Preparing method for interlayer compounding gradient-controllable complex part and special device

A technology of complex parts and special equipment, applied in metal processing equipment, additive manufacturing, manufacturing tools, etc., can solve the problems of undeveloped multi-material composite molding process and special equipment, single performance, and limited functions, so as to achieve easy promotion and Effects with many applications and types and strong compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

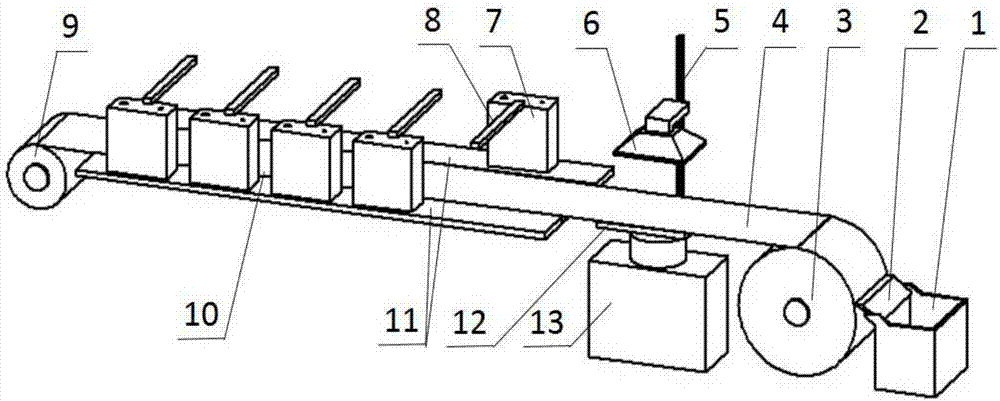

[0040] Figure 5 The process block diagram of the preparation method provided by the present invention, the method specifically includes the following steps:

[0041]1) Use 3D modeling software to generate a 3D solid model of the part in the control unit, convert the data into an STL file, and design the thickness of each layer of the printed model, and use layering software to divide it into multiple thin layers. Each layer in the layer corresponds to a corresponding material, and the layer thickness is set according to the corresponding material properties, and the layer thickness is preferably 10-200 μm;

[0042] 2) Place the prepared different light-curing materials in each material box, and the control unit selects and sets the material used for each thin layer; the light-curing material is pure photosensitive resin, fiber or whisker added Photosensitive resin, photosensitive resin with nano filler added, photosensitive ceramic paste or photosensitive metal paste;

[00...

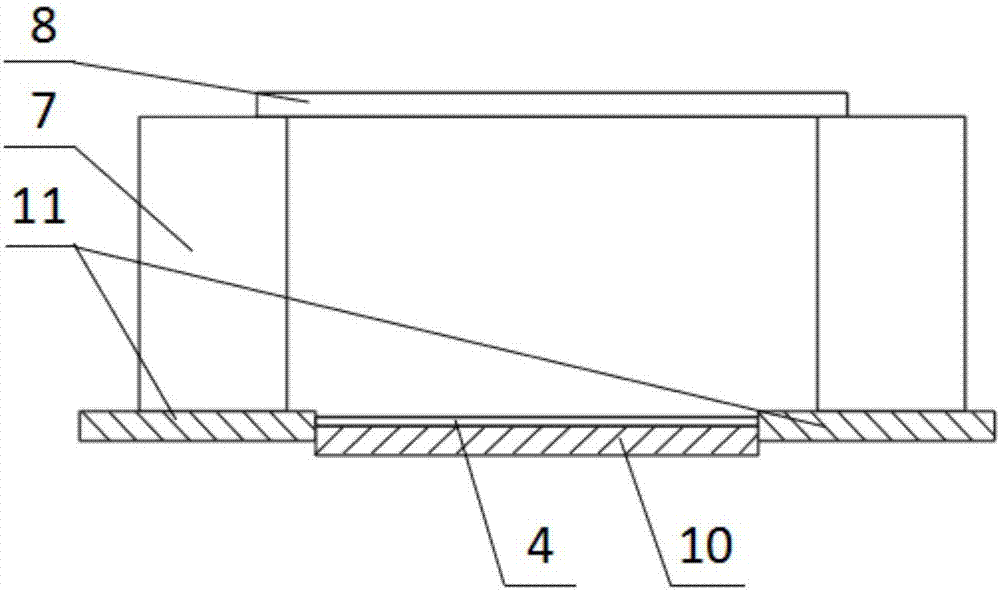

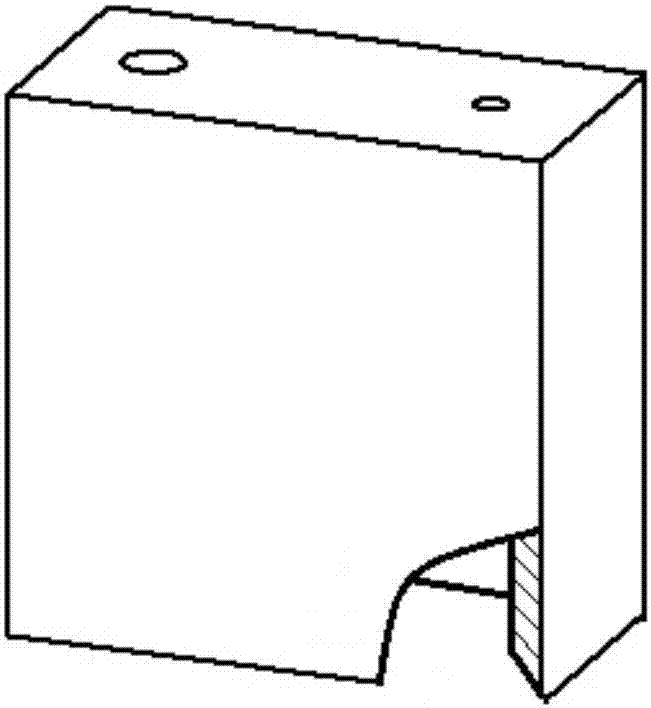

Embodiment

[0047] Embodiment: use three-dimensional modeling software to generate parts in computer ( Figure 7 ), the 3D modeling software can choose Pro / E or Solidworks, and convert the data into STL files; use layering software to layer it, and the thickness of the layers can be 10-500 μm to obtain the shape of each layer structure. Input the material box number corresponding to the material to be called into the computer. Such as Figure 6 As shown, the material boxes 7 are numbered a, b, and c from left to right. The material box a is pure photosensitive resin, the material box b is photosensitive resin with glass fiber added, and c is photosensitive resin with nano filler added. The thicknesses of slices corresponding to the materials were 100 μm, 50 μm and 80 μm, respectively. Firstly, the material box a is called to control its movement from one side of the film 4 to the other side to spread the material, and a layer of 200 μm pure photosensitive resin coating 14 is formed on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com