Intelligent lithium battery pole piece cutting device

A slicing device and lithium battery technology, applied in the direction of shearing device, nibbling cutting device, driving device, etc., can solve the problems of high work intensity of workers, easy wrinkling of pole pieces, uneven stress on pole pieces, etc. Achieve fast and stable cutting, easy to use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

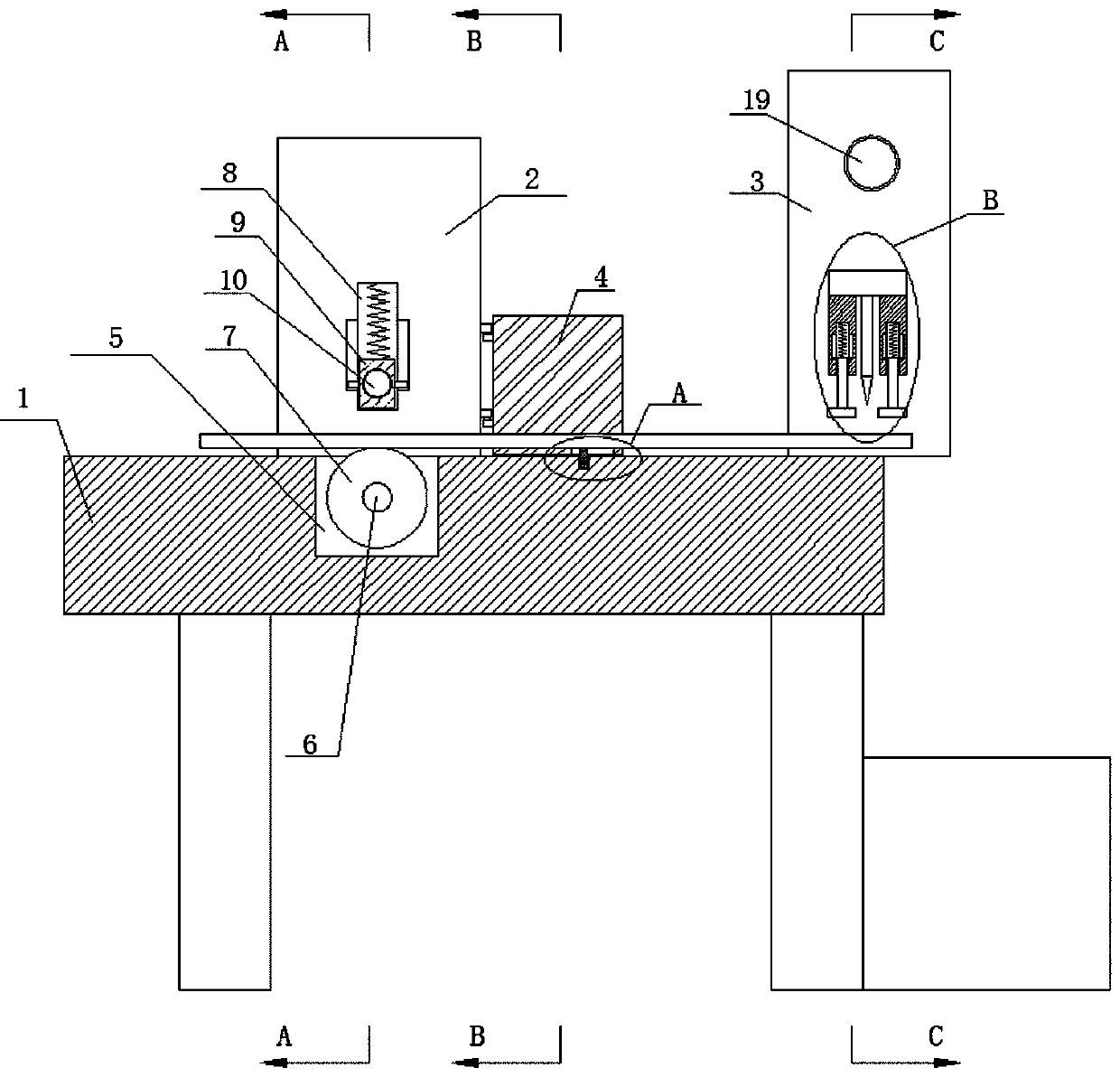

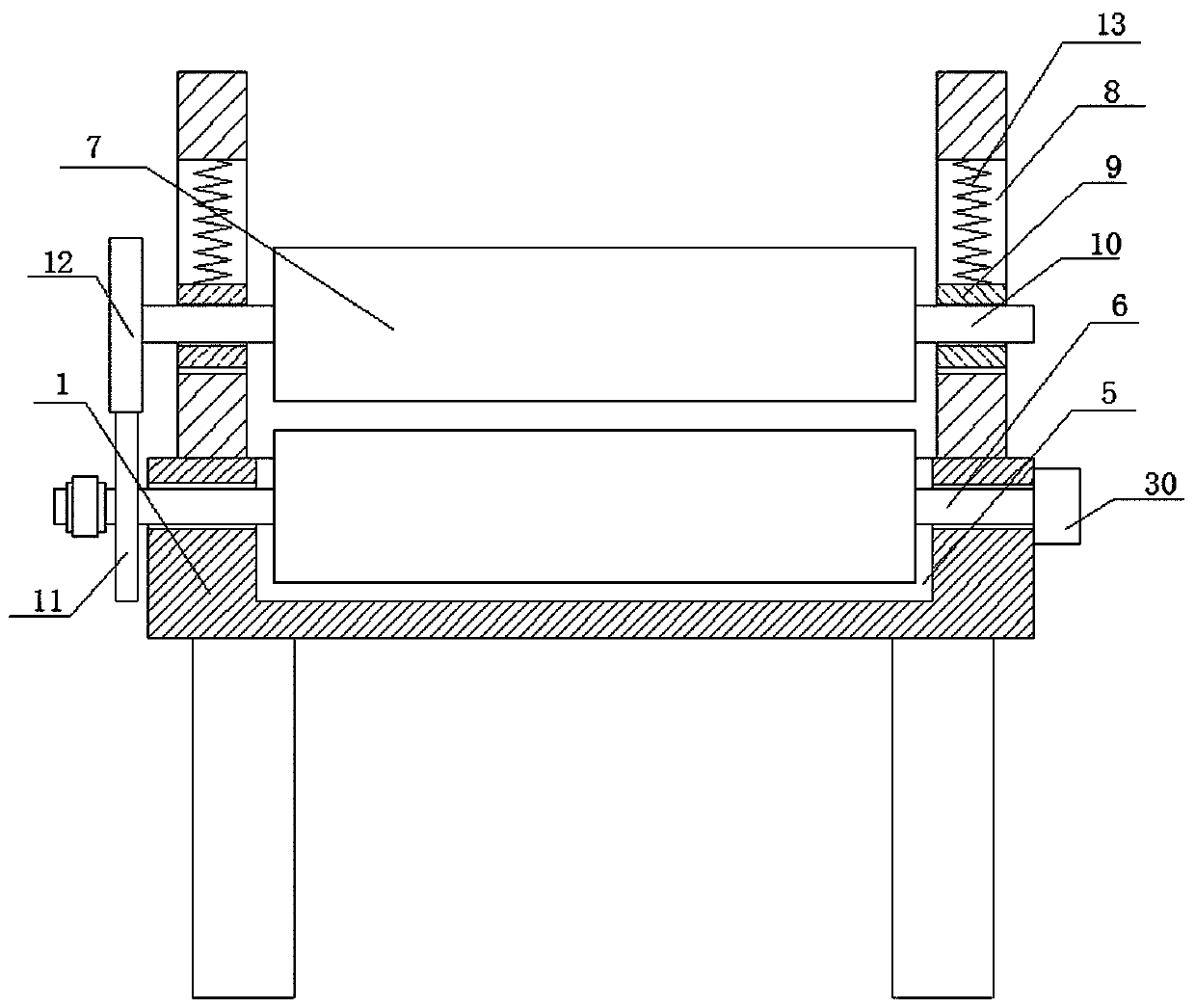

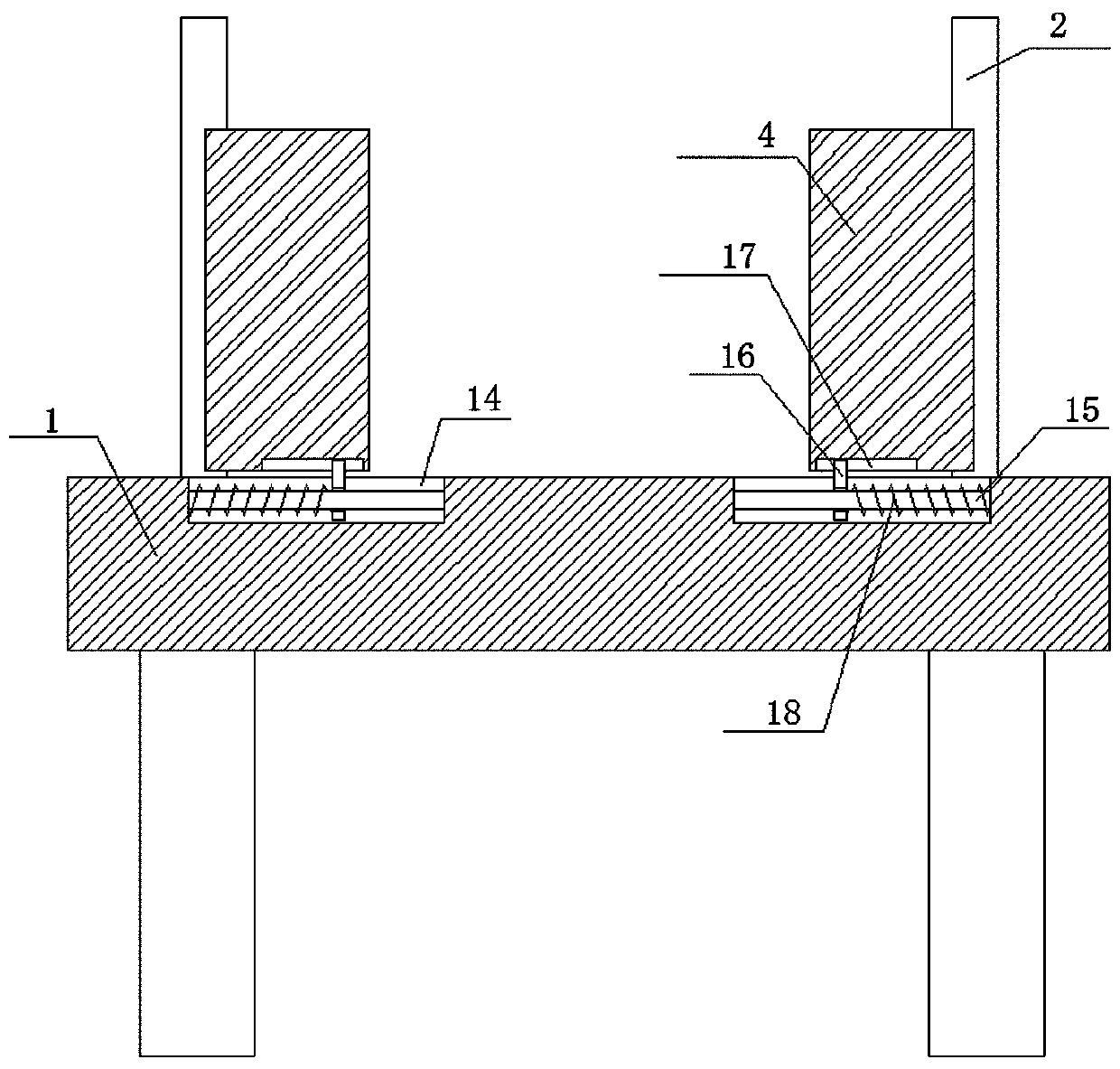

[0028] refer to Figure 1-6 , an intelligent slicing device for lithium battery processing pole pieces, comprising a base 1, two symmetrically arranged first support plates 2 and two symmetrically arranged second support plates 3 are fixedly installed on the top of the base 1, and the bottom of the base 1 is provided with There is a rotating groove 5, and the rotating groove 5 and the two first support plates 2 are respectively rotatably connected with a first rotating rod 6 and a second rotating rod 10, and the outer sides of the first rotating rod 6 and the second rotating rod 10 are fixedly sleeved There is a rotating roller 7, the same third rotating rod 19 is rotatably connected to the two second supporting plates 3, and the same moving plate 23 is slidably connected to the two second supporting plates 3, and the bottom of the moving plate 23 is fixedly equipped with a blade twenty four.

[0029] In the present invention, the bottom of the moving plate 23 is fixedly inst...

Embodiment 2

[0039] refer to Figure 1-6, an intelligent slicing device for lithium battery processing pole pieces, comprising a base 1, two symmetrically arranged first support plates 2 and two symmetrically arranged second support plates 3 are fixedly installed on the top of the base 1, and the bottom of the base 1 is provided with There is a rotating groove 5, and the rotating groove 5 and the two first support plates 2 are respectively rotatably connected with a first rotating rod 6 and a second rotating rod 10, and the outer sides of the first rotating rod 6 and the second rotating rod 10 are fixedly sleeved There is a rotating roller 7, the same third rotating rod 19 is connected to the two second supporting plates 3 in rotation, the same moving plate 23 is slidingly connected to the two second supporting plates 3, and the bottom of the moving plate 23 is welded with a blade 24 .

[0040] In the present invention, the bottom of the moving plate 23 is welded with four positioning sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com