Submerged-arc welding technology of big-thickness low-temperature steel plate with yield strength of 690MPa grade

A yield strength, submerged arc welding technology, used in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of low strength of welded joints, restricted development, strong delayed crack sensitivity, etc., and achieve high strength and low temperature impact toughness. Good, preventing serious welding deformation and overcoming cold crack sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

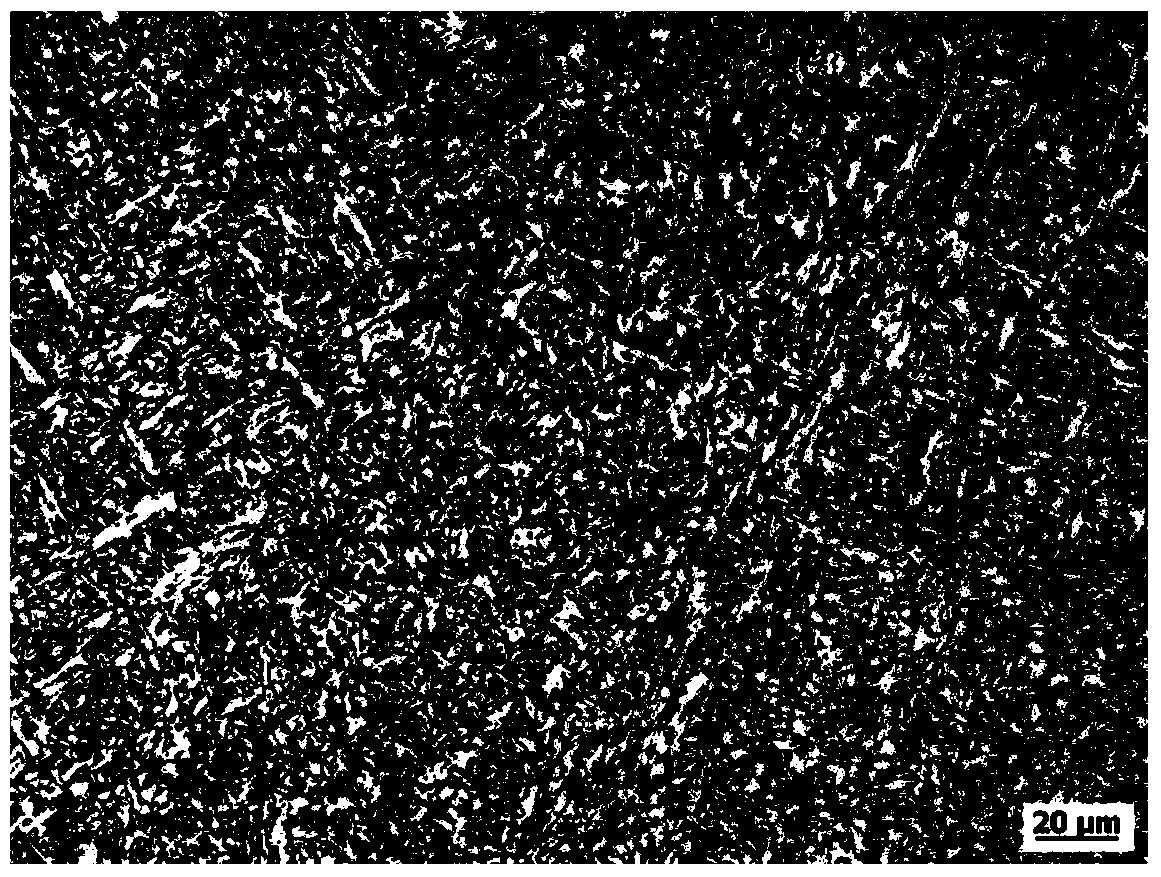

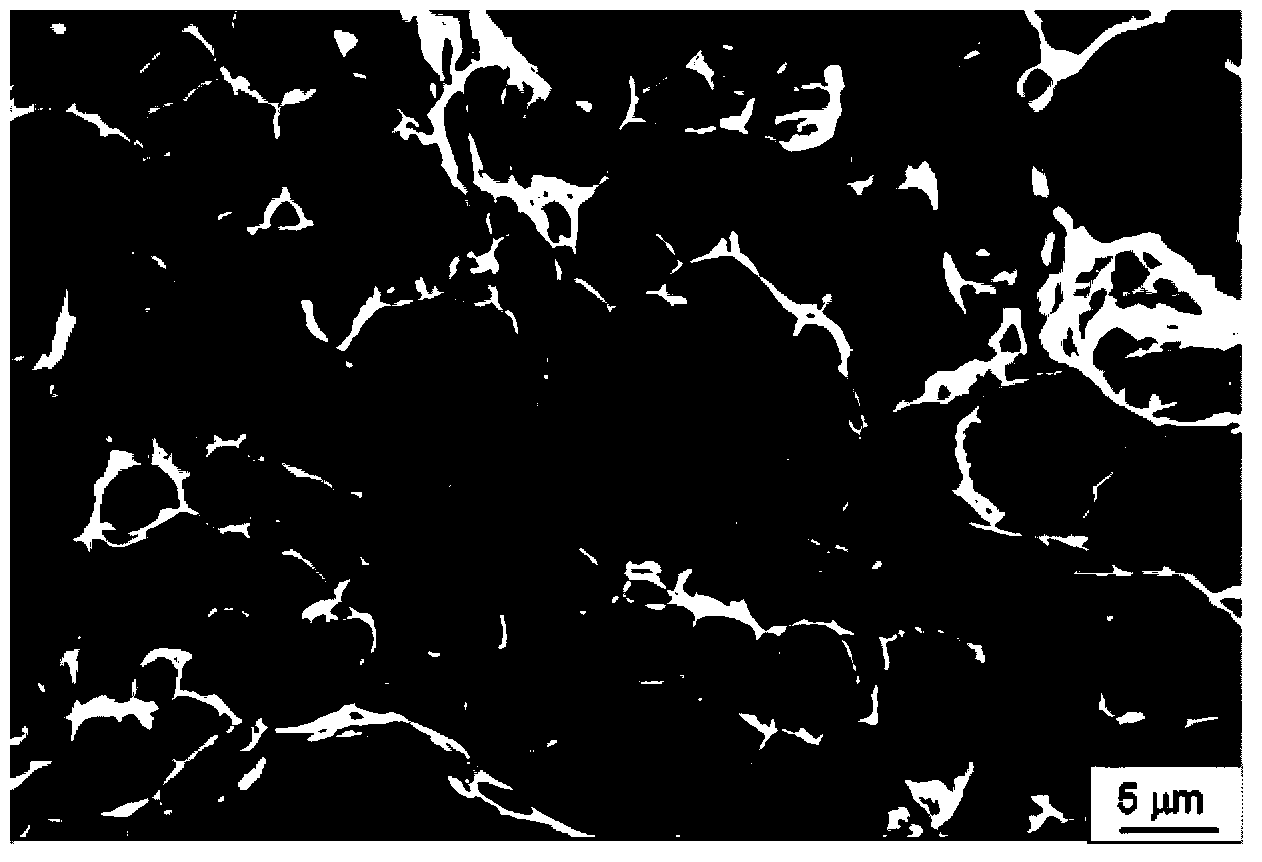

[0022] The thickness of the substrate steel plate is 100mm thick quenched and tempered steel plate F690, the yield strength is 730MPa, the tensile strength is 860MPa, the elongation is 16%, and the impact energy at -60°C is 305J. The size of the welding plate is 1000mm (length) × 500mm (width); the groove is a symmetrical double U shape, the groove angle is 35°, the thickness of the blunt edge is 4.5mm, and the gap between the blunt edge is 2mm.

[0023] The results of welding cold crack susceptibility test are shown in the table below:

[0024] pre-heat temperature

room temperature / no preheating

50℃

100℃

150℃

200℃

250℃

Crack rate

90%

75%

52%

25%

0%

0%

[0025] According to the above results, it is necessary to preheat over 200°C to effectively prevent the occurrence of welding cold cracks; select the following welding process parameters for submerged arc welding: welding current 480A, welding voltage 31V,...

Embodiment 2

[0030] The thickness of the substrate steel plate is 80mm thick quenched and tempered steel plate F690, the yield strength is 745MPa, the tensile strength is 855MPa, the elongation is 17%, and the impact energy at -60°C is 285J. The size of the welding plate is 1000mm (length) × 500 (width); the groove is a symmetrical double U shape, the groove angle is 32°, the thickness of the blunt edge is 4mm, and the gap between the blunt edge is 1mm.

[0031] The results of welding cold crack susceptibility test are shown in the table below:

[0032] pre-heat temperature

room temperature / no preheating

50℃

100℃

150℃

200℃

250℃

Crack rate

90%

75%

52%

25%

0%

0%

[0033] From the above results, it is necessary to preheat over 200°C to effectively prevent the occurrence of welding cold cracks; select the following welding process parameters for submerged arc welding: welding current 650A, welding voltage 35V, welding spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com