Miniature ceramic bearing hole abrading machine

A technology of ceramic bearings and grinding machines, which is applied in the direction of machine tools, grinding machines, grinding/polishing equipment designed for grinding the rotating surface of workpieces, etc. It can solve the problems that the accuracy cannot meet the requirements, so as to improve the grinding efficiency, improve the working environment, The effect of improving the grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further described through the following drawings, so that the purpose, features and advantages of the present invention can be further understood.

[0028] The accompanying drawings are explained as follows:

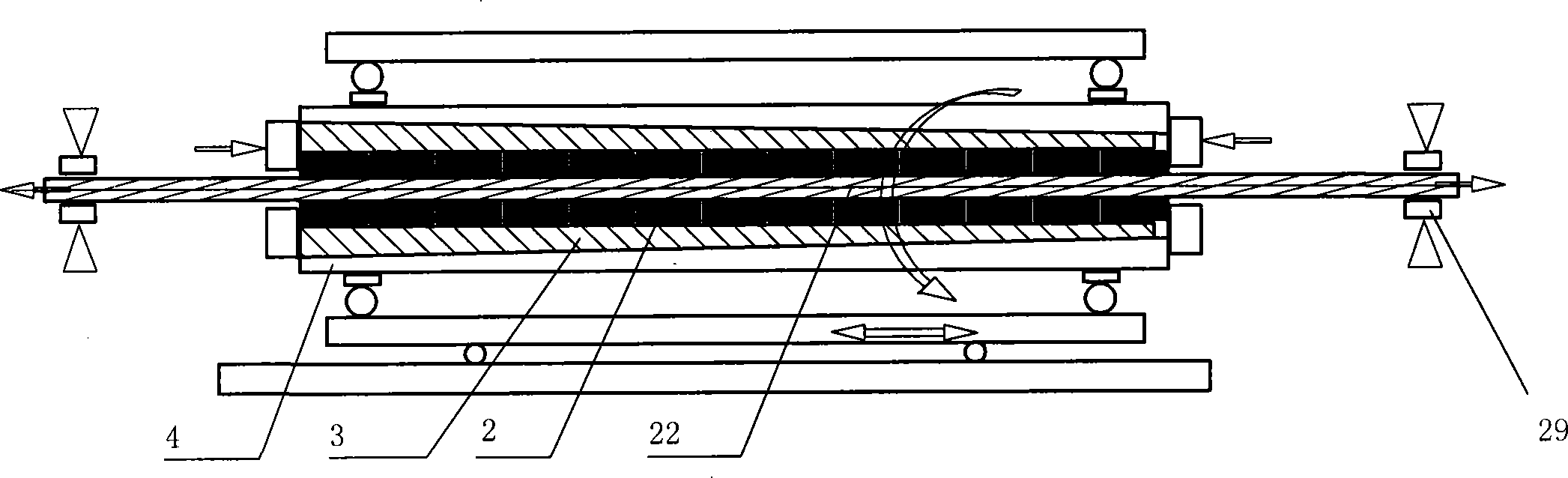

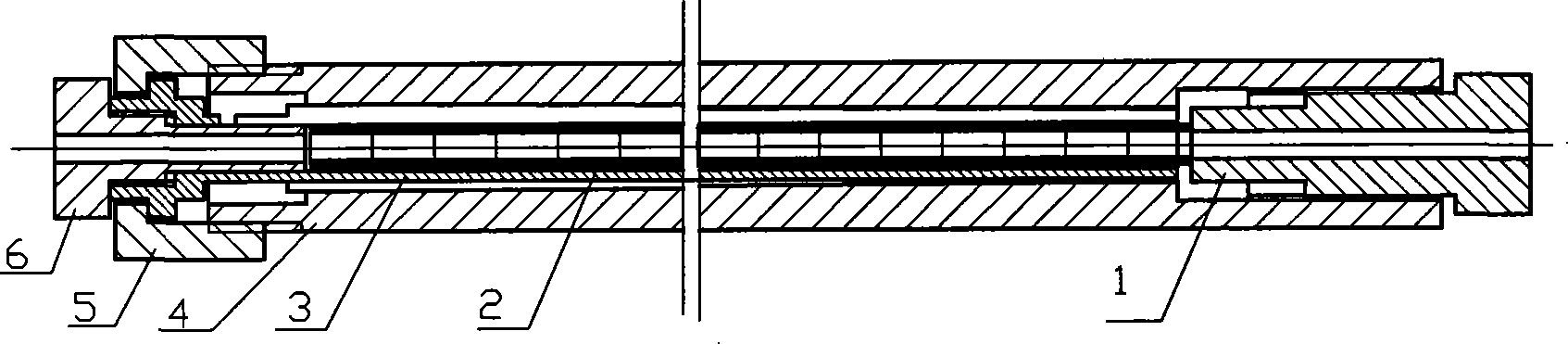

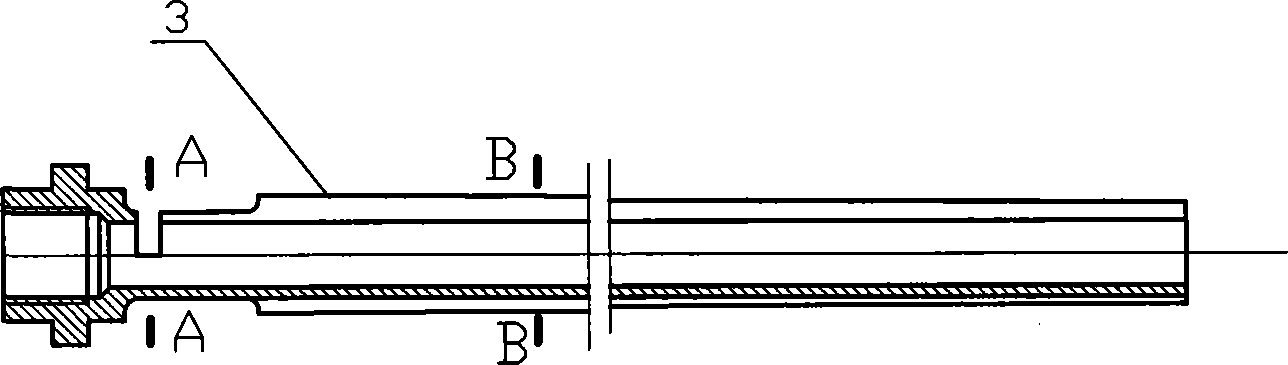

[0029] figure 1 It characterizes the relative positional relationship and relative motion relationship between the workpiece 2 (ceramic bearing), the fixture (centering clamping mechanism) and the processing tool (grinding wire rope 22): the centering axis of the workpiece 2, the centering clamping mechanism The axis of the grinding wire coincides with the axis of the grinding wire rope; the grinding wire rope 22 runs through the inner hole of the workpiece 2 to be ground, and the two ends are tensioned and fixed. Rotating and reciprocating, the elasticity of the grinding wire rope 22 in the circumferential direction keeps it in contact with and rubbing against the inner hole wall of the workpiece 2, and the grinding paste applied on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com