Welding tooling for pantograph mounting seat assembly welding and pantograph mounting seat welding method

A welding tool and pantograph technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of high insulator, difficult production process, affecting the installation of pantograph, etc., achieve high stability, reduce self Weight, the effect of avoiding flexural deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

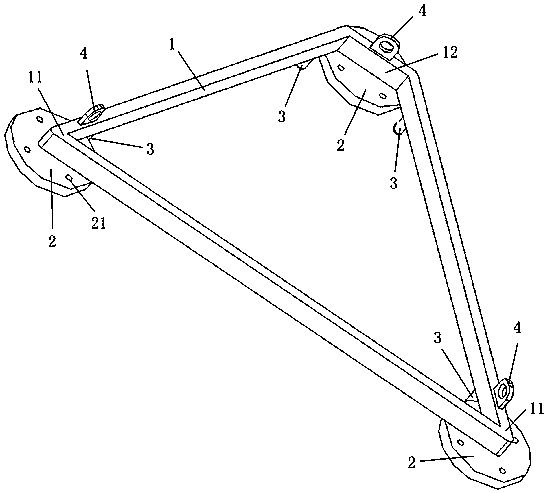

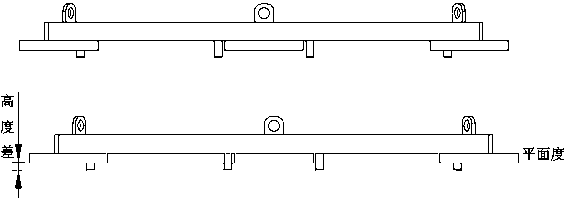

[0033] Such as figure 1 with 2 As shown, a welding tool suitable for the assembly and welding of the pantograph mounting seat of a 160KW urban train is provided to ensure that the flatness between the upper surfaces of the pantograph mounting seat meets the pantograph assembly requirements, which includes the tooling frame 1 and the The flatness control unit and height positioning unit on the tooling frame. The flatness control unit includes three positioning plates 2 set according to the number, size and relative position of the pantograph mounting seats of urban trains. Each pantograph mounting seat A corresponds to Fit a positioning plate 2, the flatness of the surface where the positioning plate is attached to the pantograph mounting seat is ≤0.5, the overall flatness of the flatness control unit is compatible with the pantograph mounting seat, and the positioning plate 2 is provided with a through hole 21 For installation on the pantograph mounting seat A; the height pos...

Embodiment 2

[0041] A method for welding a pantograph mounting seat by using the above-mentioned welding tool for pantograph mounting seat assembly welding of an urban train, comprising the following steps:

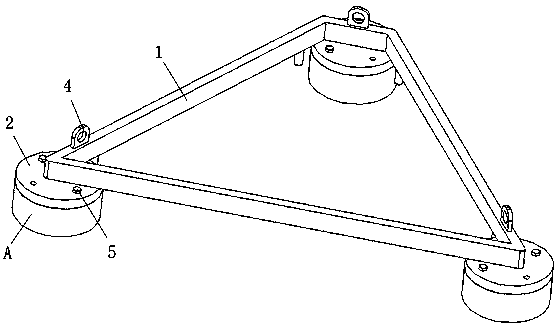

[0042] S1. Assemble the pantograph mounting seat A with the steel screw sleeve and pre-install it on the through hole of the positioning plate 2. For a pantograph mounting seat, select a set of through holes at the diagonal positions on the positioning plate to pre-tighten with the connecting piece 5 ,See image 3 shown;

[0043] S2. Lift the welding tool with a general sling, hoist the three pantograph mounts to the pantograph plate after preheating the welding position, adjust the direction so that the pantograph mounts are installed into the corresponding holes of the pantograph plate bit;

[0044] S3. Loosen the sling, make the height positioning unit bear the whole welding tooling, tighten the connecting piece at the pre-tightening part of the through hole with a force of 18N-25N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com