Rotary kiln body pair-combining splicing-assembly alignment device and construction method

A construction method and technology of rotary kiln, applied in auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult to precisely control spacing, deviation of kiln body roundness, heavy diameter and weight, etc., so as to reduce construction costs and improve work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

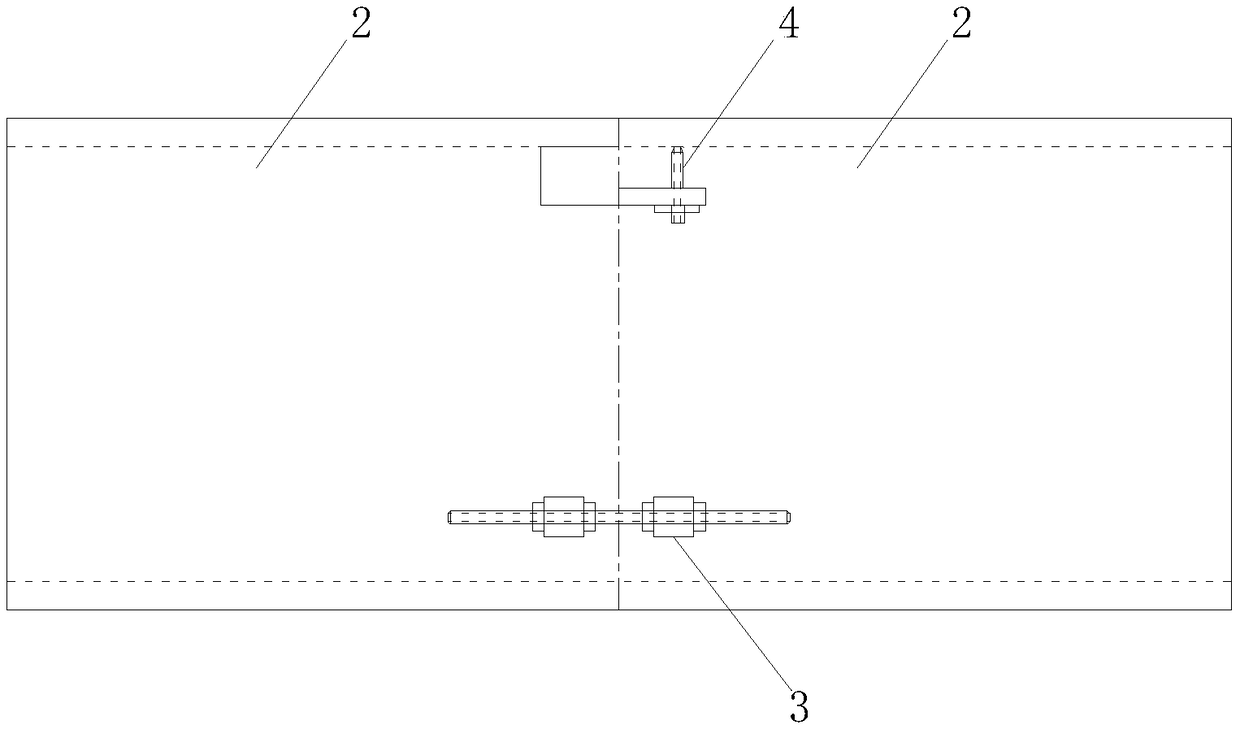

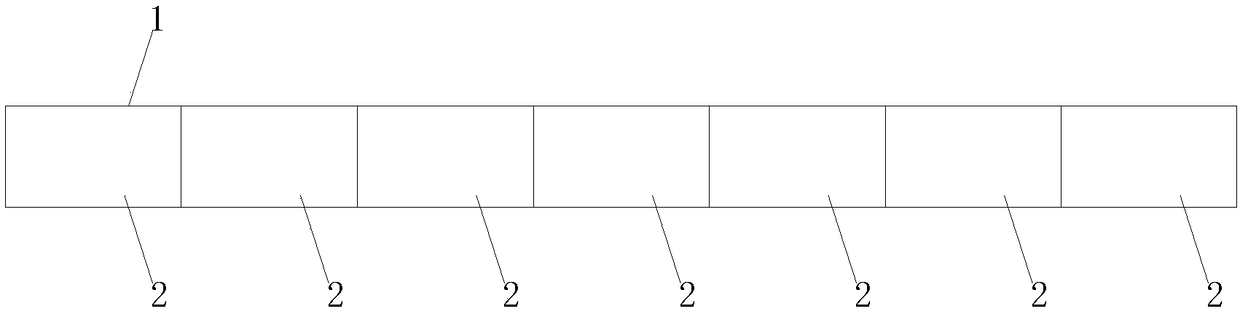

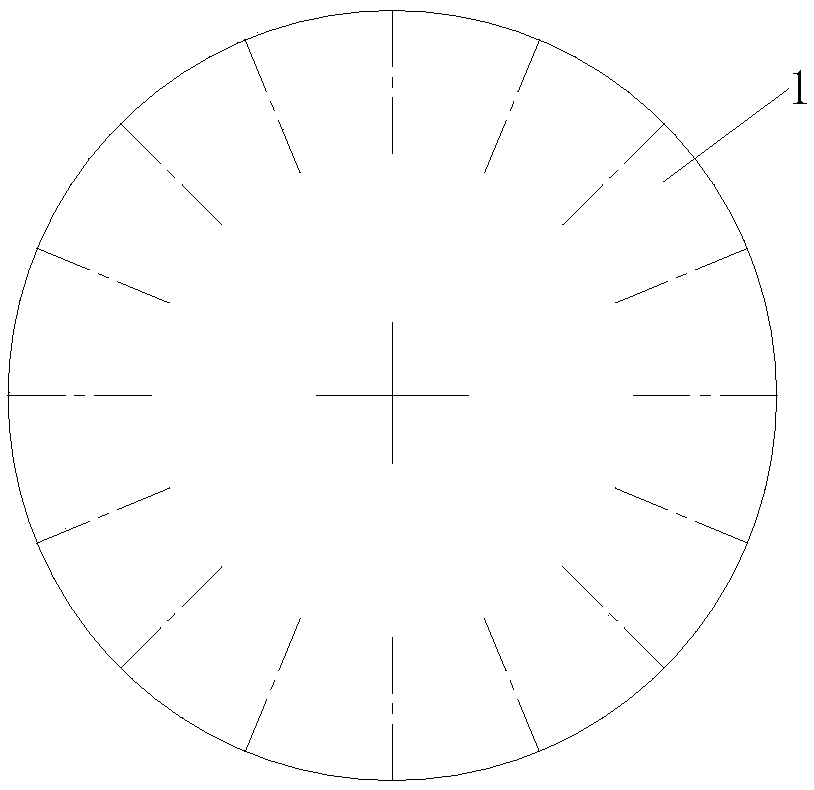

[0032] From Figure 1-5 It can be seen that a rotary kiln body assembly alignment device of this embodiment includes a cylinder body 1, the cylinder body 1 is composed of seven cylinder sections 2, and the inner surfaces of the cylinder sections 2 are respectively equipped with longitudinal adjustment devices 3 and the radial adjustment device 4, the longitudinal adjustment device 3 is composed of a fixed support 31, an inner nut 32, a fixed screw rod 33 and an outer nut 34, the fixed supports 31 are arranged at intervals on the inner surface of the cylinder section 2, and the fixed supports 31 are composed of four The steel plates are welded to each other into a "mouth" shape, and one side of the fixed support 31 is inserted with a fixed screw 33, and the outer ring of the fixed screw 33 is also respectively sleeved with an inner nut 32 and an outer nut 34, and the fixed screw 33 passes through the inner nut 32. 1. Assemble the outer nut 34 with the fixed support 31, loosen t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com