Electrospark wire-electrode cutting and punching combined machine tool

A technology of electric spark wire and combined machine tool, which is applied in the field of electric spark wire cutting and punching combined machine tool, can solve the problem of not being able to save time and accuracy, and achieve the effect of eliminating handling and ensuring position accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

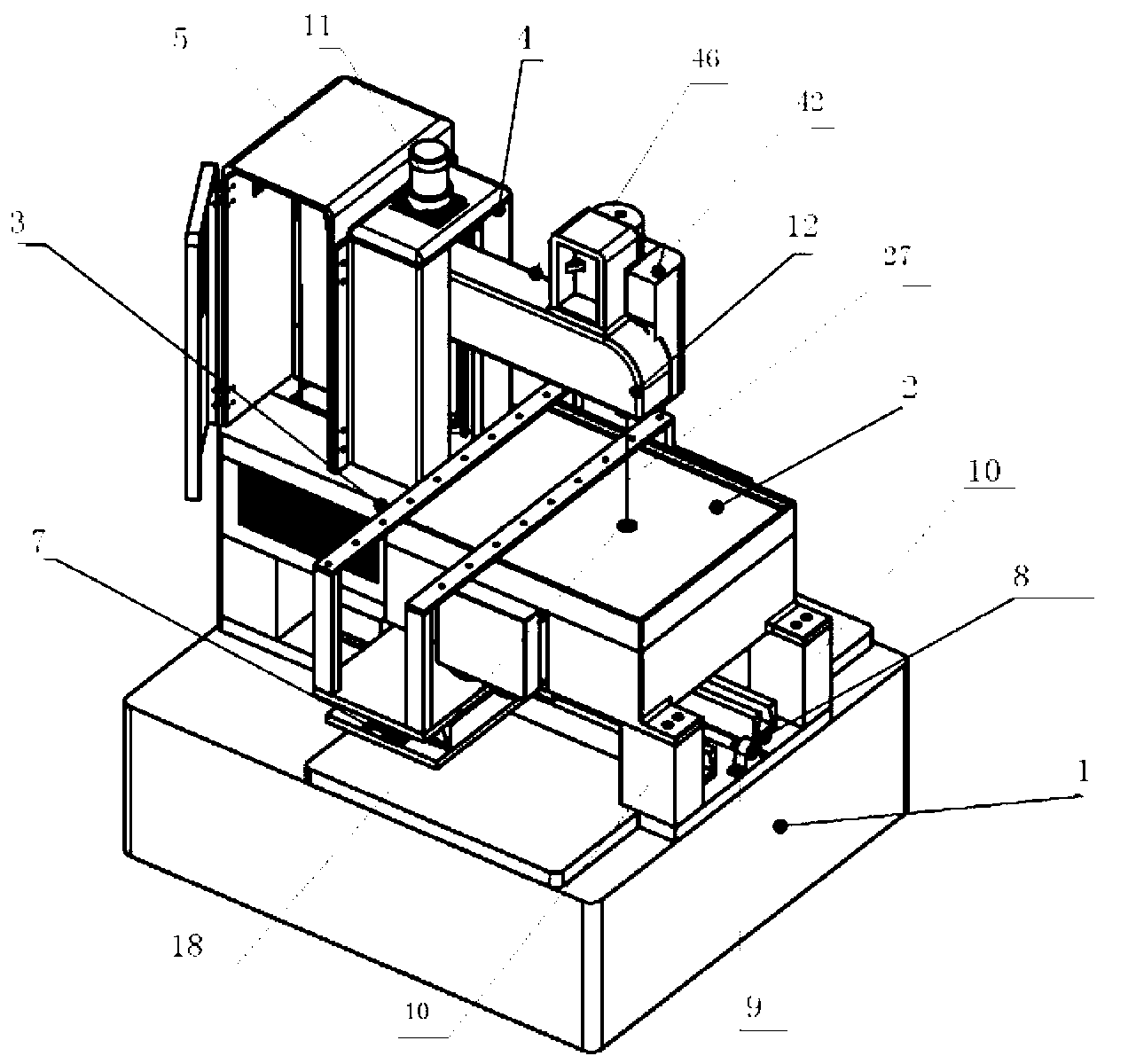

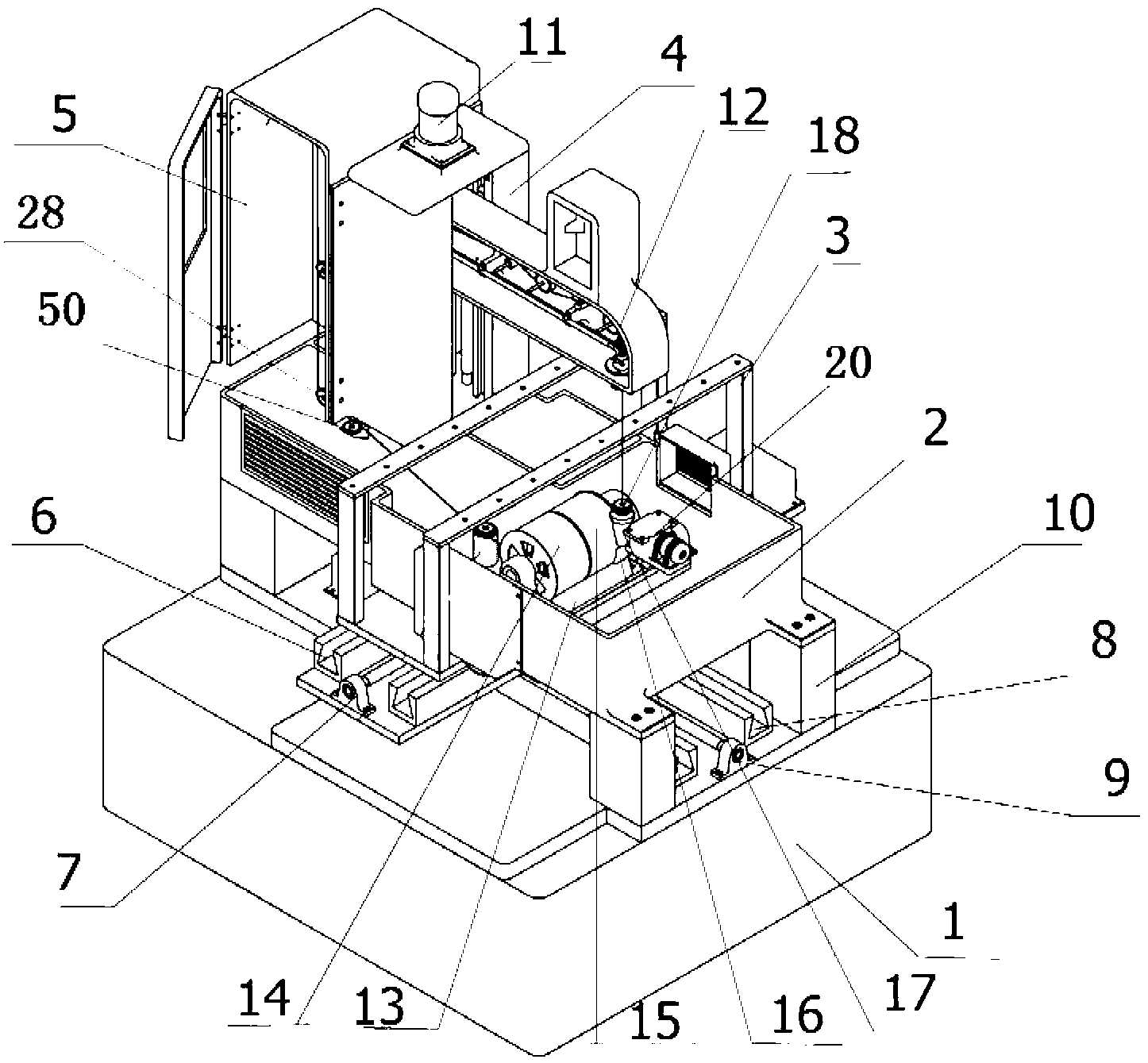

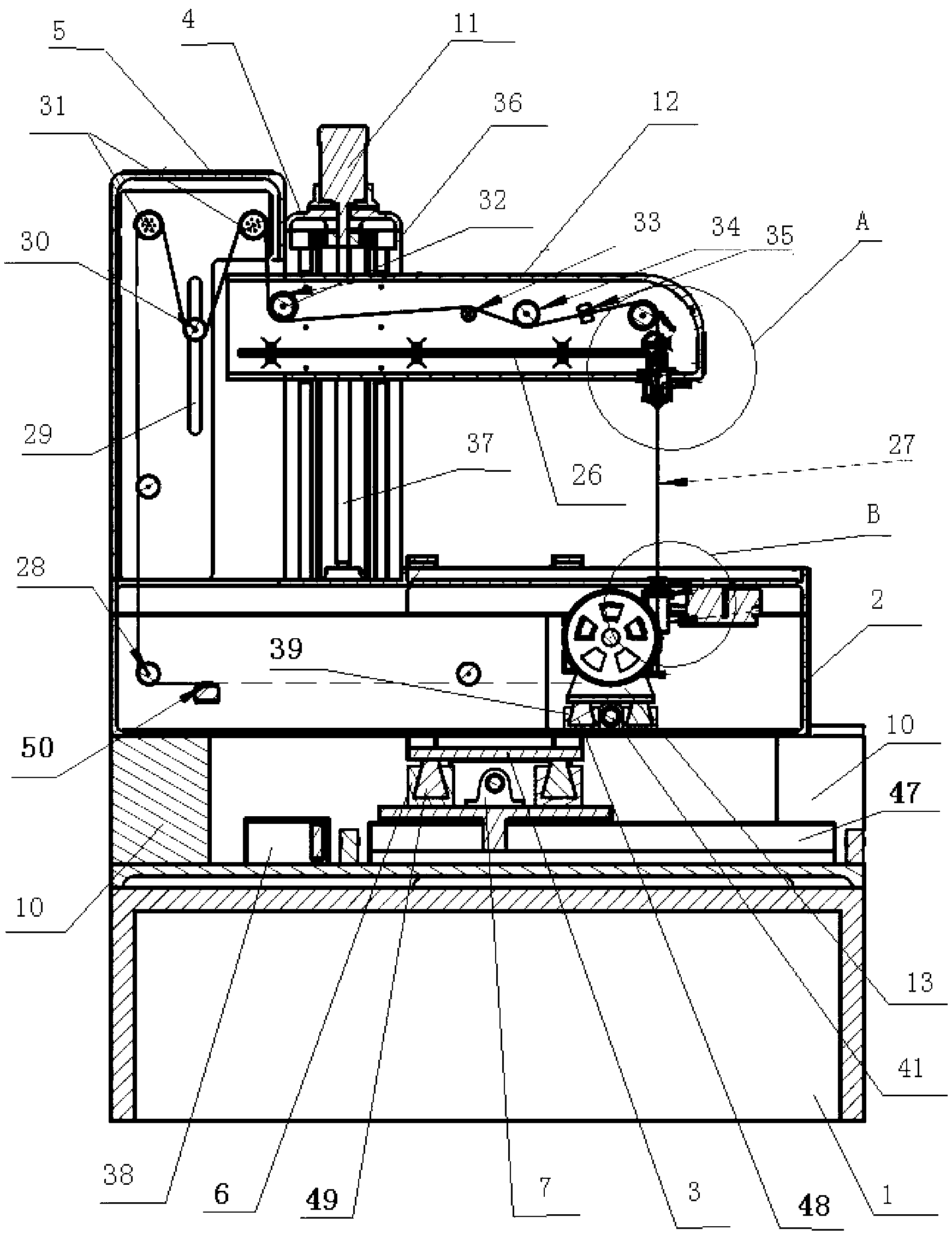

[0031] Such as Figure 1-Figure 7 Shown is the structure diagram of the combined wire electric discharge cutting and punching machine tool of the present invention. Wire electric discharge cutting and punching combination machine tools include machine parts, EDM part , automatic threading part and control part,

[0032] The machine part includes base 1, guide frame 5, column 4, horizontal guide rail 6, horizontal screw 7, longitudinal slide rail 8, first slider 47, second slider 49, longitudinal screw 9, motor box 2, cantilever 12. Shock absorbing support 10, first motor 38 and workpiece holder 3;

[0033] The automatic wire threading part includes a wire storage drum support 13, a main wire storage drum 14, an auxiliary wire storage drum 15, flying shears 19, a wire outlet nozzle 21, a high pressure water nozzle 22, an anti-broken wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com