Spray method for carbon-doped coating on spherical surface

A spherical surface, carbon coating technology, applied to the surface coating liquid device, coating, pretreatment surface, etc., can solve the problems of coating appearance quality defect, long coating transportation path, poor uniformity of coating thickness, etc. , to achieve the effect of improving appearance quality and thickness uniformity, improving appearance quality and thickness uniformity, and improving coating thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

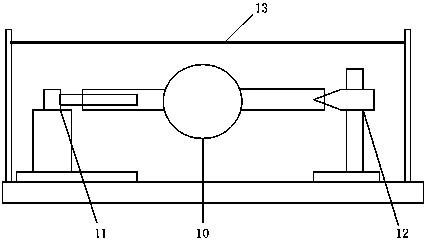

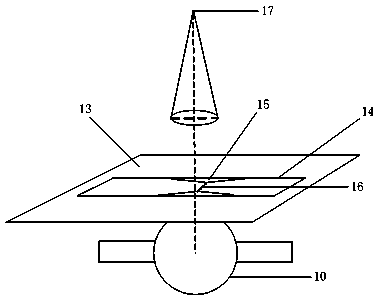

[0024] The sample is a spherical workpiece, the diameter of the ball: SΦ=60mm, the surface roughness: Ra0.3μm, and the specific operation steps are:

[0025] (1) The manual spray gun is clamped on the robot arm;

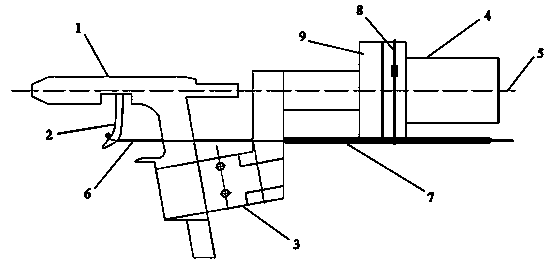

[0026] Disassemble the automatic spray gun from the robot arm, carry out reasonable tooling design according to the flange 9 interface, and fix the manual spray gun 1 on the robot arm 4 through the connecting tool 3, which requires the axis 5 of the gun nozzle and the gun body and the robot arm 4 The axes 5 are consistent to ensure the movement and positioning accuracy. The method of flexible connection is used to punch a hole on the trigger 2 of the spray gun, tie the nylon wire 6 to the trigger 2, and pass the other end through the elongated rubber sleeve 7 with certain rigidity. The rubber sleeve 7 is fixed on the robot arm 4 with a wire brake 8 along the direction in which the spray gun trigger 2 is pulled, and the staff can grasp the end of the rubber sleeve at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com