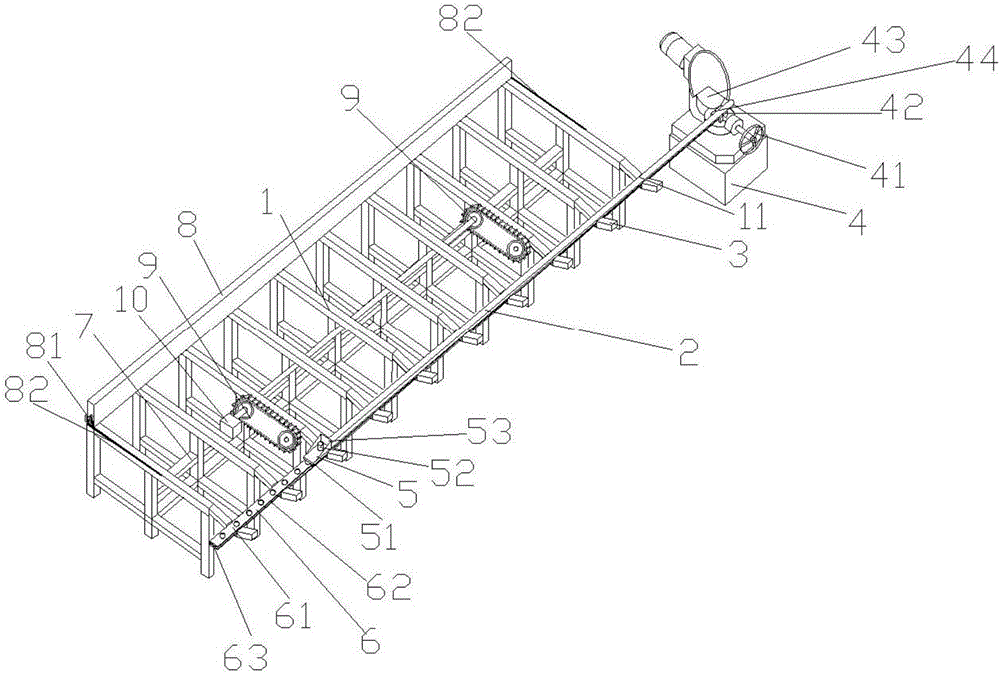

Steel tube fixed-length cutting device

A technology of steel pipe and ruler groove, which is applied in the field of steel pipe cutting and sizing devices, which can solve the problems that there is no effective sizing device and cannot meet the requirements of steel pipe cutting, and achieve the effects of large sizing range, small steel pipe length error, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

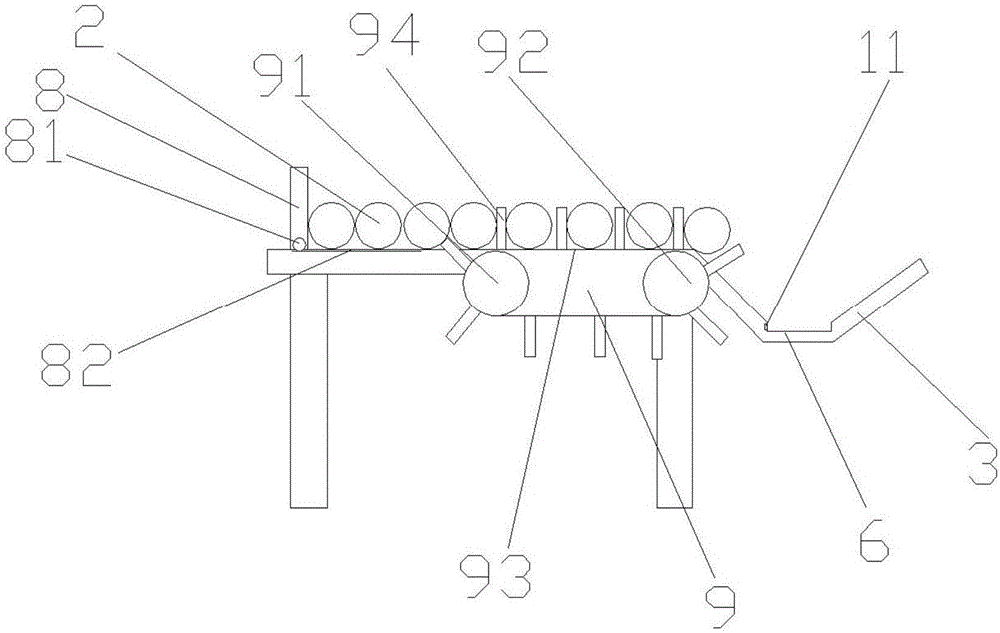

[0033] As shown in the figure, the present invention is a steel pipe cutting and sizing device. The steel pipe to be cut is placed on the material stand 1 by a crane, and the power supply of the moving baffle is turned on. The moving baffle 8 drives the gear set to move on the gear guide rail through the motor. , push the steel pipe 2 into the feeding plate 94 close to the conveyor, the uniform speed motor 10 rotates to drive the chain 8 to rotate, and at the same time drives the feeding plate 94 evenly distributed on the chain 93 to rotate, and the steel pipe 2 in the material stand 1 falls into the feeding Between the plates 94, since the height of the feeding plate 94 is between the radius and the diameter of the steel pipe 2, and the distance between the feeding plates 94 is between the diameter of the steel pipe 2 and twice the diameter, the distance between the feeding plates 94 The steel pipe 2 that falls can not be more than one, when needing to cut the steel pipe 2 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com