Equal-length cutting device for construction industry

A cutting device and industrial technology, applied in positioning devices, manufacturing tools, metal processing and other directions, can solve the problems of increasing cutting error, insufficient cutting accuracy, large measurement error of soft ruler, etc. The effect of the force area and the firmness of the clamping part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

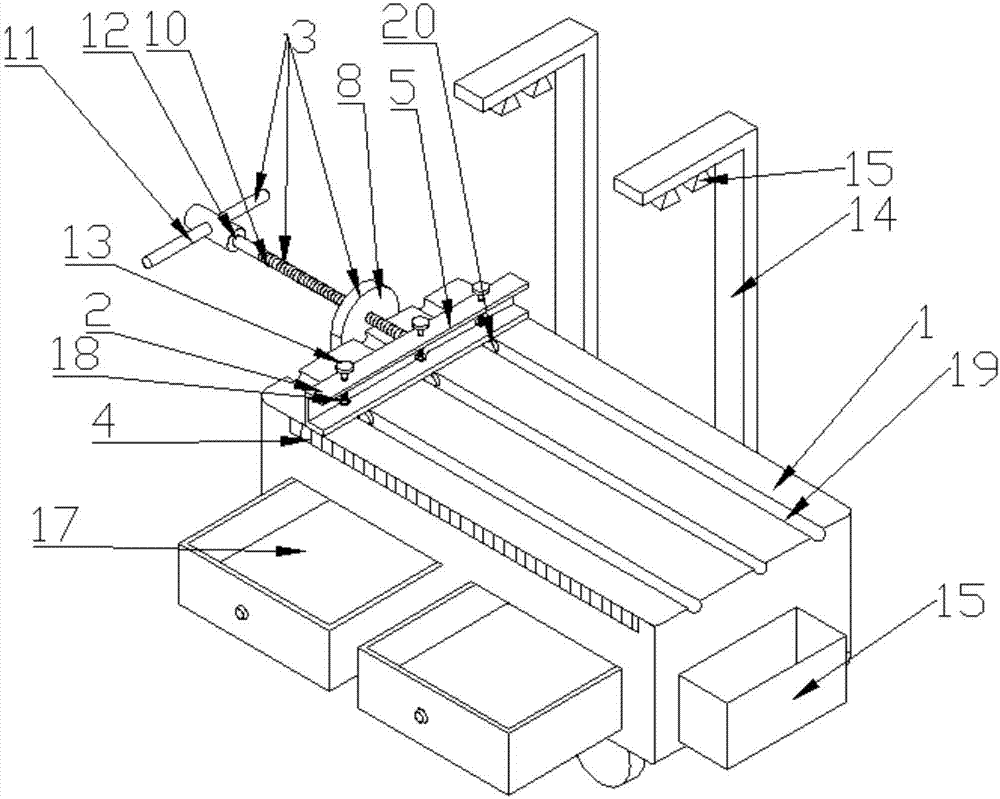

[0031] Such as figure 1 As shown, a kind of isometric cutting device for construction industry in this embodiment includes a horizontal workbench 1, and is arranged on the horizontal workbench 1. 1, the driving part 3 that moves left and right, the side of the horizontal workbench 1 is provided with a scale 4 near the top end of the horizontal workbench 1, and the horizontal workbench 1 is provided with a plurality of semicircular grooves 19. The groove 19 is set as a semicircle, which can better fit the steel bar and prevent the steel bar from being worn out. The number of the groove 19 is arbitrarily set. In this embodiment, for the convenience of viewing and understanding, the number of the groove 19 Set to 3. In practice, setting more numbers can make cutting more efficient.

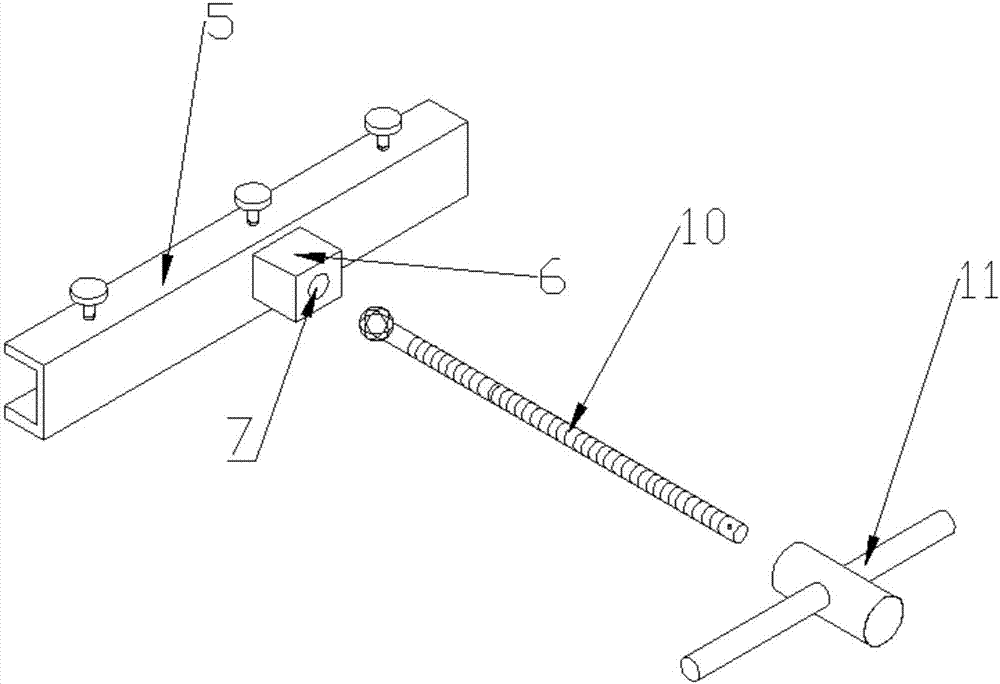

[0032] The clamping part 2 includes a U-shaped steel 5 placed horizontally, the side wall of the U-shaped steel 5 is in contact with the top of the horizontal workbench 1, the back of the U-shaped s...

Embodiment 2

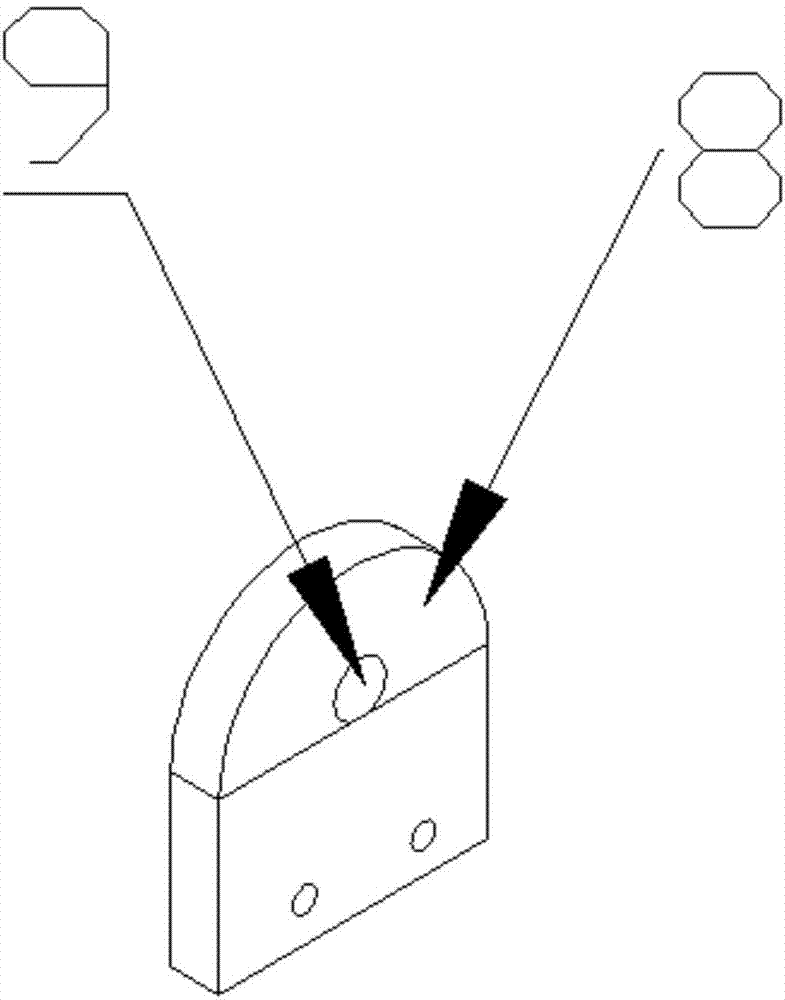

[0036] On the basis of Example 1, the other side wall of the U-shaped steel 5 is provided with a channel 4, and the inside of the channel 4 is also provided with an internal thread, and the U-shaped steel 5 is provided with a vertical screw 13. After the vertical screw 13 passes through the tunnel 4 and the U-shaped steel 5, the vertical screw 13 moves up and down to give the U-shaped steel 5 a vertical downward force. By turning the vertical screw 13 up and down, the compression degree of the bottom of the vertical screw 13 to the vertical direction of the locking part 2 can be freely adjusted, so that the locking part 2 is firmer and easier to move.

Embodiment 3

[0038] On the basis of embodiment 1 or embodiment 2, a gasket 18 is provided between the bottom of the vertical screw 13 and the U-shaped steel 5, which increases the stress area between the vertical screw 13 and the U-shaped steel 5, and protects the The top of the vertical screw 13 and the inside of the U-shaped steel 5 prevent damage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com