Numerically controlled grinder special for slewing bearing processing

A technology for slewing bearings and CNC grinding machines, which is applied to grinding machines, metal processing equipment, and parts of grinding machine tools. It can solve the problems of low efficiency and low precision machining of slewing bearings, and achieve reliable and reliable quality improvement. Effect of shape accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

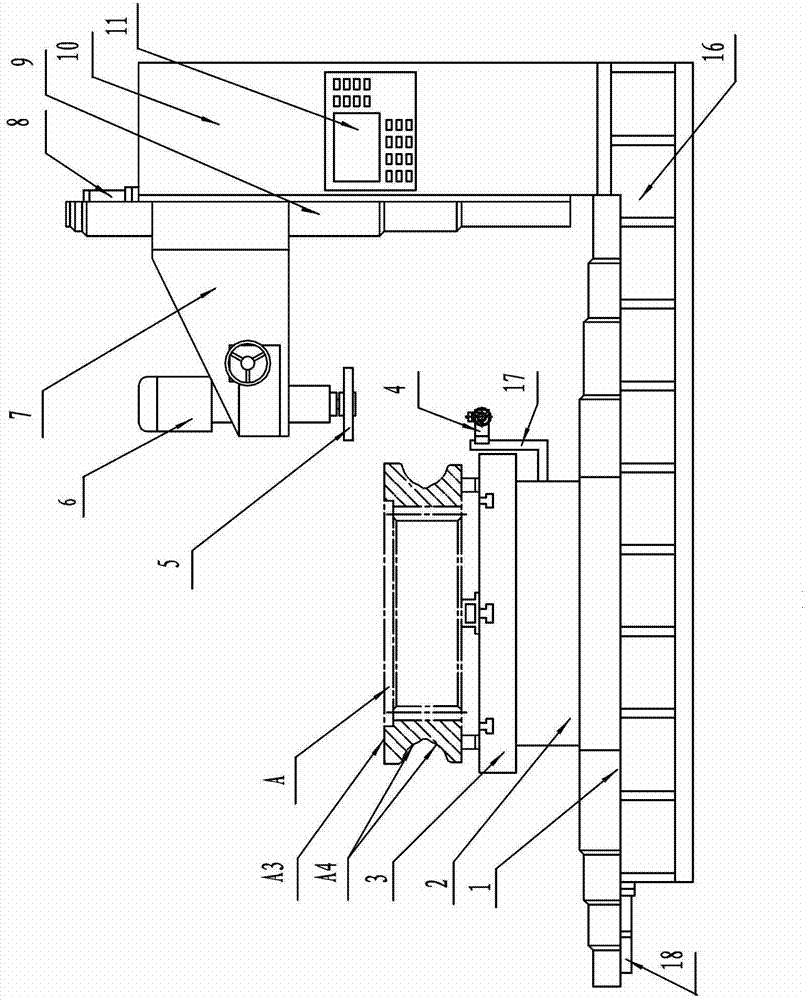

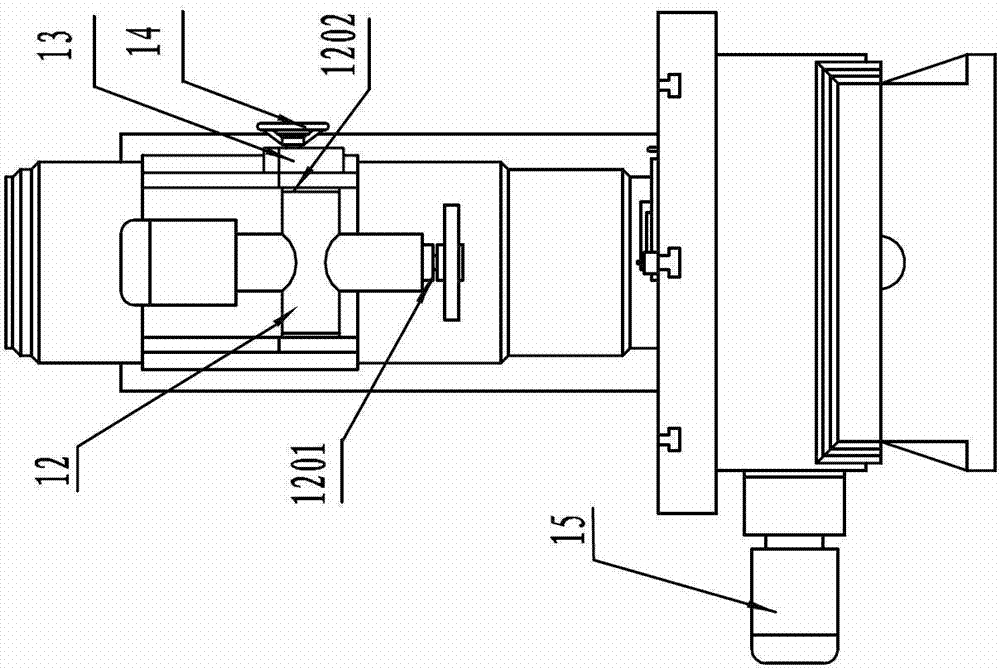

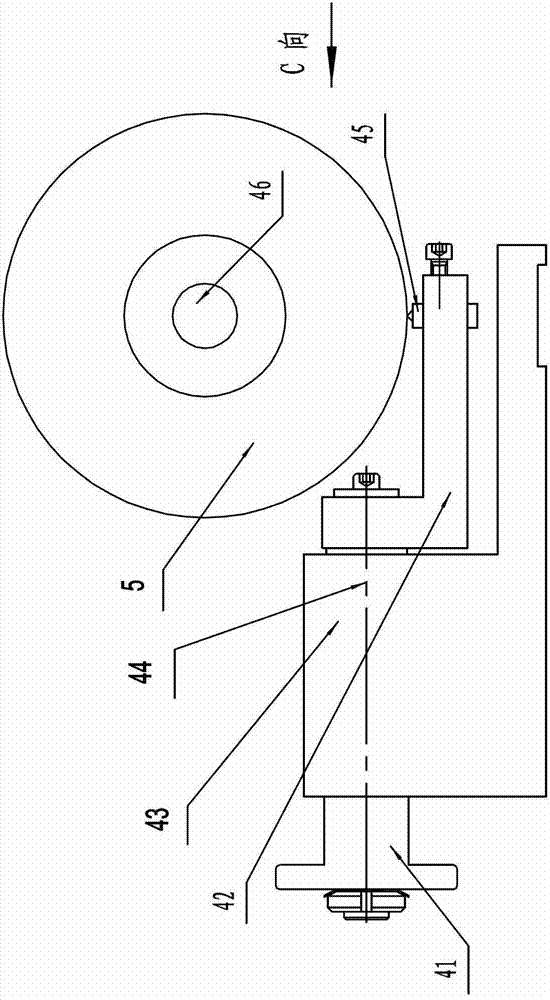

[0026] A special CNC grinding machine for slewing bearing processing with a grinding wheel dresser, including: a bed and a worktable, a column and a grinding head assembly, a grinding wheel dresser, a numerical control system, and a cooling system (see Figure 1-1 ~ Figure 1-2 ,); Among the above five components, the numerical control system is a mature technology and need not be repeated. The cooling system mainly cools the workpiece during the grinding process, including the cooling pump and the water receiving plate installed under the work turntable. It is also a mature technology. It is not shown in the figure and will not be repeated here.

[0027] Combine below Figure 1-1 ~ Figure 1-2 The differences in the structure of the special CNC grinding machine with grinding wheel dresser for slewing bearing processing and ordinary CNC machine tools are explained in detail.

[0028] The bed and the worktable include a bed 16 and a work turntable part; the work turntable part c...

Embodiment 2

[0035]A special CNC grinding machine for slewing bearing processing, the second embodiment is a simplified form of the first embodiment, and its basic structure is the same as that of the first embodiment, the difference is: it does not install the grinding wheel dresser 4; the grinding wheel 5 as the grinding head needs to be removed In addition, the quality and work efficiency are not as high as the one with the grinding wheel dresser in the first embodiment; but it is controlled by the numerical control system, and the grinding head grinding wheel has two working positions, parallel and vertical, so that it can be clamped at one time and grind the slewing bearing at the same time. The inner and outer circles, raceways and installation planes improve the machining dimensional accuracy, roughness and position tolerance of the slewing bearing, and improve work efficiency; Good quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com