Automatic steel tube feeding unit

A technology of automatic cutting and steel pipe, applied in the field of cold working devices, can solve the problems of waste, large material consumption, exceeding the finishing allowance, etc., and achieve the effects of improving production efficiency, high flatness of truncation surface, and good economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

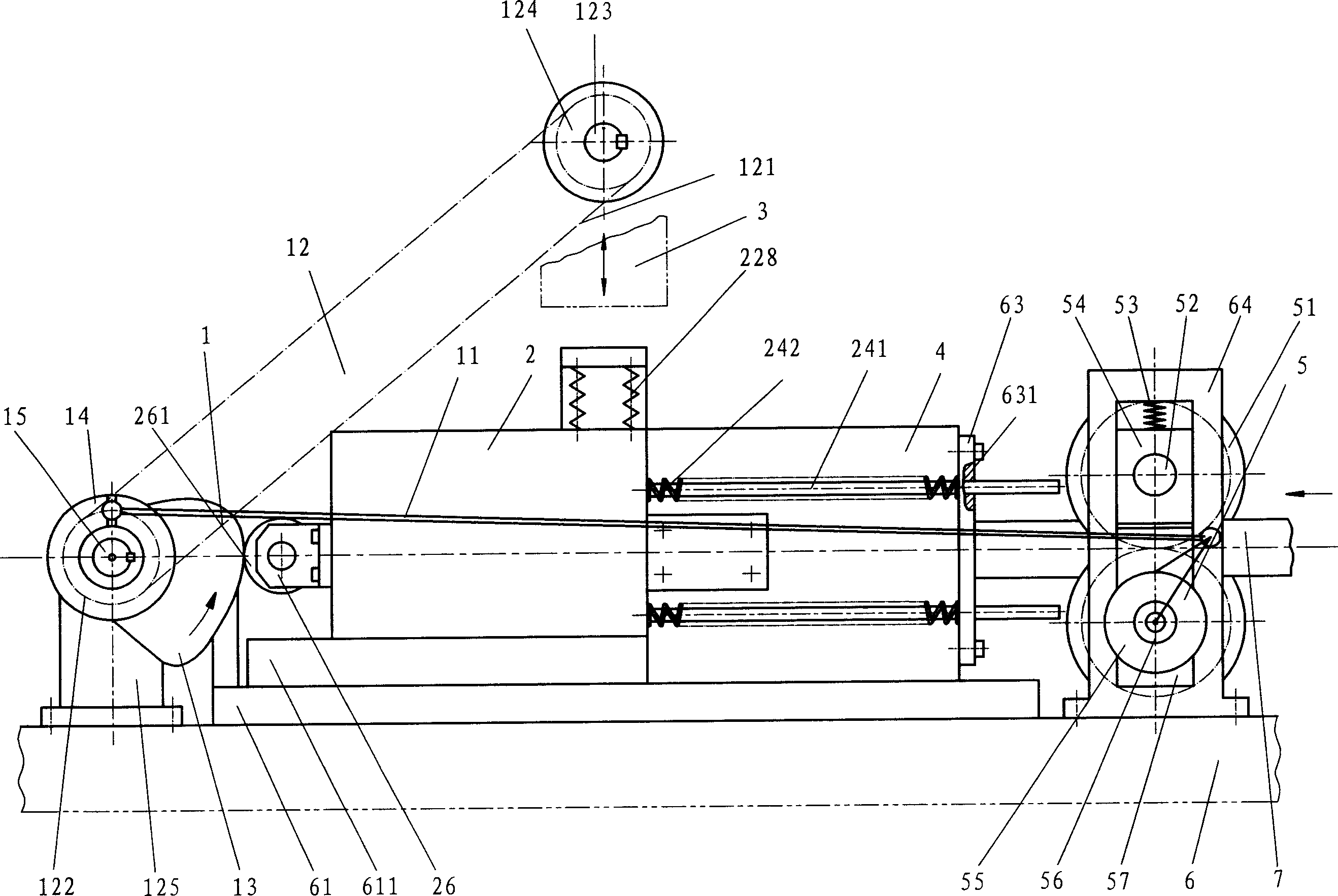

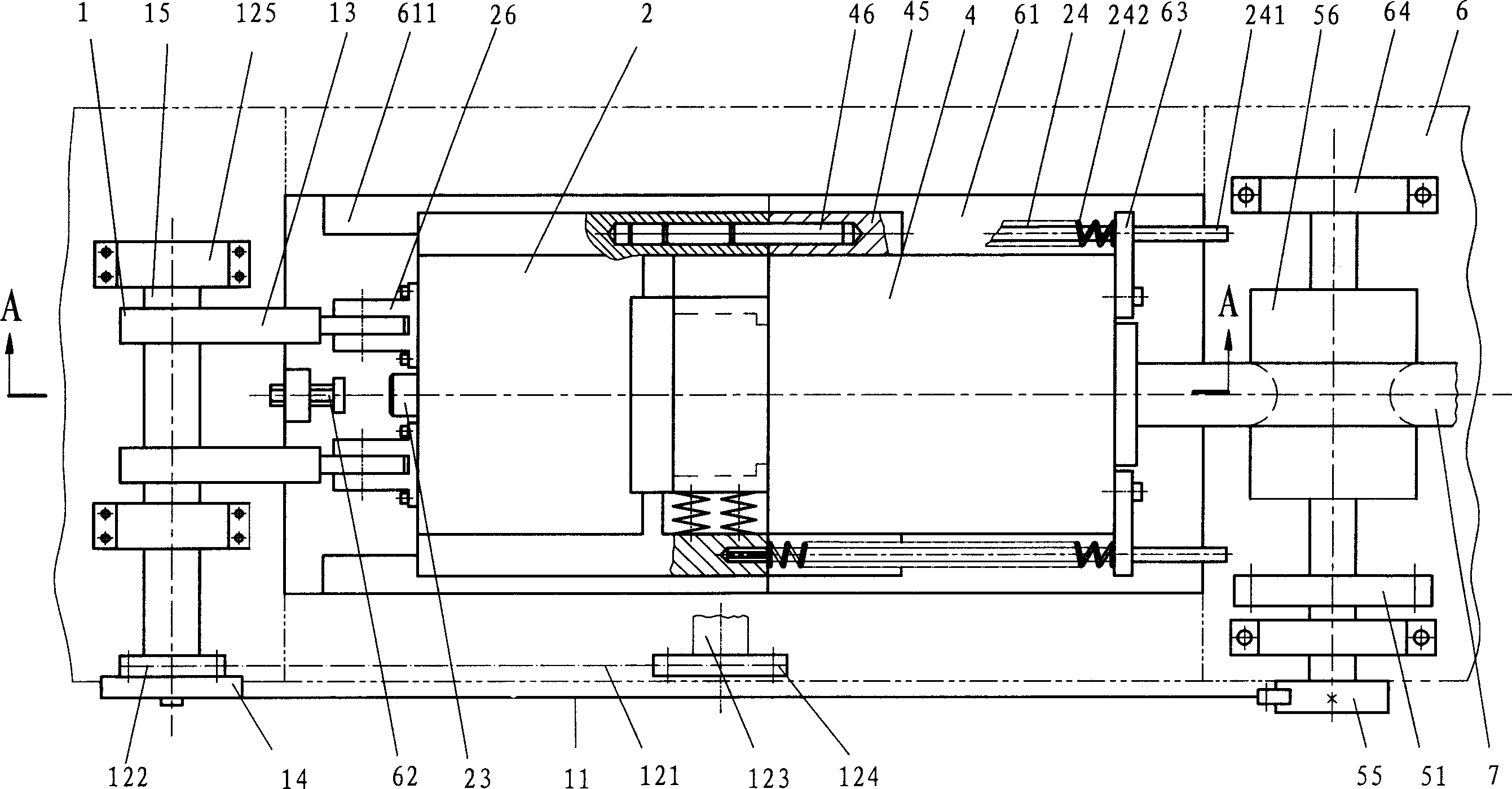

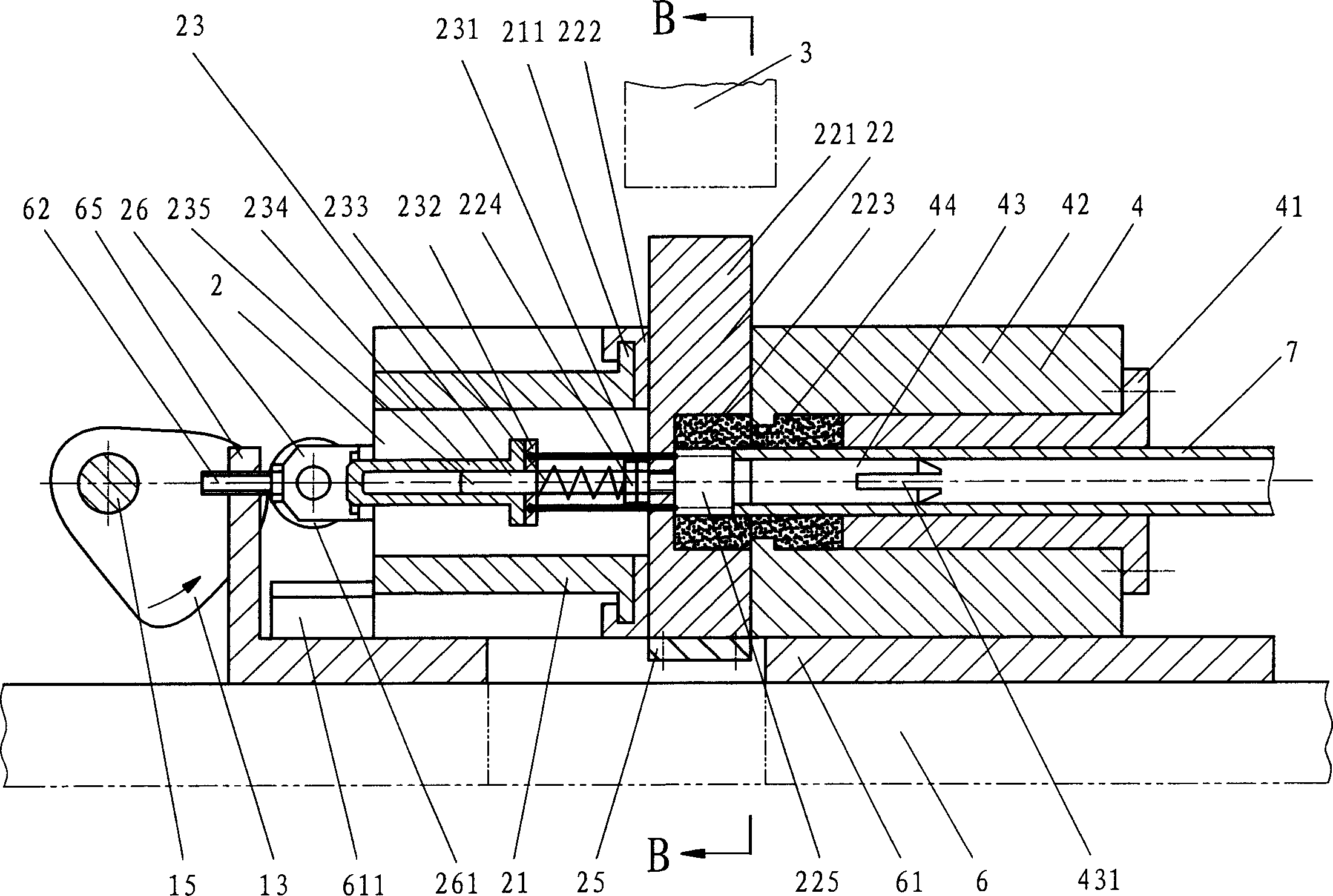

[0017] An embodiment of the present invention will be described below in conjunction with the accompanying drawings. It is composed of a transmission part 1, a moving die 2, a punch 3, a static die 4, a feeding part 5, and a worktable 6. The moving die 2 is located on the workbench 6, and the static die 4 is fixedly mounted on the workbench 6. Above the moving die 2 is the punch 3, on one side of the workbench 6 is the transmission part 1, and on the other side is the feeding part 5, the transmission part 1 can drive the moving die 2 to move, and the transmission part 1 can drive the feeding part 5 to move , the punch 3 is driven by the press crankshaft 123 transmission slider to move. Workbench 6 is made of base plate 61, seat frame 64, vertical frame 65, and base plate 61 one side is vertical frame 65, and the other end has two seat frames 64, and platform guide rail 611 is arranged on the base plate 61.

[0018] Static die 4 is made of guide sleeve 41, static die body 42, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com