A kind of freeze-drying method of live vaccine

A drying method, vacuum freeze-drying technology, applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., can solve the problems of unstable quality, large loss of potency, high rejection rate, and achieve uniform sublimation rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

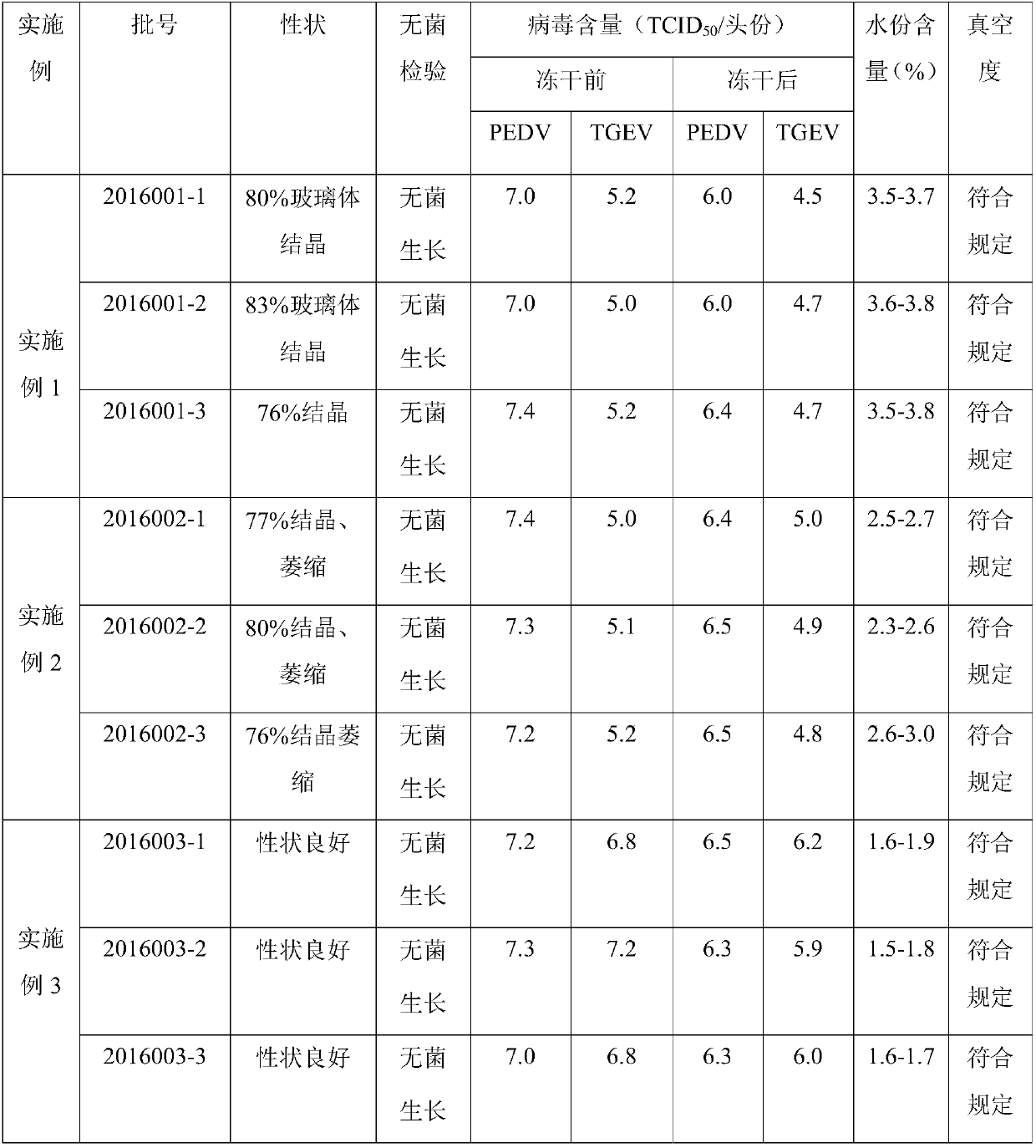

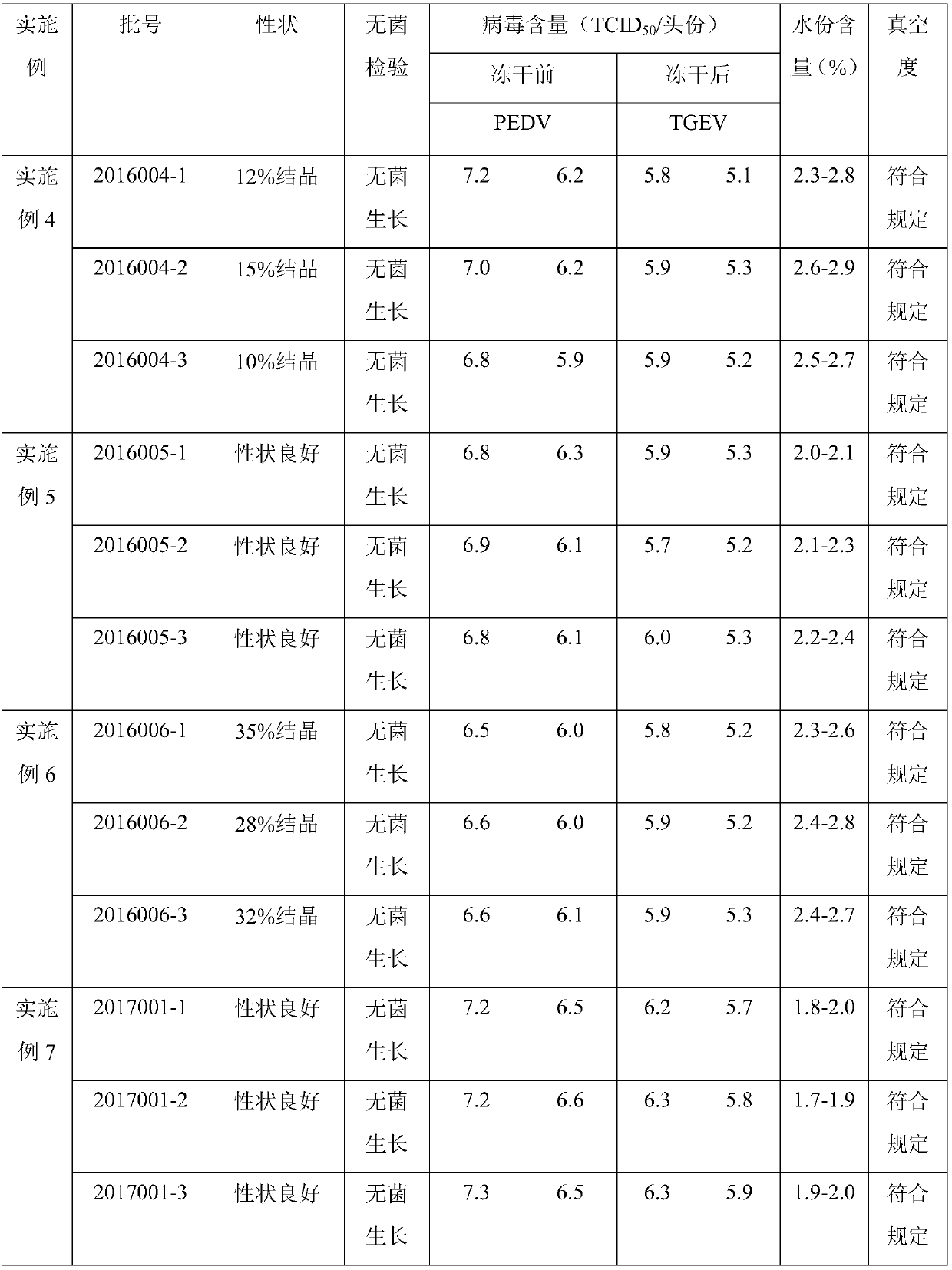

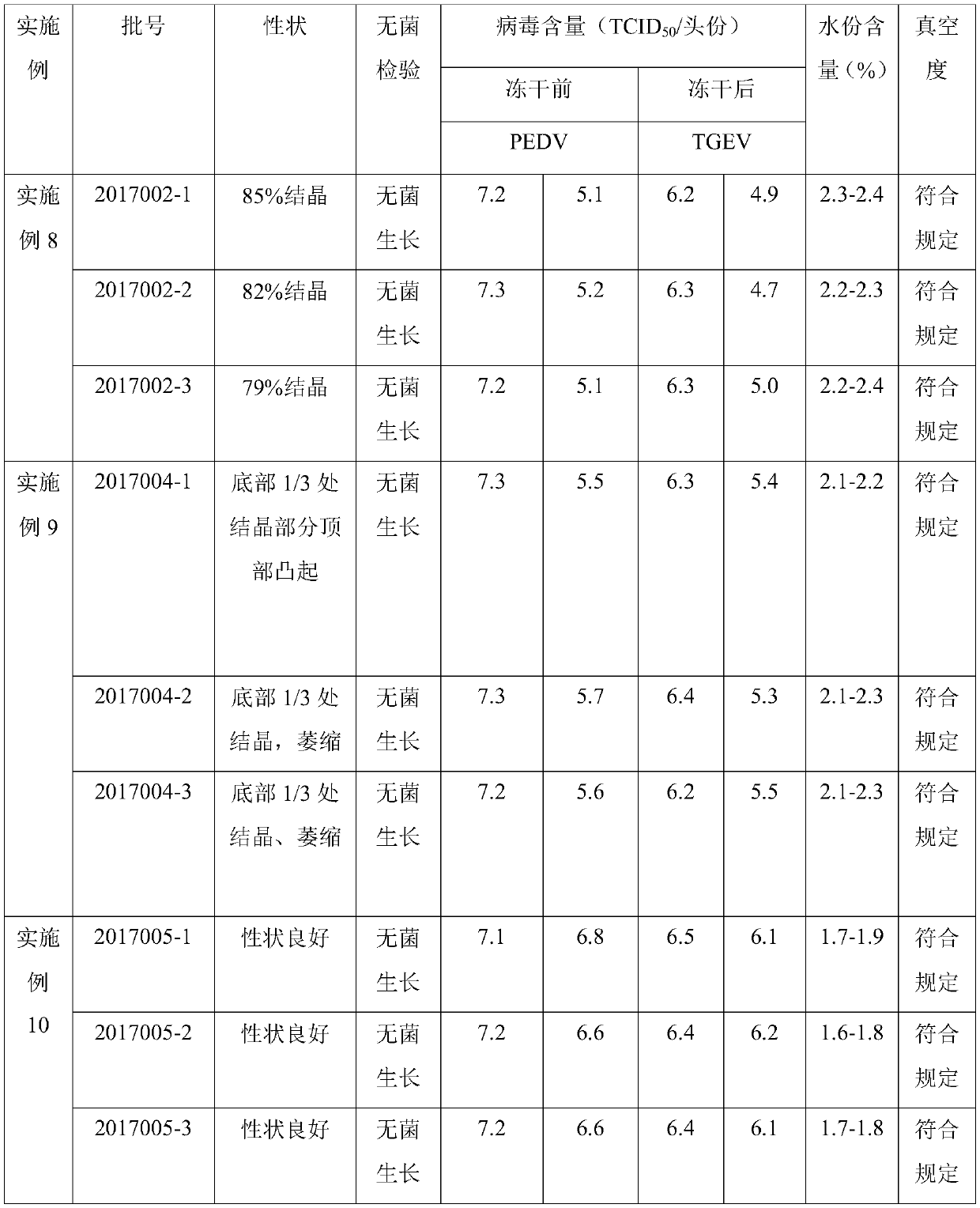

Embodiment 1

[0030] A kind of freeze-drying method of porcine transmissible gastroenteritis, epidemic diarrhea virus dual live vaccine, comprises the following steps: the porcine transmissible gastroenteritis (SCJY-1 strain) and epidemic diarrhea virus (SCSZ-1 strain) two Add the seed virus liquid into the seedling matching tank, control the temperature in the tank at 10°C, stir evenly, add heat-resistant protective agent, continue stirring evenly, and then divide it into 10ml vials, 2.6ml per bottle. While filling, the temperature of the plate layer is controlled at about 0°C; after the filling is completed, the machine will automatically half stopper, then put the filled product into the suction chassis and send it to the freeze-drying box in time, close the box door, and use 10min Time to reduce the temperature of the plate fluid of the vacuum freeze dryer to -43°C, keep it for 5 hours, and then start vacuuming, when the vacuum degree reaches below 15Pa, start to heat up; when the temper...

Embodiment 2

[0033] A kind of freeze-drying method of porcine transmissible gastroenteritis, epidemic diarrhea virus dual live vaccine, comprises the following steps: the porcine transmissible gastroenteritis (SCJY-1 strain) and epidemic diarrhea virus (SCSZ-1 strain) two Add the seed virus liquid into the seedling matching tank, control the temperature in the tank at 10°C, stir evenly, add heat-resistant protective agent, continue stirring evenly, and then divide it into 10ml vials, 2.6ml per bottle. While filling, the temperature of the plate layer is controlled at about 0°C; after the filling is completed, the machine will automatically half stopper, then put the filled product into the suction chassis and send it to the freeze-drying box in time, close the box door, and use 10min Time to reduce the temperature of the plate fluid of the vacuum freeze dryer to -23°C and keep it for 1.5h; cool the product at a rate of 1°C / h and drop it to -25°C; adjust the temperature in the vacuum freeze ...

Embodiment 3

[0036]A kind of freeze-drying method of porcine transmissible gastroenteritis, epidemic diarrhea virus dual live vaccine, comprises the following steps: the porcine transmissible gastroenteritis (SCJY-1 strain) and epidemic diarrhea virus (SCSZ-1 strain) two Add the seed virus liquid into the seedling matching tank, control the temperature in the tank at 10°C, stir evenly, add heat-resistant protective agent, continue stirring evenly, and then divide it into 10ml vials, 2.6ml per bottle. While filling, the temperature of the plate layer is controlled at about 0°C; after the filling is completed, the machine will automatically half stopper, then put the filled product into the suction chassis and send it to the freeze-drying box in time, close the box door, and use 10min Time to reduce the temperature of the plate fluid of the vacuum freeze dryer to -16°C and keep it for 2 hours; then lower the temperature of the product at a rate of 1°C / h to -25°C; adjust the temperature in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com