Hollow blade as well as manufacturing method and application thereof

A hollow blade and blade technology, applied in the direction of blade support elements, engine elements, machines/engines, etc., can solve the problems of shrinkage holes, difficult control of inner cavity and hole surface roughness, insufficient quality control, etc., and achieve aerodynamic performance improvement. , to ensure efficient processing and reliable work, to ensure the effect of shape accuracy and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0079] According to one embodiment of the present application, the manufacturing method of the hollow blade includes at least the following steps:

[0080] (1) The overall profile structure of the manufactured blade;

[0081] (2) Processing inner cavity;

[0082] (3) Processing cooling structure;

[0083] (4) A transition structure is obtained to obtain the hollow vane.

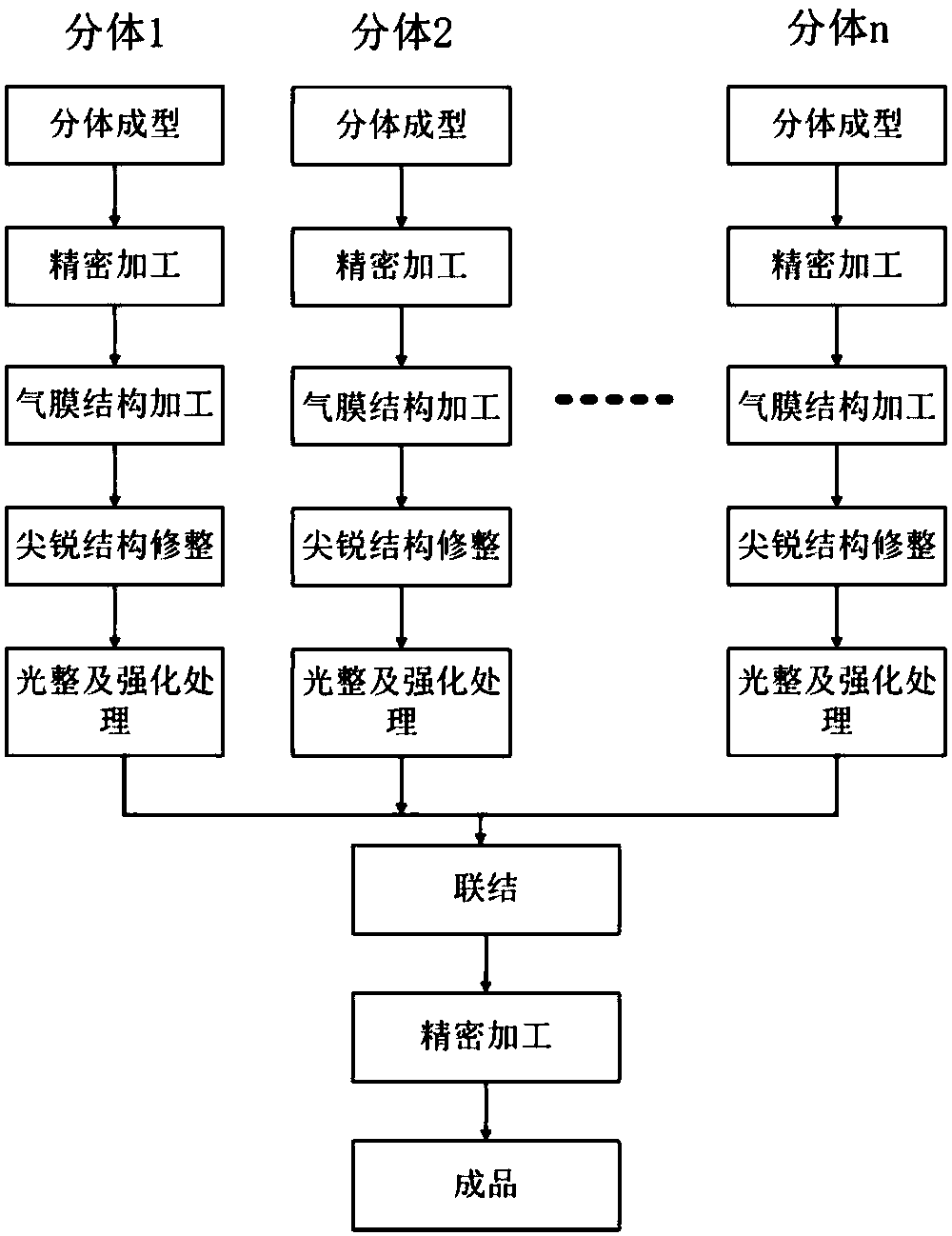

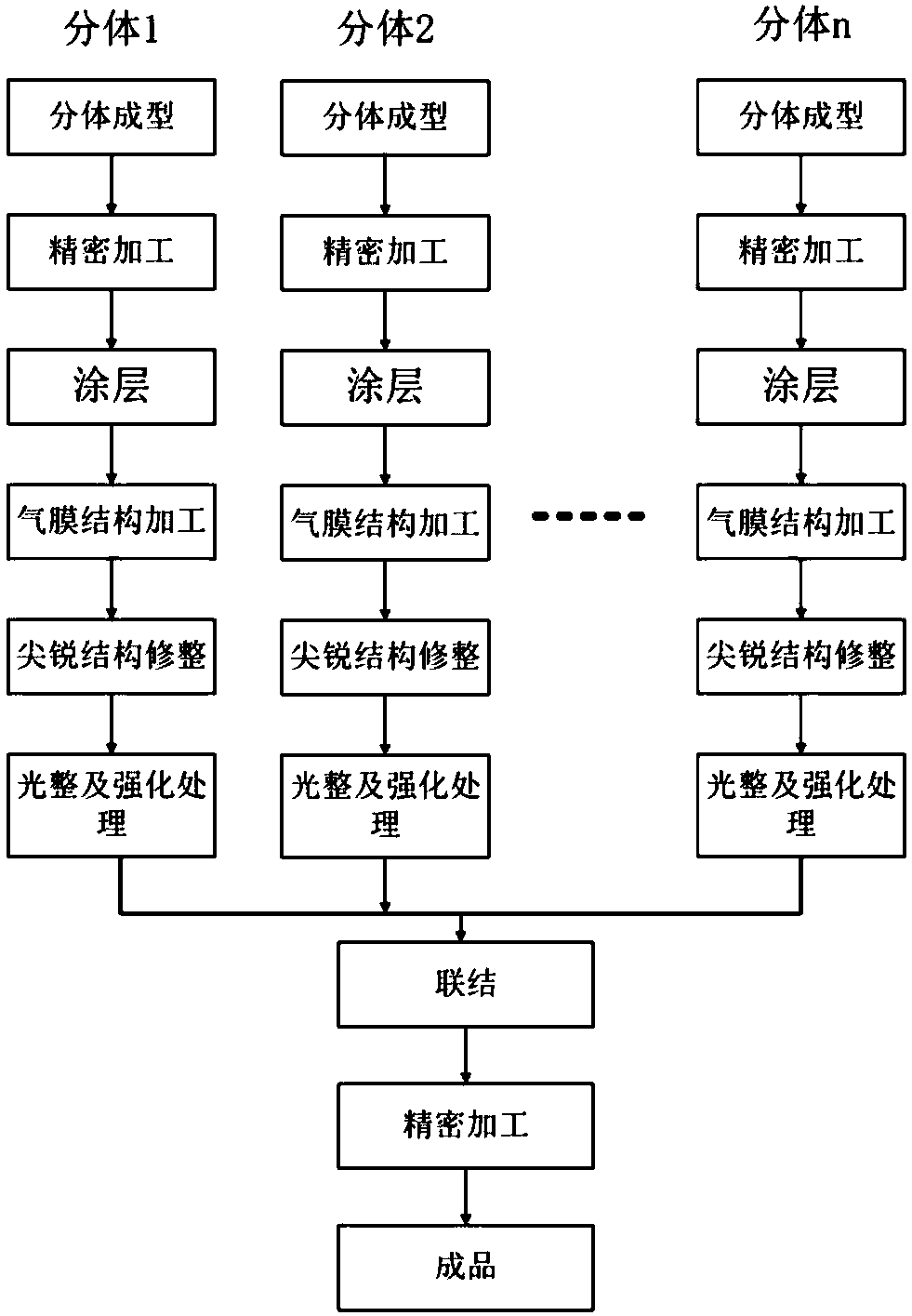

[0084] figure 1 It is a schematic flow chart of a hollow blade with a novel film cooling structure and a manufacturing method thereof for the present application, and the method includes the following steps:

[0085] Step 101: split molding: decompose the blade into several (n≥2) split parts that are easy to process, and manufacture the overall outline structure of different split parts of the blade separately;

[0086] In this step, at least one method of forging, casting, wire cutting, and 3D printing can be used to manufacture the overall contour structure of the different split parts of the blade.

...

Embodiment 1

[0106] A novel air film cooling hollow blade and its manufacturing method, such as figure 1 As shown, including: metal, high temperature resin, polyimide, ceramics and other materials.

[0107] Step 1. Decompose the blade into several (n≥2) split parts that are easy to process, and use forging, casting, wire cutting, 3D printing and other manufacturing processes to separately manufacture the overall outline structure of different split parts of the blade;

[0108] Step 2. According to the geometric design requirements of the hollow blade, the hollow inner cavity contour is processed on different blade split structures. The processing methods that can be used include precision machining, electrolytic processing, laser processing, ultrasonic processing, EDM, etc.;

[0109] Step 3. Air film holes are processed on the split parts of different blades. Laser drilling, electro-hydraulic beam drilling, electrolytic drilling, electric spark drilling and other processes can be used; Co...

Embodiment 2

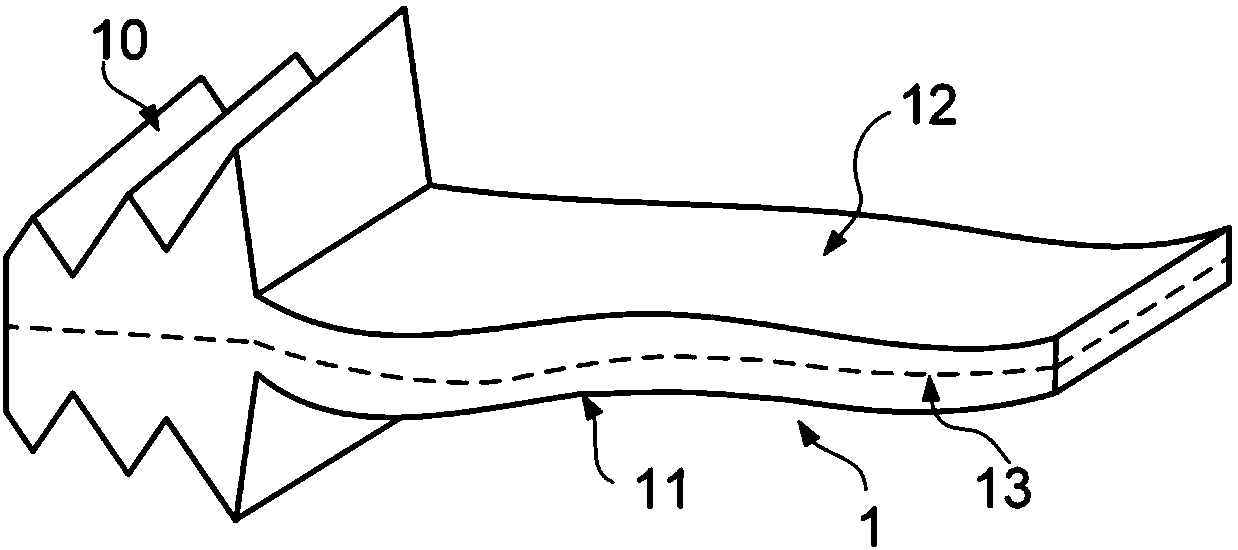

[0116] Aeroengine hollow blade 1 looks like image 3 As shown, along the dividing line 13, it is decomposed into the sub-body 11 and the sub-body 12, tenon parts of the blade 1, and the manufacturing process of the blade 1 is as follows:

[0117] (1) Using mechanical forging, casting, wire cutting, 3D printing and other manufacturing processes to separately manufacture different split parts of the blade, including split 11 and split 12, such as image 3 shown;

[0118] (2) According to the geometric design requirements of the hollow blade, hollow contours are processed on different blade split structures. The processing methods that can be used include precision machining, electrolytic machining, laser machining and EDM. Such as Figure 4 As shown, taking the split body 11 as an example, the hollow cavity 20 is processed inside the blade split body 11 as the gas flow channel of the hollow blade 1. This method can be used to process the gas flow channel with complex shape, hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com