lead ingot slicer

A slicer and lead ingot technology, which is applied in the direction of shearing device, nibbling cutting device, and accessory device of shearing machine, etc. It can solve the problems of cutter snapping and lead ingot warping, etc., and achieve long service life , less waste, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

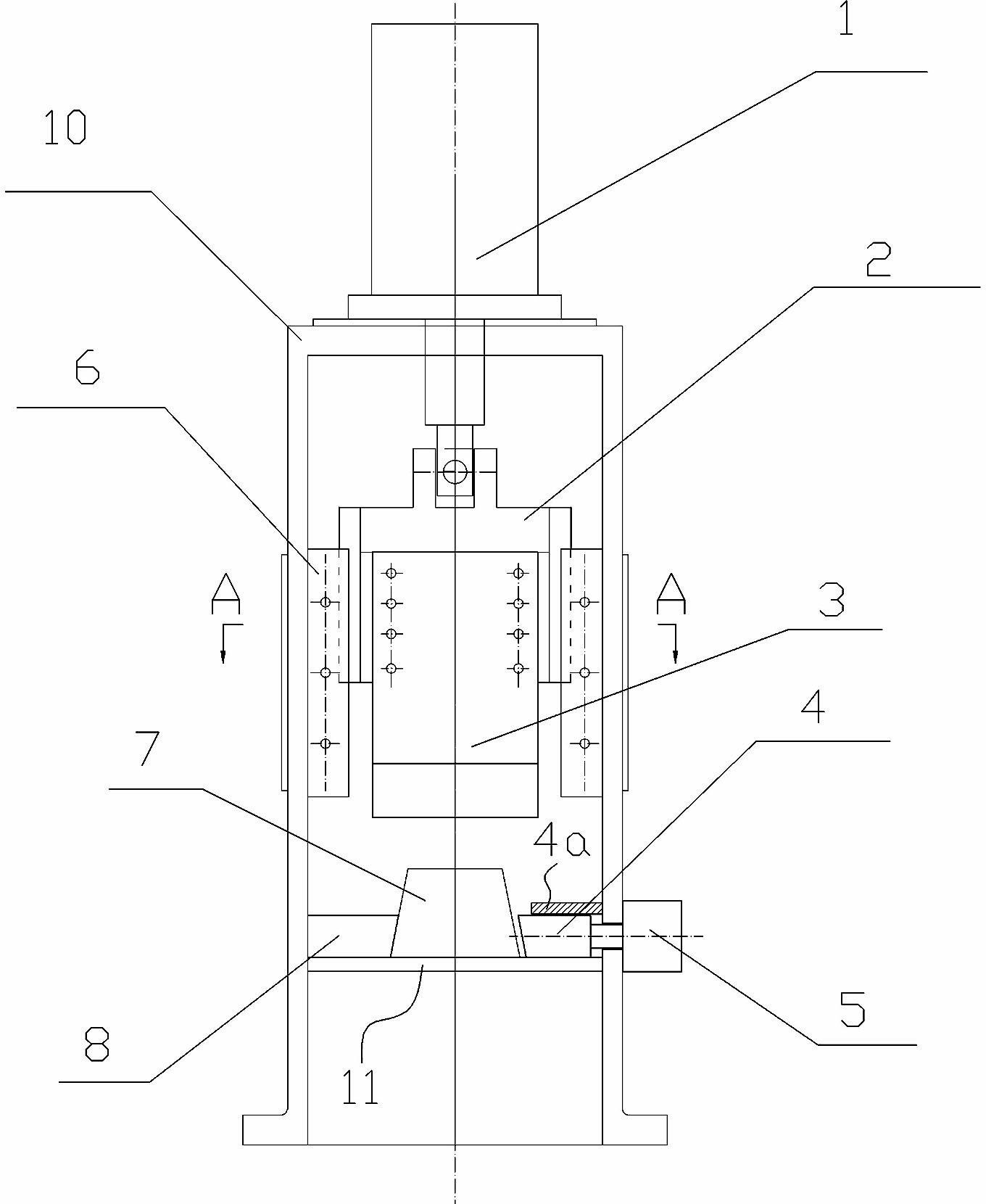

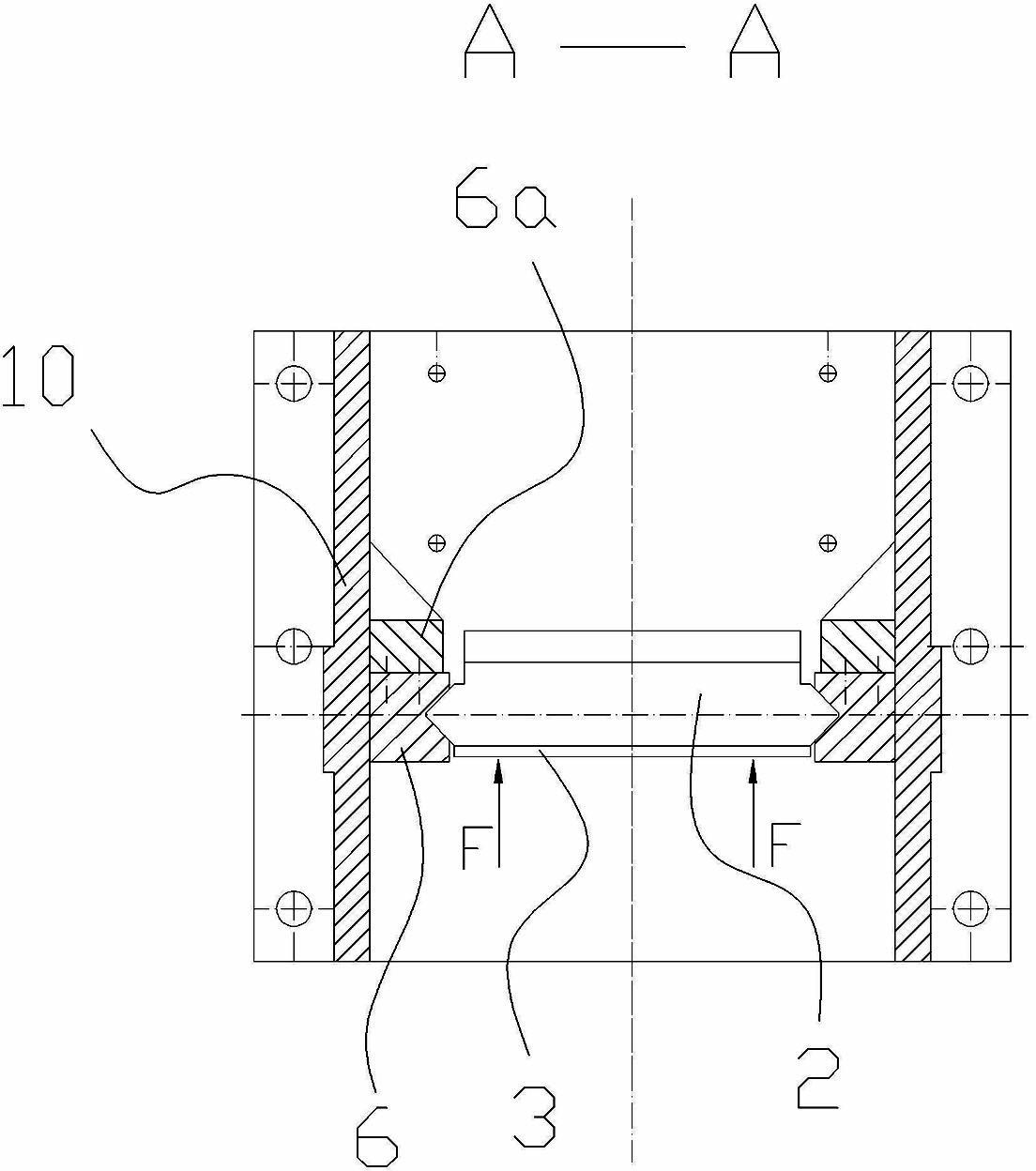

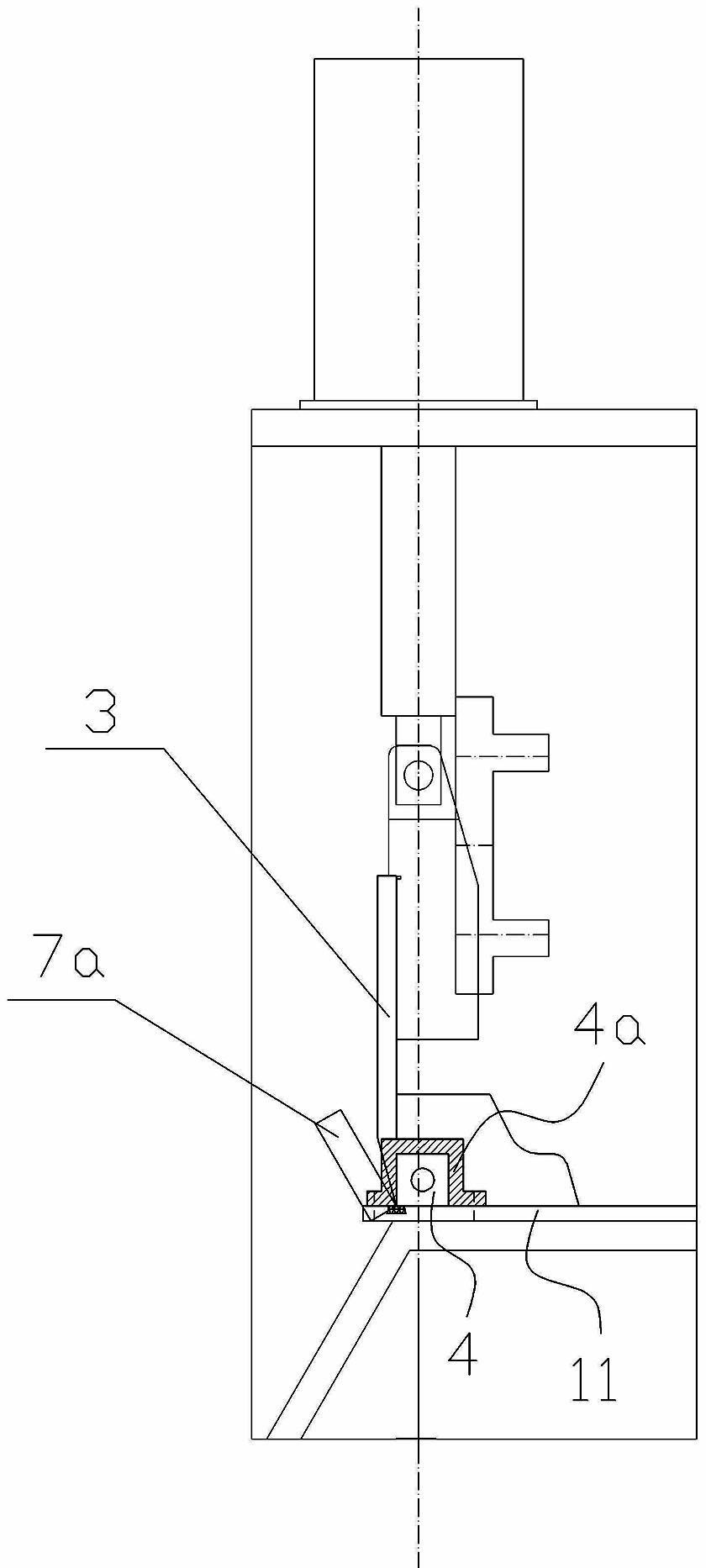

[0012] like figure 1 , figure 2 As shown, a kind of lead ingot slicing machine provided by the present invention includes a frame 10, a guide groove 6 is respectively arranged on the inner side walls of the frame, and a slide block 2 that slides and fits is arranged in the guide groove 6, and the slide block 2 The upper end is connected to the hydraulic cylinder 1 arranged on the upper end of the frame, a cutter 3 is connected to the slider, and a lead ingot conveying platform 11 is arranged below the cutter 3, and the feature is that a fixed conveyor is arranged on the conveying platform 11 on one side of the frame Positioning block 8, a cylinder 5 is arranged on the other side wall of the frame, the piston rod of the cylinder 5 is connected with a movable positioning block 4, which slides with the guide sleeve 4a provided on the conveying platform 11, and the fixed positioning block 8 and the movable positioning block 4 The opposite end faces are respectively provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com