Steering wheel and its manufacture method

A processing method and steering wheel technology, which is applied to the steering control and handwheel installed on the car, can solve the problems of scrapping, uneven thickness of the outer ring of the disc, welding slag or welding deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

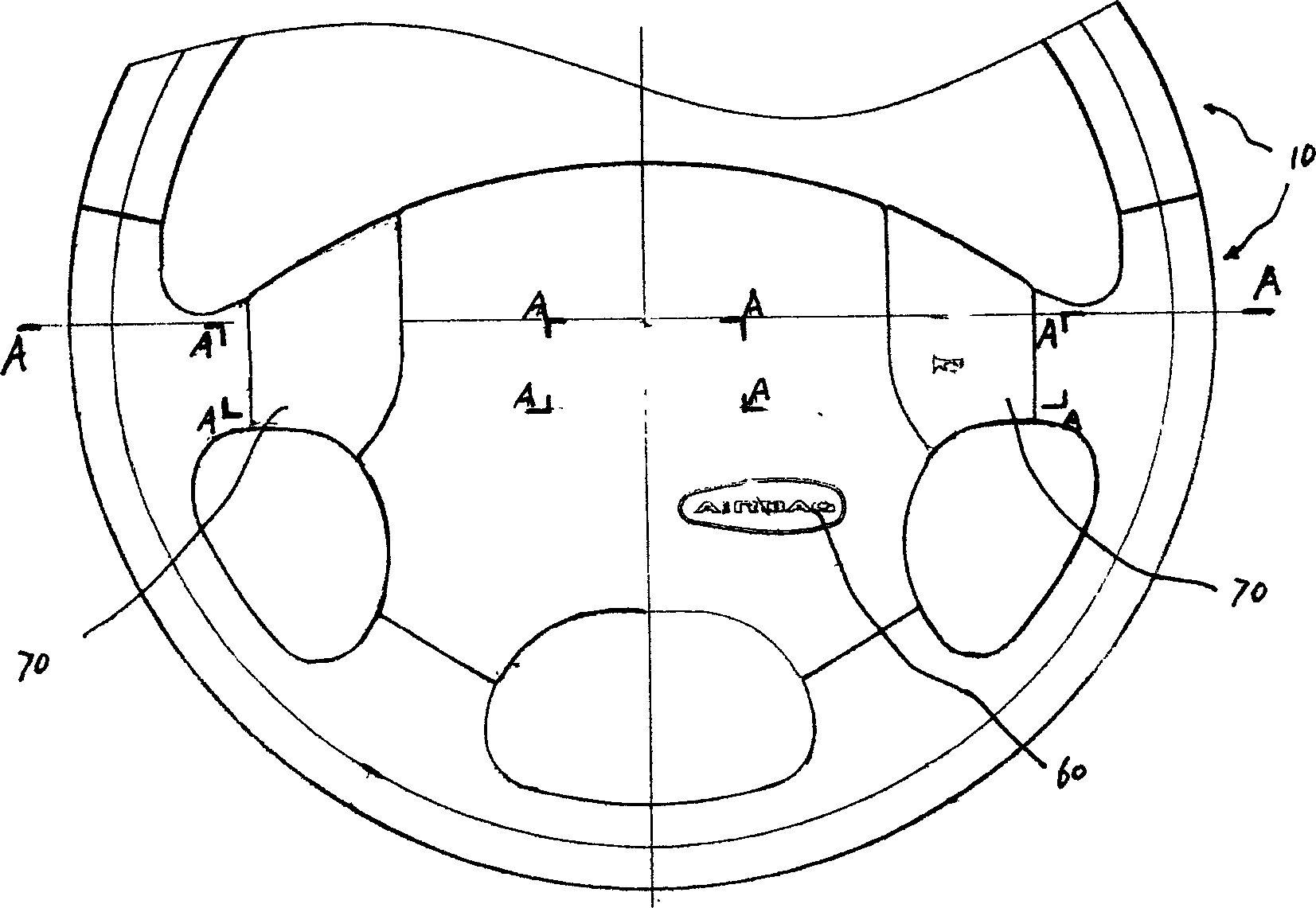

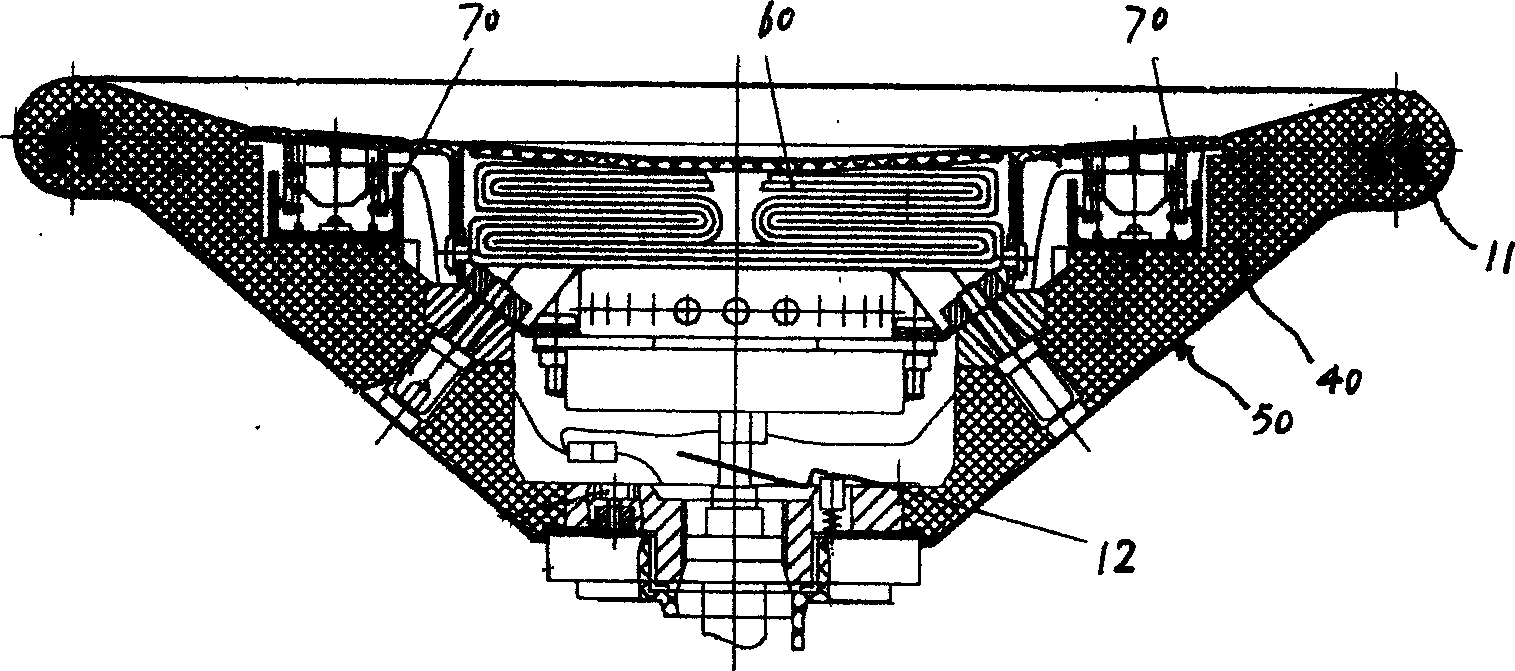

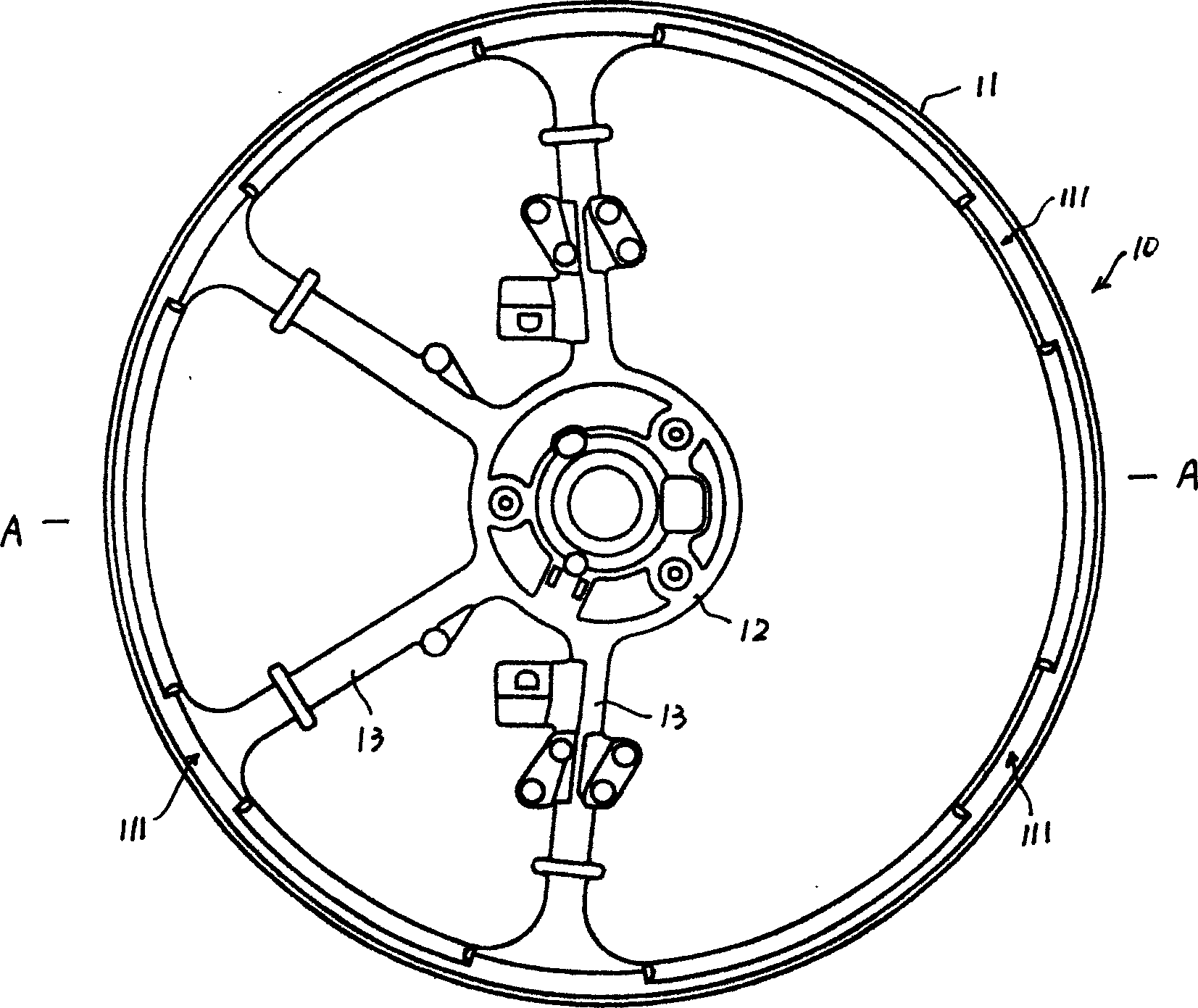

[0025] combine figure 1 , 2, 4, 5, the steering wheel includes a magnesium alloy skeleton body 10 that includes an annular upper rim 11, a lower base 12, and several auxiliary ribs 13 that are die-cast into an integral structure, such as Figure 4 , 5 As shown, the magnesium alloy is used to make the skeleton, which has light weight, high specific strength and specific stiffness, and has electromagnetic and vibration absorption properties. It also has good high and low temperature performance, and small deformation is conducive to dimensional stability and good mold release performance. The small half upper disc edge 11 on the disc body 10 is injection molded with an ABS coating 20, such as Figure 6 , 7 , the ABS cladding layer 20 is provided with a transfer layer 30 of mahogany texture, such as Figure 9 , 11 , the structure not only has good appearance and aesthetic effect, but also has good wear resistance and strength. The rest of the upper disc rim 11 is provided wi...

Embodiment 2

[0030] Such as image 3 As shown, the processing method of the steering wheel in the present invention simply includes die-casting, ABS injection molding, foaming, transfer printing, leather wrapping and assembly process, and the steps are described in detail below:

[0031] Such as Figure 4 , 5 As shown, a die-casting method is used to form a magnesium alloy skeleton disk body 10 with an integral structure including an annular upper flange 11, a lower base 12, and several auxiliary ribs 12 arranged therebetween. The magnesium alloy skeleton disk body 10 in the present invention According to the specific requirements of customers, the specific structure of the lower base 12 and several auxiliary ribs 12 arranged therebetween can be provided to meet the requirements of installing or optional air bag assembly 60 and horn assembly 70, as well as the cooperation with the specific structure of power-assisted steering. The magnesium alloy frame body is molded at one time by cold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com