Shearing control device for foils for manufacturing microporous aluminum honeycomb material

A control device, aluminum honeycomb technology, applied in the direction of metal processing, etc., can solve the problems that the position identification of the rubber strip and the control of the cutting length cannot be accurately realized, and the regularization of the honeycomb core grid cannot meet the specified requirements, so as to ensure the quality performance Requirements, improve the normalization, and reduce the effect of length error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

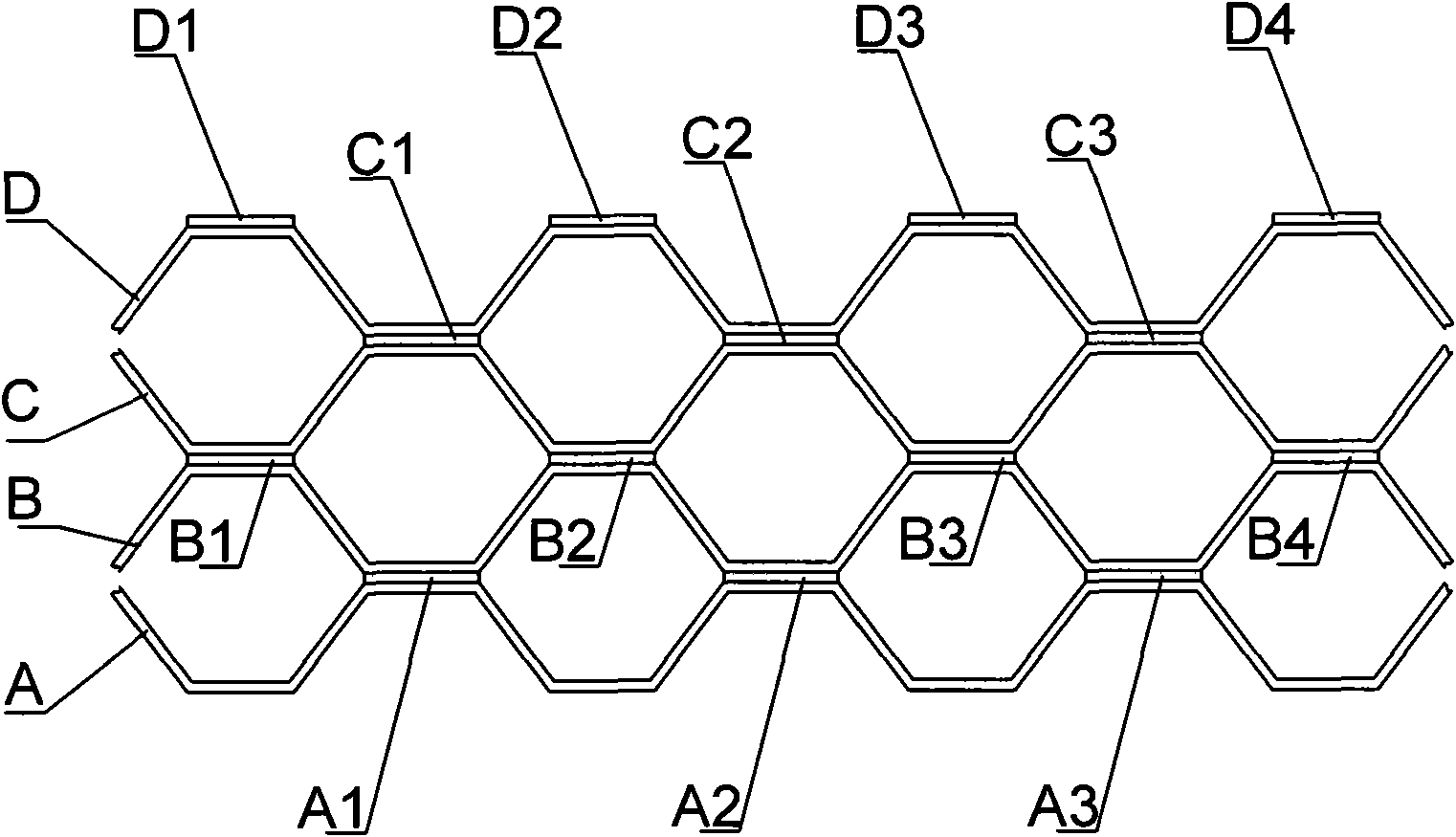

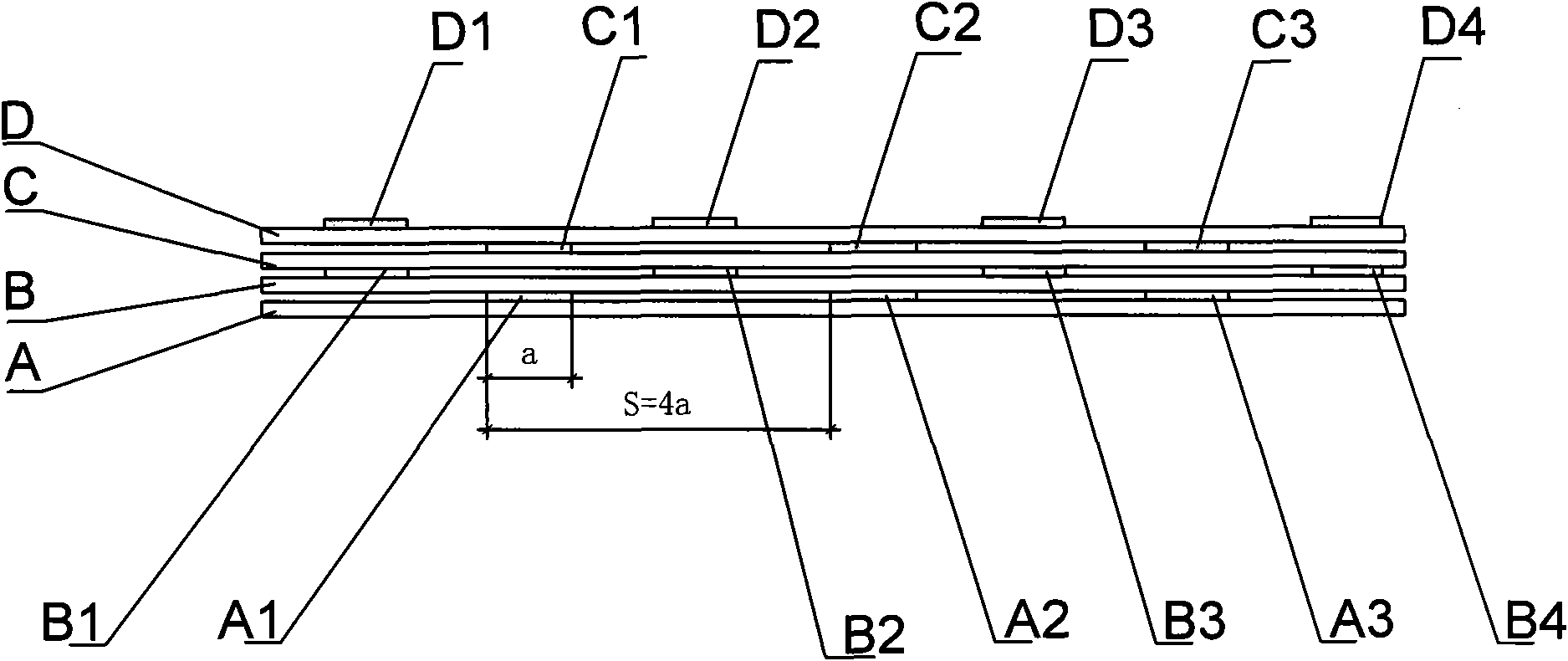

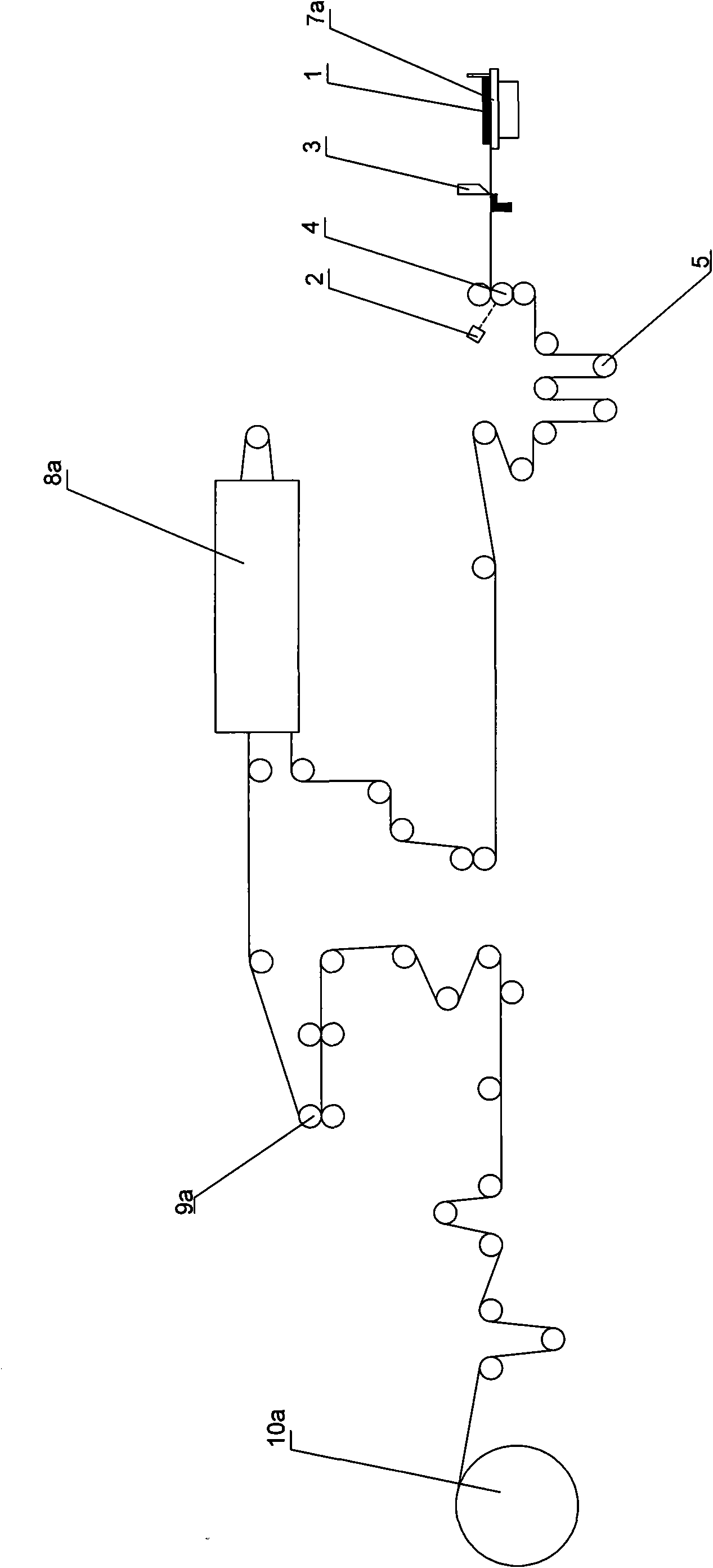

[0015] figure 1 It is a structural schematic diagram of a stretched aluminum honeycomb, figure 2 to form figure 1 Schematic cross-sectional view of the shown structure before stretching. figure 1 The structure shown is composed of four layers (A, B, C, D layers) of aluminum foil, wherein the adhesive strips on the A layer of aluminum foil are A1, A2, A3, and the adhesive strips on the B layer of aluminum foil are B1, B2, B3, B4 , the adhesive strips on the C layer aluminum foil are C1, C2, C3, and the adhesive strips on the D layer aluminum foil are D1, D2, D3, D4. The spacing of the adhesive strips on each layer of aluminum foil (the distance between the front or rear edges of two adjacent adhesive strips) s=4a, wherein, a represents the side length of the honeycomb hexagon, and the width of the adhesive strips is the same as the edge of the honeycomb equal in length. The positions of the adhesive strips separated by two layers of aluminum alloy foil sheets are the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com