Double-wire welding method

A welding method and welding groove technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of large heat input in submerged arc welding, welding deformation, cumbersome procedures, etc., and achieve the effect of low heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

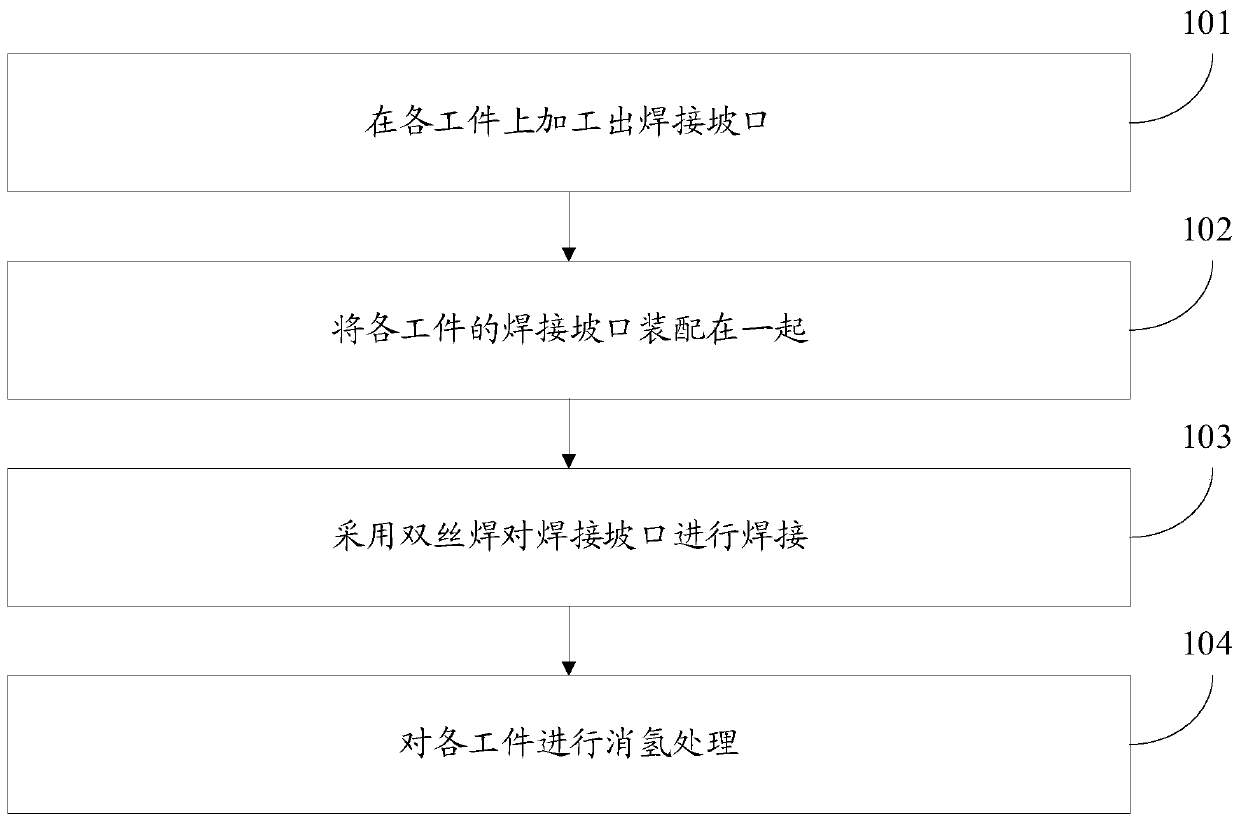

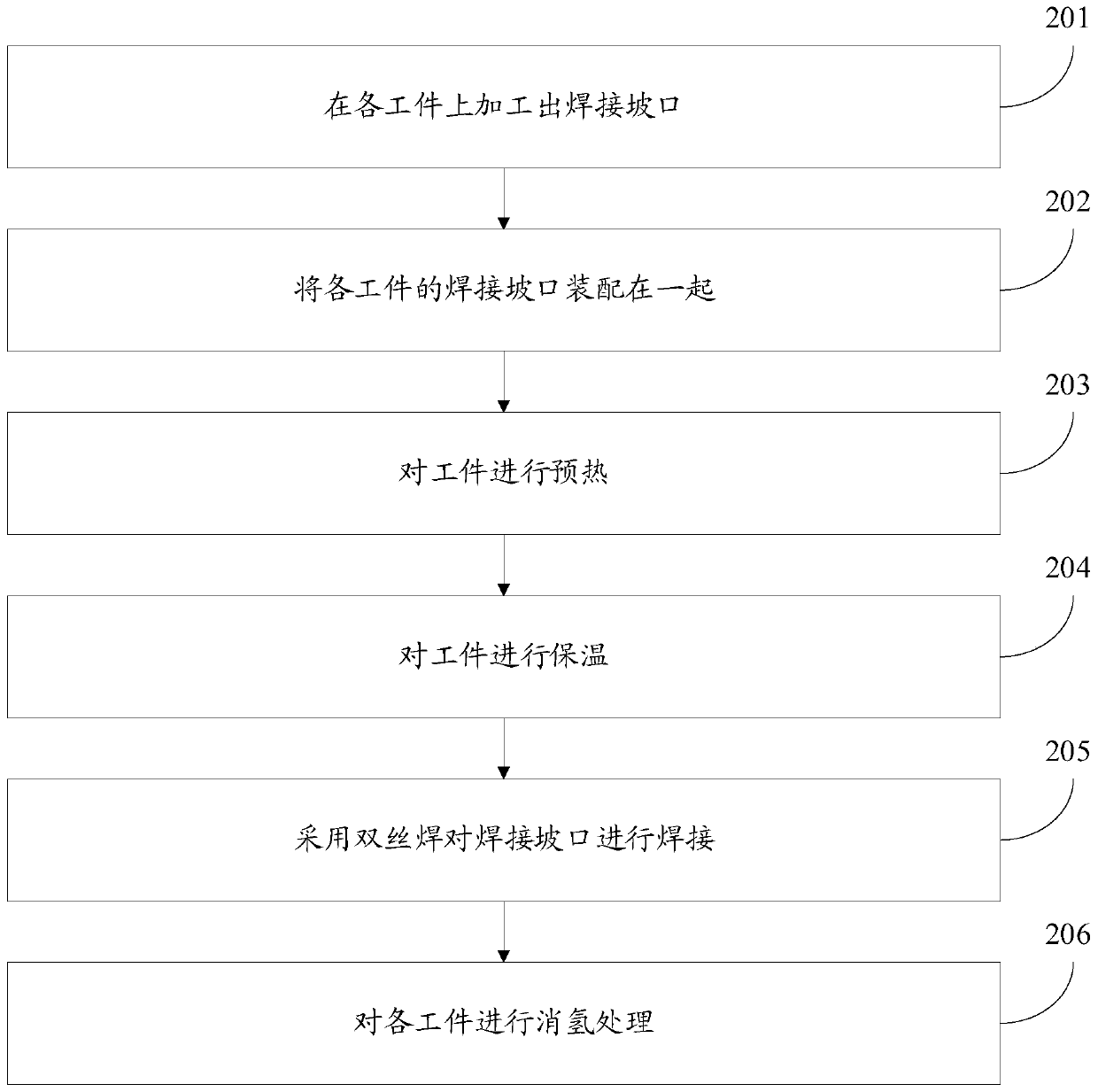

[0034] The embodiment of the present invention provides a kind of twin-wire welding method, and this method is applicable to EQ70 high-strength steel, such as figure 1 As shown, the welding method includes:

[0035] Step 101: Process welding grooves on each workpiece.

[0036] Step 102: Assemble the welding grooves of the workpieces together.

[0037] In the above implementation mode, when two workpieces need to be welded together, the welding grooves of the two workpieces can be butted together, and the welding grooves of the two workpieces can be positioned and docked by means of clamping tooling or spot welding Together, the specific positioning manner is not limited in this application.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com