Pulse laser drilling device and drilling method thereof

A technology of pulsed laser and perforation device, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of the hole wall material being greatly affected by heat, the hole shape accuracy is not easy to control, and the workpiece processing quality is affected, and the shape accuracy is achieved. Guarantee, reduce the scope, eliminate the effect of too much slag spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

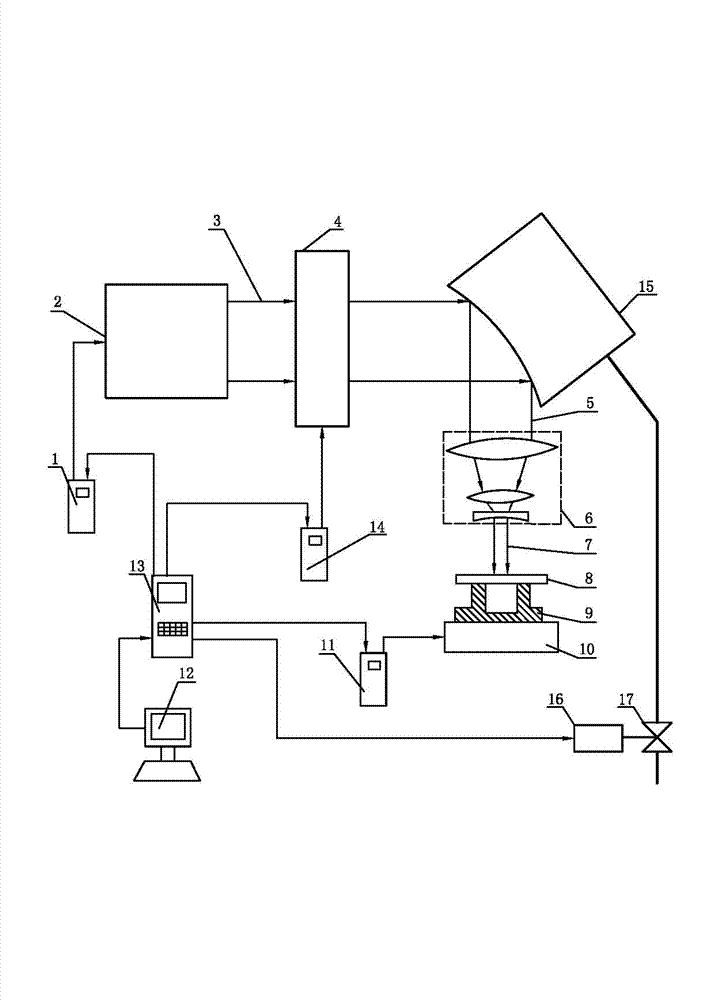

[0015] like figure 1 A pulse laser perforation device and perforation method thereof are shown, the device includes a laser generator, an ultra-pulse converter, a pneumatic zoom mirror, a converging lens group and a fixture are sequentially arranged on the optical path of the laser generator, and the laser generator The signal input end is connected to the signal output end of the numerical control box through the laser generator control device, the air pressure zoom mirror is controlled by the air pressure valve control device, the signal input end of the air pressure valve control device is connected to the signal output end of the control box, and the ultra-pulse converter The signal input end of the digital control box is connected to the signal output end of the numerical control box through the super pulse converter control device. The fixture is fixedly installed on the numerical control workbench. The CNC box is connected with the computer;

[0016] The method include...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com