Zinc concentrate oxygen pressure acid leaching high-sulfur slag safety analysis method

A technology of oxygen pressure acid leaching and analysis method, which is applied in the field of safety analysis of zinc concentrate oxygen pressure acid leaching high-sulfur slag, can solve problems such as complex occurrence characteristics of toxic elements, achieve a comprehensive understanding of ignition characteristics, reduce errors, and alleviate The effect of environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0076] 1 Determination of ignition point

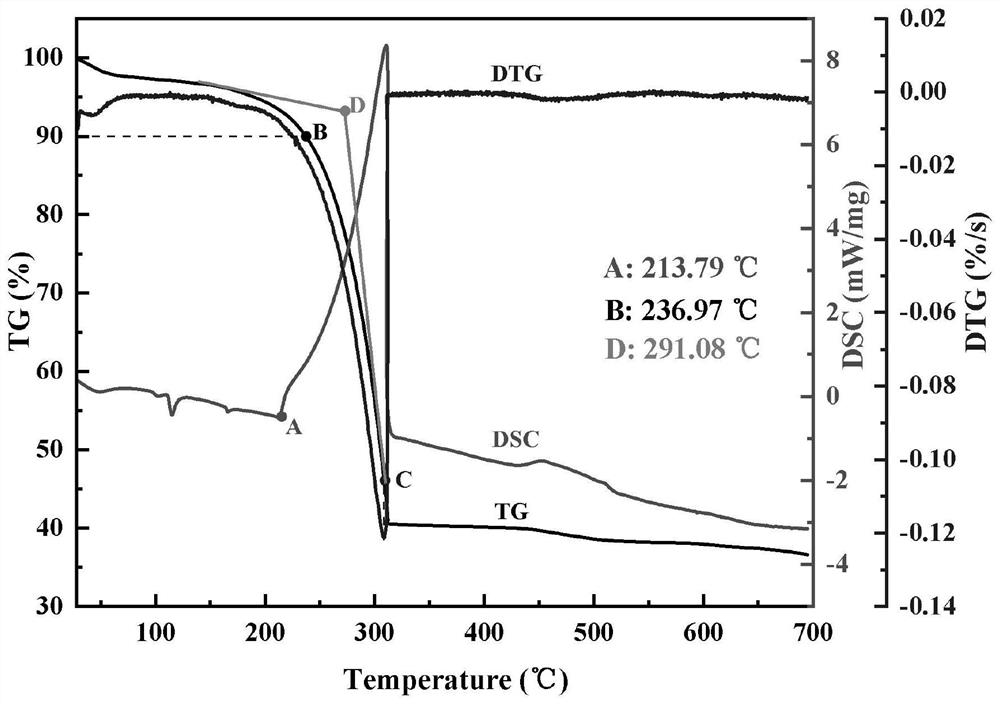

[0077] 1.1 Using the Mettler 1100LF thermogravimetric analyzer to obtain the thermogravimetric curve of oxygen pressure acid leaching high sulfur slag in a large-scale wet zinc smelting plant in South China at a heating rate of 5°C / min in the air environment, as shown in figure 1 shown.

[0078] 1.1 Fixed weight loss method: the temperature point corresponding to the point on the combustion curve when the weight loss rate reaches 10% is defined as the ignition point, such as figure 1 Shown at point B. According to this definition, the ignition temperature of high-sulfur slag is 236.97°C.

[0079] 1.2 TG-DTG method: Select the minimum peak point on the DTG curve as a vertical line intersecting with the TG line at point C, which is the abrupt combustion point. The intersection point D of the tangent line passing through point C of the TG curve and the parallel line at the beginning of weight loss corresponds to the ignition temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com