12-station adjustable fly-cutter head structure for lathe

A flying cutter head and adjustable technology, applied in the field of flying cutter head, can solve the problems of length error of tool extension or storage, affecting the machining accuracy of lathe, rigid structure of flying cutter head, etc., to reduce centrifugal force, compact structure, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

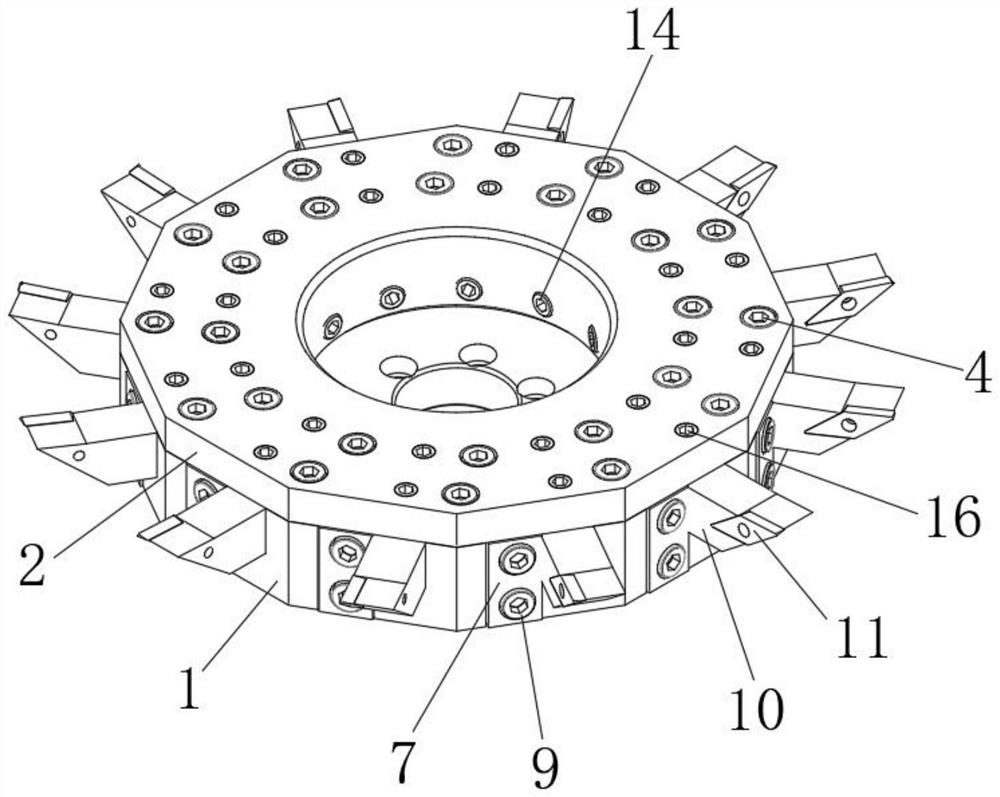

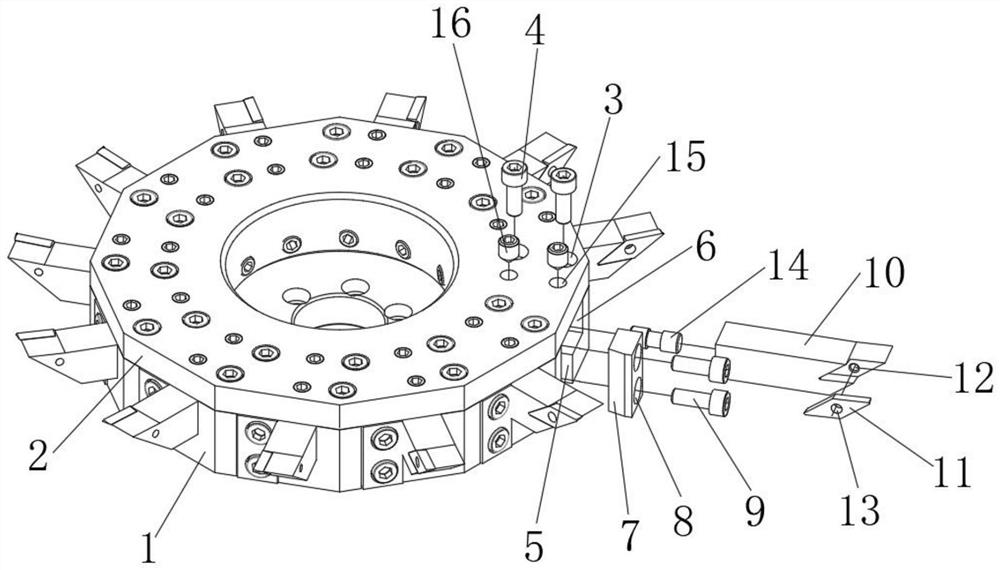

[0022] A 12-station adjustable flying cutterhead structure for lathes, including a flying cutterhead main body 1, the top of the flying cutterhead main body 1 is connected with a flying cutterhead cover 2 by screws, and the flying cutterhead main body 1 There are fixed grooves 5 equidistant on the outer side of the fly cutter head body 1 and one side of the fixed groove 5 is provided with a knife groove 6, and the inside of the fixed groove 5 is connected with an oblique pressure block 7 by screws. , the inside of the sipe 6 is inserted with a square knife bar 10 that matches its shape, and the end of the square knife bar 10 away from the sipe 6 is connected with a flying blade 11 by a screw, and the square knife bar 10 is convenient for more Fix and install the flying blade 11; the inner wall of the flying cutter head body 1 is equidistantly threaded with positive and negative screws 14, and the ends of the positive and negative screws 14 near the knife groove 6 extend to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com