Bent product

A bending and bending technology, applied in the field of bending products, can solve problems such as core material deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

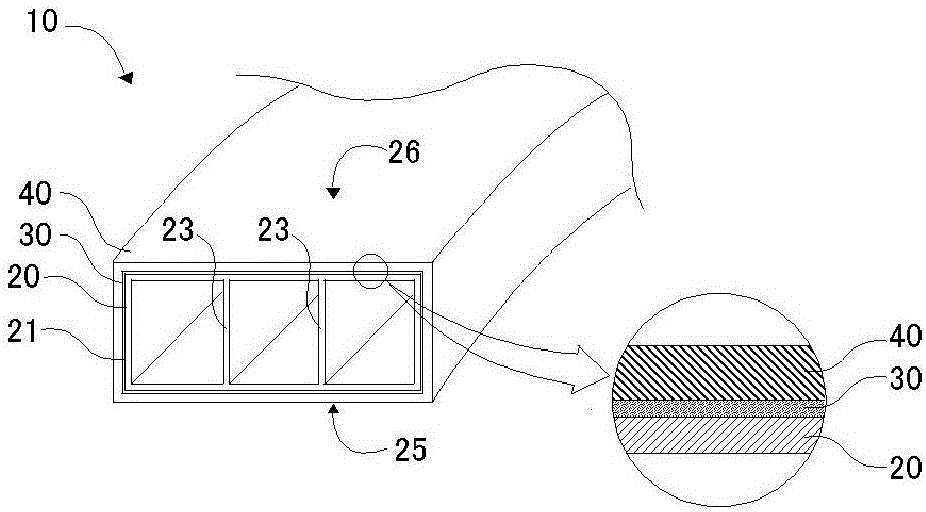

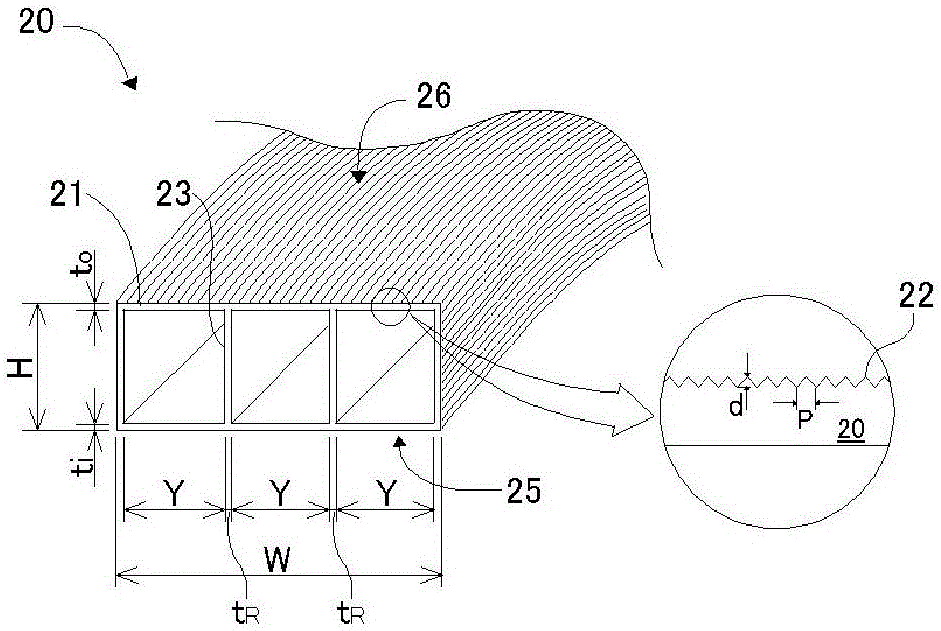

[0142] As a hollow core material, it is manufactured by extrusion molding such as figure 2 The cross-section shown is a generally rectangular hollow aluminum core. However, the number of partition walls was 1, 2, 3, or 6, respectively, depending on the examples and comparative examples. Grooves extending in the longitudinal direction were formed on the aluminum core material by knurling, and then an oxide film was formed by aluminum oxide film treatment (without sealing treatment). As for the material of the aluminum alloy, an aluminum alloy having an extrusion grade of alloy number 6063 was used. The groove pitch is 0.5mm, and the groove depth is 0.1mm. Alumina film treatment uses the sulfuric acid method.

[0143] For the pellets (pellets) for the coating layer, in 100 parts by weight of maleic acid-modified polypropylene resin (maleic acid content is about 2% by weight, melting point is 150°C, MFR is about 10g / min), 30 parts by weight of wood powder (with a particle si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com