Processing method of twisted guide rail

A processing method and technology of guide rails, which are applied in the directions of track contact elements, railway car body parts, transportation and packaging, etc., can solve the problem that the size of the L-shaped flange of the slide rail cannot be guaranteed, the grinding of the corrugated surface cannot be realized, and the mechanical deformation is large. and other problems, to achieve the effect of significant cost saving, high yield and qualified acceptance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

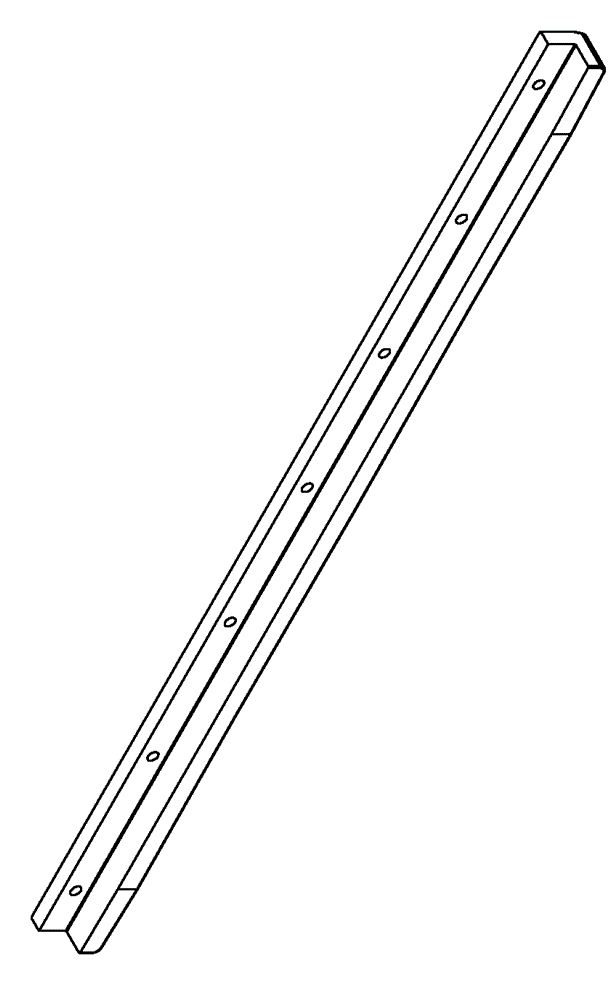

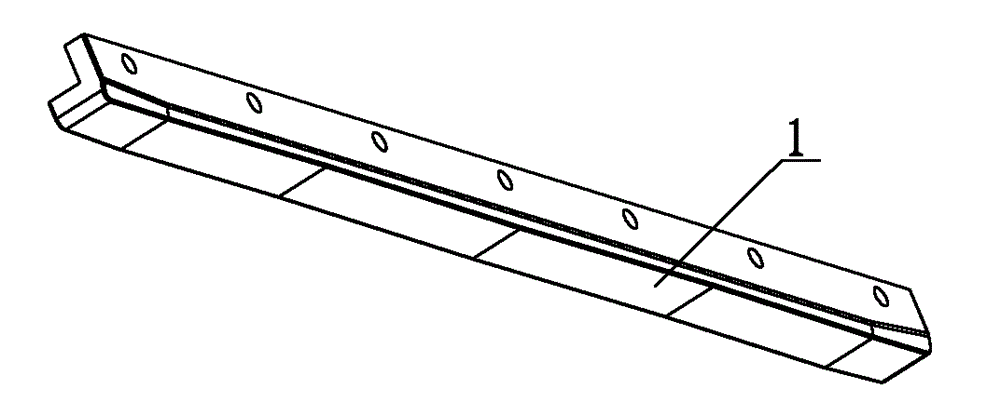

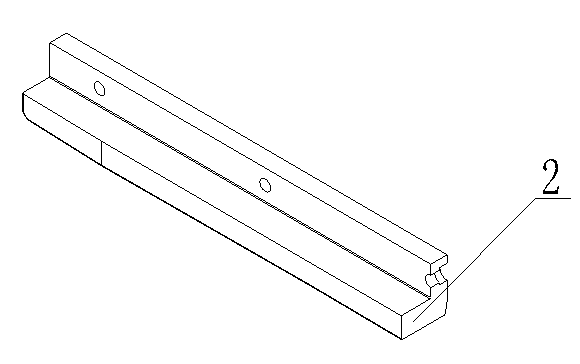

[0030] see Figure 1 to Figure 5 ,

[0031] The action principle of the present invention is:

[0032] 1. The forging material is a rectangular strip blank of 42CrMo, which is inspected according to the level IV of JB / T5000.8-07;

[0033] 2. The rough machining of the blank to the shape of 70×80×1500 (mm), the L-shaped surface has a 5mm allowance on one side, and the roughness of all surfaces reaches 6.3. During processing, such as Figure 4 , Figure 5 , keep the iron meat at the design reinforcement;

[0034] 3. Quenching and tempering HB310-350 and cleaning the surface of the workpiece;

[0035] 4. For tire fitting orthopedics, the straightness is within 2mm;

[0036] 5. Non-destructive testing: Ultrasonic, tensile strength and hardn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com