Flame retardant, flame-retardant resin composition and method for producing flame retardant

A technology of resin composition and flame retardant resin, applied in the field of flame retardants, can solve the problems of discolored appearance of resin composition, decreased mechanical strength of resin, brittle resin, etc., and achieves the effect of not producing appearance defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

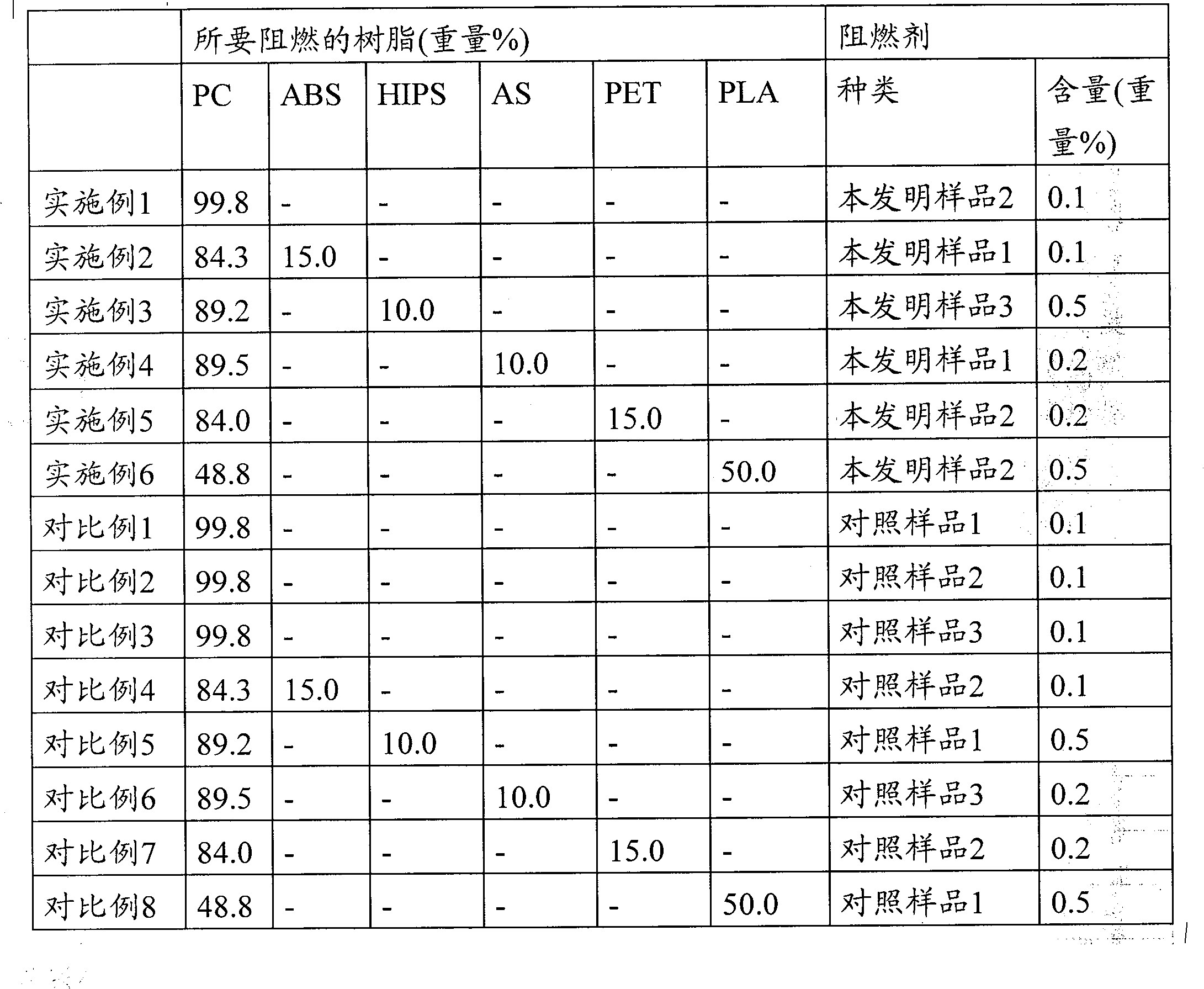

[0105] In Example 1, 99.8 parts by weight of polycarbonate resin (bisphenol A) hereinafter referred to as PC as the resin to be flame-retardant, 0.1 part by weight of the sample 2 of the present invention as a flame retardant, and 0.1 parts by weight of the following Polytetrafluoroethylene having fibril-forming properties, referred to herein as PTFE, was mixed together as an anti-dripping agent to prepare a flame retardant resin precursor. This flame retardant resin precursor is supplied to an injection molding machine, kneaded and pelletized at a predetermined temperature. The pellets thus prepared are charged into an extruder and injection molded at a predetermined temperature. Thus, a 1.5 mm-thick bar-shaped test piece formed of the flame-retardant resin composition was prepared.

Embodiment 2

[0107] In Example 2, a bar-shaped test piece was prepared in the same manner as in Example 1 above, except that 84.3 parts by weight of PC and 15 parts by weight of an acrylonitrile-butadiene-styrene copolymer hereinafter referred to as ABS resin Resin (acrylonitrile / butadiene / styrene weight ratio = 24 / 20 / 56) as the resin to be flame-retardant, 0.1 part by weight of the present invention sample 1 as a flame retardant, 0.5 part by weight of a polymer hereinafter referred to as SI Methylphenylsiloxane was mixed as a silicon-based flame retardant (used as another flame retardant), and 0.1 parts by weight of PTFE as an anti-dripping agent to prepare a flame retardant resin precursor.

Embodiment 3

[0109] In Example 3, strip test pieces were prepared in the same manner as in Example 1 above, except that 89.2 parts by weight of PC and 10 parts by weight of rubber-modified polystyrene (polybutadiene, hereinafter referred to as HIPS resin) / polystyrene weight ratio=10 / 90), 0.5 parts by weight of the sample 3 of the present invention as a flame retardant, and 0.3 parts by weight of PTFE as an anti-dripping agent were mixed to prepare a flame retardant resin precursor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com