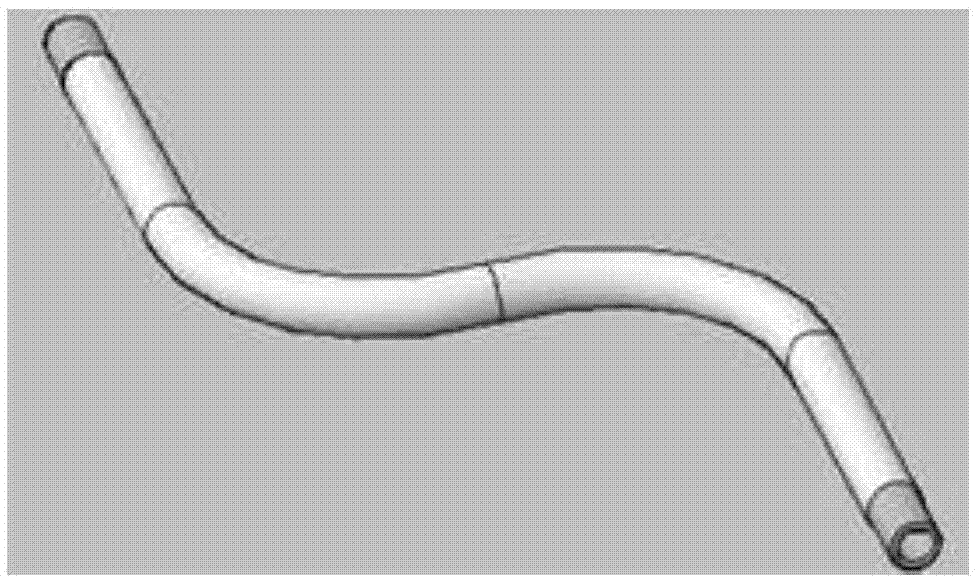

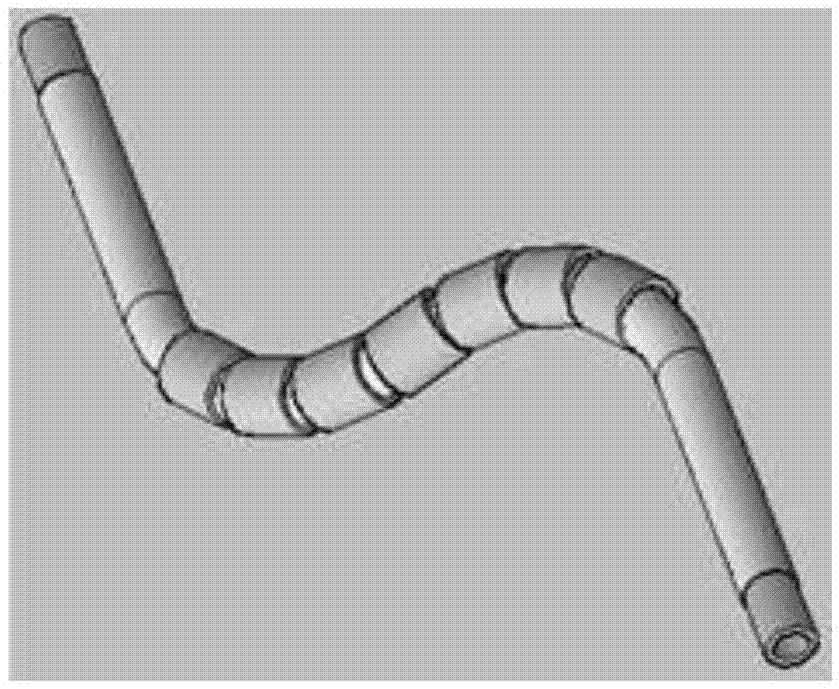

Bent product

ActiveCN106660096ALightweightEasy to processMetal-working apparatusRigid pipesEngineeringMechanical engineering

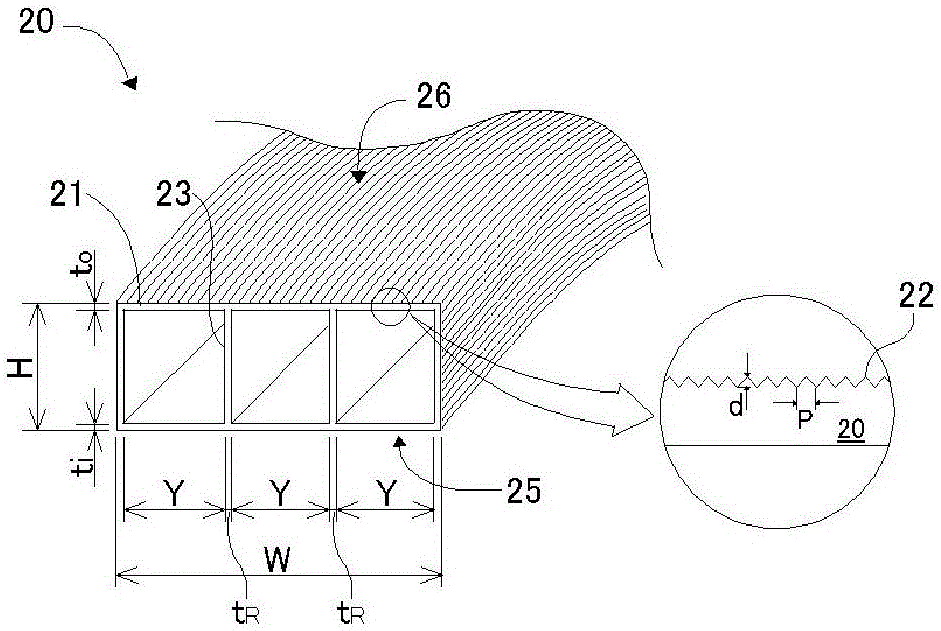

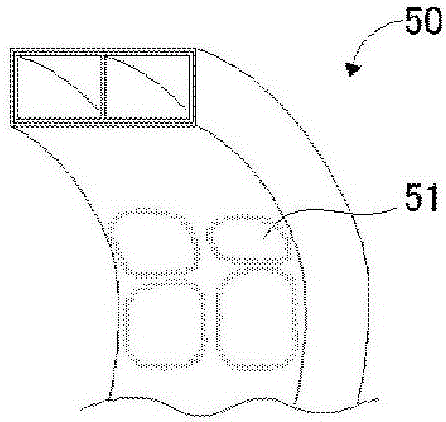

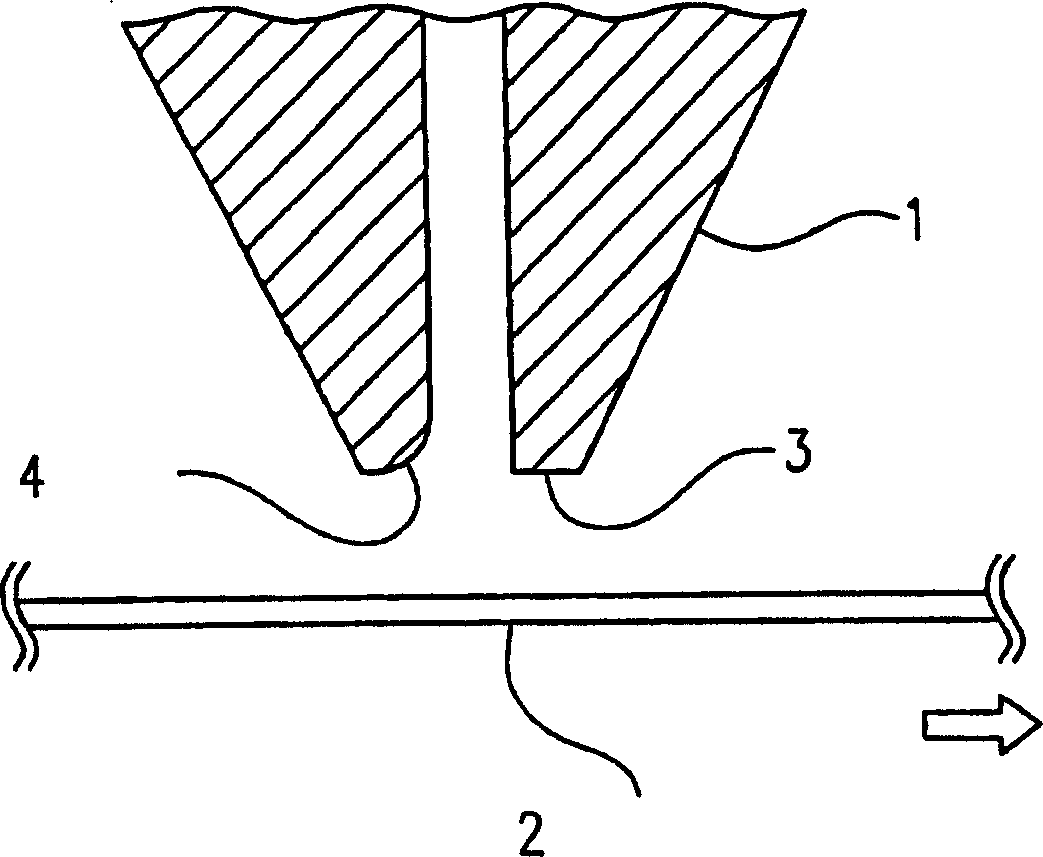

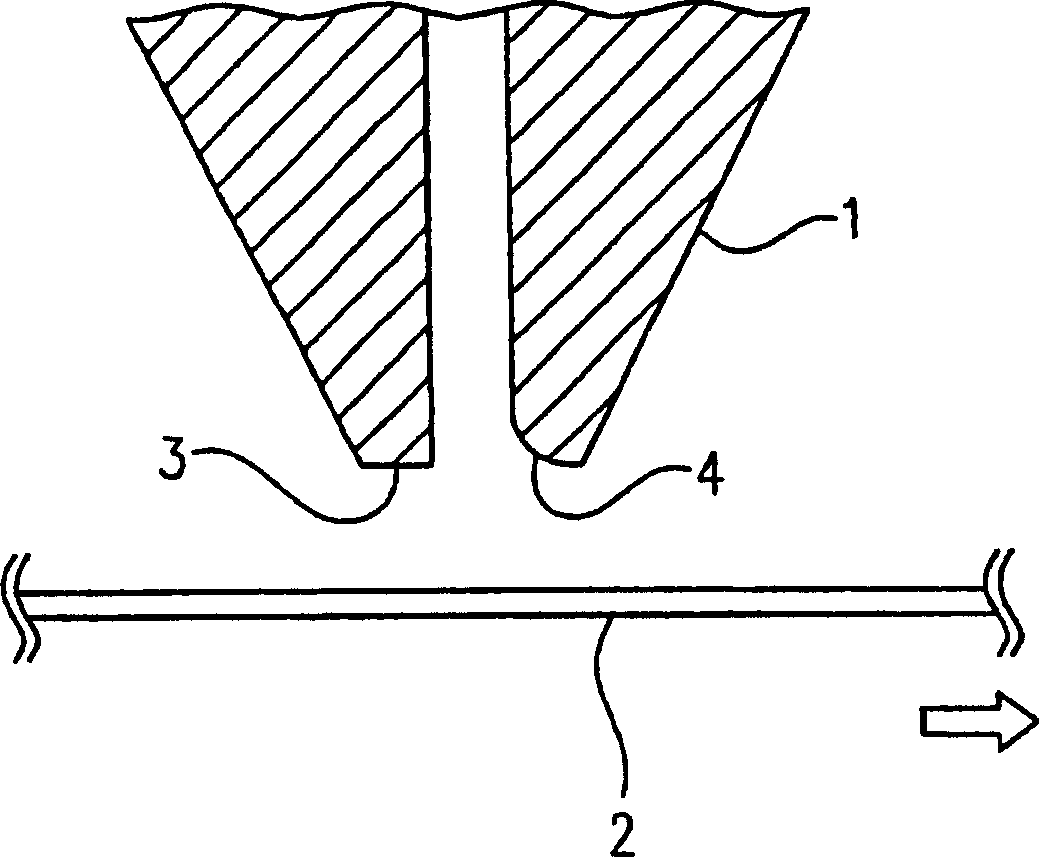

To provide a bent product from an integrally extrusion molded body without the loss of lightweight properties or the like. [Solution] A bent product (10) that is formed by bending an integrally extrusion-formed body and has: a metal core material (20) provided with a tube-shaped peripheral wall (21) and a first partition wall (23) that extends in the longitudinal direction of the tube shape and divides the inner space of the peripheral wall in the direction of the major axis of the cross section perpendicular to the longitudinal direction of the tube shape; and a covering layer (40) that is formed on the outer surface of the core material and contains at least a thermoplastic resin. The thickness (t) of the peripheral wall is 0.8-2.3mm, and a reinforcing means is provided to the inner space side of the peripheral wall at a section (25) thereof to the inside of the bend.

Owner:KURASHIKI BOSEKI KK

Method of manufacturing coating sheet, coating sheet, polarizing plate, optical element and image display device

InactiveCN1909976ANo appearance defectsUniform film thicknessSynthetic resin layered productsPolarising elementsDisplay deviceSolvent

Owner:NITTO DENKO CORP

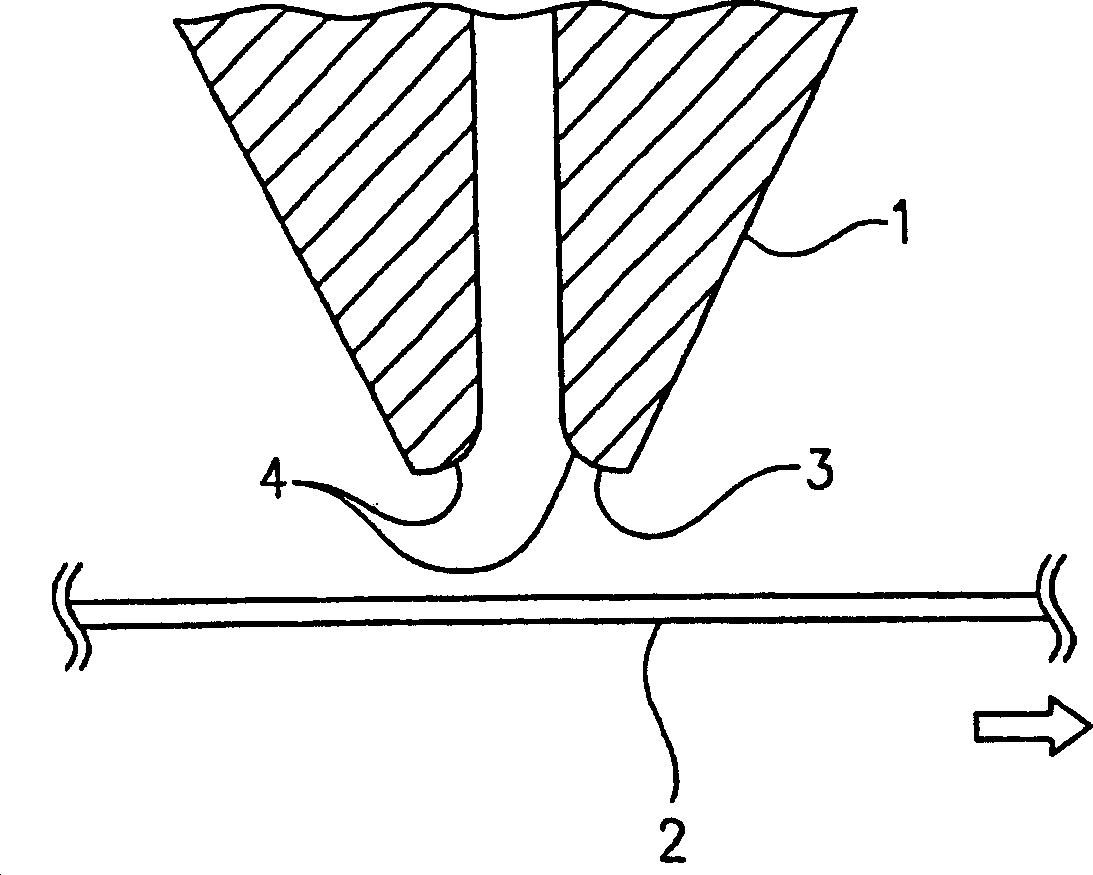

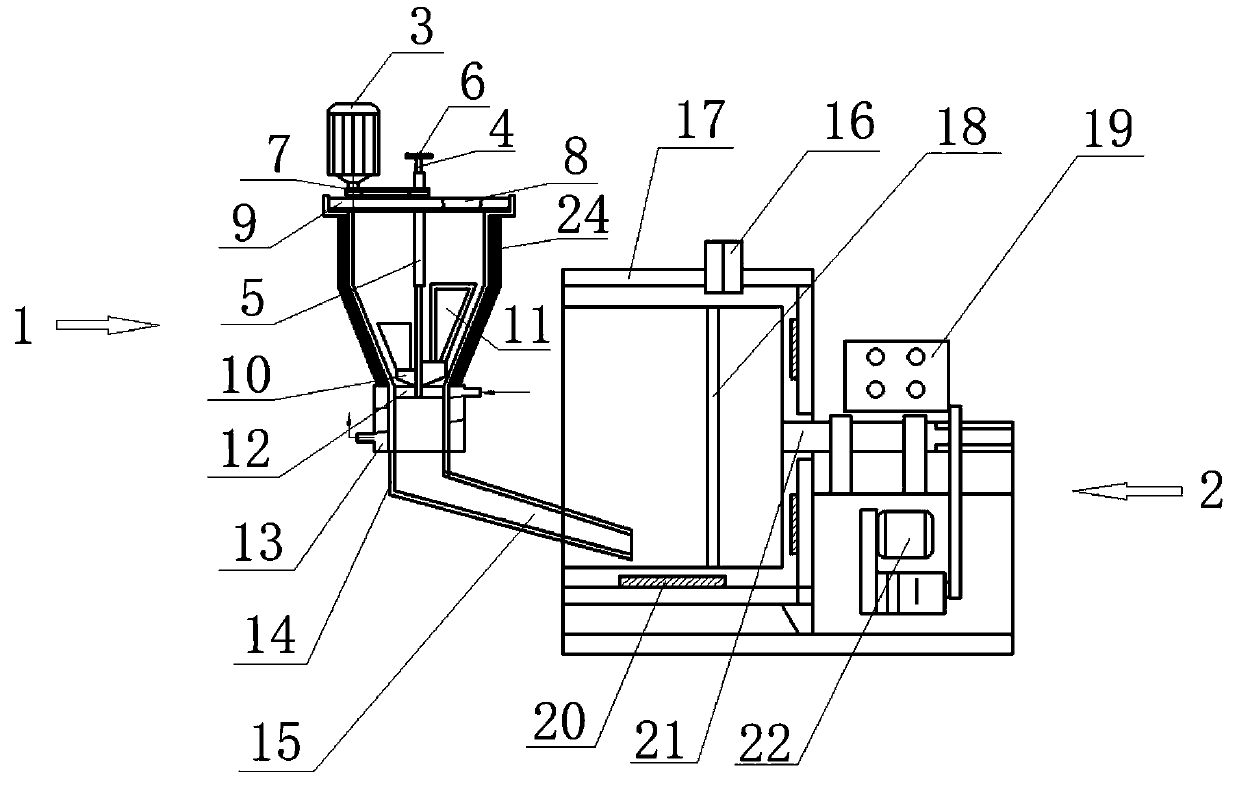

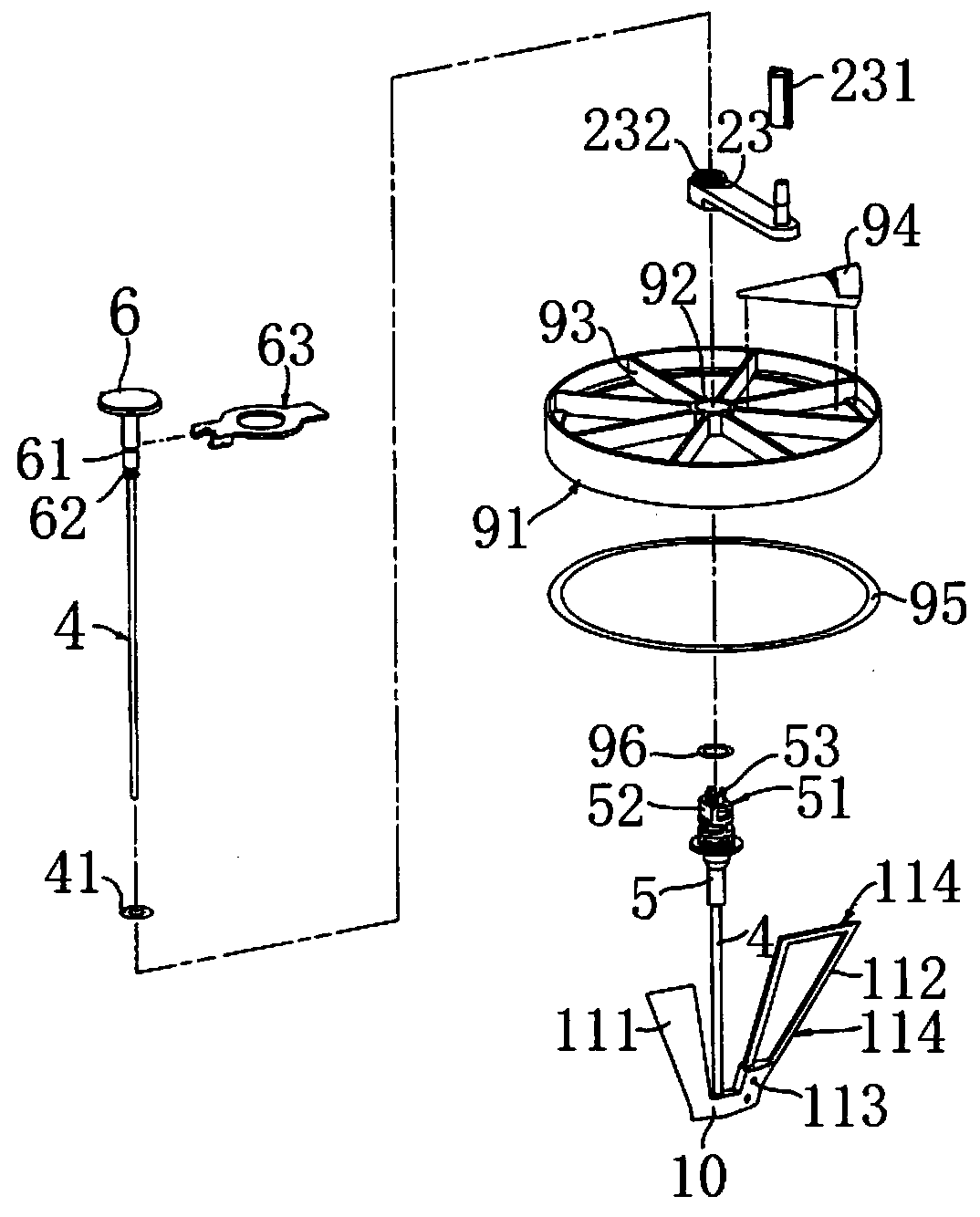

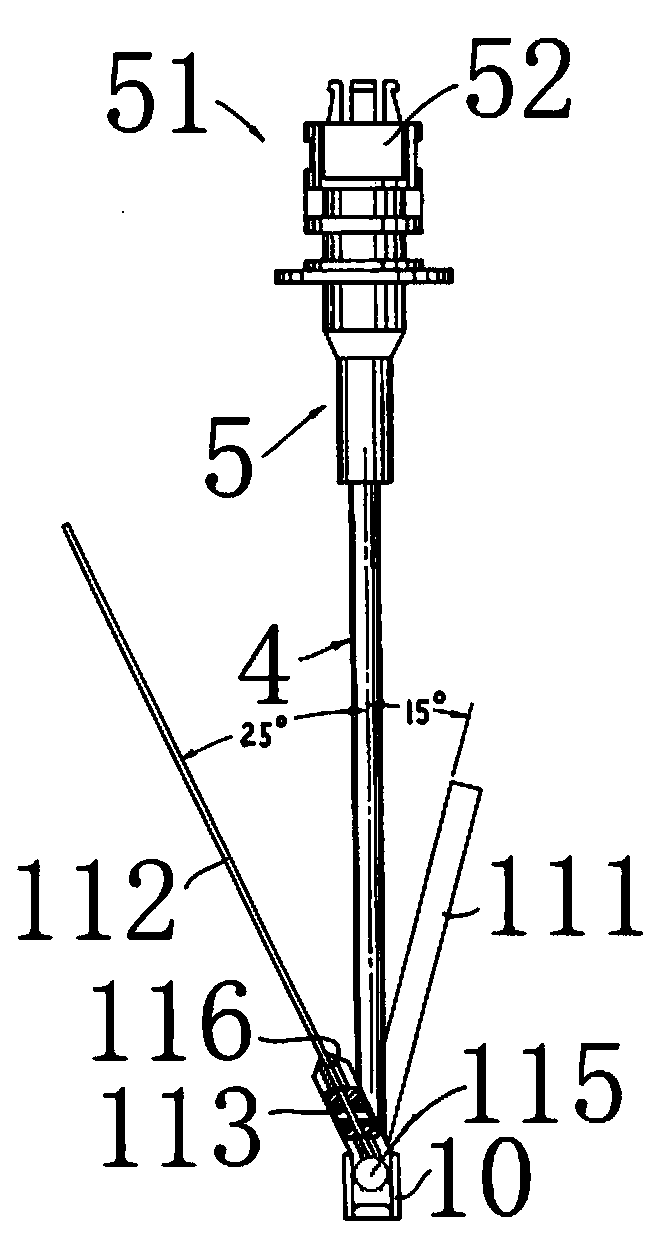

Conveying belt skirt side manufacturing system and method

InactiveCN110978357AReduce volumeImproved erosion and wear resistanceDomestic articlesCoatingsMechanical engineeringManufacturing systems

The invention provides a conveying belt skirt side manufacturing system and method. The system comprises a mixing device and a centrifugal forming device. The end, located on the centrifugal forming device, of the mixing device is vertically located on the upper stream, the mixing device is used for mixing a raw material used for manufacturing a conveying belt skirt side, the centrifugal formingdevice is arranged on the lower stream of the mixing device, and the centrifugal forming device is used for centrifugally forming the mixed raw material into the conveying belt skirt side. The conveying belt skirt side manufacturing system is designed, particularly, through structural design of the mixing device, an end cover assembly is arranged, one-instruction one-moving type mixing of the workmode of the centrifugal forming device can be matched, the size of the mixing device is reduced, through a paddle assembly, a stirring paddle is subjected to structural reasonable design, the mixingefficiency is greatly improved, the economic effect is obvious, and the conveying belt skirt side produced through the method is free of appearance defect, low in cost and quite high in product yield.

Owner:REMA TIPTOP TIANJIN RUBBER TECH

Freezing-drying method for live vaccine

ActiveCN107543373ANo crystalAvoid large ice crystalsDrying solid materials without heatAntiviralsFreeze-dryingVacuum sublimation

The invention discloses a freezing-drying method for live vaccine. The freezing-drying method comprises the steps that the eutectic point range of a to-be-frozen and to-be-dried vaccine is tested, then, the live vaccine is placed in a vacuum freezing-drying machine pre-cooled to 0+ / -1 DEG C, when the temperature of a plate layer of the vacuum freezing-drying machine is reduced to be higher than the eutectic point of the live vaccine by 1-2 DEG C, the current state is kept for 1-2 h, and continuous cooling is conducted with the rate of 1 DEG C / h till all vaccine is frozen; and cooling is immediately conducted to the temperature needed for sublimation, and finally vacuum sublimation is conducted according to the normal procedure. The product obtained through the method is not provided with large ice crystals, sublimation is easy, and after freezing-drying, a good product physical behavior can be obtained, and the freezing-drying titer losses are minimal.

Owner:SICHUAN HUAPAI BIO PHARMA

Composite structural part manufacturing method

The invention provides a composite structural part manufacturing method. The method comprises the following steps of feed preparation, wherein first material powder and second material powder which have different melting points are provided, and the first material powder and the second material powder are uniformly mixed with an adhesive separately to obtain first granular feed and second granularfeed; injection molding, wherein an injection mold is provided, injection molding is conducted by adopting a double feed cylinder injection machine, two feed cylinders are filled with the first granular feed and the second granular feed respectively, first feed granules are injected till the first feed granules are formed into a first green body, and then second feed granules are injected into the outer surface of the first green body till the second feed granules are formed into a second green body; degreasing, wherein the adhesive in the first green body and the adhesive in the second greenbody are removed; sintering, wherein the first green body and the second green body form a structural part which is compact in structure; the grain size of powder low in melting point in the first material powder and the second material powder is larger than that of the powder high in melting point.

Owner:宿迁启祥电子科技有限公司

A heat-resistant freeze-drying protectant for pseudorabies live vaccine, preparation method, freeze-dried vaccine and preparation method

ActiveCN107281481BAccelerated sublimationAvoid sublimationViral antigen ingredientsAntiviralsMonosodium glutamateSucrose

The invention provides a heatproof lyoprotectant for a live vaccine against pseudorabies. The heatproof lyoprotectant comprises, by weight, 3 to 10 parts of gelatin, 1 to 5 parts of trehalose, 5 to 15 parts of sucrose, 0.1 to 2 parts bovine serum albumin, 1 to 8 parts of tryptone, 2 to 10 parts of enzyme-hydrolyzed casein, 1 to 5 parts of thiourea, 0.8 to 2 parts of L-monosodium glutamate, 0.1 to 3 parts of arginine, 0.5 to 5 parts of polyvinylpyrrolidone (PVP-K30) and 0.1 to 2 parts of mannitol. The invention also discloses a preparation method of the heatproof lyoprotectant and a lyophilized vaccine prepared from the heatproof lyoprotectant. When the heatproof lyoprotectant is used for protecting the vaccine and a specific lyophilization process is employed, lyophilization loss of viruses can be effectively reduced, the temperature tolerance of the viruses can be improved, and the vaccine can still maintain good physical properties and titer after long-term storage; i.e., the vaccine has stable characters and has the characteristics of heat resistance and long storage time.

Owner:SICHUAN HUAPAI BIO PHARMA

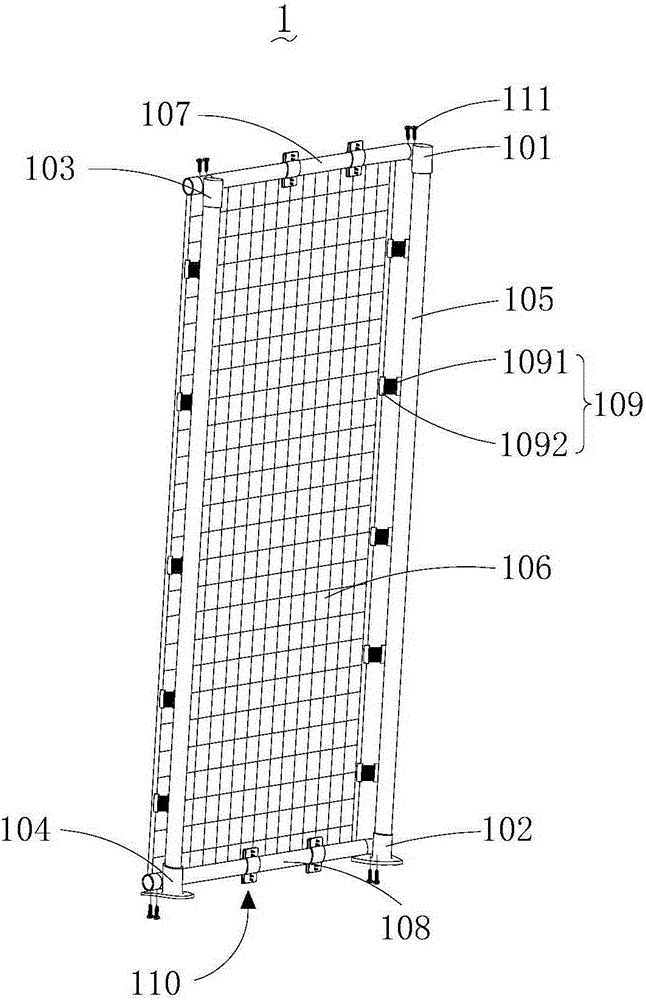

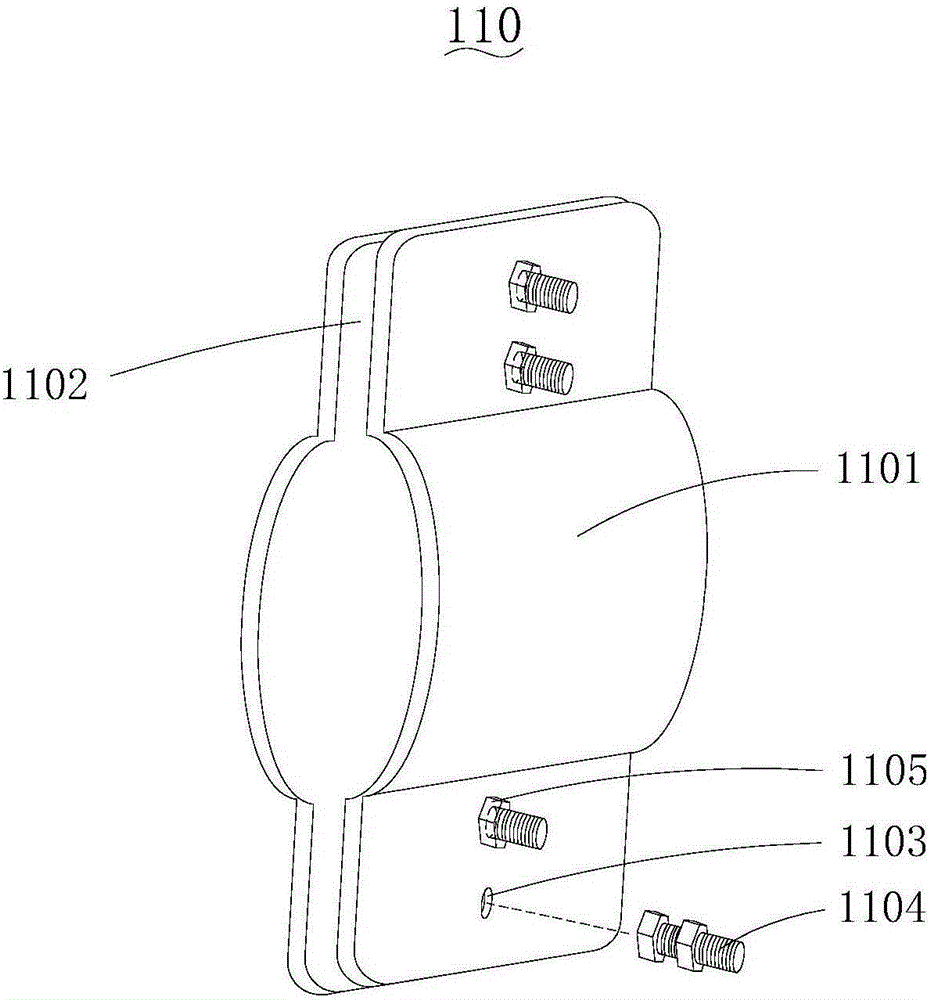

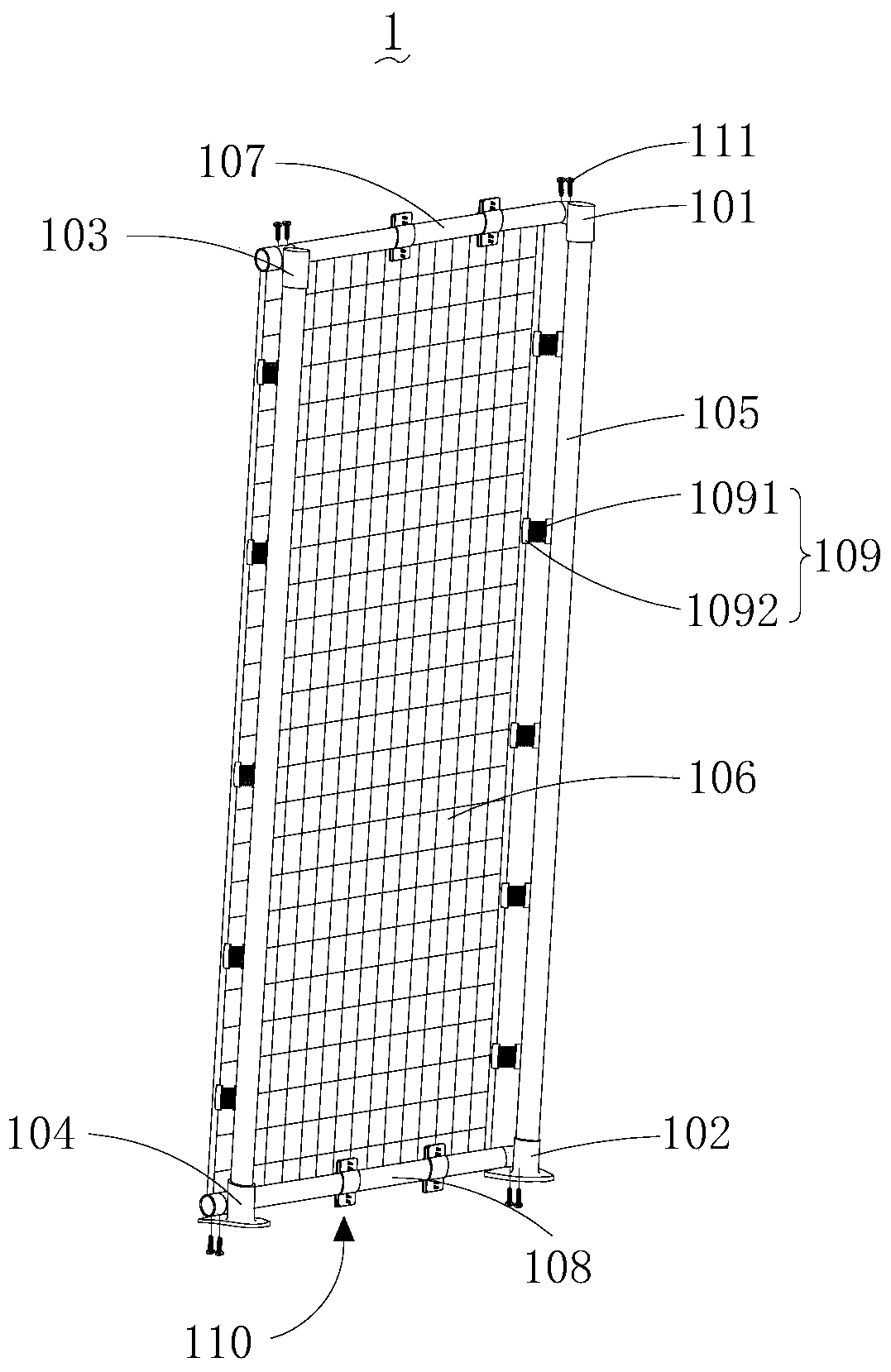

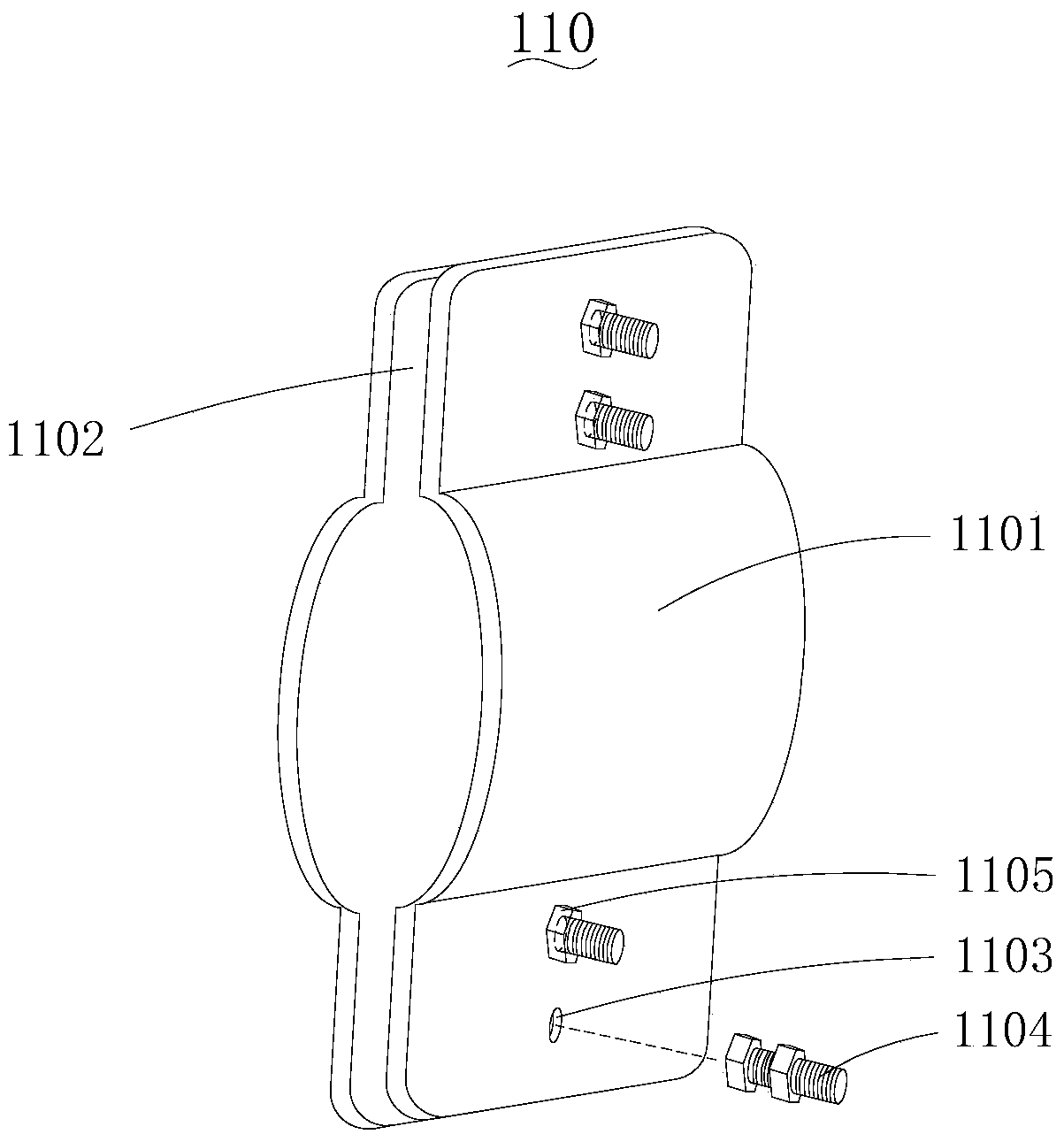

Suspended aluminum alloy cage type football field purse net device

ActiveCN105169683ANo appearance defectsNo welding deformationSki bindingsWater-skiingMaterials scienceHeavy weight

The invention provides a suspended aluminum alloy cage type football field purse net device. The suspended aluminum alloy cage type football field purse net device comprises a connecting corner, a connecting corner base, a connecting through piece, a connecting through base, two columns, a purse net, an upper hanging beam, a lower hanging beam, a plurality of spring seats and a plurality of sliding blocks. The connecting corner and the connecting corner base are arranged at the two ends of one column respectively. The connecting through piece and the connecting through base are arranged at the two ends of the other column respectively. The two ends of the upper hanging beam are connected with the connecting corner and the connecting through piece respectively, and the two ends of the lower hanging beam are connected with the connecting corner base and the connecting through base respectively. The plurality of the spring seats are arranged on the two columns respectively. The plurality of the sliding blocks are arranged on the upper hanging beam and the lower hanging beam respectively. The purse net is connected with the sliding blocks and the spring seats. According to the suspended aluminum alloy cage type football field purse net device, the technical problems that in the prior art, the purse net device is inconvenient to install and dismantle, and the purse net is inconvenient to convey because of the heavy weight are solved.

Owner:HEBEI QIFAN TEACHING EQUIP MFG

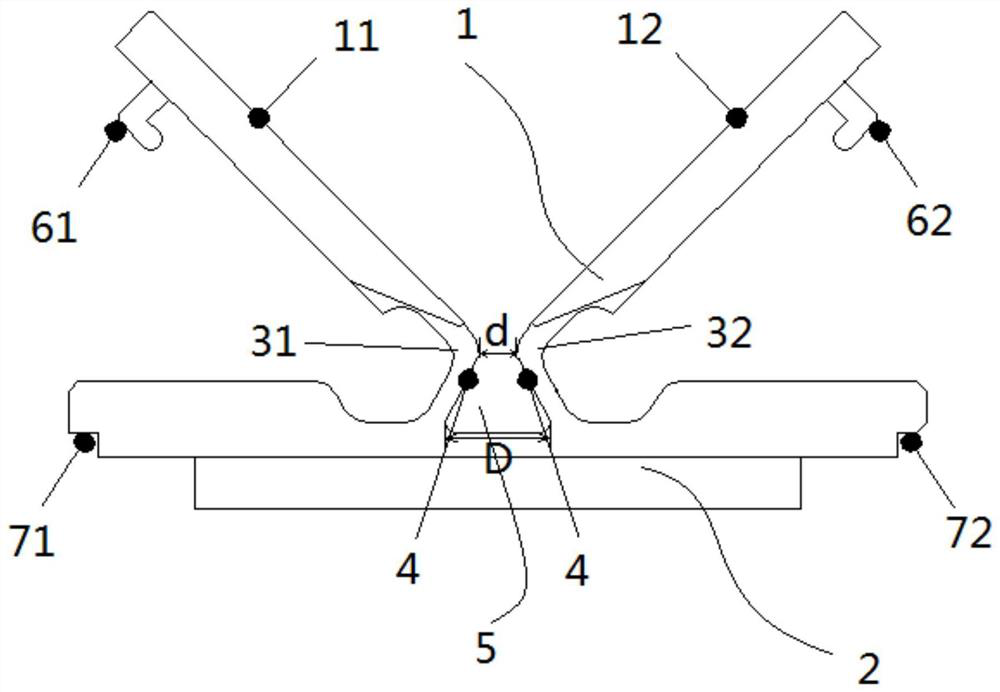

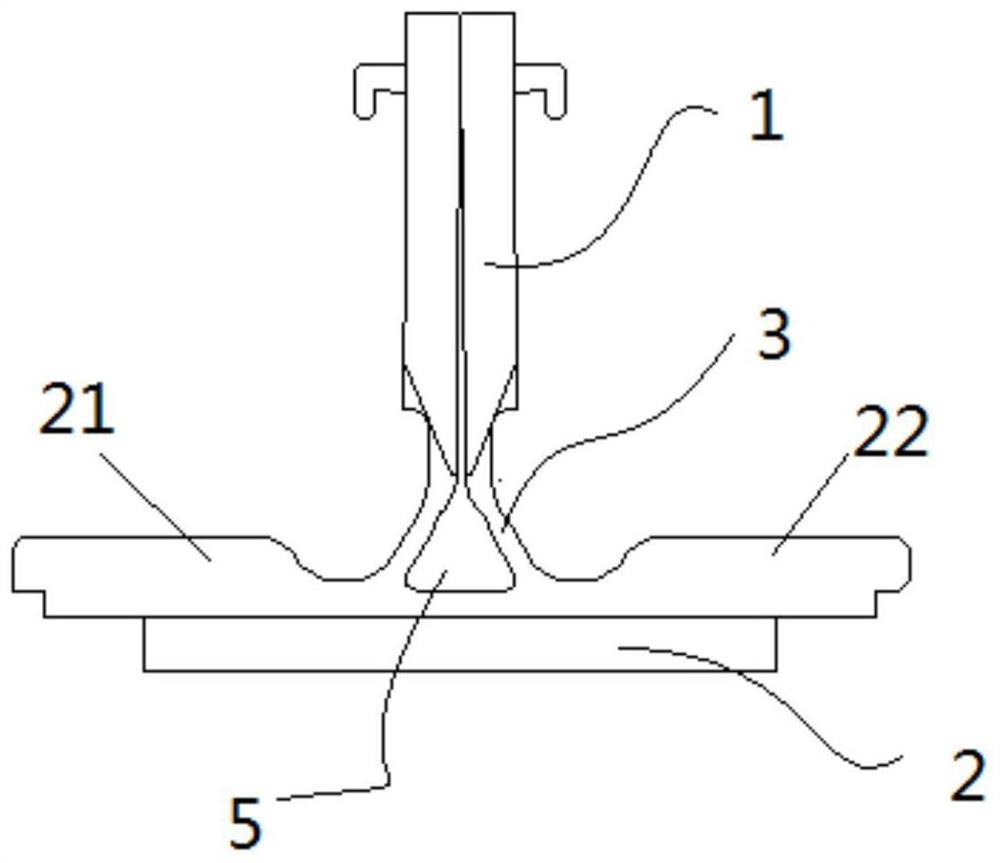

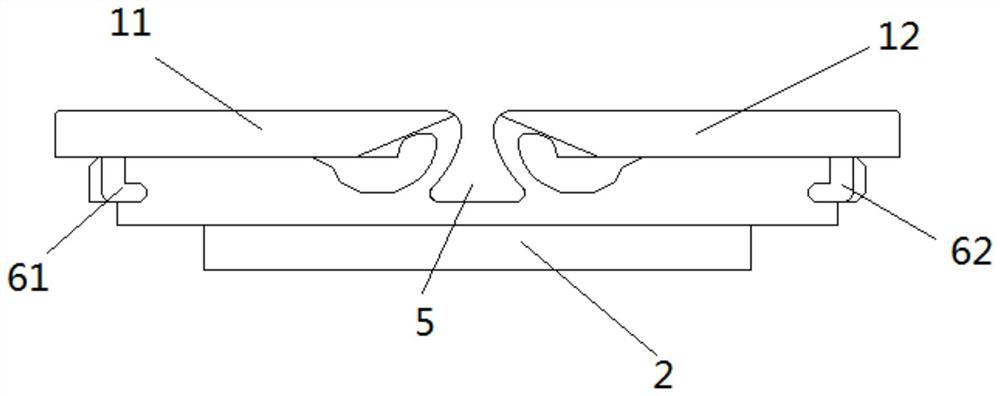

Hidden knob, switch and lockset

The invention relates to a hidden knob, a switch and a lockset. The hidden knob comprises a handle (1) and a rotating disc (2), the handle (1) is composed of a left handle body (11) and a right handle body (12) which can rotate towards the two sides respectively, the bottoms of the left handle body (11) and the right handle body (12) are fixed to the rotating disc (2), and the tops of the left handle body (11) and the right handle body (12) form a handle after being vertical. And the tops of the left handle body (11) and the right handle body (12) are overturned towards two sides and then attached to the rotating disc (2) to form a plane parallel to the rotating disc (2). And the knob is used for a switch or a lockset. Compared with the prior art, the hidden knob has the advantages of long service life, safety, reliability, wide application range and the like.

Owner:上海天原集团胜德塑料有限公司

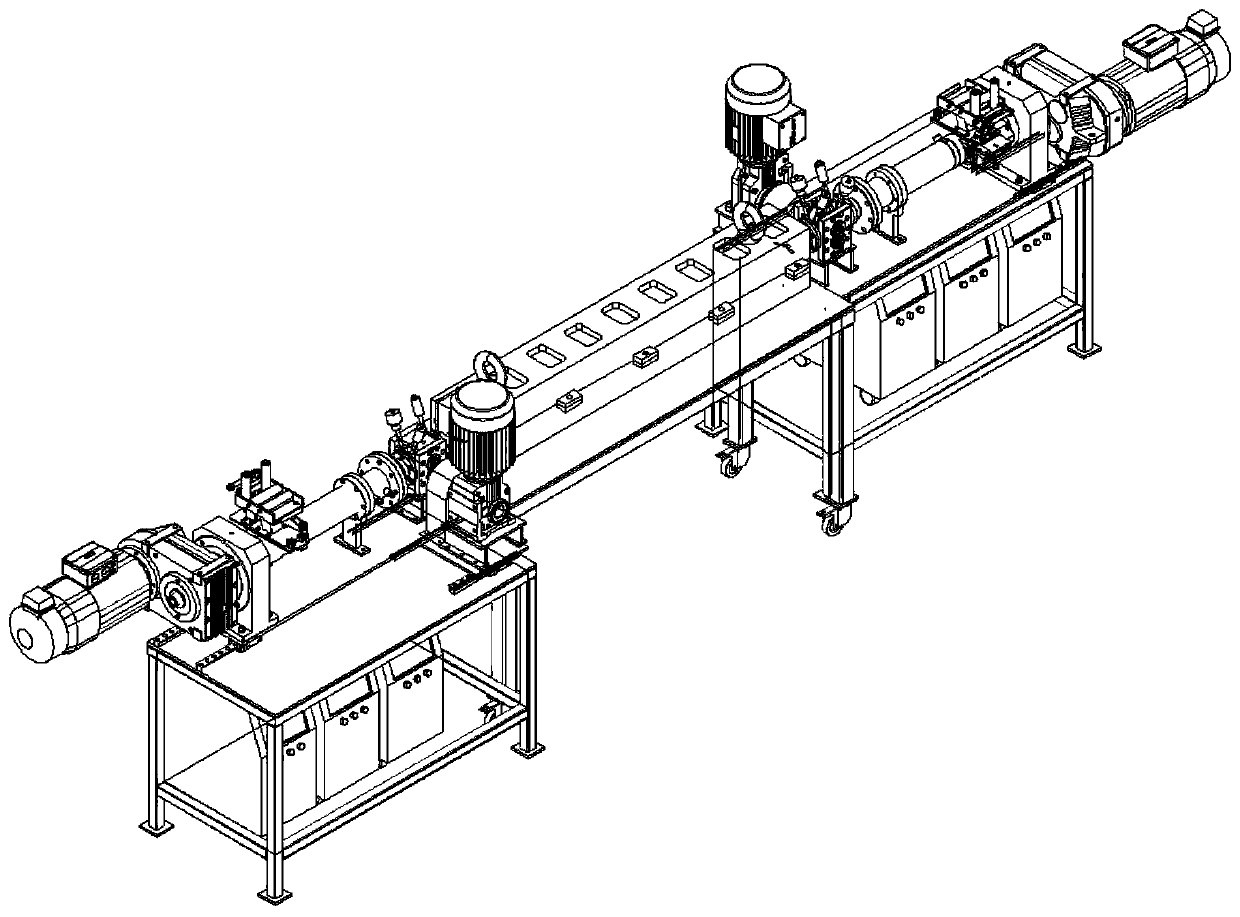

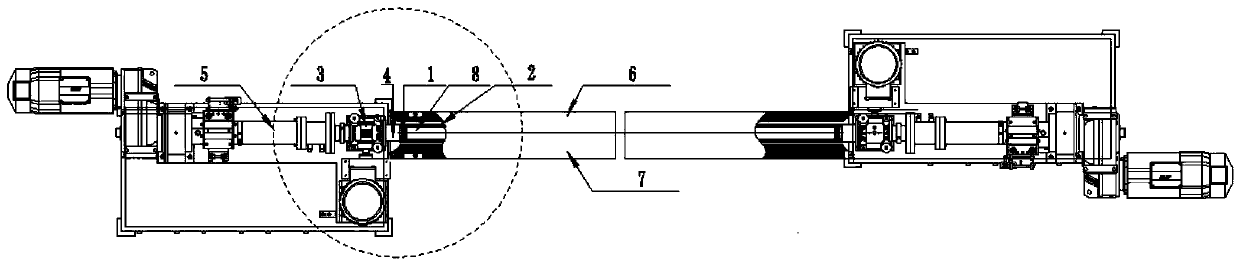

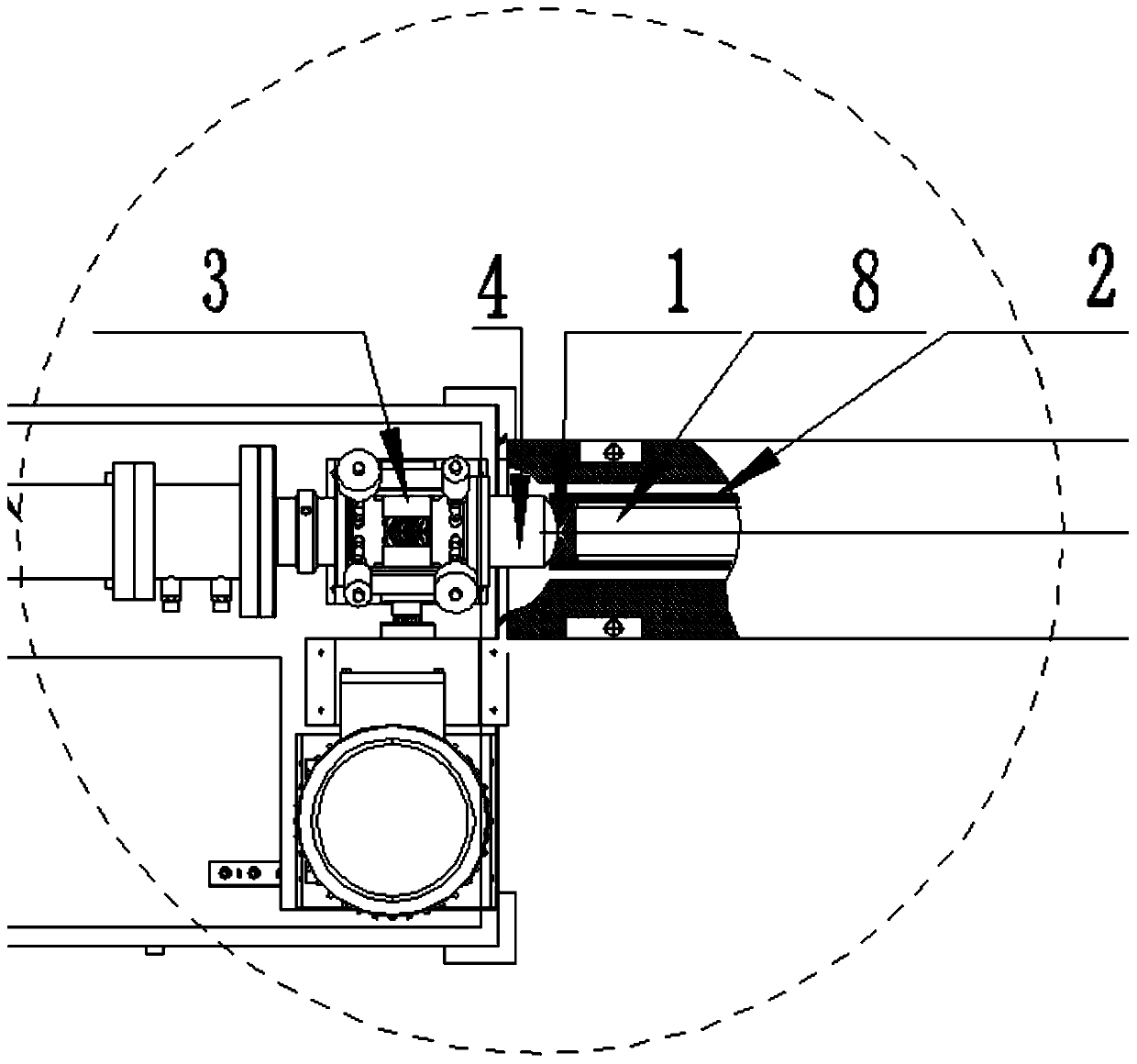

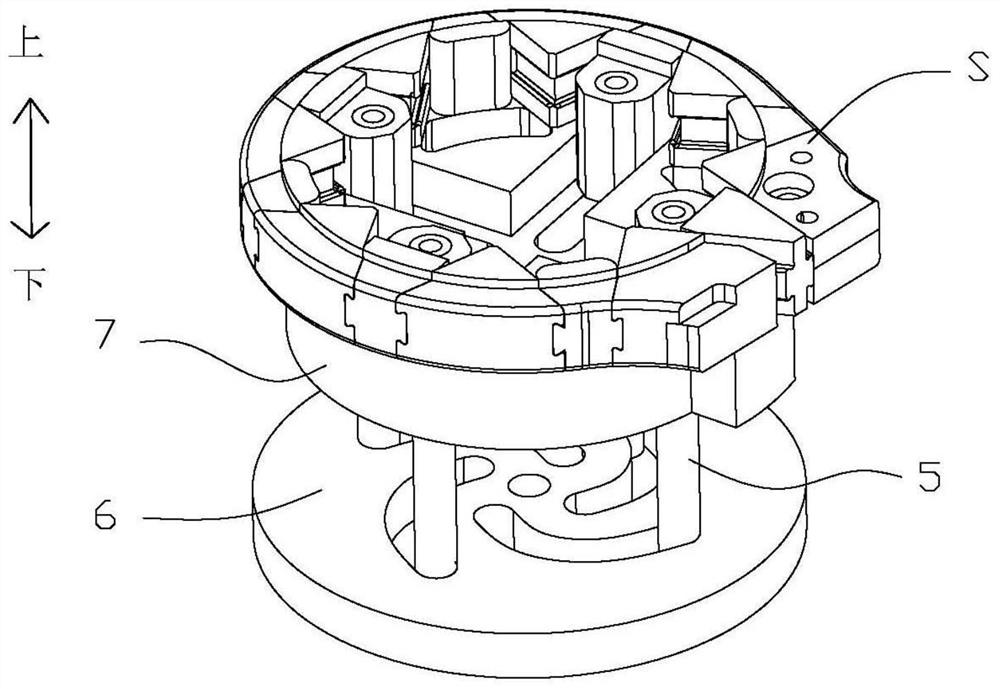

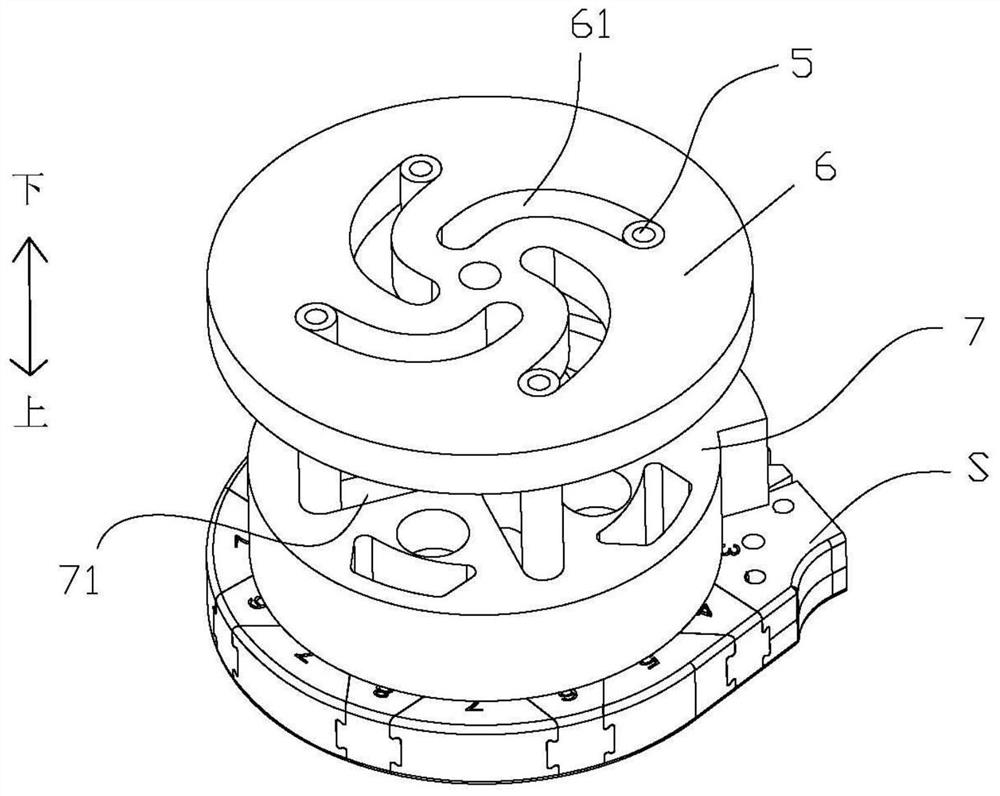

Screw pump stator rubber bushing forming device and method

The invention provides a screw pump stator rubber bushing forming device and method. The screw pump stator rubber bushing forming device comprises a gear pump, a flange, an extruder, a temperature control system and a control panel, wherein the flange is fixedly connected with one end of the gear pump and provided with an arc-shaped end surface, the extruder is fixedly connected with the other endof the gear pump, the temperature control system and the control panel are located below the extruder and are connected with the forming device, the screw pump stator rubber bushing forming device further comprises a screw pump stator pipe which is in spherical linear sealing connection with the arc-shaped end surface of the flange provided with the arc-shaped end surface, a forming runner is arranged in the screw pump stator pipe, a Y-shaped runner is arranged at the joint between the screw pump stator pipe and the arc-shaped end surface of the flange provided with the arc-shaped end surface, and Y-shaped runner double-head end surface runner openings communicate with a forming runner in the screw pump stator pipe. According to the screw pump stator rubber bushing forming device and method, the technical problems that in the prior art, rubber with relatively large viscosity is difficult to inject, a large-scale product injection runner is too long, equipment investment is large and the like are solved, the structure is simple and compact, the work is reliable, the automation degree is high, the production efficiency is high, and plasticizing molding metering continuity is realized.

Owner:QINGDAO UNIV OF SCI & TECH

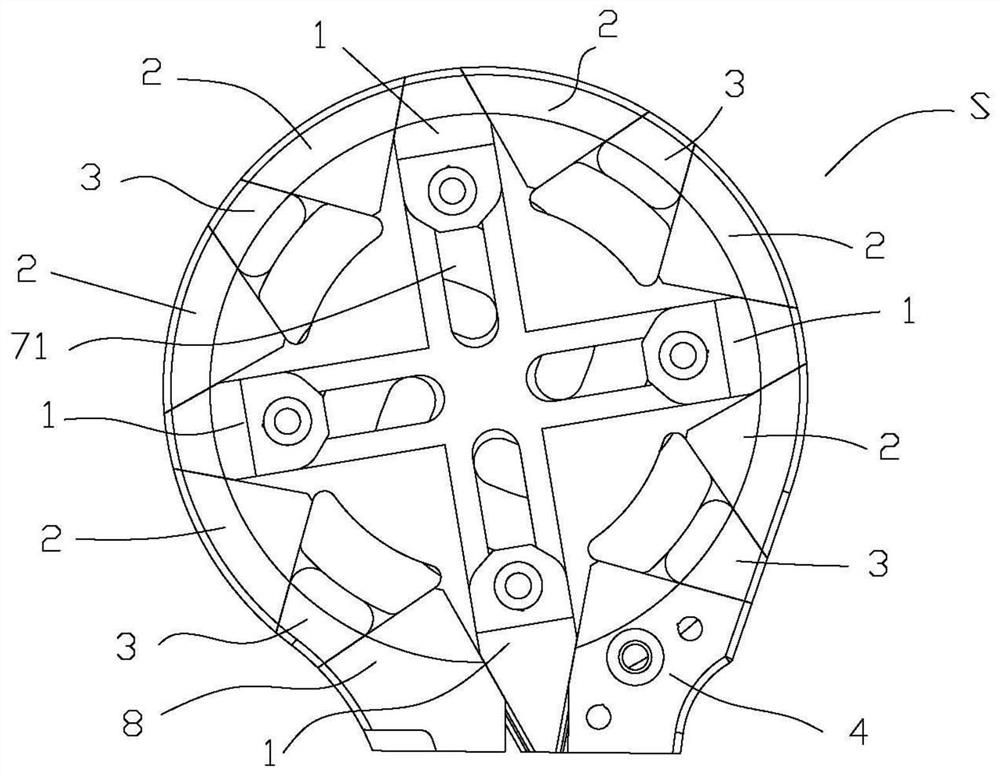

Shrinkage mold core structure capable of horizontally shrinking and free of material shortage on edge

InactiveCN113333590AGuarantee product qualityNo appearance defectsShaping toolsWheel driveStructural engineering

The invention discloses a shrinkage mold core structure capable of horizontally shrinking and free of material shortage at the edge. The shrinkage mold core structure comprises a power wheel and a guide block, wherein, the guide block is parallel to the power wheel, the guide block is located above the power wheel, a shrinkage assembly is arranged above the guide block, and the power wheel drives the shrinkage assembly, so that the shrinkage assembly expands or shrinks. According to the shrinkage mold core structure, when a mold core works, the outer circle can be shrunk to be small in size, and no large gap exists in the peripheral shape when the mold core is reset; due to the fact that the gap is small, the quality of a machined product is guaranteed, and the automatic production is achieved; and no too large gap exists between the spliced mold core sliding blocks, and produced parts do not have appearance defects.

Owner:泰州双井车业有限公司

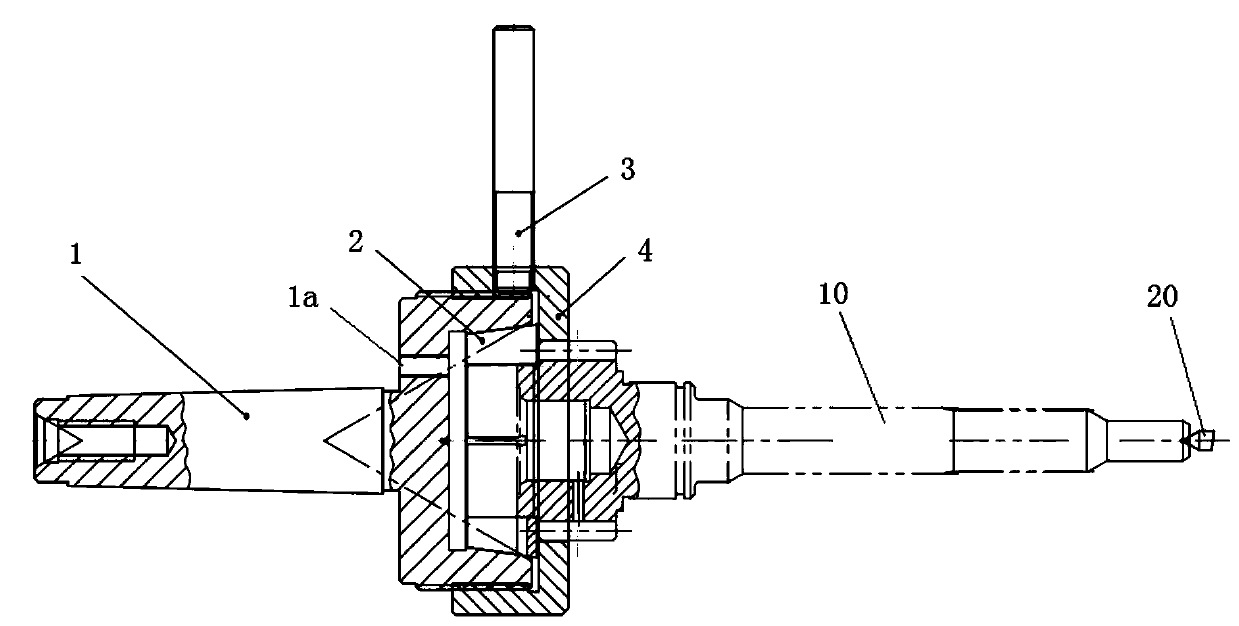

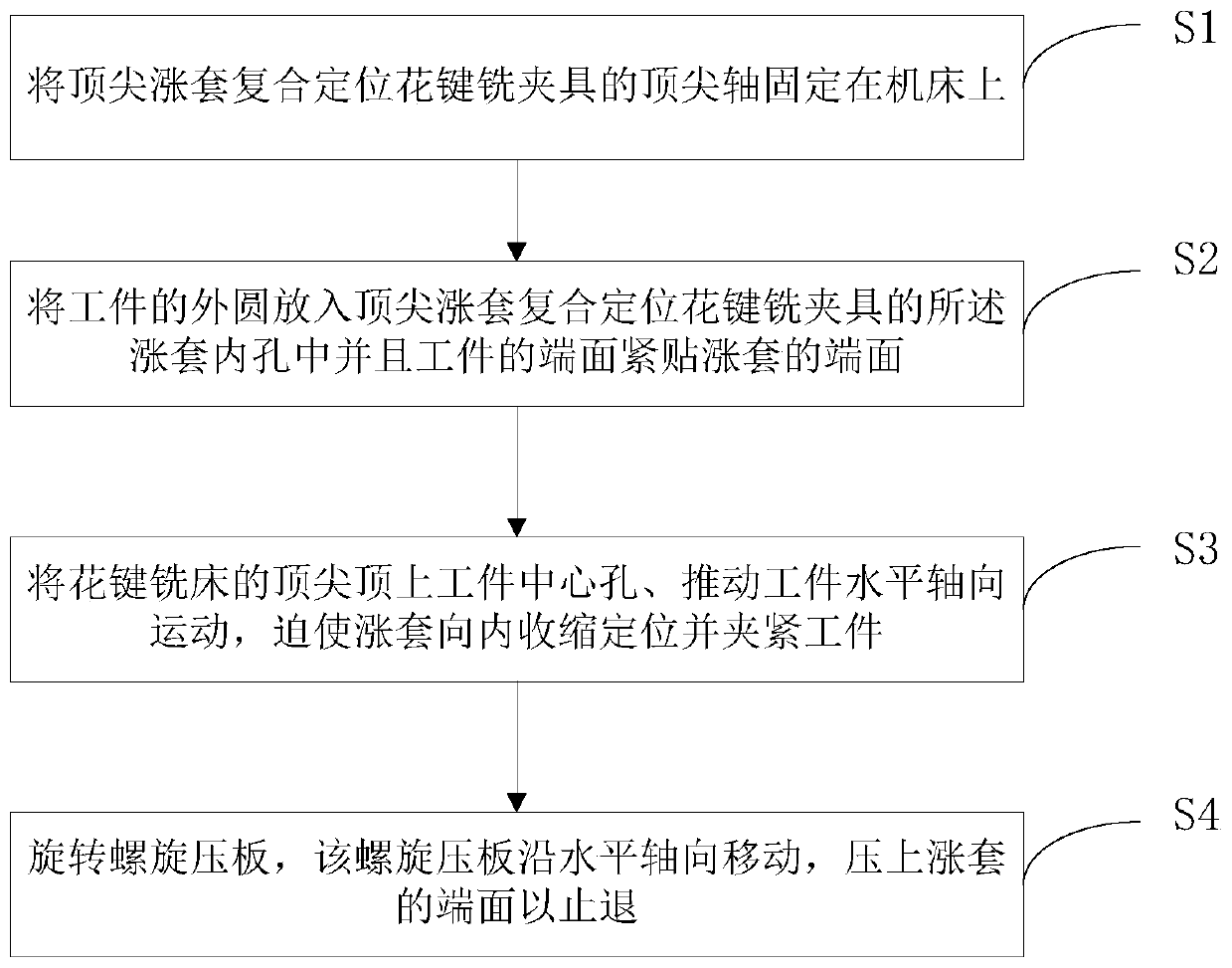

Compound positioning spline milling clamp with center expansion sleeve and workpiece clamping and positioning method

PendingCN110293432ANo appearance defectsReduce labor intensityPositioning apparatusMetal-working holdersEngineeringMachine tool

The invention discloses a compound positioning spline milling clamp with a center expansion sleeve and a workpiece clamping and positioning method. The workpiece clamping and positioning method comprises the following steps of 1, fixing a center shaft of the compound positioning spline milling clamp with the center expansion sleeve on a machine tool; 2, putting the outer circle of a workpiece intoan inner hole of the expansion sleeve of the compound positioning spline milling clamp with the center expansion sleeve so that the end face of the workpiece can be close to the end face of the expansion sleeve; 3, ejecting a center hole of the workpiece by a center of a spline milling machine to push the workpiece to move horizontally and axially, and forcing the expansion sleeve to shrink inward to position and clamp the workpiece; and 4, rotating the spiral pressing plate, wherein the spiral plate moves axially in the horizontal direction and presses the end face of the expansion sleeve tostop retraction. According to the compound positioning spline milling clamp with the center expansion sleeve and the workpiece clamping and positioning method, the ideal positioning and clamping method is provided for spline milling process, and the center force of the spline milling machine is used to clamp the workpiece, so that the labor intensity is reduced, and the outer circle of the workpiece clamped by the expansion sleeve has no indentation and other appearance defects.

Owner:ANHUI XINGRUI GEAR TRANSMISSION

A kind of freeze-drying method of live vaccine

ActiveCN107543373BNo crystalUniform sublimation rateDrying solid materials without heatAntiviralsFreeze-dryingVacuum sublimation

The invention discloses a freezing-drying method for live vaccine. The freezing-drying method comprises the steps that the eutectic point range of a to-be-frozen and to-be-dried vaccine is tested, then, the live vaccine is placed in a vacuum freezing-drying machine pre-cooled to 0+ / -1 DEG C, when the temperature of a plate layer of the vacuum freezing-drying machine is reduced to be higher than the eutectic point of the live vaccine by 1-2 DEG C, the current state is kept for 1-2 h, and continuous cooling is conducted with the rate of 1 DEG C / h till all vaccine is frozen; and cooling is immediately conducted to the temperature needed for sublimation, and finally vacuum sublimation is conducted according to the normal procedure. The product obtained through the method is not provided with large ice crystals, sublimation is easy, and after freezing-drying, a good product physical behavior can be obtained, and the freezing-drying titer losses are minimal.

Owner:SICHUAN HUAPAI BIO PHARMA

Suspended aluminum alloy cage football field fence device

ActiveCN105169683BNo appearance defectsNo welding deformationSki bindingsWater-skiingEngineeringCantilever

The invention provides a hanging fence device of an aluminum alloy cage type football field. The suspended aluminum alloy cage football field fence device includes connecting corners, connecting corner bases, connecting straight-throughs, connecting straight-through bases, two columns, fences, upper hanging beams, lower hanging beams, multiple spring seats and multiple sliders, The connection corner and the connection corner base are respectively arranged at two ends of a column, the connection straight-through and the connection straight-through base are respectively arranged at two ends of another column, and the two ends of the upper suspension beam are respectively connected to the connection The corner is directly connected to the connection, the two ends of the lower suspension beam are respectively connected to the connection corner base and the connection straight-through base, a plurality of the spring seats are respectively arranged on the two columns, and a plurality of the sliders are respectively arranged on the upper suspension beam and the lower suspension beam, The fence connects the slider and the spring seat. The suspended aluminum alloy cage-type football field fence device provided by the present invention solves the technical problems of inconvenient disassembly and installation, bulky and inconvenient transportation in the prior art.

Owner:HEBEI QIFAN TEACHING EQUIP MFG

Welding process of supporting end cover plate of large equipment

ActiveCN109434254BQuality improvementImprove compactnessArc welding apparatusMass Spectrometry-Mass SpectrometryWeld line

The invention discloses a welding process for supporting end cover plates of large-scale equipment, which includes the following steps: S1. Grinding steps before welding, inspecting welding equipment and welding positioners, and grinding the cover plates to be welded and the cover plate flange components ; S2, the pre-welding step, combining the cover plate and the cover plate flange components, and pre-welding the joint position; S3, the welding step, fixing the pre-welded cover plate and the cover plate flange components on the On the welding positioner, adjust the welding positioner to the welding station, and then perform welding processing on the cover plate and cover plate flange components; S4, the detection step, the finished product that has finished welding and completed cooling is welded Remove it from the positioner and inspect the finished product. The welding technology of the invention has stable quality, good root fusion and can well control the welding line energy. The formed weld has good compactness, and the surface is beautifully formed without appearance defects, which greatly improves the qualified rate of weld helium mass spectrometry leak detection.

Owner:苏州市东望医疗设备有限公司

A kind of spraying method of carbon-doped coating on spherical surface

ActiveCN104384087BUniform colorStable spray patternSpraying apparatusPretreated surfacesSurface roughnessCarbon doped

The invention provides a spray method for a carbon-doped coating on a spherical surface. The spray method comprises the following steps of clamping a manual spray gun in a robot arm; clamping a spherical workpiece in a spray device; proportioning a coating; spraying by using a robot; performing curing treatment. According to the spray method for the carbon-doped coating on the spherical surface, the appearance quality and the thickness uniformity of the coating on the spherical surface are improved, the surface roughness Sa is smaller than 1.6mu m, and the thickness uniformity reaches + / -5mu m.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

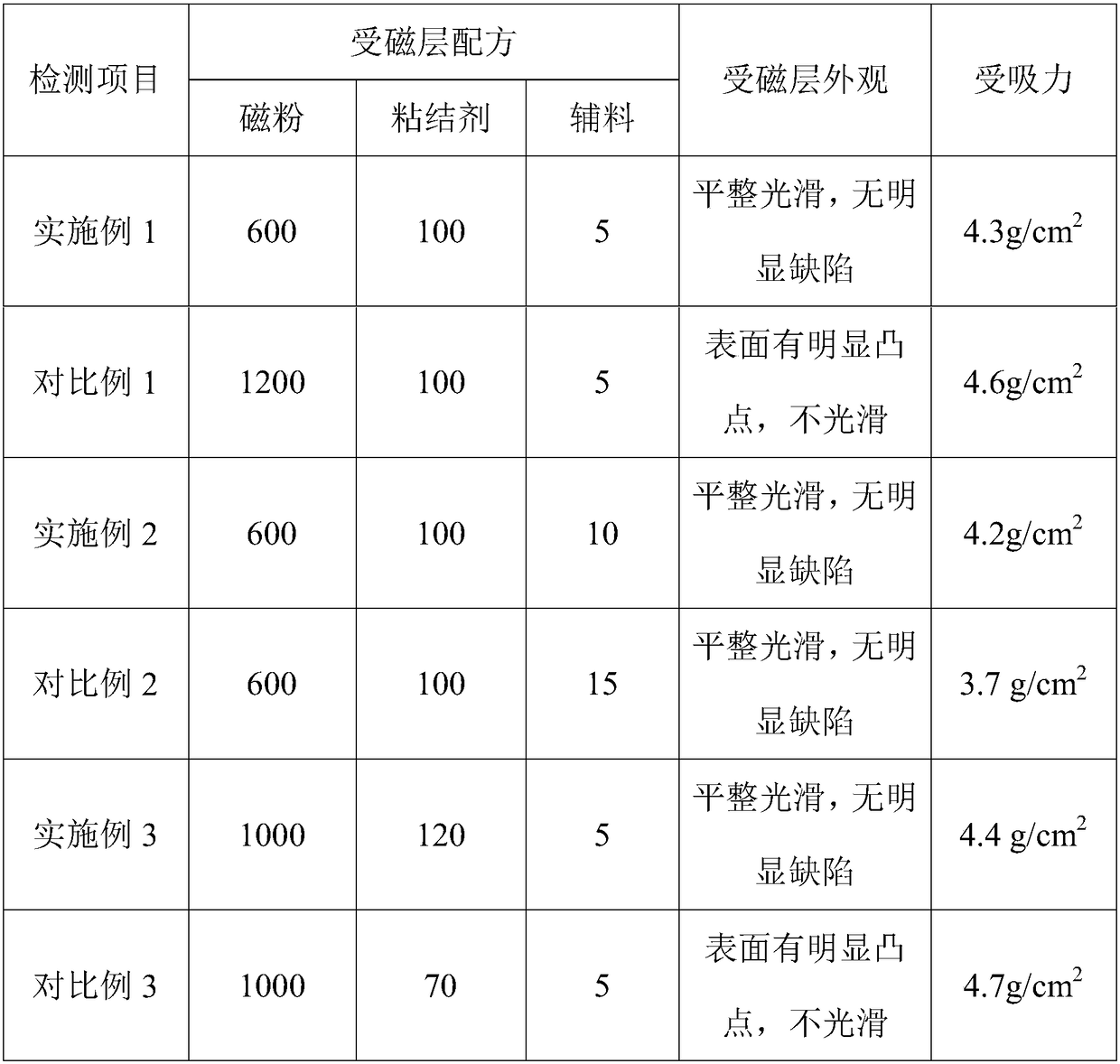

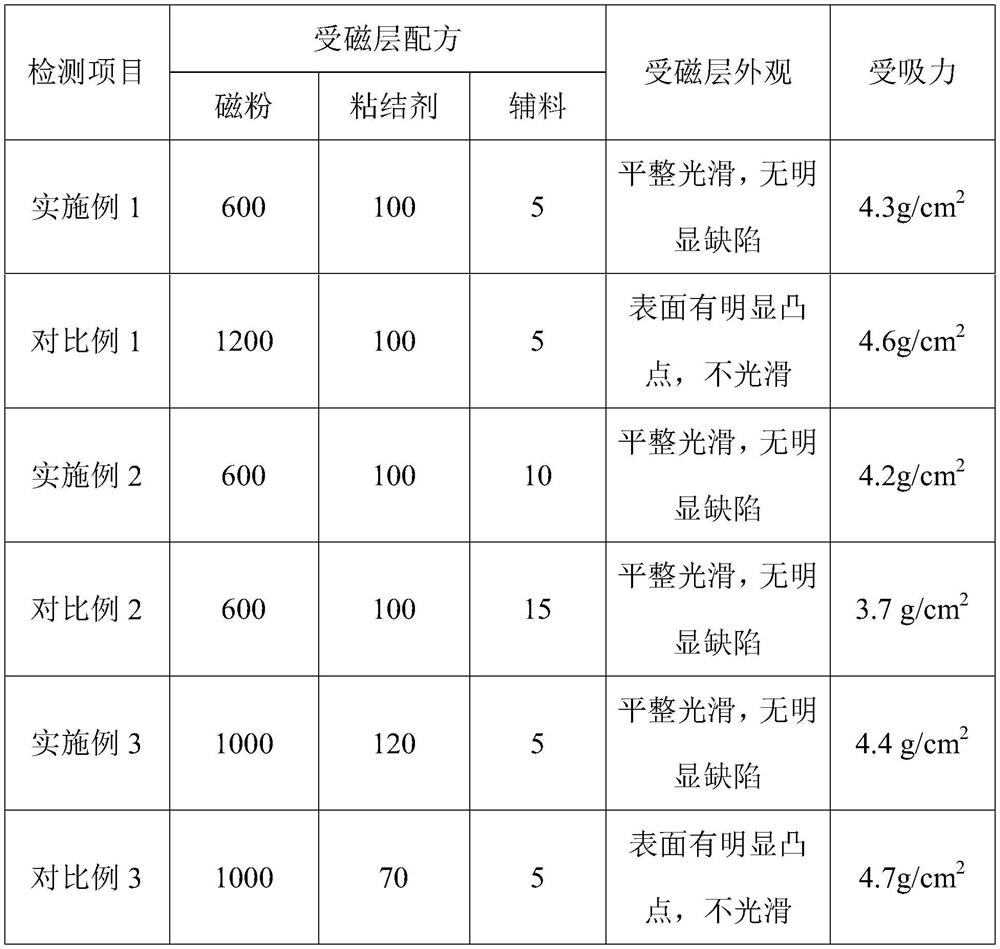

Printable magnetized composite film and preparation method thereof

ActiveCN109228716AReduce material costsReduce processing costsPermanent magnetsFlat articlesComposite filmMicrometer

The invention discloses a printable magnetized composite film and a preparation method thereof. The printable magnetized composite film comprises three layers: the upper layer is a protective layer, the middle layer is a magnetized layer and the lower layer is a printing layer; the protective layer is used to protect the magnetized layer and the protective layer has a thickness of 1 to 2 micrometers; the magnetized layer has a thickness of 0.01 to 0.1 mm; materials of the protective layer comprise varnish; and the magnetized layer comprises the following components in parts by weight: 600-1000parts of soft magnetic powder, 80-120 parts of a polymer binder and 0-10 parts of an auxiliary material. The obtained printable magnetized composite film can reduce the thickness of an entire magnetic printing material on one hand, and can avoid the phenomenon that the magnetic printing material cannot be used due to the failure of a double-sided adhesive on the other hand, and has high suction and an anti-aging characteristic.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Injection mold adopting inverted rubber intake mode

InactiveCN104943080AGlue feeding method is safe and reliableNo appearance defectsHigh surfaceEngineering

The invention relates to the technical field of injection molds, in particular to an injection mold adopting an inverted rubber intake mode. The injection mold has a baseplate, a thimble lower plate, a thimble upper plate, a movable mold, a fixed mold and a panel arranged in sequence, wherein a rubber injecting port is formed in the middle position of the baseplate; a rubber injecting nozzle penetrating through the thimble lower plate, the thimble upper plate and the movable mold in sequence is inserted in the rubber injecting port; and a positioning ring for fixing the rubber injecting nozzle is arranged in the middle position of the baseplate. The rubber intake mode of the injection mold adopting the inverted rubber intake mode is safer and more reliable; the product has no appearance defect; the product quality is greatly enhanced; and in particular, the injection mold is suitable for producing products having special structures and products having higher surface requirements.

Owner:贾玉平

Hot rolling forming process of door frame steel for civil air defense

The invention provides a hot rolling forming process of door frame steel for civil air defense, and belongs to the technical field of steel machining. A continuous casting blank serves as a raw material, in the cogging rough rolling stage, through two times of steel turnover and three-pass rolling, a vertical rib prototype is formed on the surface of the raw material, through two-pass rolling, aninclined rib prototype is formed, through eight-pass rolling, auxiliary supporting legs and supporting legs are formed, and finally, through one-pass finish rolling, hot rolling forming machining is finished. The door frame steel for civil air defense is formed at a time, high in production efficiency, free of appearance defect, precise in angle and uniform in thickness.

Owner:SUQIAN NANGANG JINXIN STEEL ROLLING CO LTD

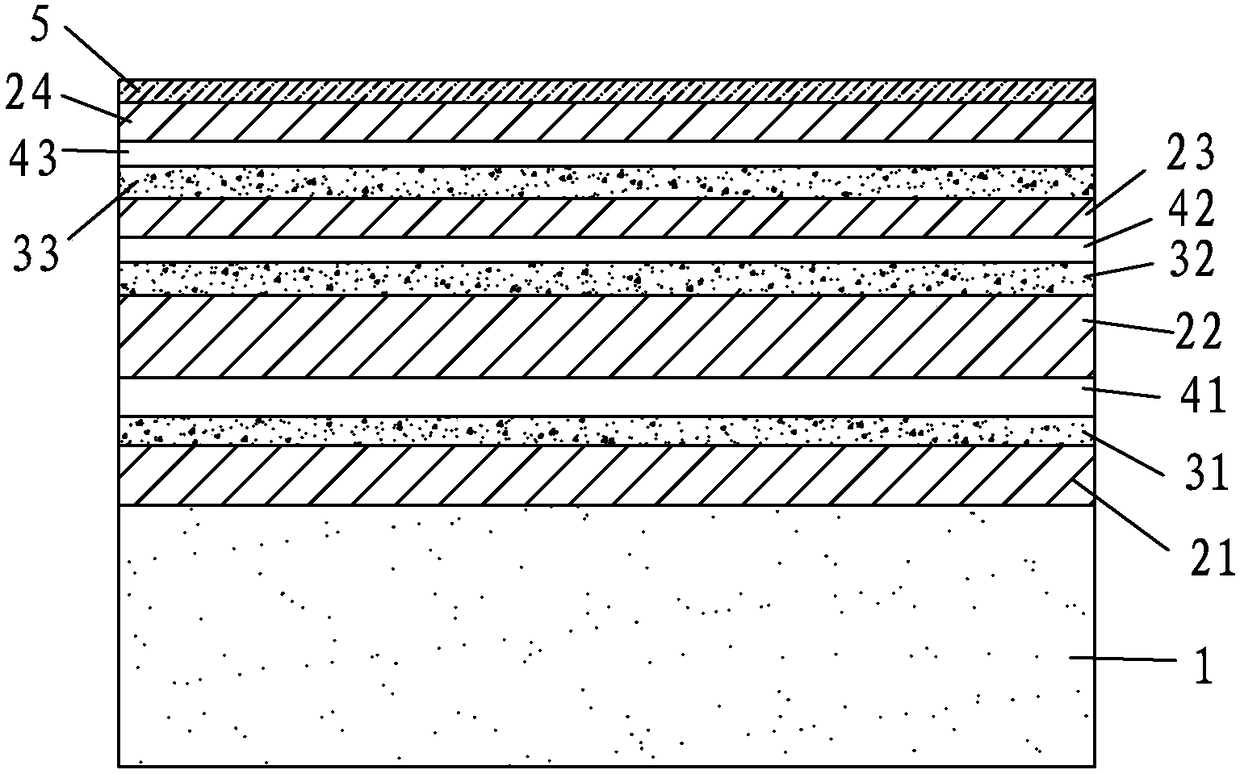

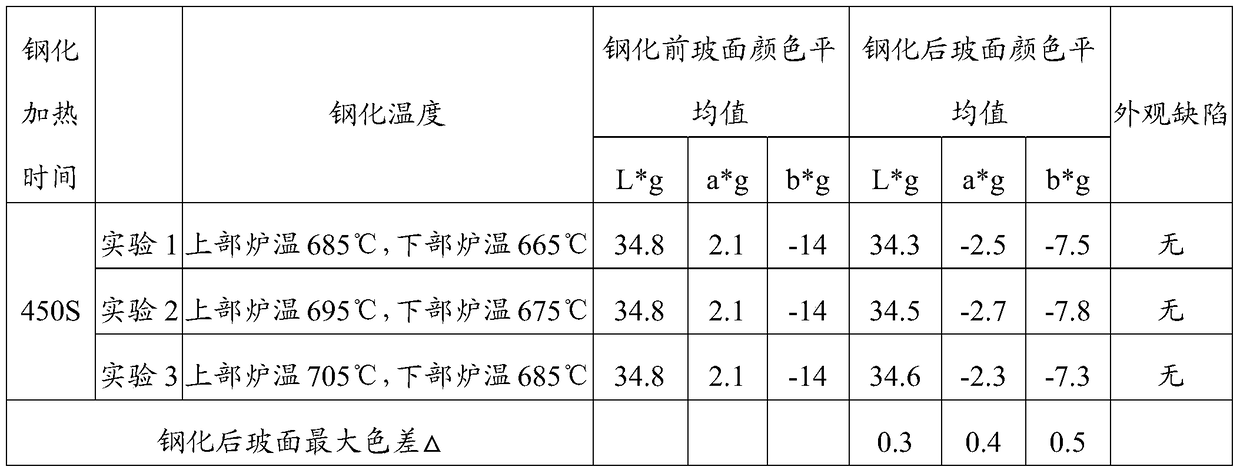

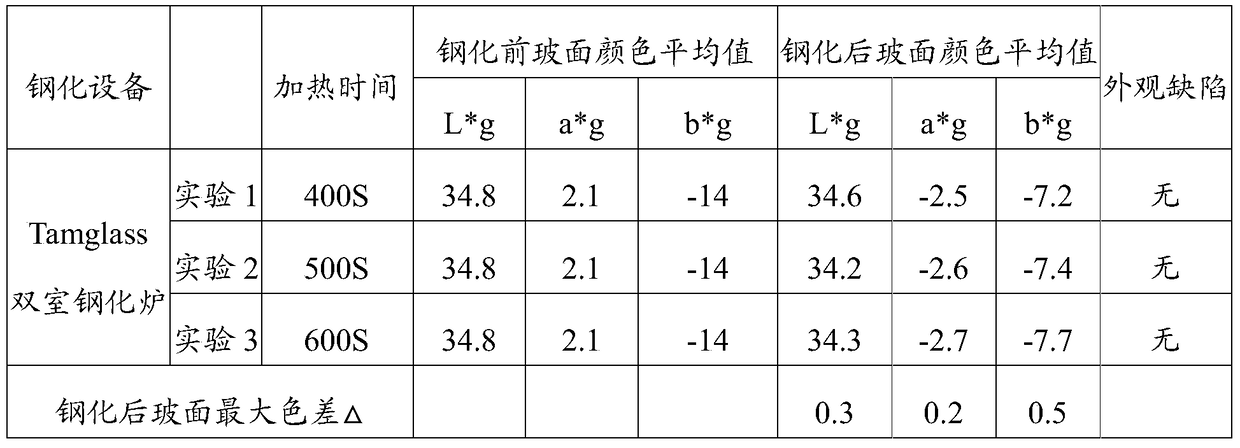

A kind of temperable triple-silver low-emissivity coated glass and preparation method thereof

Owner:东莞南玻工程玻璃有限公司 +1

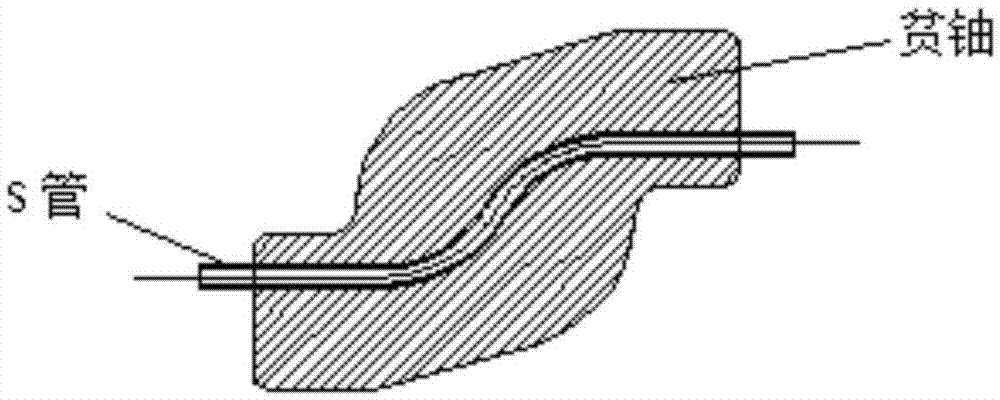

Casting method of S-channel depleted uranium shielding body

The invention is applied to the technical field of the industrial flaw detection industry and the radiological medicine industry, and particularly relates to a casting method of an S-channel depleted uranium shielding body. The casting method comprises the following steps: an S-shaped stainless steel tube is coated with a zirconium oxide and yttrium oxide coating by adopting a plasma spraying technology; a cold uranium sleeve is additionally arranged at the exterior of the S-shaped stainless steel tube provided with the zirconium oxide and yttrium oxide coating; depleted uranium molten metal flows down along a runner exactly above a mould for casting, wherein a casting mode adopts transverse casting, the middle of an inner cavity of the mould is spherical and the two ends of the inner cavity of the mould are rectangular; after the previous treatment is carried out on the S-shaped stainless steel tube, primary casting is carried out, a core having a small size is formed, and then the core is subjected to secondary casting. The S-channel depleted uranium shielding body cast by the casting method is used for nondestructive flaw detection equipment.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

A printable magnetic composite film and its preparation method

ActiveCN109228716BReduce material costsReduce processing costsPermanent magnetsFlat articlesComposite filmInter layer

The invention discloses a printable magnetized composite film and a preparation method thereof. The printable magnetized composite film comprises three layers: the upper layer is a protective layer, the middle layer is a magnetized layer and the lower layer is a printing layer; the protective layer is used to protect the magnetized layer and the protective layer has a thickness of 1 to 2 micrometers; the magnetized layer has a thickness of 0.01 to 0.1 mm; materials of the protective layer comprise varnish; and the magnetized layer comprises the following components in parts by weight: 600-1000parts of soft magnetic powder, 80-120 parts of a polymer binder and 0-10 parts of an auxiliary material. The obtained printable magnetized composite film can reduce the thickness of an entire magnetic printing material on one hand, and can avoid the phenomenon that the magnetic printing material cannot be used due to the failure of a double-sided adhesive on the other hand, and has high suction and an anti-aging characteristic.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

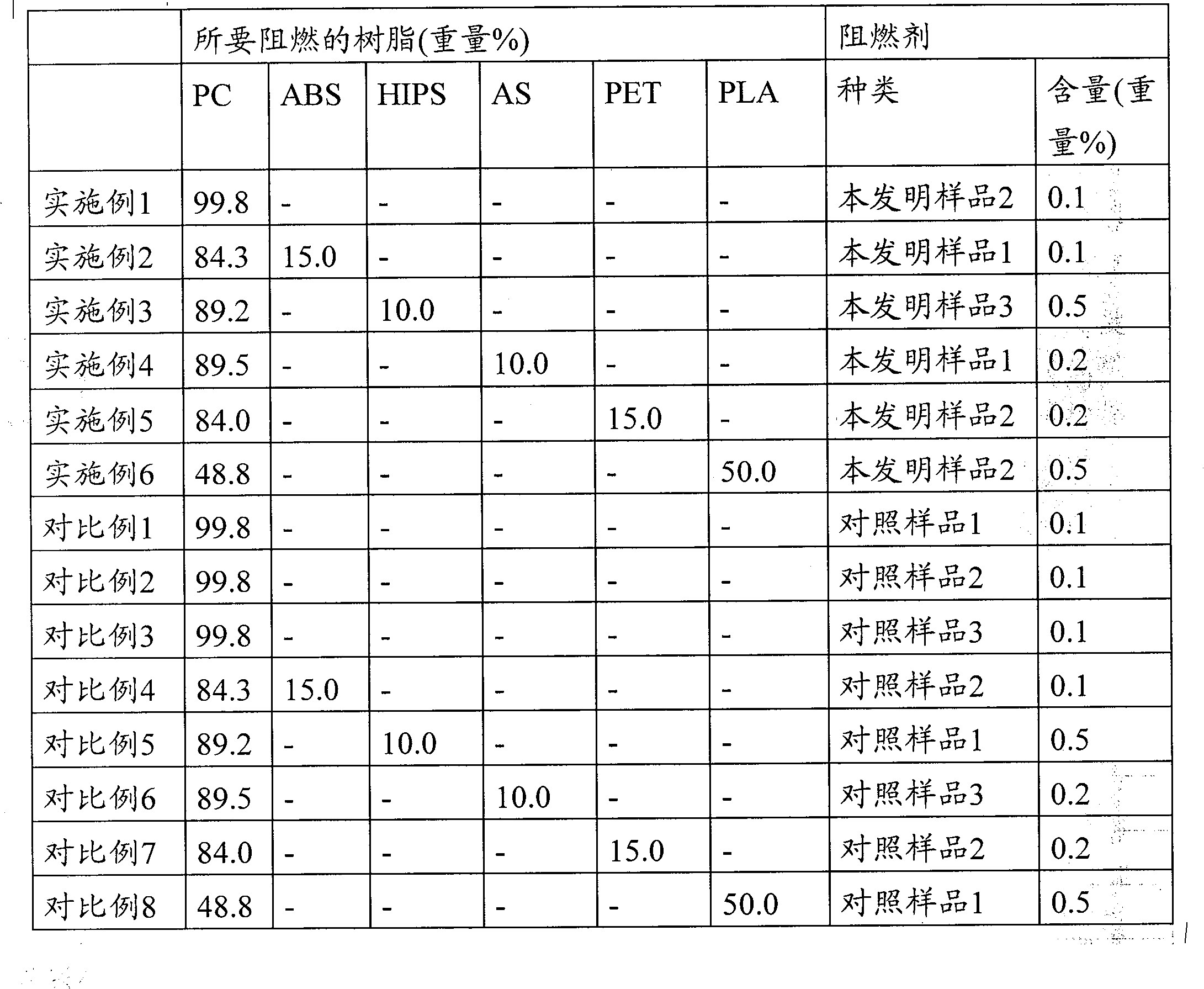

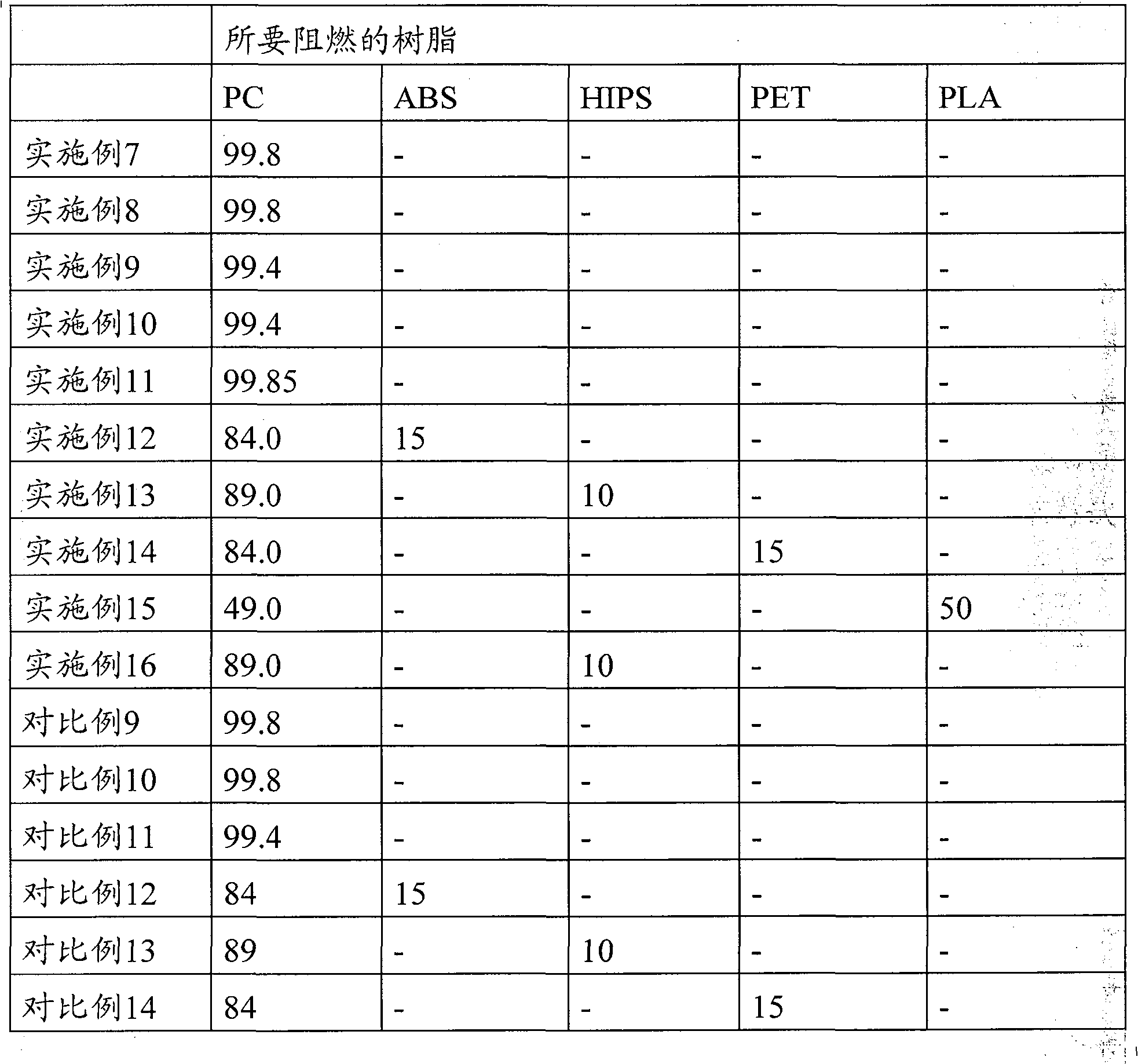

Flame retardant, flame-retardant resin composition and method for producing flame retardant

Flame-retarded resin compositions prepared by incorporating a resin to be flame-retarded with an acrylonitrile / styrene polymer having sulfonic acid groups and / or sulfonate salt groups which are introduced thereinto by sulfonation with a sulfonating agent having a water content of less than 3 wt%.

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com