Metal 3D printer using atomized metal as consumable

A 3D printer and atomized metal technology, applied in the field of metal 3D printers, can solve the problems of hindering rapid growth, unable to achieve simultaneous printing of multiple metals, and expensive laser heads, and achieve the effect of ensuring the accuracy of the shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail in conjunction with the accompanying drawings.

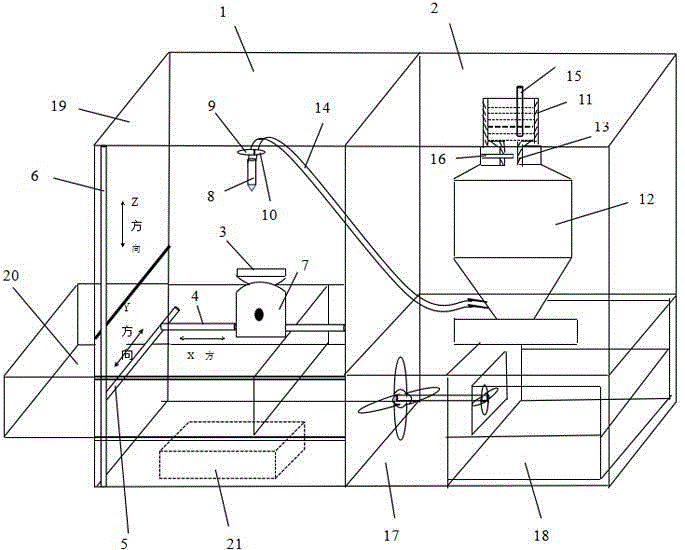

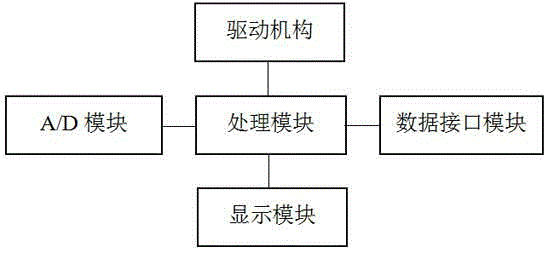

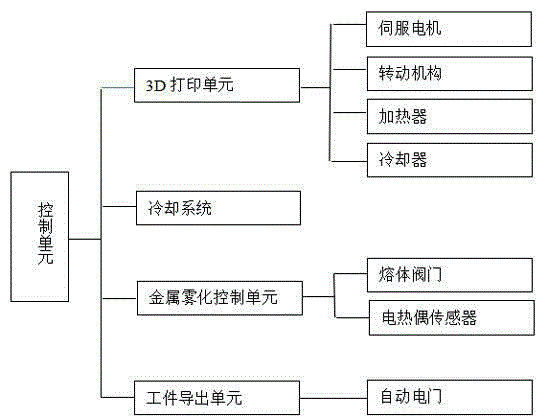

[0027] refer to figure 1 , the present invention is a metal 3D printer using atomized metal as a consumable, including: a 3D printing unit, a metal atomization control unit, a control unit, a cooling system, a moisture scrubber, and an automatic export unit for finished workpieces.

[0028] The printing unit 1 includes a workbench 3, a servo motor controlling the movement of the workbench 3, a rotating structure 7, an atomized metal spray head 8, a heater 9 and a cooler 10; wherein the servo motor includes an X-direction servo motor 4, a Y-direction servo motor The servo motor 5 and the Z servo motor 6 control the movement of the worktable 3 in the X, Y, and Z directions respectively; the X direction servo motor 4 is equipped with a rotating structure 7, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com