Extraction method of tobramycin

A technology of tobramycin and extraction method, applied in the field of biomedicine, can solve the problems of long production cycle, difficult quality control of production process, complicated process, etc., to simplify production process, reduce environmental protection discharge and processing pressure, and shorten production effect of cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

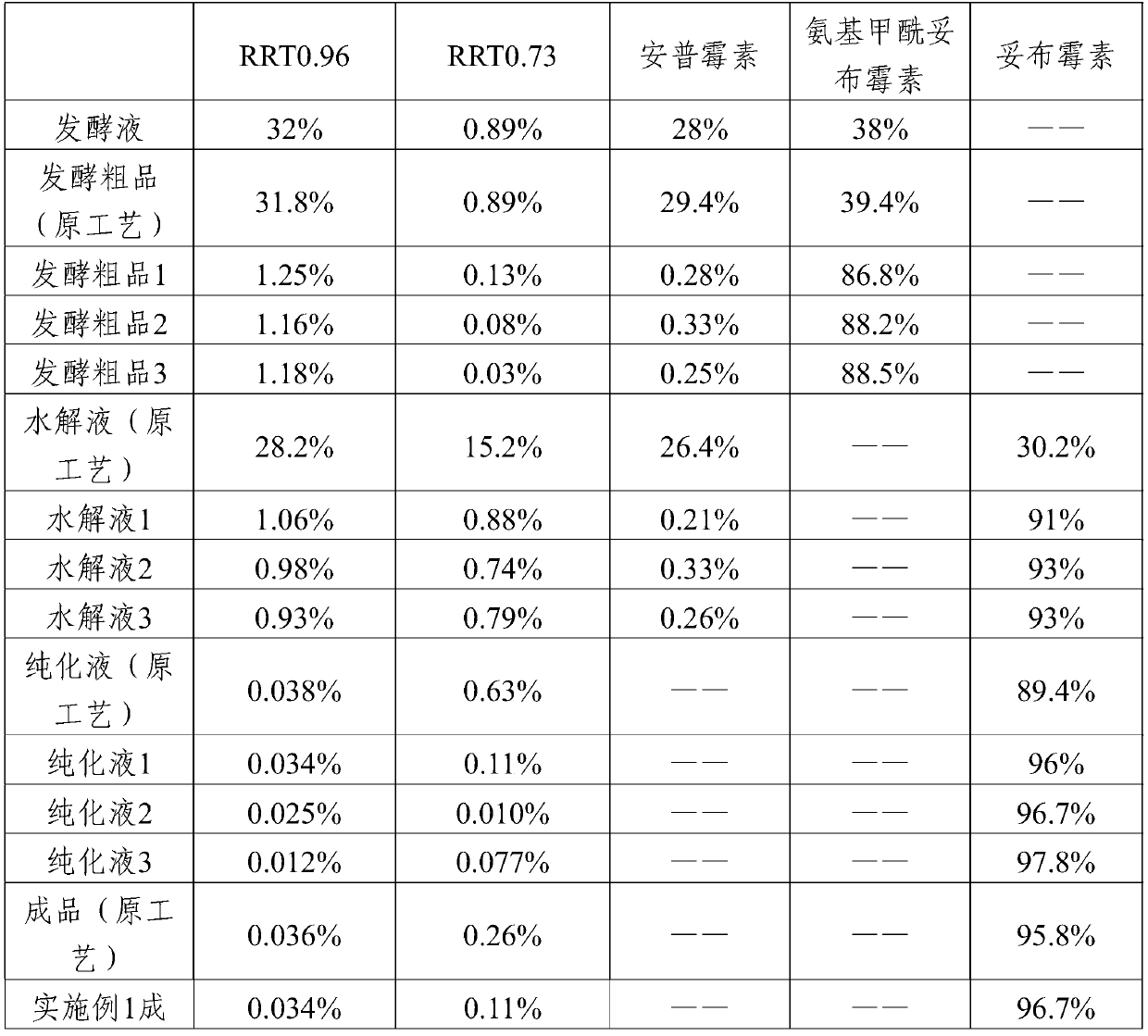

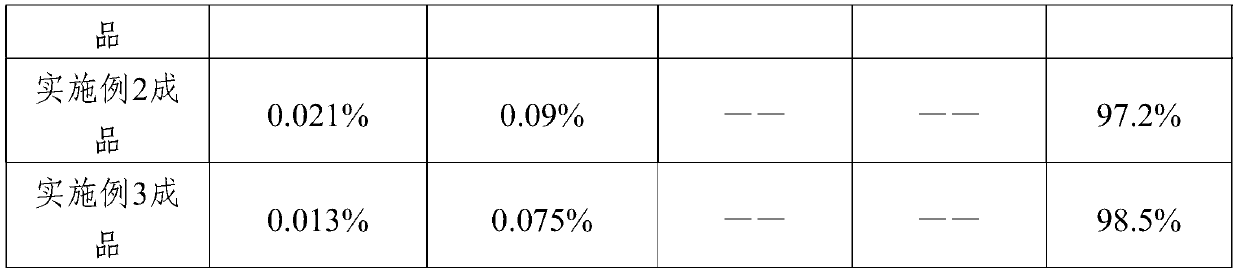

Embodiment 1

[0027] The extraction method of embodiment 1 tobramycin

[0028] 1. Adjust the fermentation filtrate (fermentation filtrate sample) of Streptomyces obscurus with ammonia water, control the pH=7.05, put the macroporous cationic resin HZ-3C into the filtrate for static adsorption, and add the resin according to 40,000 adsorption units. After the adsorption is finished, collect the resin and put it into a resin column, wash it with purified water for 8h, and then elute it with a concentration of 0.3mol / L ammonia water. During the elution process, use thin layer chromatography (TLC) to detect components. When 5 For 'carbamoyl tobramycin, replace 1.0 mol / L ammonia water for elution and collect 5' carbamoyl tobramycin (fermentation crude product 1 sample).

[0029] 2. Concentrate the collected liquid in step 1 with an ultra-nanofiltration system (first filter with an ultrafiltration membrane with a molecular weight cut-off of 5000Da, and then concentrate with a nanofiltration membra...

Embodiment 2

[0034] The extraction method of embodiment 2 tobramycin

[0035] 1. Use ammonia water to mediate the fermentation filtrate of Streptomyces obscurus, control the pH=7.20, put macroporous cationic resin HZ-3C into the filtrate for static adsorption, and calculate and add the resin according to 45,000 adsorption units. After the adsorption is completed, collect the resin and put it into the resin column, wash it with purified water for 8 hours, and then elute it with ammonia water at a concentration of 0.4mol / L. During the elution process, use TLC for component detection. When carbamoyl tobramycin appears , replace 1.5mol / L ammonia water to elute and collect carbamoyl tobramycin (fermentation crude product 2 samples).

[0036]2. Concentrate the collected liquid in step 1 with an ultra-nanofiltration system (first filter with an ultrafiltration membrane with a molecular weight cut-off of 5000Da, and then concentrate with a nanofiltration membrane with a molecular weight cut-off of...

Embodiment 3

[0041] The extraction method of embodiment 3 tobramycin

[0042] 1. Use ammonia water to mediate the fermentation filtrate of Streptomyces obscurus, control the pH=7.50, put macroporous cationic resin HZ-3C into the filtrate for static adsorption, and calculate and add the resin according to 50,000 adsorption units. After the adsorption is completed, collect the resin and put it into the resin column, wash it with purified water for 8 hours, and then elute it with ammonia water at a concentration of 0.5mol / L. During the elution process, use TLC for component detection. When carbamoyl tobramycin appears , replace 2.0mol / L ammonia water for elution and collect carbamoyl tobramycin (fermentation crude product 3 samples).

[0043] 2. Concentrate the collected liquid in step 1 with an ultra-nanofiltration system (first filter with an ultrafiltration membrane with a molecular weight cut-off of 5000Da, and then concentrate with a nanofiltration membrane with a molecular weight cut-of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com