Fixed length plate shearing machine applicable to plates of different thicknesses

A plate shearing machine and fixed-length technology, which is applied in the direction of nibbling cutting device, positioning device, shearing device, etc., can solve the problems of easy collision during storage or transportation, uneven plate surface, increased production cost, etc. problem, to avoid unqualified cutting length, improve utilization rate and reduce equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

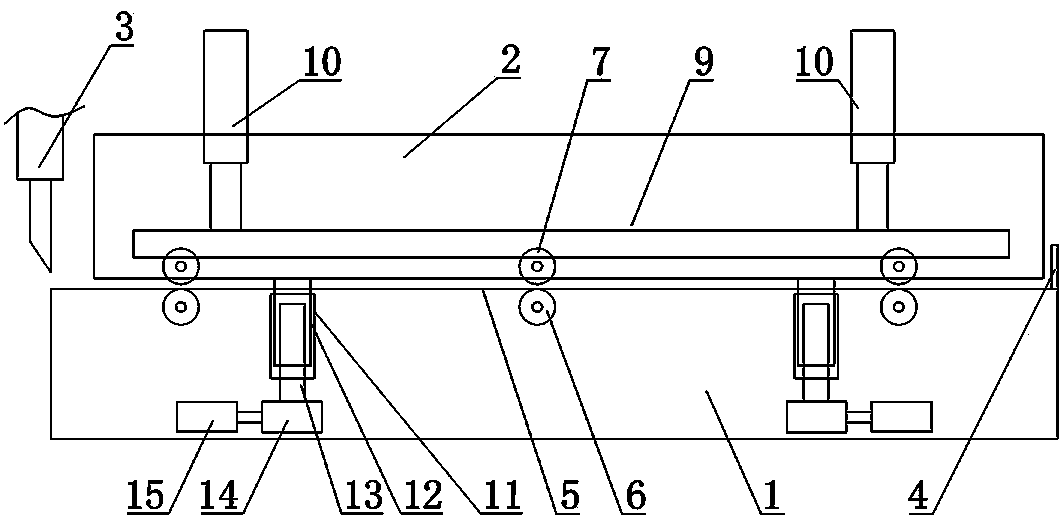

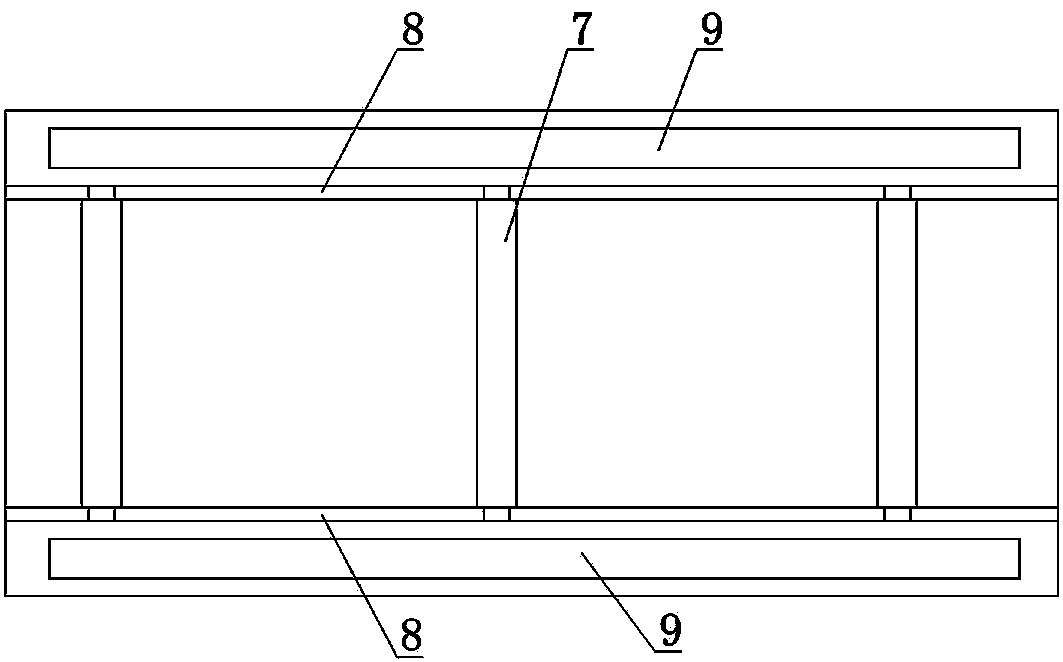

[0013] The present invention will be further described below in conjunction with the accompanying drawings, and the protection scope of the present invention is not limited to the following:

[0014] like figure 1 As shown in the figure, a fixed-length shearing machine suitable for different plate thicknesses includes a machine base 1 and a machine cover 2 arranged above the machine base 1. The upper part of the front end of the machine base 1 is provided with a shearing cutter 3, and the machine base 1 The front end is provided with a support area matched with the shearing cutter 3, the rear end of the machine base 1 is provided with a baffle plate 4, the upper part of the machine base 1 is provided with a support surface 5 for placing metal plates, and the machine base 1 at the lower part of the support surface 5 is provided The lower shaft roller 6 is installed on it, and the two ends of the lower shaft roller 6 are rotatably matched with the machine base 1. The supporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com