Construction method for connecting floor slabs and wall surface joints of multilayer light steel structure building

A light steel structure and node connection technology, which is applied to floors, buildings, building components, etc., can solve the problems of long cycle time and low construction assembly rate, and achieve the effects of convenient installation, reduced construction costs, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

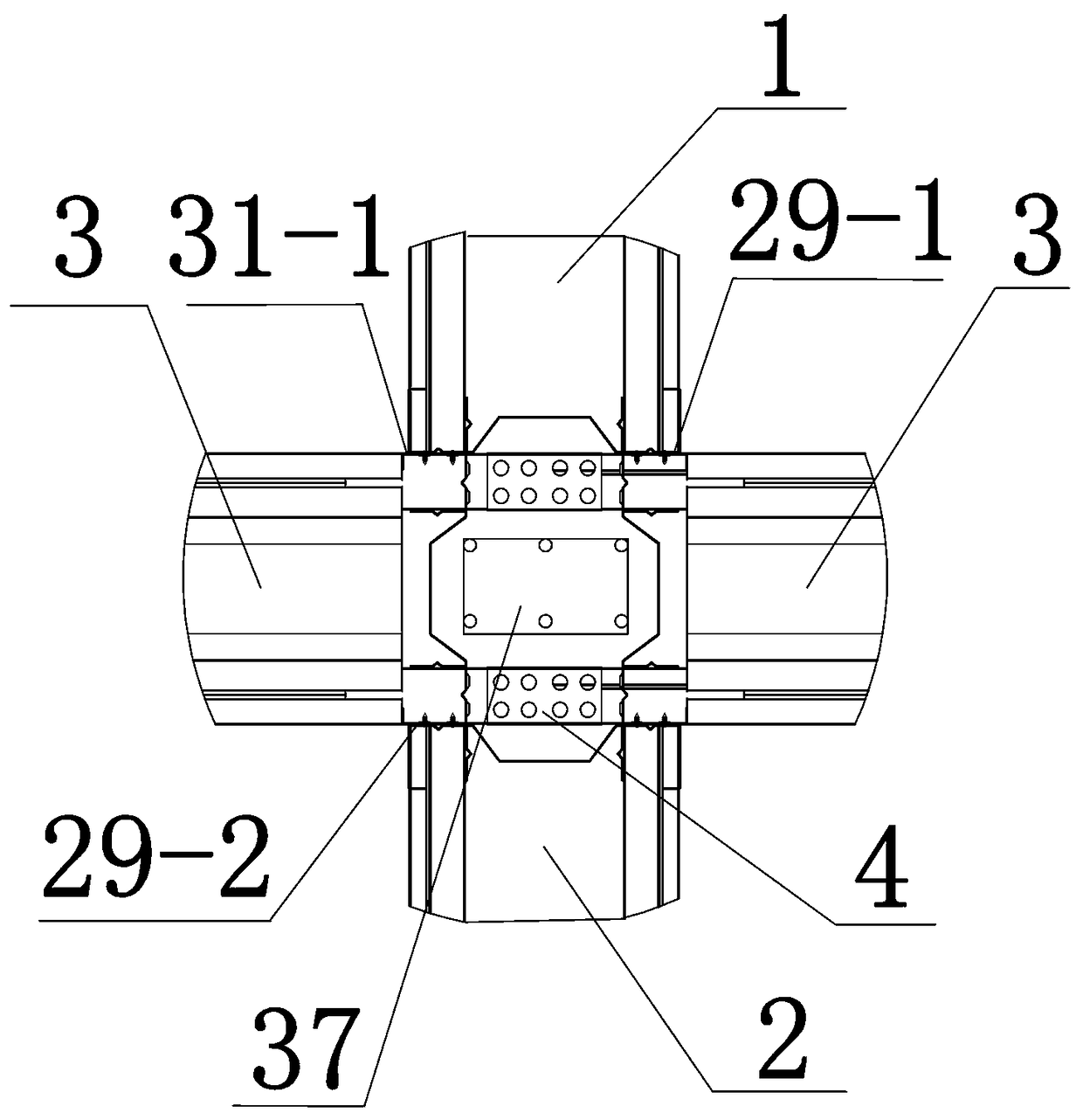

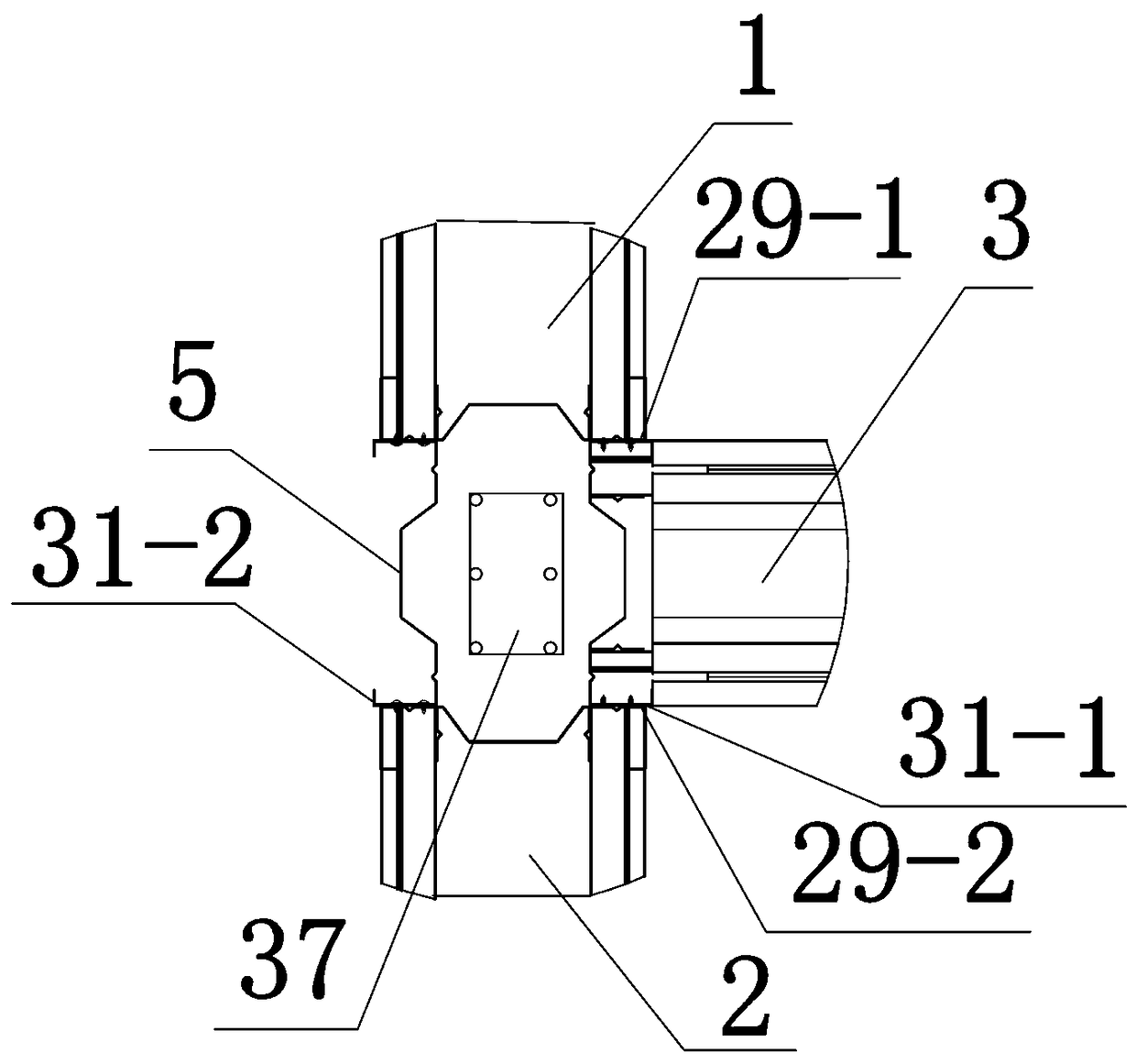

[0049] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

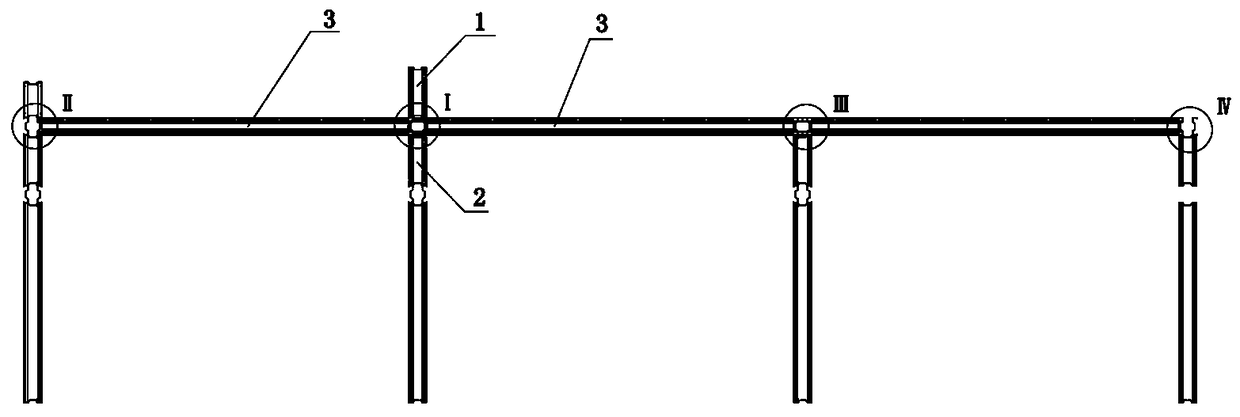

[0050] Such as Figure 1-13 As shown, the multi-layer light steel structure building floor of the present invention is characterized in that comprising the following steps:

[0051] (1) Modular production of floor structure of light steel structure assembly building;

[0052] The floor structure module includes a floor steel structure, and a floor decorative plate structure 13 covering the surface of the floor steel structure. The floor steel structure includes two floor vertical frames 9, connected to the two through corner connectors I and II. The two floor transverse frames 10 connected by the floor vertical frame 9 are horizontally arranged in a group of crossbeams 11 in the frame formed by the floor vertical frame 9 and the floor transverse frame 10, and this group of crossbeams 11 are interlaced and arranged on A group of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com