A high-efficiency water reducer with good compatibility and its preparation method

A high-efficiency water-reducing agent and compatibility technology, applied in the field of building materials, can solve the problems affecting the performance, mechanics and durability of concrete mixtures, cannot be mixed with each other, and the water-reducing rate is reduced, so as to solve the problem of treatment cost, relative Good capacity and high water reducing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

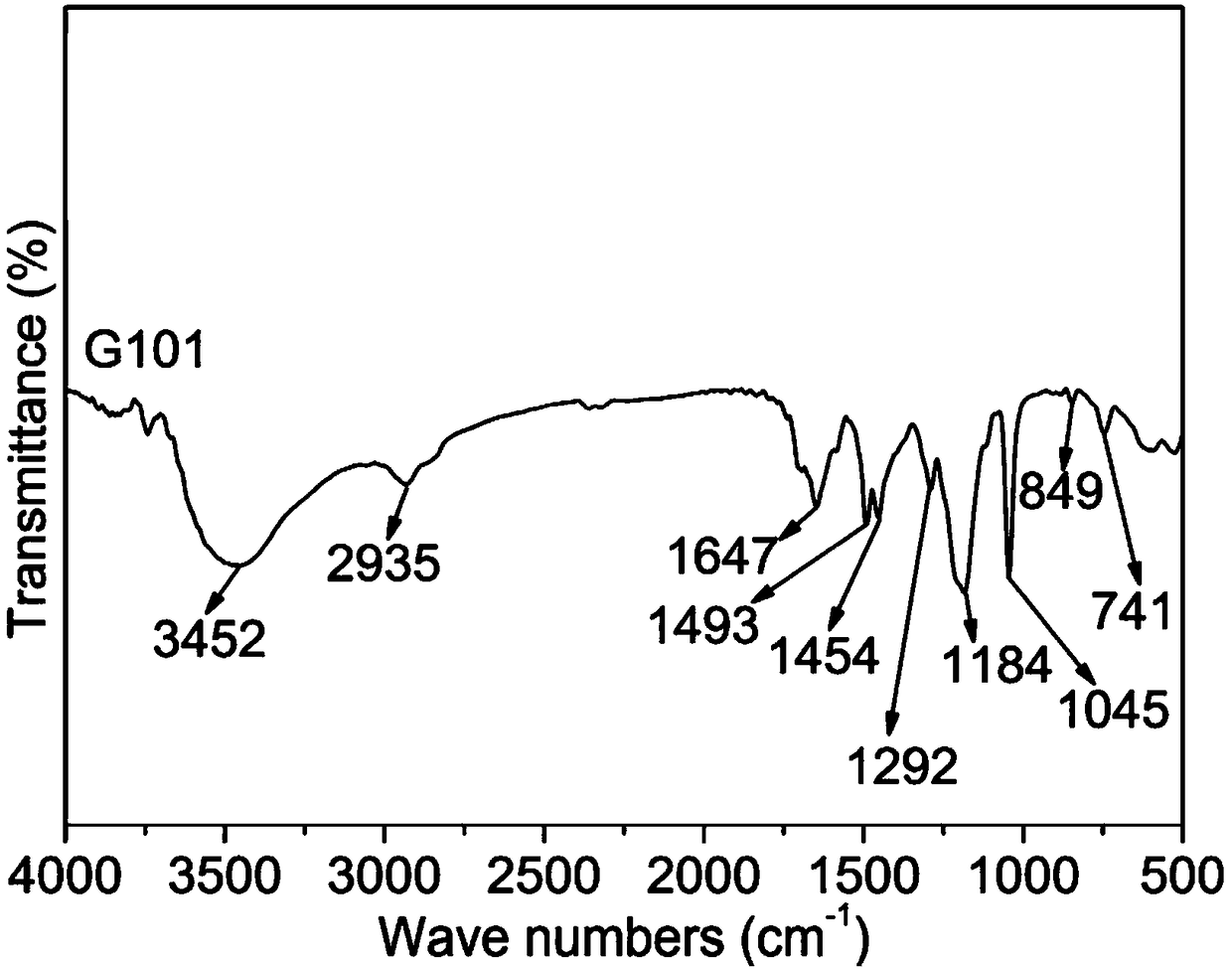

[0043] A high-efficiency water reducer G101 with good compatibility, its chemical structural formula is:

[0044]

[0045] Wherein, x=3-20, y=3-20.

[0046] The preparation method of the above-mentioned high-efficiency water reducer with good compatibility comprises the following steps:

[0047] 1) In parts by weight, take 50 parts of raw material sulfonating agent sodium sulfite, 150 parts of water, 50 parts of acetone, 15 parts of modifier guaiacol, and 140 parts of formaldehyde;

[0048] 2) Add 50 parts of sodium sulfite and 150 parts of water into the flask, stir until completely dissolved, add 50 parts of acetone and continue to stir for 10 minutes, then add 15 parts of modifier guaiacol, react at 40-45°C for 1 hour for sulfonation reaction;

[0049] 3) Continue to add 140 parts of formaldehyde dropwise to the solution system obtained after sulfonation, and the dropping time is controlled at 2 hours. After the dropwise addition of formaldehyde is completed, keep warm ...

Embodiment 2

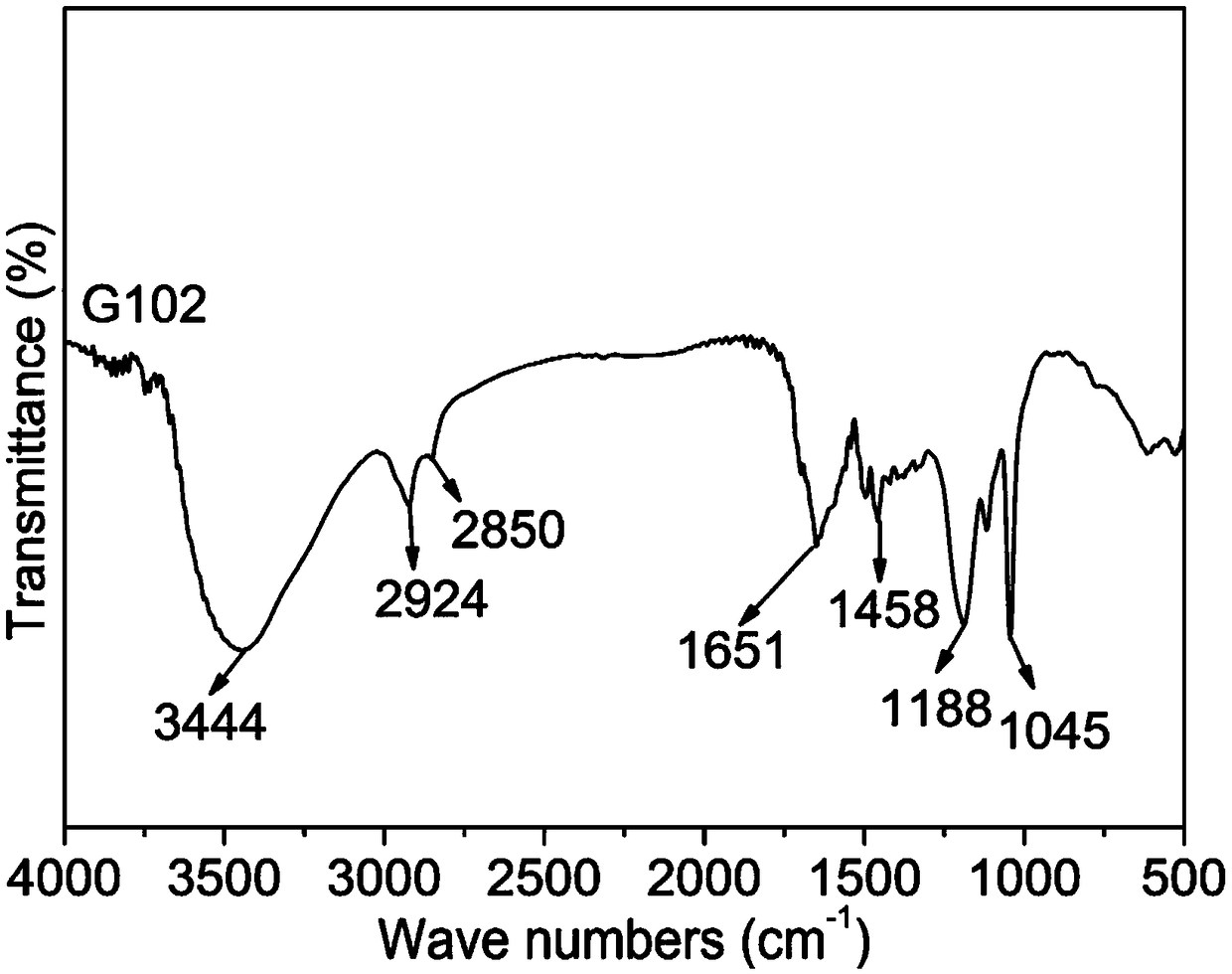

[0056] A high-efficiency water reducer with good compatibility, its chemical structural formula is:

[0057]

[0058] Wherein, Lignin is the fragment structure except the guaiacol fragment in the lignin structure; x and y are the repeating unit numbers of the polycondensate, wherein x=3-20, y=3-20.

[0059] The preparation method of the above-mentioned high-efficiency water reducer with good compatibility comprises the following steps:

[0060] 1) In parts by weight, weigh 50 parts of raw material sulfonating agent sodium sulfite, 150 parts of water, 50 parts of acetone, 75 parts of modifier lignin, and 140 parts of formaldehyde;

[0061] 2) Add 50 parts of sodium sulfite and 150 parts of water into the flask, stir until completely dissolved, add 50 parts of acetone and continue to stir for 10 minutes, then add modifier lignin (purified by acid precipitation from papermaking pulping black liquor and use liquid sodium hydroxide Dissolved 75 parts of alkali-soluble acid anal...

Embodiment 3

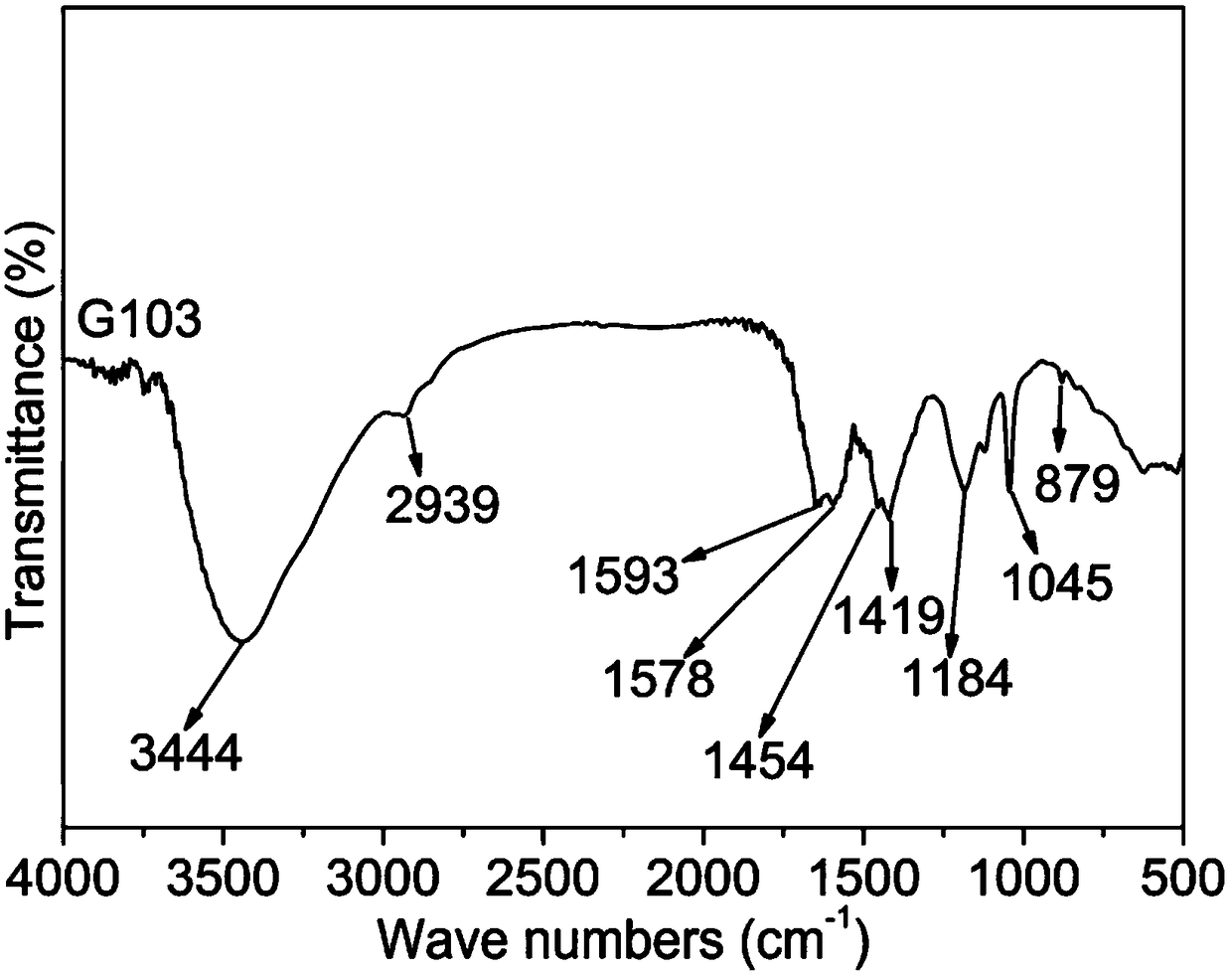

[0068] A high-efficiency water reducer with good compatibility, its chemical structure is the same as that of Example 2.

[0069] The preparation method of the above-mentioned high-efficiency water reducer with good compatibility comprises the following steps:

[0070] 1) In parts by weight, take by weighing 50 parts of raw material sulfonating agent sodium sulfite, 150 parts of water, 50 parts of acetone, 150 parts of modifier black liquor, and 140 parts of formaldehyde;

[0071] 2) Add 50 parts of sodium sulfite and 150 parts of water into the flask, stir until completely dissolved, add 50 parts of acetone and continue to stir for 10 minutes, then add 150 parts of modifier papermaking pulping black liquor (wherein the lignin content is 46.5%) and catalyst 0.2 parts, react at 40-45°C for 1 hour for sulfonation reaction;

[0072] 3) Continue to add 140 parts of formaldehyde dropwise to the solution system obtained after the sulfonation, and the dropping time is controlled at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com