Casting method of S-channel depleted uranium shielding body

A technology for shielding and depleted uranium, which is applied in metal material coating process, fusion spraying, coating, etc., can solve the problems of high brittleness, high hardness, and easy generation of holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

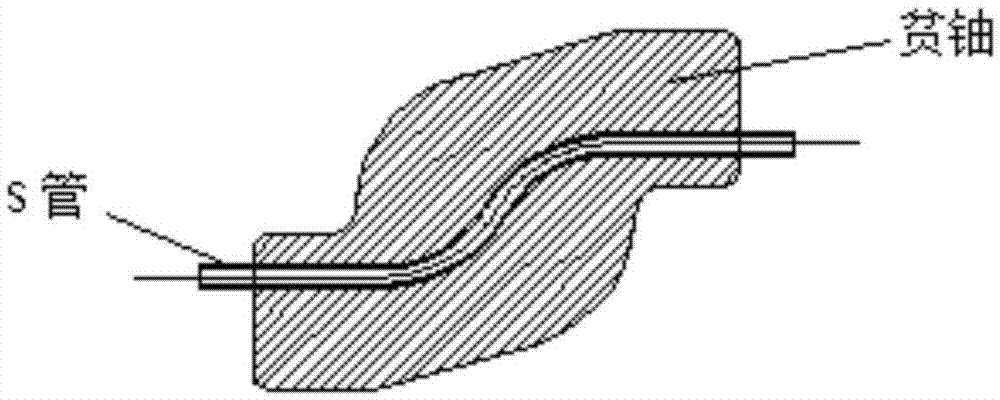

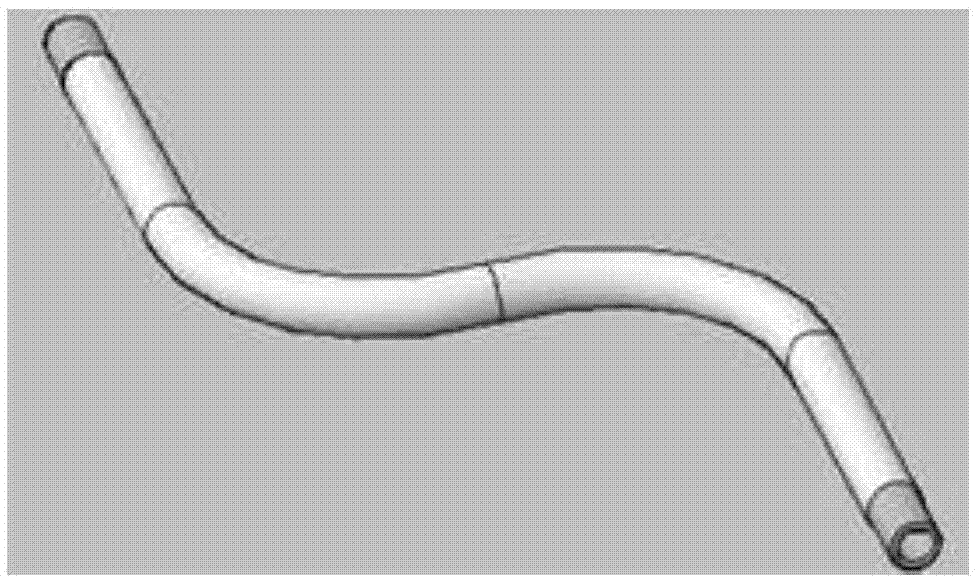

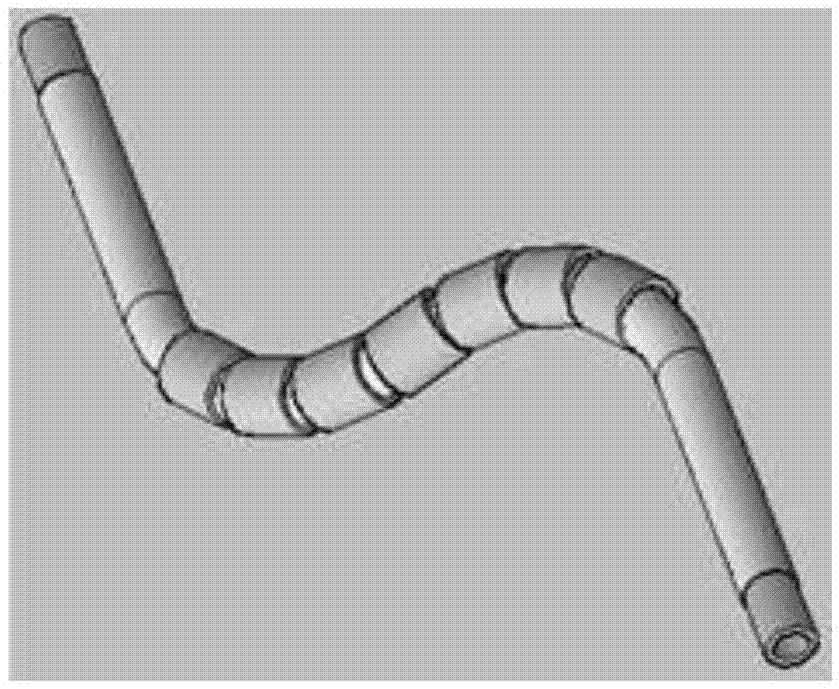

[0018] like figure 1 As shown, the S channel is wrapped with a certain thickness of depleted uranium metal outside the S-shaped stainless steel tube. The casting method used is to inject the depleted uranium metal liquid into the graphite mold, and at the same time, wrap the S-shaped stainless steel tube put in the mold before solidification. During this process, it is necessary to ensure that the shape of the S-shaped stainless steel tube does not change, and the position in the mold does not change. After solidification, a complete S-shaped cavity is formed inside the product, and the cavity can pass through steel balls with a diameter of Φ9.5 without hindrance. There are no casting defects such as shrinkage cavity and porosity inside the casting, which can achieve the purpose of completely shielding the radioactive source. The S-channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com