Laser selective laser melting rapid preheating and powder spreading device

A technology of laser selective melting and powder spreading device, which is applied in the field of additive manufacturing, can solve the problems of reducing internal stress concentration, slow cooling, and uneven heating of powder, so as to ensure shape accuracy and dimensional accuracy, ensure smooth progress, and improve The effect of molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

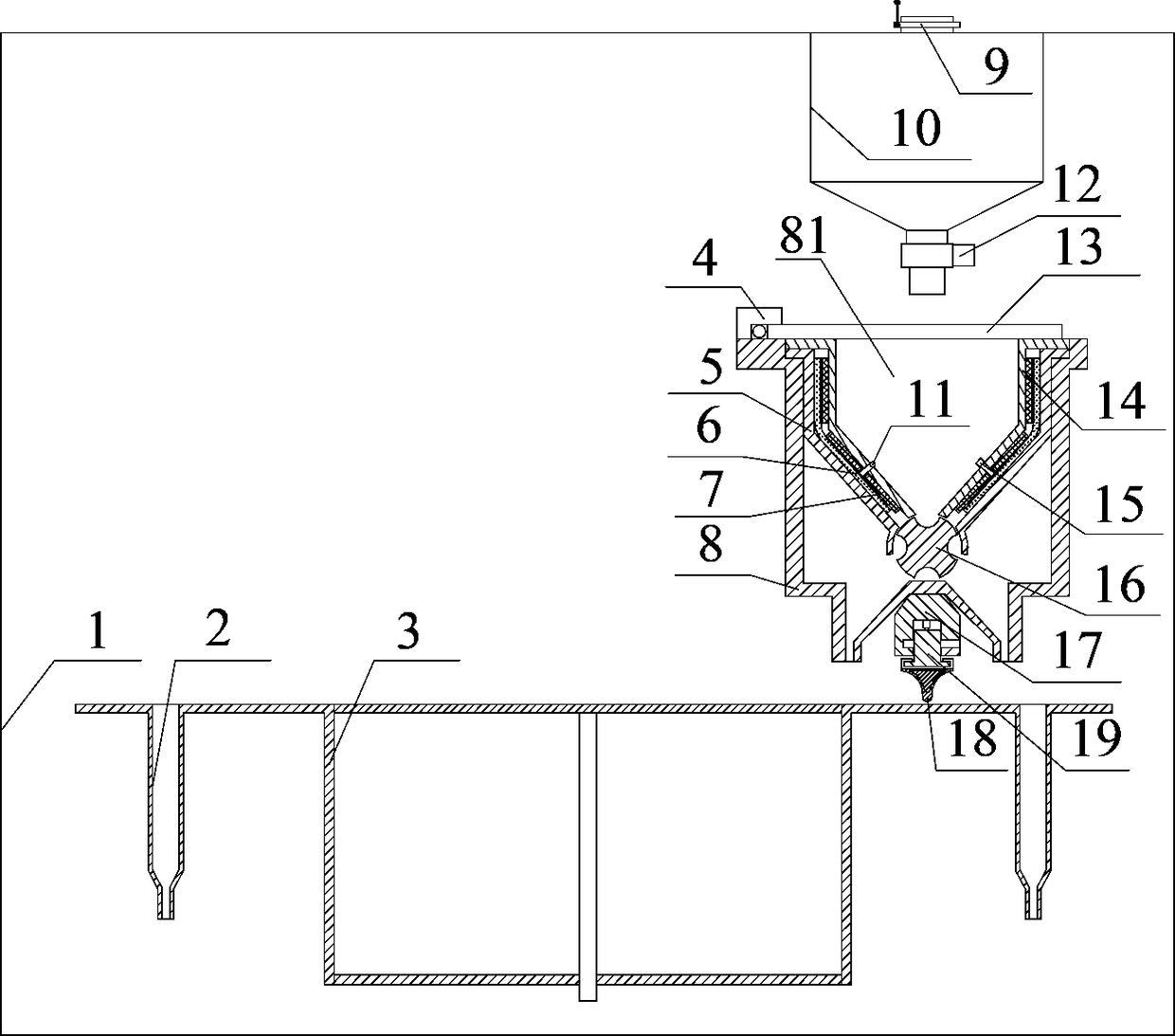

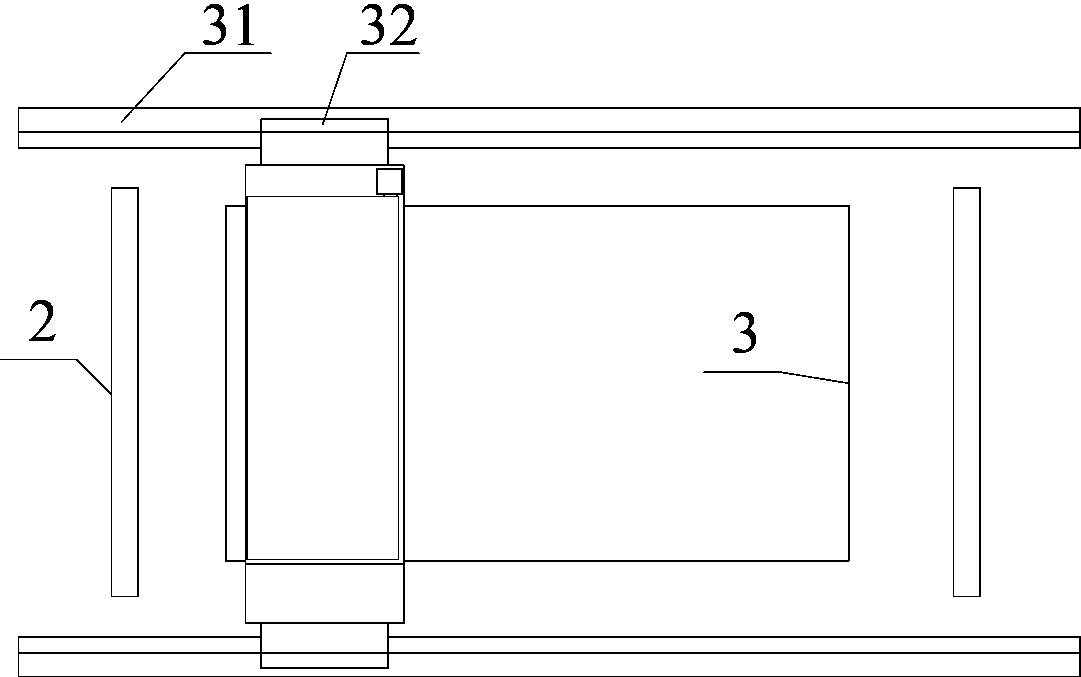

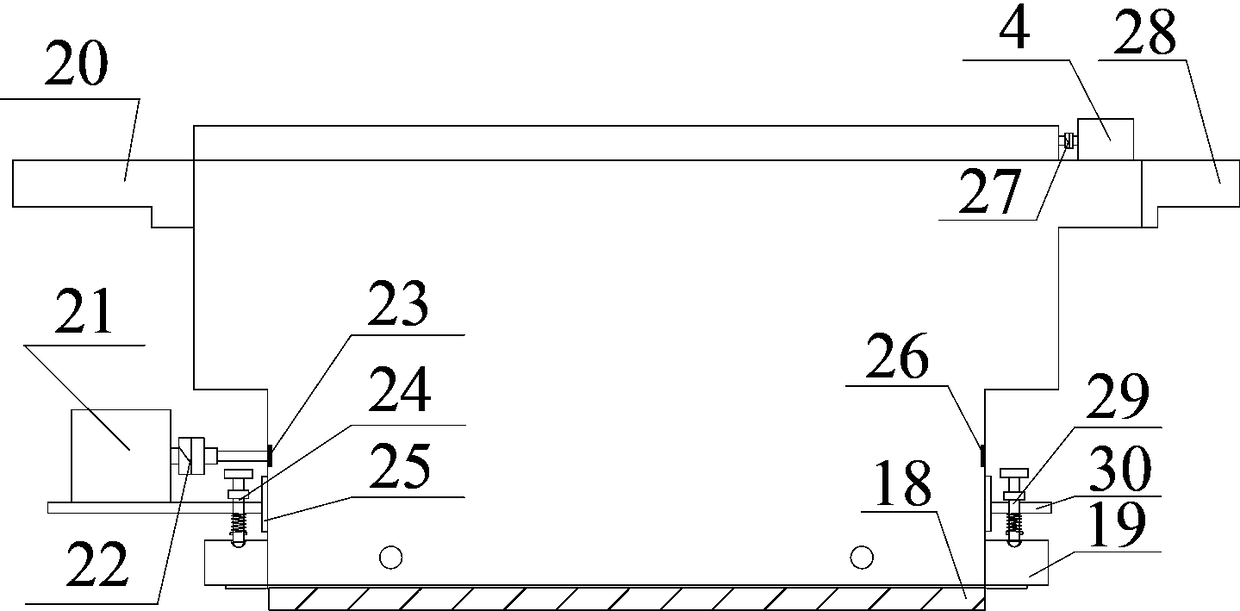

[0035] join Figure 1 to Figure 3 , a laser selective melting rapid preheating powder spreading device, comprising a closed cavity 1, a molding cavity 3 and a recovery cavity 2 are arranged in the closed cavity 1, an automatic powder adding mechanism is arranged on the upper part of the forming cavity 3, and the automatic powder adding mechanism is arranged The powder mechanism is equipped with a scraper powder spreading mechanism. The scraper powder spreading mechanism includes a powder storage cabin shell 8 with a dust cover 13 on the top and a powder outlet on both sides at the bottom. The heating chamber 81 formed by the device, the heating chamber 81 communicates with the powder storage cabin shell 8 through the powder feeding shaft 16, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com