Steel pipe glass curtain wall system

A glass curtain wall and steel pipe technology, applied to walls, building components, buildings, etc., can solve the problems of rising curtain wall construction costs, large cross-sectional size, and loss of competitive advantages, and achieve the effects of convenient construction, beautiful appearance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific implementation plan

[0026] The present invention will be described in detail below in conjunction with specific drawings and embodiments.

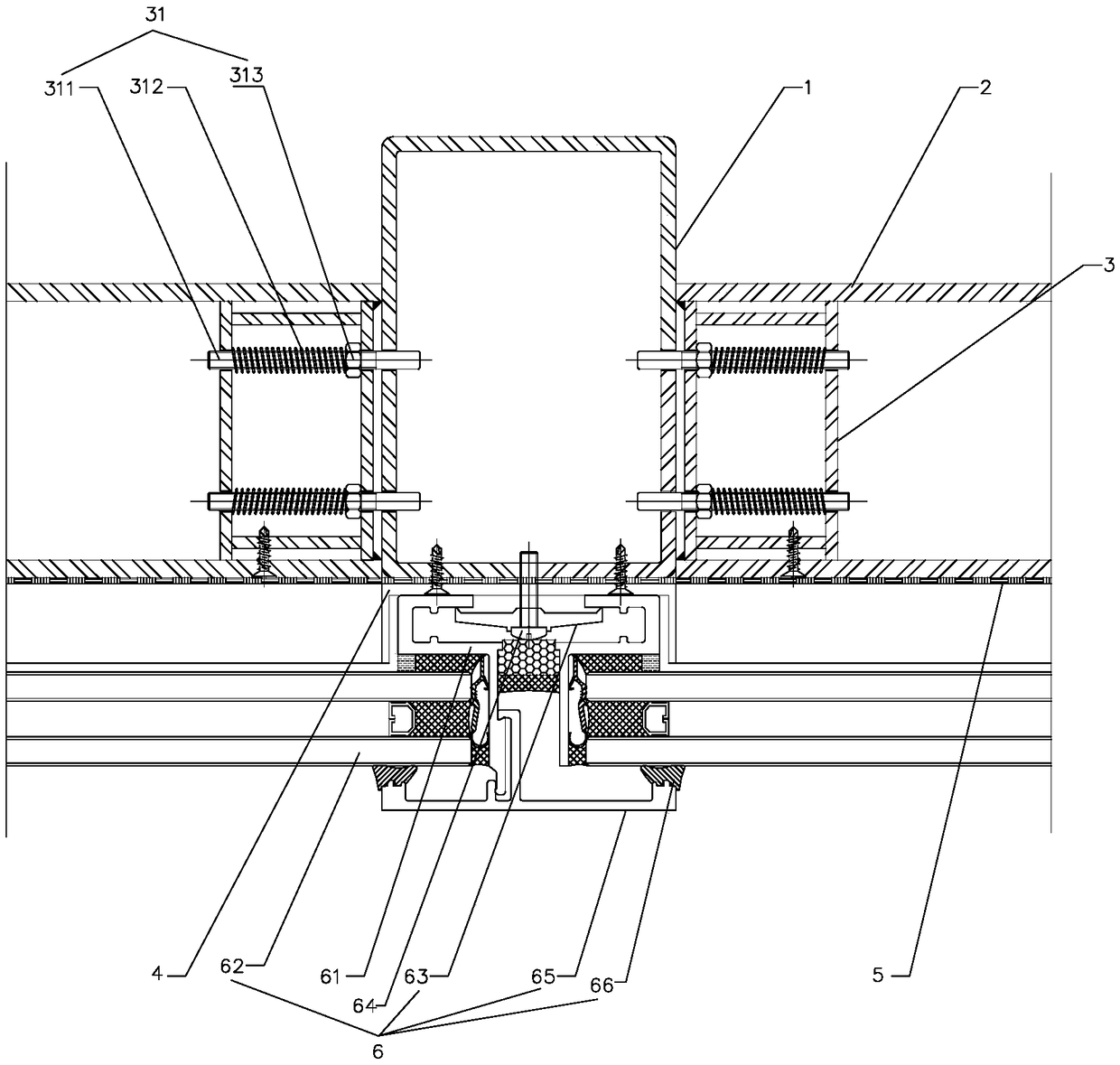

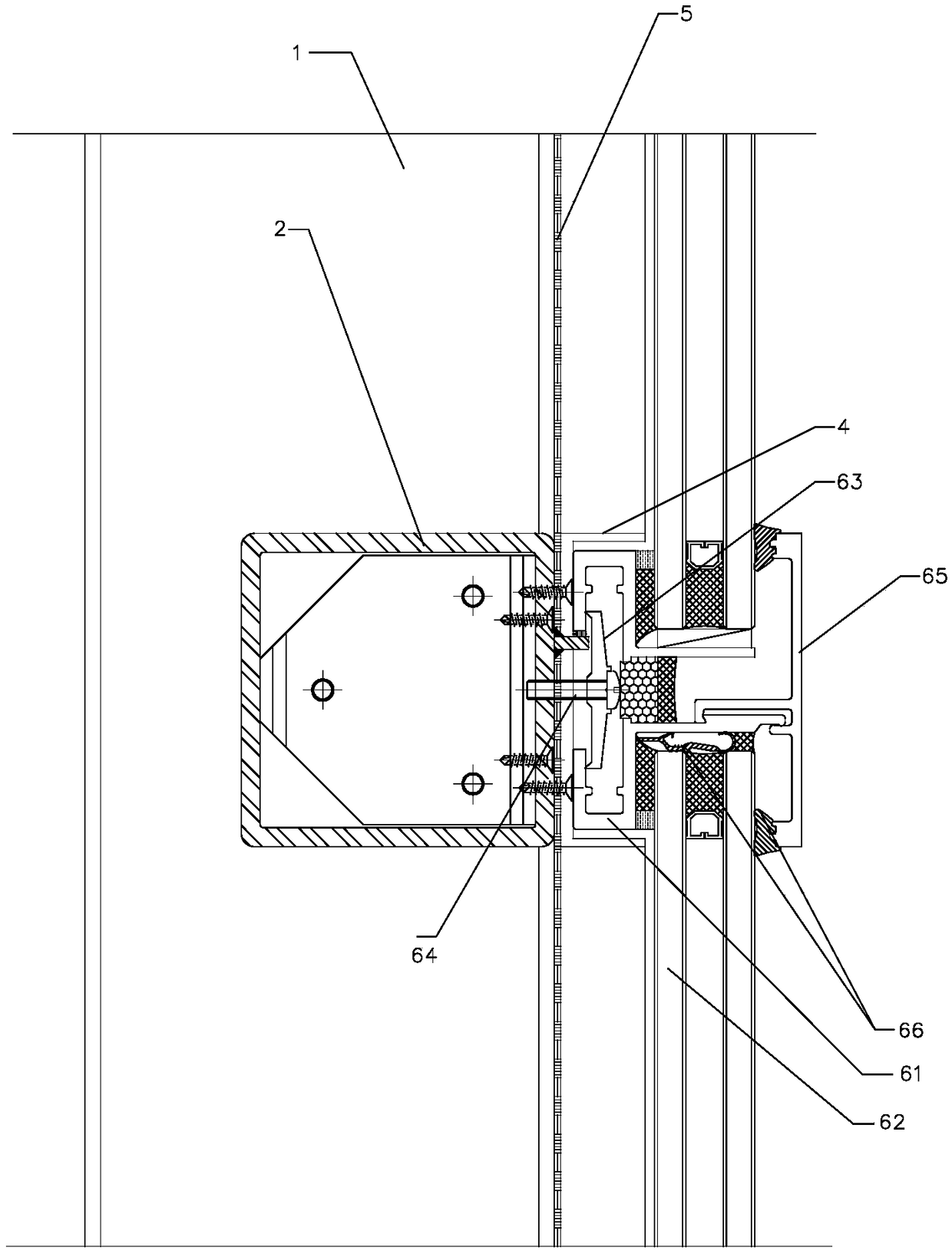

[0027] reference figure 1 This embodiment provides a steel tube glass curtain wall system, which includes a beam 2, a column 1, and an aluminum alloy fixing member 6 at the front end of the beam 2, the column 1, the beam 2 is a square steel tube, and the column 1 is a rectangular steel tube; A mechanical connection is formed with the beam 2 through a connecting piece 3 with a spring screw 31 installed.

[0028] Specifically, first, the connecting piece 3 is fixed on the inner walls of the two ends of the cross beam 2 in the width direction by welding. The connecting member 3 is provided with first connecting holes at both side walls along the longitudinal direction of the beam 2, and the two side walls of the column 1 along the width direction are respectively provided with second connecting holes corresponding to the first con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com