Rapid prototyping and investment casting combined dewaxing method facing turbine blade

A technology of turbine blades and investment casting, which is applied to casting molding equipment, molds, cores, etc., can solve the problems of high bursting rate of ceramic shells, and achieve the effect of promoting net near molding, saving factory land, and shortening the cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] The application principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

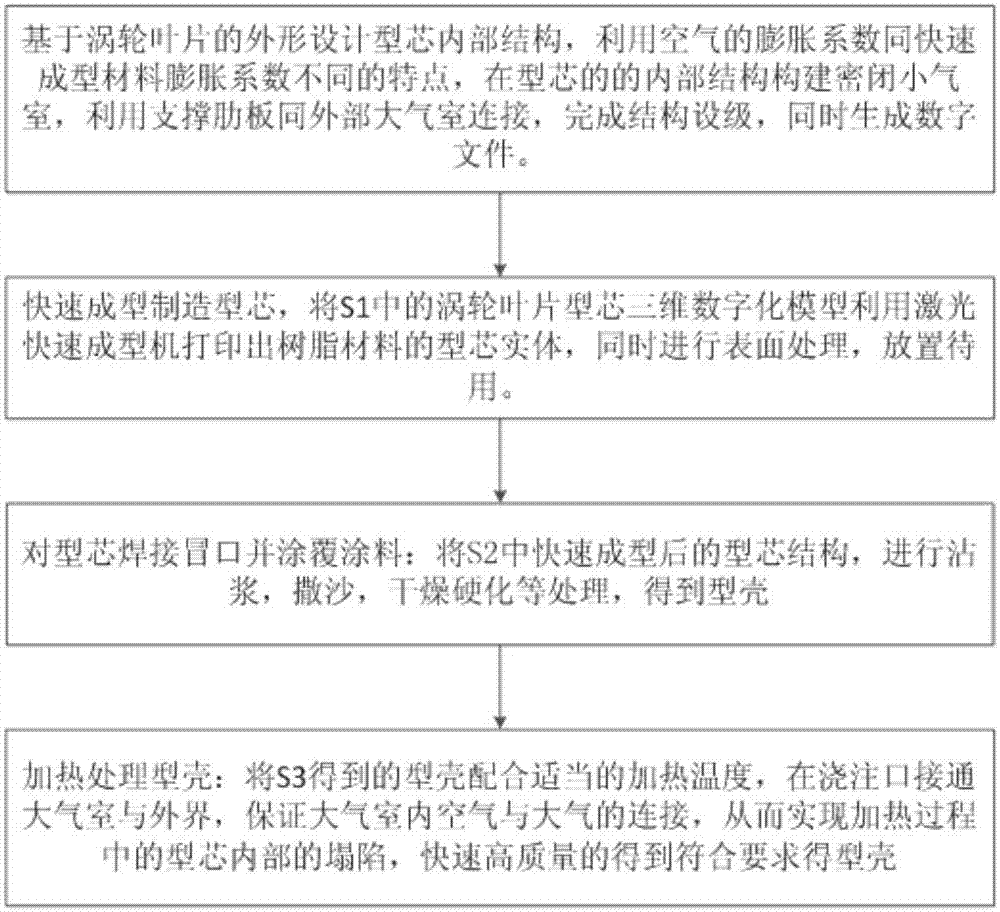

[0081] Such as figure 1 As shown, the method for the rapid melting and loss of the core when the turbine blade rapid prototyping and investment casting are combined in the embodiment of the present invention includes the following steps:

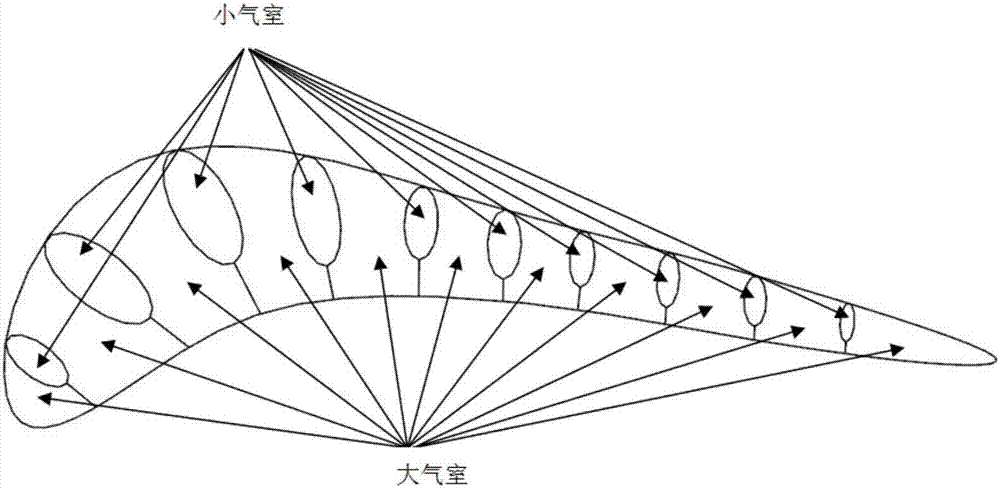

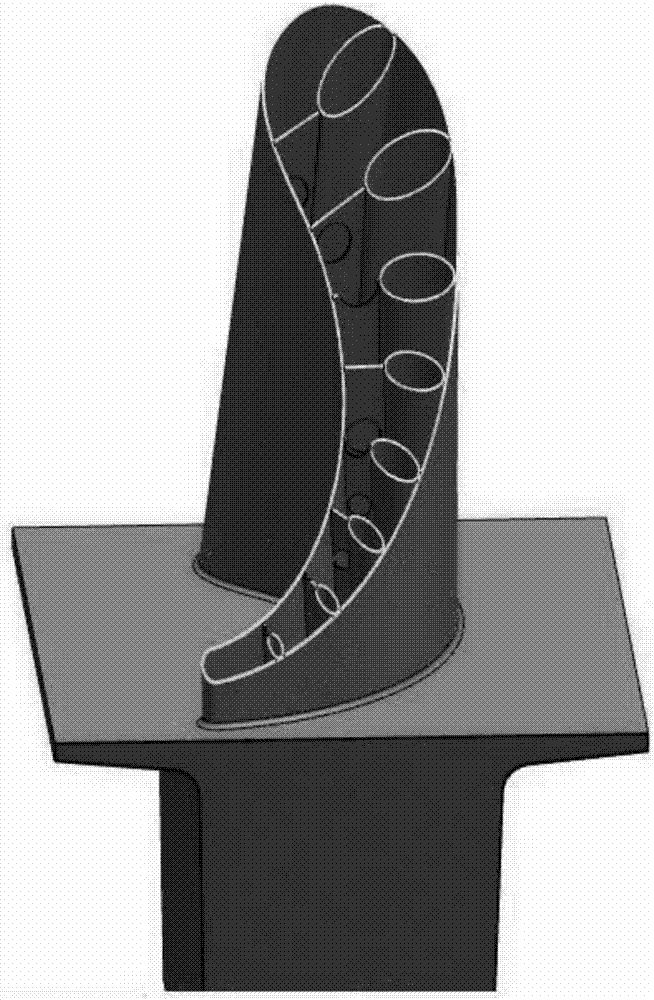

[0082] S1: Establish a three-dimensional model of the turbine blade based on the aerodynamic data, and then design the internal structure of the core according to the shape of the turbine blade, and use the characteristics of the expansion coefficient of air different from that of the rapid prototyping material to build a sealed airtight air in the internal structure of the core The room is connected with the external air room by using the supporting ribs to complete the structural design and generate digital files at the same time.

[0083] S2: Manufacturing core by rapid prototyping. Use the laser ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com