Printable magnetized composite film and preparation method thereof

A composite film and printing layer technology, which is applied to magnets, magnetic objects, flat products, etc., can solve the problems of increasing material cost and adhesive process cost, affecting the service life of printing materials, and limited adhesiveness of double-sided adhesive. Achieve the effect of saving material cost and adhesive process cost, improving anti-aging properties and increasing areal density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The composite film is mainly divided into three layers: the upper layer is the protective layer, the middle layer is the magnetic receiving layer, and the lower layer is the printing layer. The protective layer is used to protect the magnetic receiving layer. The specific material is varnish, and the thickness of the protective layer is 1 micron. , the thickness of the magnetic layer is 0.05 mm, and the printing layer is PVC film.

[0035] The magnetic receiving layer is a composite material composed of soft magnetic powder, polymer binder and auxiliary materials, wherein the soft magnetic powder is Mn-Zn ferrite powder, and the average particle size of the ferrite powder is 2.3 microns; The binder is polyurethane; the auxiliary material is a silane coupling agent.

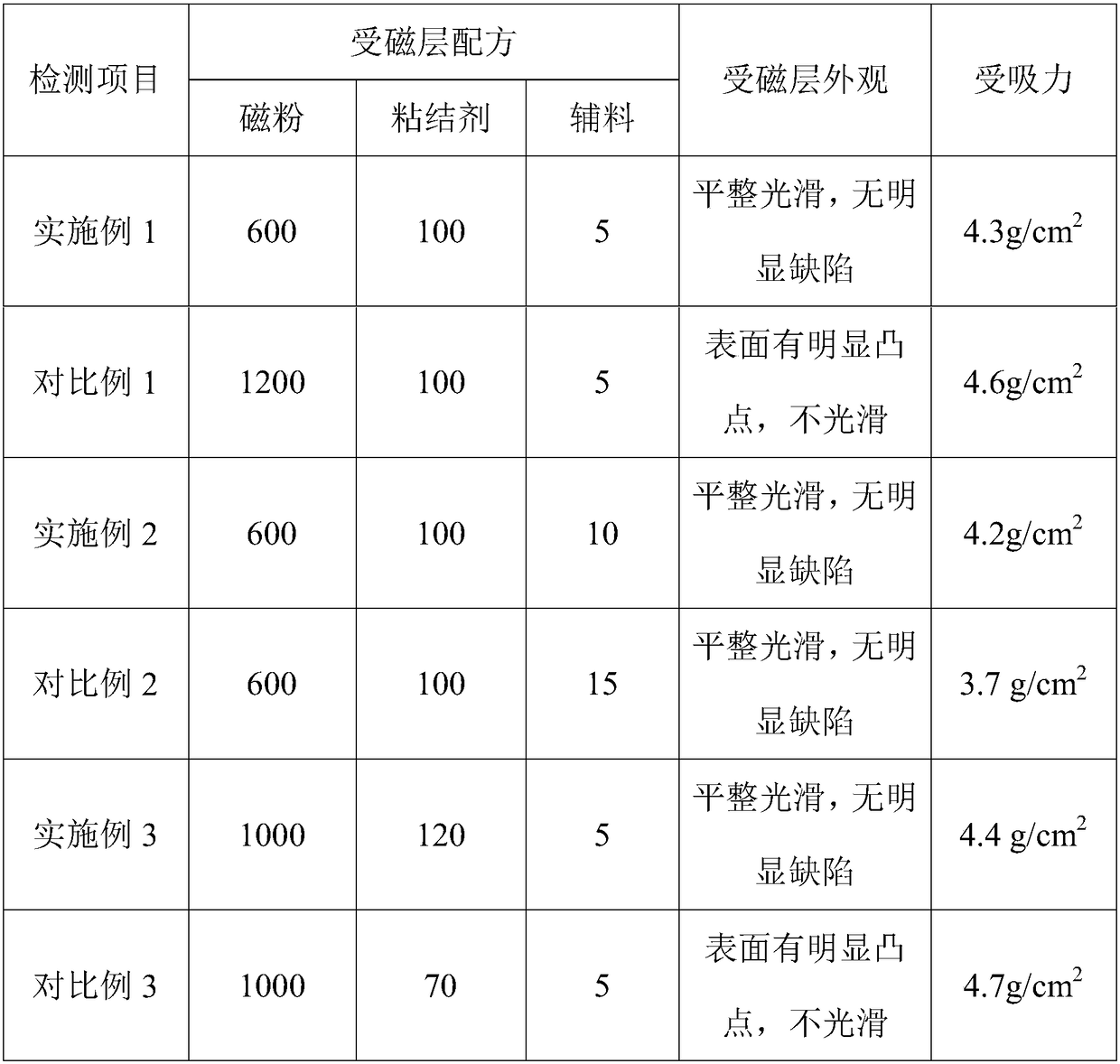

[0036] In parts by weight, the magnetic receiving layer contains 600 parts of soft magnetic powder, 100 parts of polymer binder, and 5 parts of auxiliary materials.

[0037] The preparation method is as fo...

Embodiment 2

[0046] The difference from Example 1 is that the magnetic receiving layer contains 600 parts of soft magnetic powder, 100 parts of polymer binder, and 10 parts of auxiliary materials. Other processes and formulations are the same as in Example 1.

Embodiment 3

[0048] The difference from Example 1 is that the magnetic receiving layer contains 1000 parts of soft magnetic powder, 120 parts of polymer binder, and 5 parts of auxiliary materials. Other processes and formulations are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com