Filter head apparatus of nuclear plant desalting device

A desalter and nuclear power plant technology, applied in the field of water treatment, can solve the problems of ion exchange resin loss, large welding deformation, low steel wire strength, etc., and achieve the effect of improving purified water quality, no welding deformation, and uniform gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

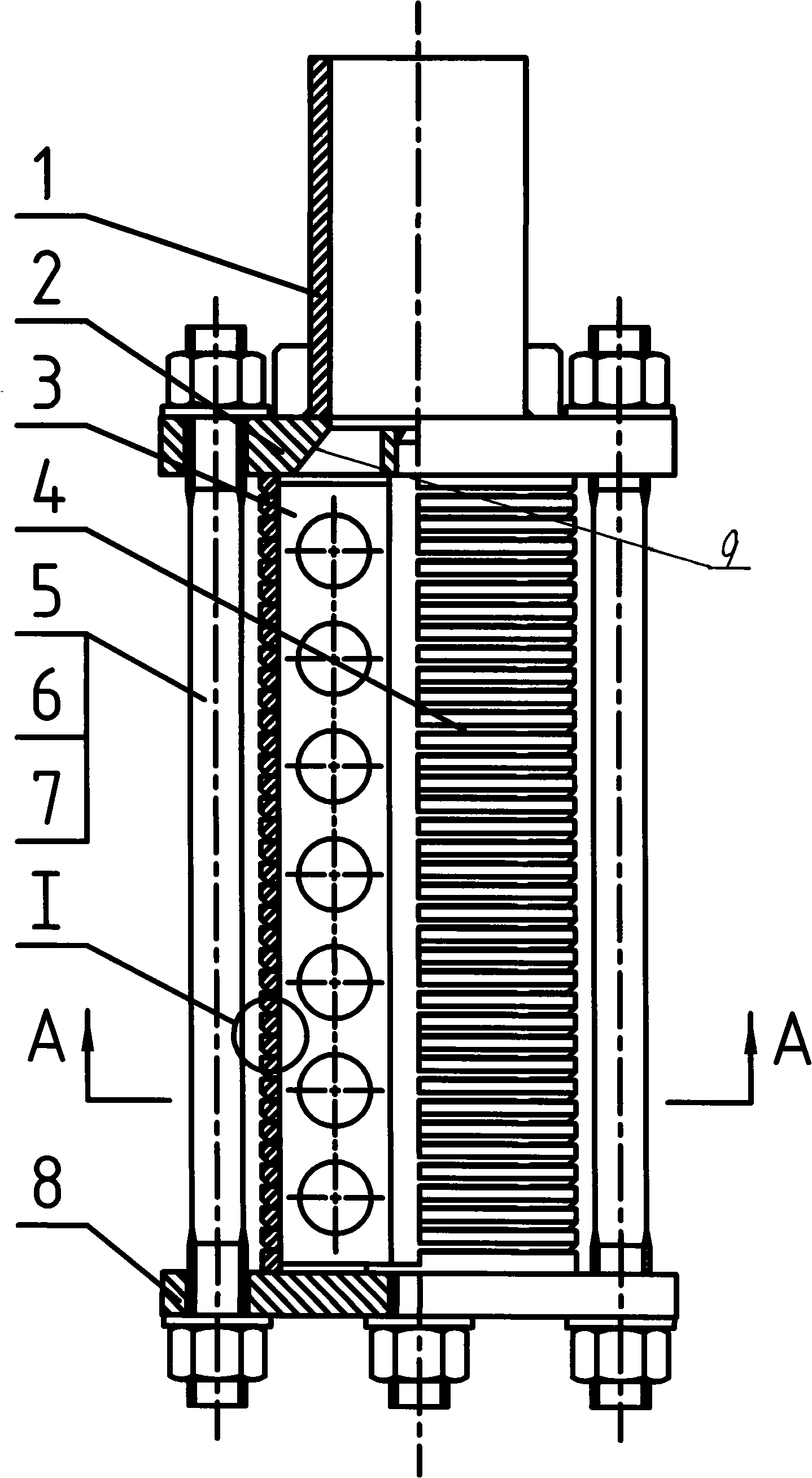

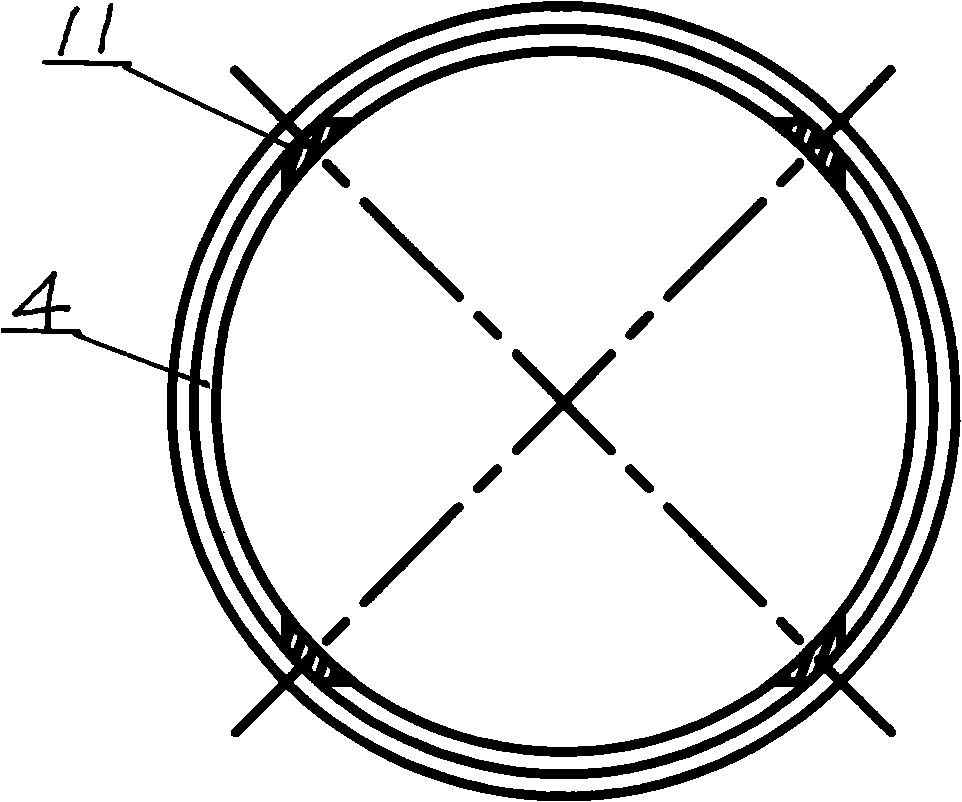

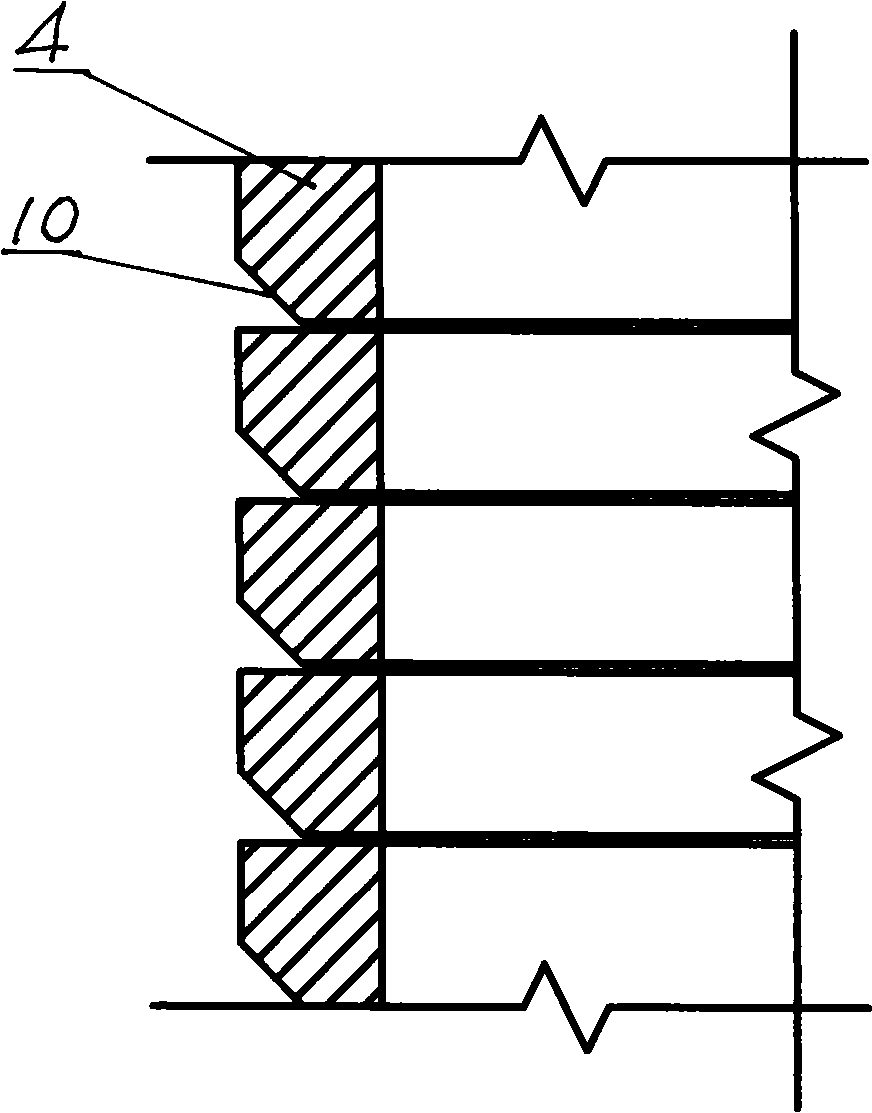

[0013] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, as figure 1 As shown, the present invention is made of connecting pipe 1, loam cake 2, filter tube 4, skeleton 3, lower cover 8, and stud 5, nut 6, gasket 7, and one end of connecting pipe 1 is welded on the loam cake 2, and the filter pipe 4 is lined with frame 3, filter tube 4 and frame 3 are fixed between upper cover 2 and lower cover 8, and filter tube 4 and frame 3 are connected and fixed by studs 5, nuts 6 and gaskets 7 to form an integral structure. The filter tube 4 is an integral structure, and has four axial isolation ribs 11 which are equidistant and integral along the circumference, and several water-passing gaps are regularly arranged between the isolation ribs 11 . When the filter tube 4 is a certain length, it is connected by two or more sections corresponding to each other. Each section is an integral structure. Each section of the filter tube 4 is cut with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com